Surprising Facts About Vehicle Connectors

Did you know vehicle connectors keep you safe on roads? These small parts are key for your car's systems to work well. In trucks, especially off-road ones, strong connectors are a must. They handle tough conditions and make sure electronics work right. As more safety features are needed, good connectors are even more important. Without them, even strong trucks could have big problems working.

Key Takeaways

Heavy-duty connectors are essential for vehicle safety, ensuring that critical systems like lights and brakes function properly, especially in tough conditions.

These connectors are built to withstand extreme environments, making them ideal for off-road and heavy-duty vehicles, where reliability is crucial.

Investing in heavy-duty connectors can save money in the long run due to their durability and reduced need for replacements compared to standard connectors.

Technological advancements in connector design are enhancing vehicle performance by improving electrical flow and enabling the integration of smart technologies.

Heavy-duty connectors are not just for large vehicles; they can also be used in smaller cars to enhance electrical system reliability.

Using the right type of heavy-duty connector for specific applications, such as waterproof or high-heat variants, is key to maintaining vehicle functionality.

Understanding the true value of heavy-duty connectors can help dispel common misconceptions about their cost and application, highlighting their long-term benefits.

What Are Heavy-Duty Connectors?

Definition and Role

Explanation of heavy-duty connectors

Heavy-duty connectors are important parts in many fields. They are used in transportation, factories, and machines. They make sure connections stay strong in tough places. These connectors are made to handle bad conditions. They help send power and data safely. You see them where protection from dust, water, and heat is needed.

Importance in vehicle functionality

In vehicles, especially big trucks, these connectors are very important. They help all electric parts work right, even in hard times. Without them, trucks might have electric problems. This can cause big issues. Heavy-duty connectors help keep vehicles safe and working well. They are very important in making cars and trucks.

Types of Heavy-Duty Connectors

Overview of different types

Heavy-duty connectors come in different kinds. Each kind is for a special job. Some are waterproof, good for wet places. Others handle high heat. These connectors are made strong to last long.

Specific applications in vehicles

In vehicles, especially big trucks, these connectors are used in key spots. They link important systems like lights and engine controls. Waterproof ones are used in off-road trucks to stop water. High-heat ones are used near engines. Using the right connector keeps vehicle systems working well, no matter what.

Surprising Facts About Heavy-Duty Connectors

Durability and Longevity

Materials used for extreme conditions

Ever wonder why heavy-duty connectors are so tough? They are made from copper, brass, and bronze. These materials conduct electricity well and don't rust easily. This helps them work in bad weather. In big vehicles, they resist dust, water, and heat. This toughness keeps connections strong.

Lifespan compared to standard connectors

Heavy-duty connectors last longer than regular ones. They are built strong with better materials. Regular connectors might break under pressure, but heavy-duty ones keep working. This means you replace them less often, saving time and money.

Technological Advancements

Innovations in design

Vehicle connectors are changing fast. New ideas like making them smaller and adding smart tech are improving them. These changes help them work better in tough places. Smaller connectors fit in tight spots without losing power. This is great for big vehicles with little space.

Impact on vehicle performance

New designs in heavy-duty connectors make vehicles work better. They improve how electricity flows and make systems more reliable. This means your vehicle runs smoothly, even in hard conditions. You have fewer breakdowns and a better ride.

Applications in Extreme Conditions

Use in off-road and harsh environments

Heavy-duty connectors work well in rough places. They keep electrical systems running in bad conditions. In big vehicles, they handle bumpy roads and bad weather. Keeping connections stable is key for safety and working right.

Case studies or examples

Think about heavy-duty connectors in big machines like construction trucks. These work in dusty, muddy, and wet places. The connectors keep systems running, avoiding costly stops. They are also used in military vehicles, where they must not fail. They ensure important systems work, even in tough situations.

