Surprising Facts About Automotive Electrical Connectors Types

Automotive electrical connectors are crucial for vehicles, ensuring secure and efficient connections. As vehicles become more advanced, the demand for superior connectors increases. The rise of electric and hybrid vehicles necessitates a greater number of connectors to manage power effectively. There are various automotive electrical connectors types, each designed for specific functions, such as transmitting data rapidly or providing waterproofing in wet conditions.

Types of Automotive Electrical Connectors

High-speed Data Connectors

High-speed data connectors are very important in cars today. They help send data fast, which is needed for new car systems. These connectors are used in many places:

Infotainment Systems: They help with smooth streaming and better driving fun.

Navigation Systems: Fast data helps keep maps updated quickly.

Safety Features: They support things like crash alerts and lane warnings.

Fast data sending has many good points. It makes sure apps work well without waiting. This is key for keeping car systems running well.

Waterproof Connectors

Waterproof connectors are vital where cars might get wet. They stop water from causing electric problems. These connectors are needed for:

Engine Compartments: Where water and liquids can be found often.

Exterior Lighting Systems: Keeping lights working in all weather.

Underbody Applications: Protecting wires from road water and dirt.

Waterproof connectors have strong seals and tough materials. These make sure they last long, even when it's rough outside.

OEM Connectors

OEM connectors fit special car models perfectly. Makers design them to meet each car's needs best. The good things about OEM connectors include:

Compatibility: They fit well with the car's other parts.

Reliability: OEMs keep connections strong, lowering failure chances.

Quality Assurance: They follow strict rules, making makers and buyers feel safe.

Picking the right automotive electrical connector types helps cars work better and stay safe. Each type has a job that helps cars be more efficient and reliable today.

Technical Aspects of Connectors

Mechanical Properties

Car electrical connectors need to be strong and tough. They must last long and work well. Durability and strength are very important. Makers build them to handle stress. This means they stay together in tough spots. For example, car connectors face bumps and shakes but still work fine. This toughness keeps them working for a long time.

The impact on connector performance is big when thinking about strength. Strong connectors carry more load without breaking down. This helps keep the car's electric parts working right. By making sure they are strong, makers make sure cars run well.

Environmental Resistance

Being tough against the weather is key for car electrical connectors too. They need to handle bad weather and chemicals to work right. Resistance to temperature and chemicals is crucial because cars can get really hot or cold and face many chemicals.

The importance for safety and reliability is huge here. Tough connectors stop electric problems that could cause accidents or breakdowns. Using good materials helps them fight off bad weather, keeping cars safe.

Picking the Right Connectors

Choosing car connectors needs knowing important things. These make sure connectors work well and keep cars safe.

Current Rating

Finding the right current amount

The current rating shows how much power a connector can take. It tells us the most power it can handle without getting too hot. Engineers check how much power car parts need to find this out. They add up all the power needed and pick connectors that can handle it well. If they choose wrong, connectors might get too hot and break or be unsafe.

How it affects choosing connectors

Current rating helps decide which connectors to use. Connectors with more power are bigger and stronger, made for heavy loads. When picking, engineers think about space and weight in cars too. The right choice makes sure car parts work well for a long time.

Compatibility

Making sure they fit with car systems

Compatibility is key when picking car connectors. They must fit perfectly with car systems already there. This means matching them with wires and other parts of the car. Wrong ones can cause bad connections, making systems fail.

Things to think about for best performance

Many things affect if connectors fit well. These include how many contacts they have, their size, and weather conditions they face. Engineers look at what each part of the car needs to work best. For example, engine area connectors need to handle heat and chemicals. By thinking about these things, engineers pick connectors that help cars run better and stay reliable.

Automotive connectors are important for cars to work well and stay safe. Good connectors keep connections strong, even in tough weather. Picking the right connector means knowing about power levels, weather toughness, and fitting with car parts. This is very important for making sure cars work right in different places. By focusing on these things, makers can make sure cars are safe and run well with new technology demands.

