Heavy-Duty Vehicle Connectors You Need to Know

In tough jobs, good vehicle connectors keep vehicles working well. These connectors hold strong electrical links, even in heat, shaking, or wetness. Heavy-duty trailer connectors are made for big power needs. They work well for trucks, building machines, and farm tools. Their strong build stops problems, cuts repairs, and keeps things running. Picking the right connectors makes vehicles safer, stronger, and last longer.

Key Takeaways

Heavy-duty vehicle connectors are essential for maintaining strong electrical links in tough conditions, ensuring vehicles operate reliably.

Choosing the right connector can significantly enhance vehicle safety, performance, and longevity, reducing repair costs over time.

Connectors like the Deutsch DT Series and AMP Superseal are designed to withstand harsh environments, making them ideal for construction, agricultural, and military applications.

Proper installation and regular maintenance of connectors are crucial for optimal performance; always check for damage and use the right tools.

Environmental resistance is key; select connectors with strong sealing features to protect against water, dust, and vibration.

Avoid common mistakes such as choosing low-quality connectors or ignoring environmental factors, as these can lead to costly failures.

Understanding the specific power and data transfer needs of your application will help you select the most suitable heavy-duty connector.

Understanding Heavy-Duty Vehicle Connectors

What Are Heavy-Duty Vehicle Connectors?

Heavy-duty vehicle connectors are important parts of modern vehicles. They handle tough electrical tasks and work in harsh conditions. These connectors carry power and signals without failing. They can handle high currents, heat, and shaking. This helps heavy-duty vehicles work properly.

You see these connectors in jobs needing strong performance. They are built to meet safety rules and offer high protection. This makes them reliable under heavy use or tough situations. Whether for building machines, farm tools, or factory systems, these connectors are strong and dependable.

Key Applications of Heavy-Duty Trailer Connectors

Automotive electronics and infotainment systems.

Heavy-duty connectors are key for car electronics and entertainment systems. They help with navigation, music, and communication features. These connectors send power and data smoothly. This keeps your vehicle's tech working well and reliable.

Construction, agricultural, and military vehicles.

In construction, farm, and military vehicles, these connectors face tough conditions. Dust, water, and shaking are common challenges. Heavy-duty connectors keep power and signals flowing. This helps machines work without stopping and boosts productivity.

Heavy-duty trailers and commercial trucks.

For trailers and big trucks, strong connectors are a must. These vehicles need connectors that handle high power and tough weather. Heavy-duty connectors keep lights, brakes, and other systems working safely. They also lower repair needs, saving time and money.

Top 10 Heavy-Duty Vehicle Connectors

Deutsch DT Series

The Deutsch DT Series is a popular pick for tough jobs. These connectors work well in harsh conditions like shaking or wetness. They are strong and reliable, even in extreme environments.

Main features include:

Sealed housing to block out water and dirt.

Size 16 contacts that handle up to 13 amps.

Different sizes, from 2 to 12 cavities, for various uses.

The Deutsch DT Series is used in transportation, construction, and motorsports. Its simple design makes setup and repairs easy. It works great for heavy-duty trailers and big trucks, offering steady performance.

AMP Superseal

The AMP Superseal connector is perfect for wet and tough places. It is waterproof and keeps connections safe in hard conditions. This makes it great for boats and other water-related uses.

Key benefits include:

Strong sealing to stop water from getting in.

Small size to fit into tight spaces easily.

Tough materials that last in rough environments.

If you need a connector for wet or harsh areas, the AMP Superseal is a smart pick. It is strong and flexible, making it a top choice for many industries.

Weather Pack

The Weather Pack connector is made for hard jobs in transport and racing. Its tough plastic body keeps it safe from bad weather and damage.

Important features include:

Options for different mounting styles, like in-line or PCB.

Built-in locks to keep contacts secure and in place.

Works with 14-20 AWG wires for many uses.

This connector gives a strong and weatherproof link. It’s perfect for trailers and trucks where reliability matters most. Using Weather Pack connectors helps avoid delays and keeps things running smoothly.

Anderson Powerpole

The Anderson Powerpole connector is known for its flexible design. It is a reliable option for strong power connections in tough jobs. These connectors can be adjusted to fit your needs. This makes them great for heavy vehicles and industrial tools.

