10 Essential Automotive Harness Connectors for Different Applications

Automotive harness connectors are important for linking car electrical parts. They keep power steady and ensure safe communication between components. As electric cars and smart systems grow, these connectors become even more important. This leads to new ideas in car wiring technology around the world.

Key Takeaways

Car harness connectors link electrical parts, providing power and signals.

Connectors like blade and pin types have special uses in cars.

Pick connectors based on weather, strength, and material for lasting use.

Blade Connectors in Automotive Wiring Harness

Features of Blade Connectors

Blade connectors are very easy to use. Even beginners can handle them without trouble. They let you quickly connect or disconnect wires, which is helpful for car systems. Their design makes them work well in fuse boxes and lights.

These connectors are small and fit into tight spaces. They are strong and can handle tough jobs without breaking. They stay in place firmly, so wires don’t come loose and cause problems in your car.

Applications of Blade Connectors

Blade connectors are popular because they can be used in many ways. They are often found in fuse boxes to keep power steady. They are also used in car lights, like headlights and taillights, to keep them working properly.

These connectors are not just for simple tasks. They can handle big jobs, like powering extra tools in trucks or off-road vehicles. They work well with high power, making them a good choice for many car projects. Whether fixing something small or doing a big job, blade connectors are dependable and flexible.

Pin Connectors for Automotive Wiring

Features of Pin Connectors

Pin connectors, also called pigtail connectors, make repairs easier. If a wire end is damaged, you can fix just that part. This saves time and money, especially in cars where damage happens often. Each pin matches a specific wire, keeping the car's electrical system working properly.

These connectors are small and fit into tight spaces. They hold wires securely, so nothing comes loose and causes problems. Their design makes them easy to install, even in tricky wiring setups. Whether fixing an engine or a car's screen system, pin connectors are reliable and precise.

Applications of Pin Connectors

Pin connectors are used in many car systems. They connect engine parts and sensors, sending important data to the car's computer. This helps the car run smoothly and keeps everything working right.

They are also found in systems like GPS and music players. These connectors help devices talk to each other, so maps and songs work without stopping. Pin connectors are strong enough for big vehicles like trucks, where they need to last and work well.

Because they handle both power and data, pin connectors are very common. Whether upgrading a car or doing repairs, they are key to keeping connections strong and dependable.

Weatherproof Automotive Wiring Connectors

Features of Weatherproof Connectors

Weatherproof connectors are built to handle tough conditions. They protect your car's electrical parts from damage caused by the environment.

Materials: Strong plastics like PEEK and PTFE resist chemicals. Metals like stainless steel and brass stop rust and add strength. Rubber and silicone make them flexible and seal tightly.

Sealing Capabilities: These connectors block water, dust, and dirt with high IP ratings (IP67, IP68, IP69K).

Resistance: They work in extreme temperatures from -40°C to 100°C. They also handle bumps and impacts without breaking.

Sealing Mechanism: Rubber or silicone gaskets and o-rings keep moisture out by forming a tight seal.

These features help weatherproof connectors last long and work well in tough places.

Applications of Weatherproof Connectors

Weatherproof connectors are used in many car systems, especially where they face harsh weather. They keep electrical parts safe from water, dirt, and temperature changes.

Common Applications: You’ll find them under the hood, near wheels, or in outdoor systems where they face rough conditions.

Examples: Sealed multi-pin connectors and waterproof wire terminals are often used. They make systems stronger and need less fixing.

Vehicle Types: These connectors are important for off-road vehicles, trucks, and cars in extreme weather.

Using weatherproof connectors stops rust and electrical problems. They help your car stay reliable, even in the hardest conditions.

Circular Connectors in Wire Harnesses

Features of Circular Connectors

Circular connectors are strong and work in tough conditions. They are made to last and avoid connection problems. Their round shape makes them easy to install, even during quick fixes. The locking system keeps them secure, even when there is shaking or movement.

These connectors can send power, data, or signals for different uses. They are built well, so they need less fixing, saving time and effort. Circular connectors are a solid choice for car wiring systems, working well in hard situations.

Applications of Circular Connectors

Circular connectors are important in many car systems. They are great for sending power and data in modern vehicles. Below is a table showing where they are often used:

Automotive System | Component Examples |

|---|---|

Lighting System | Headlights, Taillights, Turn Signals |

They are also found in engine systems, music setups, and safety tools like airbags. Their flexibility makes them useful for many car wiring needs. Whether fixing or upgrading, circular connectors are a dependable option.