See Also

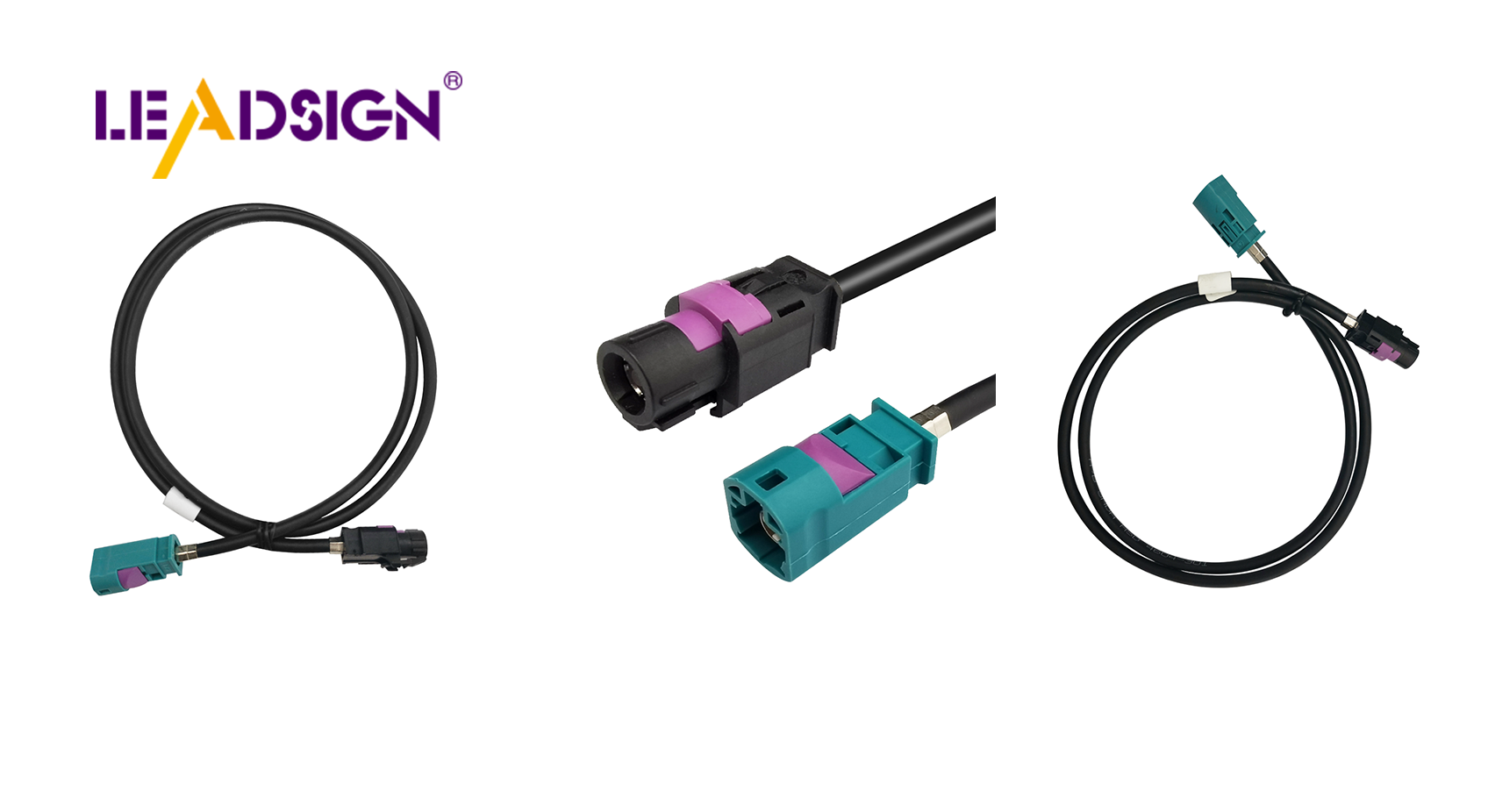

Significance of FAKRA Auto Connectors in Contemporary Cars

The Significance of FAKRA Connectors in Auto Uses

The Significance of FAKRA Connectors in Auto Sector