Main features of the Anderson Powerpole are:

Genderless Design: Both ends are the same, making setup simple. This also avoids connection mistakes.

High Current Capacity: Handles up to 350 amps for steady power. It works well in hard conditions.

Durable Construction: Built with strong materials that last a long time. It resists damage even in extreme situations.

You can find Anderson Powerpole connectors in many fields. These include cars, building machines, and communication systems. They are easy to use and handle high power, making them a top choice for professionals.

Molex MX150

The Molex MX150 connector is small but very strong. Its sealed design keeps it working well in tough places. It is a good pick for vehicles facing dirt, water, and shaking.

Key features of the Molex MX150 are:

Sealed System: Blocks water and dust for lasting connections.

Compact Size: Fits into small spaces without losing power.

Tool-Free Installation: Easy to put together, saving time and effort.

This connector is used in car electronics like engine controls and lights. Its tough build and simple use make it a great choice for improving vehicle systems.

TE Connectivity CPC Series

The TE Connectivity CPC Series connector is made for rough conditions. Its round shape gives a strong and steady connection. It works well in heavy-duty jobs.

Main benefits of the TE Connectivity CPC Series are:

Rugged Housing: Handles high heat and physical stress easily.

Multiple Configurations: Comes in different sizes and layouts for various needs.

Quick Coupling System: Makes connecting faster and reduces delays.

This connector is common in factory machines, farm tools, and military vehicles. It keeps connections stable in hard conditions, making it a useful tool for heavy-duty setups.

Amphenol AT Series

The Amphenol AT Series is a strong and trusted connector. It works well in tough places and stays reliable. Its sturdy build makes it last long and work efficiently.

Main features of the Amphenol AT Series are:

Sealed Design: Blocks water, dust, and dirt for lasting use.

Vibration Resistance: Stays connected even with constant shaking or movement.

Many Configurations: Offers different sizes to fit various electrical needs.

This series is used in farm machines, building tools, and trucks. It handles harsh conditions, making it a favorite for tough jobs.

ITT Cannon APD Series

The ITT Cannon APD Series is a flexible connector for heavy vehicles. It is made to work well in extreme conditions and tough jobs.

Key benefits of the ITT Cannon APD Series include:

Small and Light Design: Saves space but still works powerfully.

High Power Capacity: Handles up to 245 amps for big systems.

Customizable System: Easy to adjust for specific needs.

This connector is used in electric cars, buses, and off-road tools. Its flexibility and power make it great for modern heavy-duty tasks.

Delphi Metri-Pack

The Delphi Metri-Pack is small but works very well. It is a dependable choice for tight spaces needing strong connections.

Important features of the Delphi Metri-Pack are:

Sealed Design: Keeps water and dirt out for safe use.

Efficient Power Use: Reduces energy loss during operation.

Easy Setup: Quick to install, saving time and effort.

You’ll find this connector in car systems like engines and lights. Its small size and good performance make it perfect for limited spaces.

Bosch Compact Connectors

The Bosch Compact Connectors are a trusted choice for tough jobs. They are made to work well in hard conditions. Their small size helps them fit into tight spots easily.

Key Features of Bosch Compact Connectors:

Compact and Lightweight Design: Saves space but still works great. Perfect for modern vehicles.

High Durability: Strong materials stop damage from heat, shaking, or water.

Secure Locking Mechanism: A strong lock keeps them connected without slipping.

Versatile Applications: Can be used in cars, trailers, and factory machines.

Why Choose Bosch Compact Connectors?

These connectors are great for small spaces needing high performance. They handle big power and tough weather well. This makes them a top pick for experts. Use them for trailers or advanced car systems for reliable results.

They also work with many trailer plug types. This means fewer connector types are needed. It makes setup and repairs easier and faster.

Applications of Bosch Compact Connectors:

Automotive Systems: Good for engines, lights, and entertainment systems.

Heavy-Duty Trailers: Keep lights, brakes, and other systems working well.

Industrial Equipment: Send power and signals in factory and building machines.

Choosing Bosch Compact Connectors means getting strong, useful, and long-lasting parts. They improve system performance and lower repair costs.