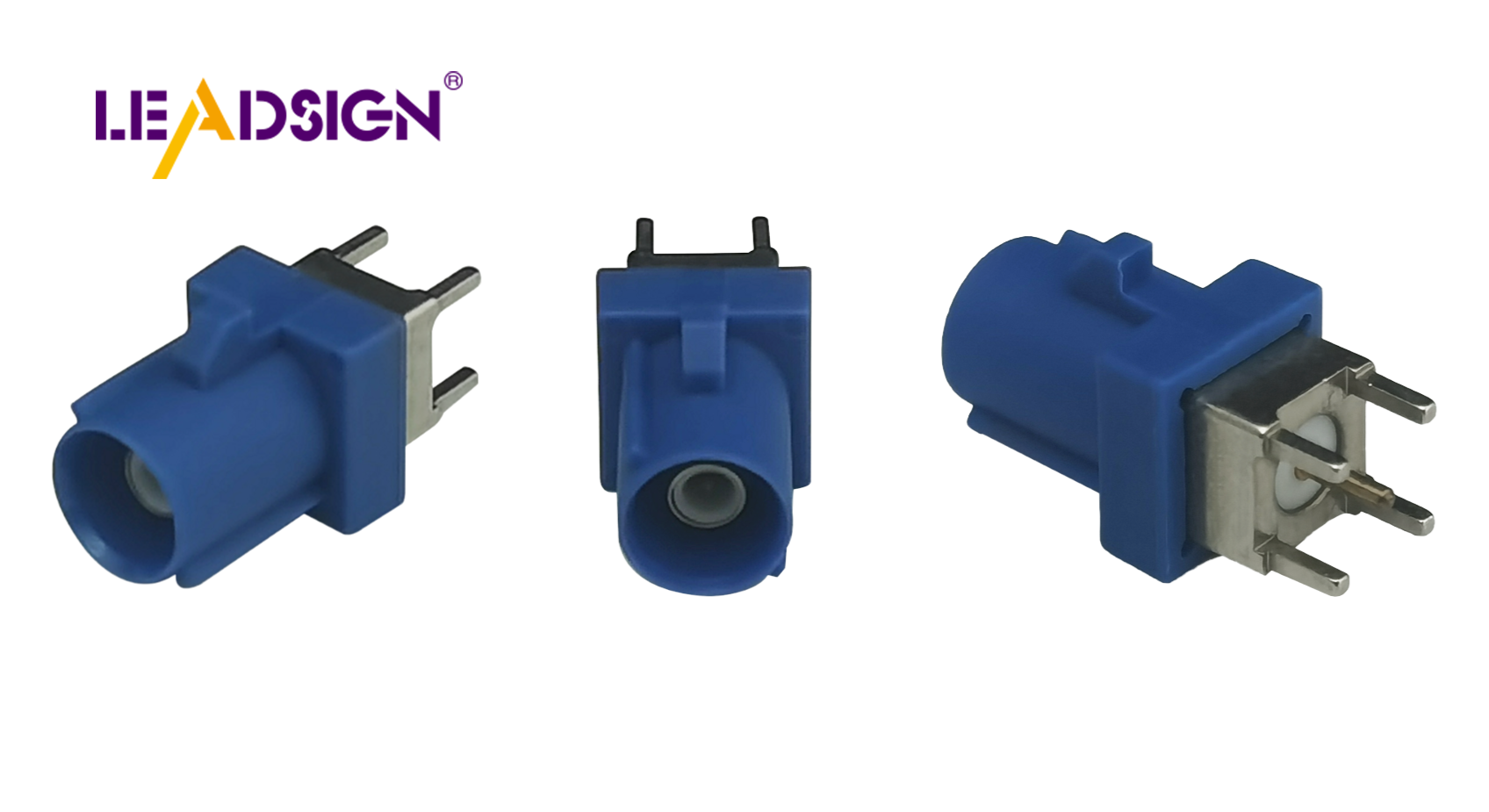

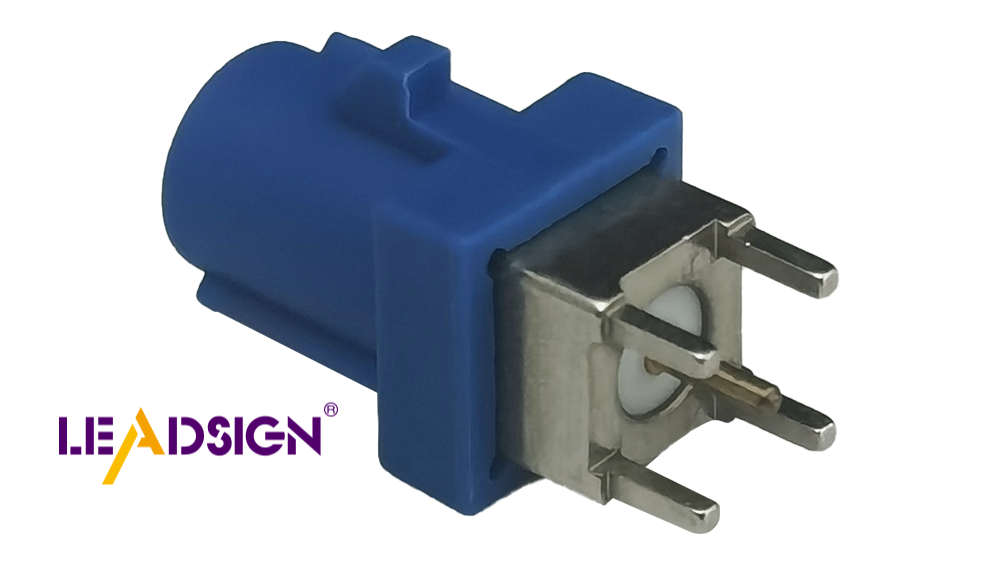

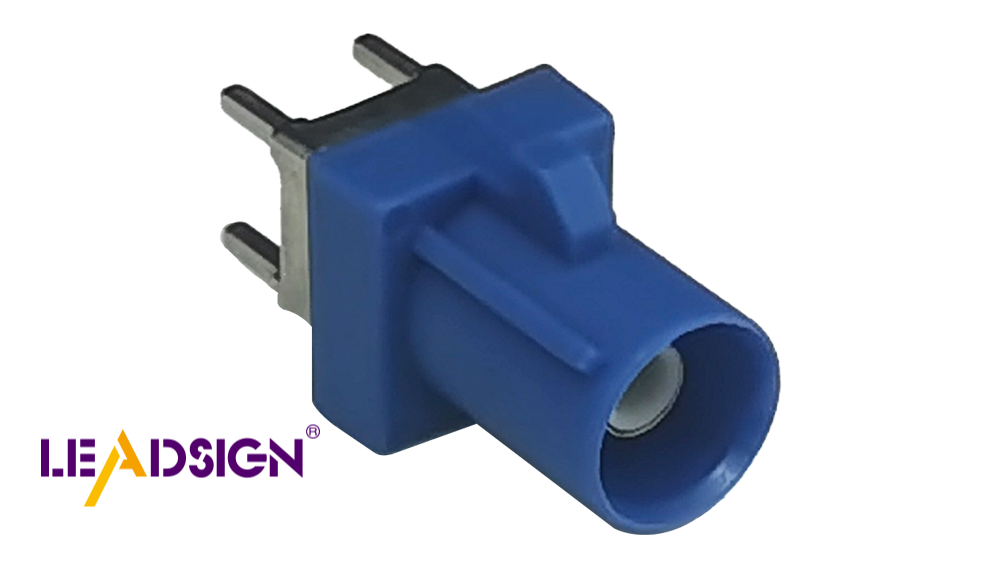

Coaxial Connectors for Automotive Systems

Features of Coaxial Connectors

Coaxial connectors are made for modern car systems. They are reliable and work well in high-performance setups.

They send data quickly, up to 9GHz, for clear communication.

Their small size saves space in car wiring systems.

They take up 75% less space on circuit boards.

They fit easily into existing coaxial systems for compatibility.

Special features stop pins from bending or connecting wrong.

Protected terminals with inward contacts make them safe and strong.

The shortest terminal design adds more room for wiring setups.

These features make coaxial connectors strong, easy to use, and long-lasting.

