Best Auto Harness Connectors for Various Automotive Applications

Car harness connectors are important for car safety and reliability. As cars get smarter, these connectors handle high-voltage power. They connect key parts like sensors and music systems. They also help with braking, air conditioning, and battery systems. This keeps everything working smoothly.

Key Takeaways

Car harness connectors link electrical parts in cars for safety.

Pick connectors with good ratings, like IP, to block water and dust.

Check and care for connectors often to avoid harm and work well.

Overview of Car Harness Connectors

What Are Car Harness Connectors?

Car harness connectors are key parts of modern cars. They connect electrical systems to ensure smooth power and communication. These connectors link wires, letting signals and electricity flow easily. You can find them in headlights, sensors, and music systems. Without them, your car’s electrical parts wouldn’t work right.

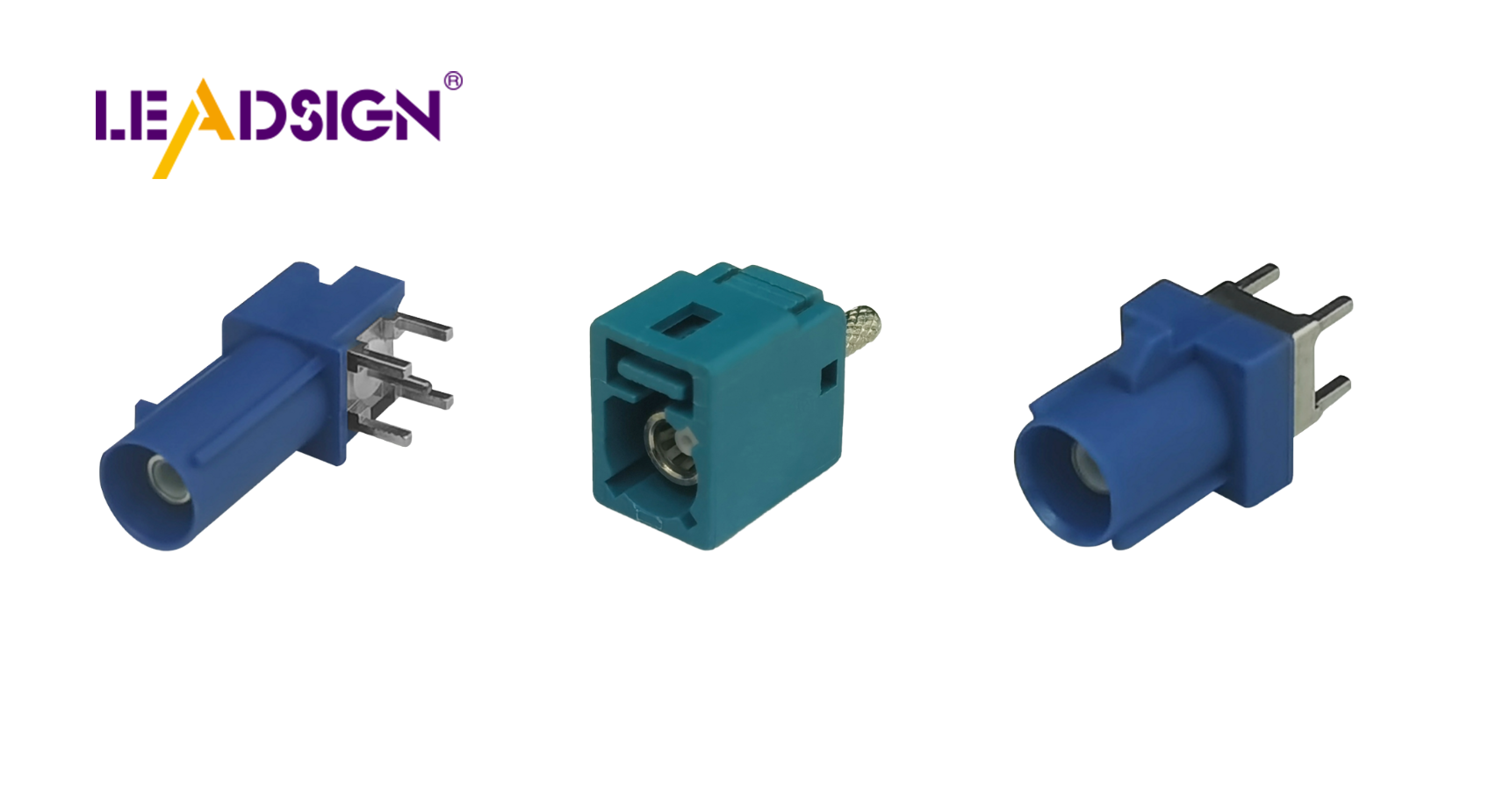

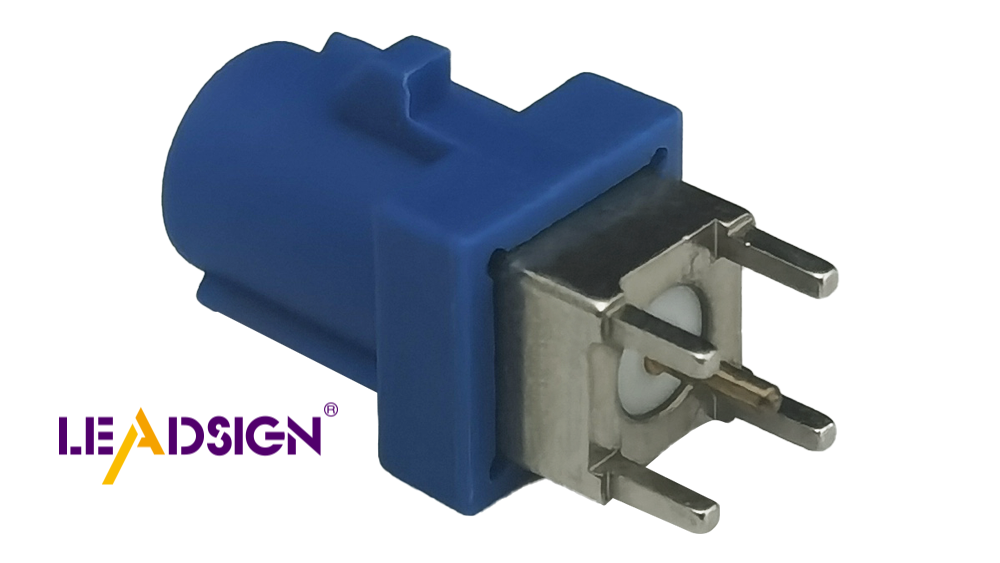

Some types include FAKRA connectors for fast data transfer. Sealed connectors keep out water and dust. Electric cars need special harnesses with high-voltage cables for their systems.

Key Features of Automotive Wiring Connectors

Good automotive wiring connectors are strong and reliable. They handle movement and vibrations to stay connected. Many have locks and strain relief to avoid disconnections. Materials like plastics or metals decide their strength and use.

How they attach also matters. Soldering, crimping, or screw-on methods affect assembly and repair. Gold or silver plating improves signals by lowering resistance. High-quality connectors often fit many systems.

Importance of Automotive Wiring Harness Systems

Wiring harness systems are the heart of your car’s electrical setup. They power important parts like headlights and safety systems. Reliable harnesses keep these systems running smoothly. In electric cars, they are even more important. They support advanced sensors and electrical parts for safety and performance.

Top 10 Car Harness Connectors for Automotive Applications

Weatherproof Connectors (e.g., AMP Superseal, Delphi Metri-Pack)

Weatherproof connectors keep car wires safe from water and dust. They work well in tough conditions. For example:

Souriau TRIM TRIO® Connectors are water-resistant with IP68/IP69 ratings.

Amphenol VG95234 Waterproof Connectors meet military standards and resist vibrations.

LEMO K-Series connectors are IP68-rated and great for outdoor use.

Choose connectors with high IP ratings and strong materials. Look for designs that block water and last long.

Multi-Pin Connectors (e.g., Molex MX150)

Multi-pin connectors link many wires at once. They are strong and handle tough conditions. Locks on them stop wires from coming loose. They are used in engines and music systems. Molex MX150 connectors are reliable and easy to use.