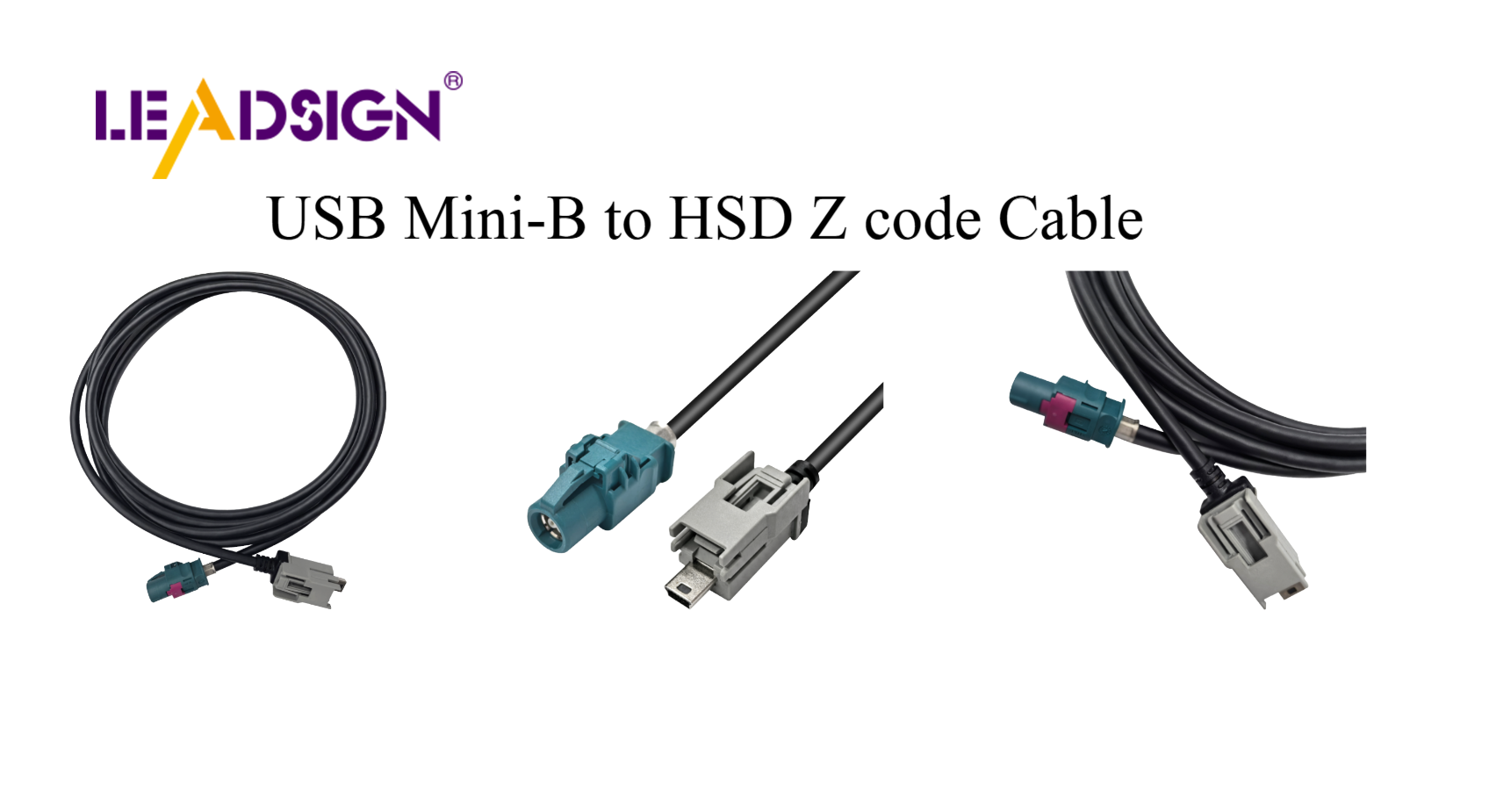

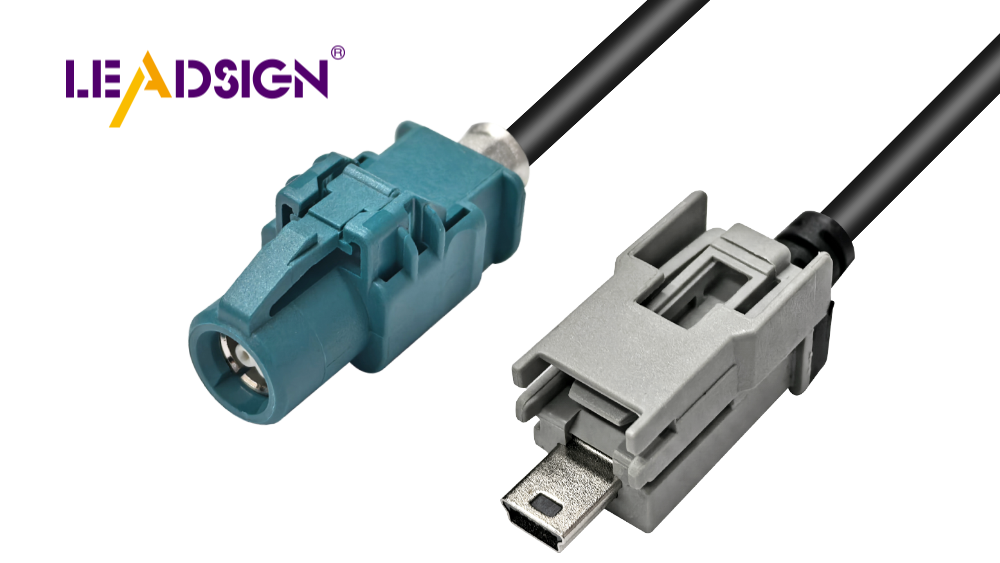

Highlighting the HSD Connector for High-Speed Data Applications

Features of the HSD Connector

The HSD Connector is a trusted tool for fast data transfer. It works well in tough places, making it great for cars and factories.

Primary and Secondary Lock Mechanisms

The HSD Connector has two locks for extra safety. The first lock keeps the connection secure. The second lock adds more protection. This stops it from coming loose during shaking or strong pulls.

High Cable Retention Force and Coding Efficiency

The HSD Connector holds cables tightly, even under stress. This is helpful where wires face pulling or movement. Its smart coding system avoids wrong connections. The plastic case has clear codes for easy setup and proper fit.

Applications of the HSD Connector

The HSD Connector is useful for many fast data tasks. It handles complex data well, even in hard conditions, making it important in many fields.

Automotive Electronics and Infotainment Systems

In cars, the HSD Connector helps with tech systems. It keeps data flowing for GPS, music, and car checks. This ensures smooth use of all features without interruptions.

USB, Ethernet, and LVDS Connections

The HSD Connector works great with USB, Ethernet, and LVDS. These are key for fast data in cars and factories. Its strong build keeps it reliable in tough spots with high power needs.

Telecom Industries and Digital Symmetrical Networks

Telecom companies use the HSD Connector for fast data in networks. It works well in radio stations and telecom setups. It also supports FireWire and Ethernet for steady, quick communication.

"The HSD Connector is a top pick for fast data needs. Its smart design and many uses make it a must-have in modern tech."

Choosing the HSD Connector means getting strong, reliable connections. It is durable, efficient, and fits well in advanced systems, making it a favorite for experts.

Comparing the Top Heavy-Duty Vehicle Connectors

Durability and Environmental Resistance

Picking strong connectors is important for tough conditions. They must handle heat, shaking, water, and dust. The Amphenol AT Series Connectors are great for harsh jobs. Their plastic body and silicone seals keep out dirt and water. This makes them perfect for trucks and factory machines.

The Amphenol MIL-DTL-38999 Series III Circular Connectors are made for extreme environments. They resist rust for 500 hours in salty air. They also work in temperatures from -65°C to +175°C. Their tough build stays reliable during constant shaking. These connectors are ideal for military vehicles and airplanes. Choosing such connectors keeps systems working in hard conditions.