Applications of Coaxial Connectors

Coaxial connectors are important in many car systems. They handle high-frequency signals, which are needed in modern vehicles.

GPS systems use them to send accurate location data.

They help multimedia systems provide clear sound and video.

Diagnostic systems use them to share data between sensors and computers.

You’ll also find them in infotainment and communication systems. Their flexibility and strength make them a popular choice for car wiring designs.

Multi-Pin Automotive Harness Connectors

Features of Multi-Pin Connectors

Multi-pin connectors make car wiring easier and faster. They let many wires connect in one place, saving time. This design lowers the chance of mistakes during installation. It ensures a strong and steady connection every time.

These connectors are small but can handle many wires at once. They are perfect for systems needing lots of connections. They stay secure even in tough conditions. Their strong build means they last long and need fewer replacements.

Using multi-pin connectors makes car wiring simpler and quicker. This improves how well the car's wiring system works overall.

Applications of Multi-Pin Connectors

Multi-pin connectors are important in cars with complex systems. They are used in engines to connect sensors and control units. This helps the engine run smoothly and efficiently.

In entertainment systems, they link screens, speakers, and controls. This makes it easy to enjoy music, videos, and navigation.

They are also used in safety systems and car lights. Their flexibility makes them useful for regular and high-performance cars. Whether fixing or upgrading, multi-pin connectors are reliable and effective.

Quick Disconnect Connectors in Automotive Wiring

Features of Quick Disconnect Connectors

Quick disconnect connectors make car wiring jobs much easier. You can connect or remove wires fast without special tools. Their simple design means even beginners can use them easily. This is very useful for repairs or maintenance, saving both time and effort.

These connectors work in many car systems and are very reliable. They keep electrical parts connected securely, so everything works well. Their small size makes them perfect for tight spaces in cars. They are also strong enough to handle shaking and tough conditions in vehicles.

Applications of Quick Disconnect Connectors

Quick disconnect connectors are used in many car systems. They make replacing or fixing parts much simpler. Here are some common uses:

Battery Connections: Easily attach or remove battery terminals during maintenance.

Lighting Systems: Quickly change headlights, taillights, or other lights.

Audio Systems: Swap out speakers or audio parts without trouble.

Engine Components: Provide strong connections for sensors and engine parts.

These connectors are important for any car wiring system. Whether fixing lights, audio, or engines, they keep connections safe and working well.

High-Current Connectors for Automotive Wiring Harness

Features of High-Current Connectors

High-current connectors carry large amounts of electricity in cars. They work well even in tough conditions. These connectors are strong and efficient, making them important for high-power systems.

They are made to handle extreme heat, moisture, and dirt. A high IP rating keeps them reliable for a long time. They are built with locking parts and strain relief to stop wires from coming loose during movement or shaking.

Different materials are used based on the job. Plastic is good for light tasks, while metal is better for heavy-duty needs. Wires are connected using crimping or soldering to keep signals strong. Gold or silver-plated contacts help reduce signal loss and improve performance. The table below shows key features of these connectors:

Requirement | Description |

|---|---|

Environmental Conditions | Handle heat, moisture, and dirt with a high IP rating. |

Mechanical Factors | Locking parts and strain relief keep wires secure. |

Type of Termination | Use crimping, soldering, or screw-on methods for strong connections. |

Material | Plastic for light jobs, metal for heavy-duty tasks. |

Signal Integrity | Gold or silver-plated contacts reduce signal loss. |

Interchangeability | Work with different systems to make sourcing easier. |

Applications of High-Current Connectors

High-current connectors are used in many car systems. They are found in engines to help with fuel injection and ignition timing. These connectors also simplify complex systems by allowing multiple wires to connect in one place.

They are important in electric cars, managing high-voltage power. They are also used in batteries to transfer energy efficiently. Their ability to handle high power makes them essential for modern cars with advanced electrical systems.

Sensor Connectors in Automotive Wiring Systems

Features of Sensor Connectors

Sensor connectors are very important in today’s cars. They help sensors send information to the car’s control systems. These connectors can handle both power and data easily. Their small size lets them fit into tight spaces in car wiring.

They are made from strong materials to last a long time. These connectors can handle heat, water, and shaking without breaking. Many have locks to stop wires from coming loose, even in moving cars.