Quick Disconnect Connectors (e.g., Blade and Bullet Connectors)

Quick disconnect connectors make repairs faster. You can replace parts without turning off the system. They help with maintenance and improve system performance. These connectors handle heat well, making them good for modern cars.

High-Temperature Connectors

High-temperature connectors survive very hot conditions. They use strong materials like steel or special plastics. For example, VEAM CIR Series connectors can handle up to 800°C (1,472°F). They are important for electric cars and advanced engines.

Sealed Connectors (e.g., FAKRA Connectors)

Sealed connectors, like FAKRA, are strong and resist damage. They keep signals clear and transfer data quickly. These are great for safety systems and music systems. Their small size and easy setup save time and money.

Modular Connectors

Modular connectors are flexible and can be customized. They transfer data quickly and reduce wire damage. They are future-ready, so they work with new technologies without big changes.

Heavy-Duty Connectors

Heavy-duty connectors are made for tough jobs. They use strong materials like aluminum and have IP65 to IP69k protection. ITT Cannon Trident Neptune Metal connectors are good for heavy equipment. They work well in harsh conditions.

Miniature Connectors

Miniature connectors fit in small spaces but still work well. Mini Fakra connectors send data fast and stay strong in tough conditions. They are a good choice for modern cars because they save space and money.

Circular Connectors

Circular connectors are used in airbags, brakes, and engines. Their shape makes connections secure and reliable for important car systems.

Customizable Connectors

Customizable connectors are made for specific needs. They improve performance with features like sealed covers and heat resistance. Custom wiring harnesses use these connectors to balance cost and function.

How to Pick the Best Car Wiring Connector

Matching with Car Wiring Systems

Make sure the connectors fit your car's wiring system. Check things like current, voltage, and environment needs. For example, a high current rating stops power loss and failures. Here's a table of what to look for:

Factor | What It Means |

|---|---|

Current rating | Stops power loss and keeps systems working. |

Voltage rating | Prevents sparks and keeps it safe. |

Number of contacts | Helps signals stay clear and useful. |

Environmental Conditions | Handles heat, cold, and dirt. |

Mechanical factors | Stays connected during movement with locks and supports. |

Type of termination | Keeps wires connected properly for good signals. |

Material | Plastic for light use or metal for tough jobs. |

Signal integrity | Good materials stop signal problems. |

Interchangeability | Easy to find replacements when needed. |

Strong and Good Materials

Strong materials like copper and special plastics last long. They handle tough conditions and protect wires. Metal connectors are strong for heavy jobs. Plastic ones are lighter and cheaper.

Weather and Temperature Protection

Car connectors need to survive bad weather. Sealed ones block water and dirt. Use materials like nickel-plated brass to stop rust. They should also work in hot and cold weather.

Strong against shaking to avoid problems.

Rust-proof to handle liquids.

Works well in changing temperatures.

Easy to Use and Fix

Make setup and fixing simple by doing these steps:

Get wires ready.

Put wires in the connector tightly.

Test to make sure it works.

Check connectors often for damage.

Clean gently and use rust-proof sprays.

These tips keep your wiring system working well.

Balancing Cost and Quality

Think about cost and quality together. Brass connectors are cheap but rust easily. Stainless steel lasts longer but costs more. Look at long-term costs like repairs. Spending more on good connectors saves money later.

Picking the right connectors keeps cars safe and working well. Good connectors last longer and need fewer repairs. Don’t use the wrong size or reuse one-time connectors. Check with experts or product details to match connectors to car systems.

FAQ

What do car harness connectors do in vehicles?

Car harness connectors join electrical parts in cars. They help power flow smoothly and connect systems like lights, sensors, and music players.

How can you take care of car wiring connectors?

Check connectors often for any damage. Clean them softly to remove dirt. Use sprays to stop rust and keep them working well.

Should you reuse car wiring connectors?

Do not reuse one-time connectors. They may not work well again. Always pick new ones to keep your car safe and efficient.

See Also

Why HSD Connectors Matter in Automotive Engineering

Key Benefits of HFM Connectors for Cars

Understanding HSD Connectors in Vehicle Technology