Electrical Performance and Compatibility

Good electrical performance keeps systems running smoothly. Look for connectors that carry high power and send signals well. The Amphenol MIL-DTL-38999 Series III Circular Connectors handle 1.5A to 5.0A currents. They also block EMI for steady power in advanced systems. These are great for jobs needing precise power flow.

Compatibility is also key. Heavy-duty connectors should fit with your current systems. The Amphenol AT Series has flexible designs for different setups. This means you can use them with many trailer plugs and tools. Fewer connector types make repairs easier and save time.

Installation and Maintenance Considerations

Easy setup and care save time and money. The Amphenol AT Series has a latch system for secure connections. This makes installation simple and prevents accidental unplugging. The Amphenol MIL-DTL-38999 Series III Circular Connectors use a thread system for quick assembly.

For care, pick connectors that need little fixing. Sealed connectors like the Amphenol AT Series block damage from the environment. This reduces repair needs. Regular cleaning and checks can make them last longer and work better.

"Using strong, reliable connectors improves systems and lowers repair costs."

By focusing on strength, performance, fit, and easy use, you can find the best heavy-duty connectors for your needs.

Picking the Best Heavy-Duty Trailer Connector

Things to Think About

Protection from weather and shaking.

When picking a heavy-duty trailer connector, focus on sealing and shaking resistance. These features help the connector work well in tough conditions. Dust, water, and heat can harm weak connectors, causing problems. For example, Bosch Kompakt Compact 1 Connectors have strong seals rated IP69K. This keeps out water and dirt. Their tough design also handles shaking, making them great for engines and hard jobs. Choosing connectors like these means they last longer and need less fixing.

Matching with your current setup.

Always check if the connector fits your system. Wrong connectors can cause problems or damage your tools. Think about the trailer wiring and trailer plug types you need. For example, connectors for new vehicles might not fit old ones without extra parts. Picking the right match saves time and avoids mistakes. Check the pin layout, wire size, and how it mounts to ensure it fits perfectly.

Power needs and job requirements.

Know how much power your trailer needs before choosing a connector. Heavy jobs need connectors that handle high power without getting too hot. For instance, Bosch Kompakt Compact 1 Connectors can handle up to six pins. They work well in temperatures from -40°C to 150°C. This makes them good for lights, brakes, and sensors. Picking a connector that matches your power needs keeps your system safe and working well.

Mistakes to Watch Out For

Forgetting about the environment.

A big mistake is ignoring how weather affects connectors. Bad weather, dirt, and shaking can ruin weak connectors. For example, using a regular connector in wet places can cause rust and power problems. Always pick connectors made for the conditions your trailer faces. Bosch Kompakt Compact 1 Connectors are great for tough spots because they seal well and resist shaking.

Choosing cheap over good quality.

Another mistake is buying cheap connectors instead of good ones. Cheap ones might save money now but break quickly, costing more later. Good connectors last longer and work better. For example, connectors with strong locks and heat resistance are worth the price. Always think about cost and quality together to make a smart choice.

"Picking the right heavy-duty trailer connector means thinking about weather, fit, and power. Avoiding mistakes keeps your system strong and working well."

By focusing on these tips and avoiding errors, you can choose connectors that improve your trailer's performance and lifespan.

Tips for Installing and Maintaining Vehicle Connectors

How to Install Connectors the Right Way

Installing connectors properly helps them work well and last long. Follow these simple steps for a safe and strong setup:

Check Parts Before Starting

Look at all parts for damage like cracks or rust. Broken parts can cause bad connections or system problems.Use Correct Tools

Always use tools made for your connector type. Crimping tools attach wires well, and torque wrenches tighten without breaking. Wrong tools can harm the connectors.Pick the Right Connectors

Choose connectors that fit your system's needs. For tough jobs, use Heavy Duty Connectors. They handle high power and rough conditions.Follow Instructions

Read and follow the maker's guide. It tells you how to align pins, route cables, and secure parts. Skipping this can lead to bad connections.Match Trailer Wiring

Make sure trailer wiring fits the connector. Wrong wiring can cause electrical trouble. Check if the connector matches the trailer plug types.Test After Installing

Test connectors to see if they work right. Use a multimeter to check voltage and continuity. This finds problems before using the system.

"Good installation avoids costly fixes and keeps systems running well."