Another great feature is their fast data transfer. This helps send important details, like engine performance, to the car’s computer quickly. These features make sensor connectors a must-have for car wiring systems.

Applications of Sensor Connectors

Sensor connectors are used in many car systems. They are often found in engines to connect sensors for fuel, temperature, and pressure. This helps the engine work better and use fuel efficiently.

They are also used in safety systems like airbags and anti-lock brakes. These connectors help keep you safe by linking important sensors. Advanced systems like lane-keeping and collision alerts also rely on them.

In entertainment systems, they connect sensors to screens for better driving experiences. Their strength and usefulness make them key parts of car wiring designs.

USB and Data Connectors in Automotive Wiring

Features of USB and Data Connectors

USB and data connectors are very important in cars today. They help car parts communicate, improving how cars work and stay safe. These connectors are made to be strong and easy to use.

They only fit one way, so they don’t get damaged.

Each USB connector has at least four parts for power and data. They provide 5V power up to 500mA, good for charging devices.

Special shielding keeps signals clear, even with electrical noise around.

They are tough and waterproof, lasting long in hard conditions.

New designs keep improving car electronics, making connections better and faster.

These features make USB and data connectors a must-have for car wiring systems. They help cars work smoothly and last longer.

Applications of USB and Data Connectors

USB and data connectors are used a lot in cars because they are helpful and flexible. They are found in infotainment systems, letting you play music or connect devices easily. They also charge phones, tablets, and other gadgets while you travel.

Besides entertainment, USB connectors are important for fixing cars. Mechanics use them to connect tools for checking and repairing cars, keeping them in good shape. Advanced connectors also let cars share information with each other, making driving safer.

From playing music to fixing problems, these connectors are used in many ways. They handle both power and data, making them an important part of car wiring systems.

How to Choose the Right Automotive Harness Connectors

Factors to Consider

When picking automotive harness connectors, think about these key points:

Environmental Conditions: Make sure connectors can handle heat, cold, and moisture. For outdoor or engine use, pick ones with high IP ratings like IP67 or IP68.

Mechanical Factors: Check if they can handle shaking and movement in systems like chassis or powertrain wiring.

Type of Termination: Choose between crimping, soldering, or screw-on types based on ease and strength.

Material: Use plastic for light jobs or metal for tough conditions. Stainless steel or aluminum stops rust in harsh places.

Signal Integrity: Pick connectors with low resistance to keep signals strong, especially for high-speed data systems.

Interchangeability: Find connectors that work with different brands and systems for easier repairs.

These tips help you pick connectors that work well and last long in car wiring.

Tips for Selecting the Best Connector for Your Application

Choosing the right connectors for your car wiring is simple with these steps:

Think about the environment. Pick connectors that resist heat, cold, and dirt.

Get connectors that can handle shaking and movement in cars.

Pick the right type for your wires. Crimping is strong, while soldering keeps signals clear.

Use materials that fit the job. Metal like stainless steel works well in tough places.

Check the power capacity to ensure the connectors can handle the load.

Choose connectors with locks to stop them from coming loose.

Follow these steps to make sure your car wiring works well and lasts a long time, whether for simple or advanced systems.

Automotive harness connectors are important for keeping your car's electrical systems working well. They help parts communicate and can handle tough conditions like heat and moisture. Strong connectors keep your car safe and running smoothly.

Different connectors have special uses, like weatherproof ones for outdoor areas or high-power ones for electric cars. They make wiring easier, improve how things work, and make cars more reliable overall.

To pick the right connectors, check your car's needs, like size, material, and fit. Look at your car manual for help and buy from trusted sellers. Choosing good connectors helps your car stay safe and perform well for a long time.

FAQ

What do automotive harness connectors do?

These connectors join electrical parts in cars. They help systems like engines, lights, and screens work better by sending power and data smoothly.

How can you pick the best connector for your car?

Think about where it will be used, how much power it needs, and the type of wires. Choose strong materials, good locks, and ones that fit your car's system.

Can you put in automotive connectors yourself?

Yes, you can install them using simple tools. Follow the steps, match the wires right, and make sure they are tightly connected for safety and good performance.

See Also

Understanding HSD Connectors' Role in Automotive Technology

Why FAKRA Connectors Matter for Automotive Solutions

Key Benefits of HFM Connectors for Automotive Use