Keeping Connectors in Good Shape

Regular care helps connectors last longer and work better. Use these tips to keep them in top condition:

Clean Often

Dust and dirt can build up on connectors. Use a soft brush or air to clean them. For tough dirt, use a mild cleaner and cloth. Avoid rough materials that can scratch.Check for Damage

Look for worn wires, loose pins, or broken seals. Pay extra attention to connectors in tough spots like trailers or heavy machines.Protect from Weather

Use sealed connectors to block water, dust, and shaking. HSD Connectors are waterproof and great for tough jobs. Add grease to stop rust and improve connections.Keep Connections Tight

Loose connections can cause power loss. Check locks often, especially in vibrating systems like trailers or construction vehicles.Replace Broken Parts Quickly

Don’t use damaged connectors or wires. Replace them fast to avoid bigger problems. Keep spare parts ready for quick fixes.Check Trailer Wiring Regularly

Look for worn or exposed wires in trailer setups. Fixing these issues prevents electrical problems and ensures proper plug compatibility.Plan Regular Maintenance

Set a schedule to check connectors and systems. Regular care stops sudden failures and keeps everything working smoothly.

"Maintenance prevents problems before they happen. It saves time and money."

By installing and maintaining connectors properly, they will work well in any condition. Taking care of them ensures they last longer and perform better.

Picking the right vehicle connectors helps systems work well in tough jobs. Each connector has special features, like being strong or saving power, for different uses. For instance, the Deutsch DT Series works great in rough places, and the HSD Connector is perfect for fast data. Installing them correctly and taking care of them makes them last longer and work better. Using good connectors and following smart steps can cut delays, make things safer, and help your equipment last longer.

FAQ

What are heavy-duty vehicle connectors used for?

Heavy-duty connectors send power and data in tough conditions. They are used in cars, construction tools, farm machines, and military vehicles. These connectors handle strong electricity and survive heat, shaking, and wetness.

How do I choose the right heavy-duty connector for my application?

First, know what your system needs. Think about where the connector will be used. If it faces water or dust, pick one with strong seals like an IP69K-rated connector. Check the power it needs and make sure the connector can handle it. Always match the connector to your system for a good fit.

Why is environmental resistance important for heavy-duty connectors?

Environmental resistance helps connectors work well in hard conditions. Heat, water, and dirt can harm connectors. A sealed connector stops these problems. For example, silicone seals or rust-proof materials work great in extreme places.

What makes a connector “heavy-duty”?

Heavy-duty connectors handle strong electricity and tough environments. They have strong bodies, resist shaking, and lock securely. These connectors meet safety rules to work well in important jobs.

Can heavy-duty connectors be used for data transfer?

Yes, some heavy-duty connectors also send data. For example, the HSD Connector is great for fast data like USB or Ethernet. Its strong design keeps it working in hard conditions.

How do I maintain heavy-duty connectors?

Taking care of connectors makes them last longer. Clean them often to remove dirt. Check for loose pins or broken seals. Use grease to stop rust. Replace damaged parts quickly to avoid problems.

What are the most common mistakes when selecting heavy-duty connectors?

A big mistake is ignoring the environment. Using the wrong connector in tough places can cause failures. Another mistake is buying cheap ones that break fast. Always pick connectors that fit your system’s needs.

Are heavy-duty connectors compatible with all systems?

Not all connectors fit every system. Check the pin layout, wire size, and how it mounts. Some, like the Deutsch DT Series, can fit many setups. Always check before buying.

How do I ensure proper installation of heavy-duty connectors?

Follow the maker’s guide carefully. Use the right tools to avoid damage. Line up the pins and secure the connection tightly. Test the system after installing to make sure it works.

What standards should I look for in heavy-duty connectors?

Look for connectors that follow safety rules like ISO or MIL standards. These rules ensure the connector is safe and works well. For example, military connectors often meet MIL-DTL-38999 standards for strength and reliability.

See Also

Why HSD Connectors Matter in Today's Automotive Sector

Understanding HSD Connectors for Automotive Applications

Benefits of HFM Connectors for Automotive Technology

Boosting Data Transfer with High-Speed Automotive Connectors