Benefits of Using Heavy-Duty Connectors

Reliability and Safety

How they stop problems

You need your vehicle to work well, especially in tough places. Heavy-duty connectors help stop problems. They are made for bad weather, keeping connections safe from dust, water, and heat. Unlike regular connectors, heavy-duty ones are strong and less likely to break. This is very important for heavy-duty trucks and off-highway vehicles. If they fail, it can be expensive and dangerous.

Helping vehicle safety

Safety is very important for vehicles. Heavy-duty connectors help a lot with this. They keep electrical connections steady, so lights, brakes, and engines work right. In rough areas, these connectors make sure safety features work, lowering accident risks. They handle high power and tough conditions, keeping trucks and big vehicles safe.

Performance Enhancement

Better electrical work

Heavy-duty connectors make vehicles work better by improving electricity flow. They are made to transfer power well, wasting less energy. This is great for heavy-duty trucks that need a lot of power. By using electricity better, these connectors save energy, improving fuel use and cutting costs.

Boosted vehicle skills

With heavy-duty connectors, vehicles can do more. Their design lets you connect different systems easily, making upgrades simple. This is key for off-highway jobs where vehicles need special setups. By supporting new tech and smart tools, heavy-duty connectors help vehicles do complex tasks, staying strong and efficient in hard places.

Common Misunderstandings About Heavy-Duty Connectors

Misunderstanding 1: Only for big vehicles

Some think these connectors are just for big trucks. That's not true. They are used in many vehicles, not just large ones. They help all electric parts work well. Heavy-duty connectors keep connections strong in different places. They make sure things like the engine and radio work right. Even in small cars, these connectors might be used to keep them running well.

Misunderstanding 2: Too costly for normal use

People often think these connectors are too pricey. They do cost more at first than regular ones. But they save money over time. They last longer, so you replace them less. They handle tough conditions, stopping electric problems. This means fewer repairs and less downtime. For any vehicle, good connectors are a smart buy. They keep systems working well and save money in the end.

Heavy-duty connectors are key for keeping vehicle systems working. They help trucks and cars run well, even in tough places. These connectors make vehicles safer and work better. They link systems like lights, air conditioning, and safety tools. In hard conditions, they keep connections steady and stop problems. When you think about vehicle connectors, remember how they help trucks stay safe and perform well.

FAQ

Why are wire connectors important in car history?

Wire connectors are key in car tech growth. They changed to fit new cars with many electronic parts. Each connector has a job, making sure all parts work together well. This shows how car tech has improved over time.

How are heavy-duty connectors different from regular ones?

Heavy-duty connectors are strong and tough. They handle bad weather, heat, and dirt. Unlike regular ones, they keep working in hard places. This makes them great for big cars and off-road use.

Why do heavy-duty connectors matter for car safety?

Heavy-duty connectors keep cars safe by holding electric parts steady. They help lights, brakes, and engines work right. In tough spots, they keep safety parts working, lowering accident chances and keeping cars safe.

Can small cars use heavy-duty connectors?

Yes, small cars can use heavy-duty connectors too. They work in all kinds of cars. They give strong connections, good for any car needing better electric work and strength.

Are heavy-duty connectors worth the cost?

Heavy-duty connectors cost more at first but save money later. They last long, so you change them less. They stop electric problems, cutting repair costs and downtime.

What are heavy-duty connectors made of?

Heavy-duty connectors use copper, brass, and bronze. These materials carry electricity well and don't rust. They work well in bad weather and last a long time.

How do new tech changes affect heavy-duty connectors?

New tech makes heavy-duty connectors better. They are smaller and work well in tight spots. These changes make car systems more reliable and efficient.

Where do you find heavy-duty connectors?

Heavy-duty connectors are used where strength is needed. They are in big trucks, off-road cars, building machines, and army vehicles. They work well in tough places.

What wrong ideas exist about heavy-duty connectors?

Some think heavy-duty connectors are only for big cars. But they fit many car types. Others think they cost too much, but they save money over time and are a good buy.

How do heavy-duty connectors boost car performance?

Heavy-duty connectors help cars by moving power well. They save energy, making fuel use better and costs lower. Their strong build helps add new tech, making cars work better.

See Also

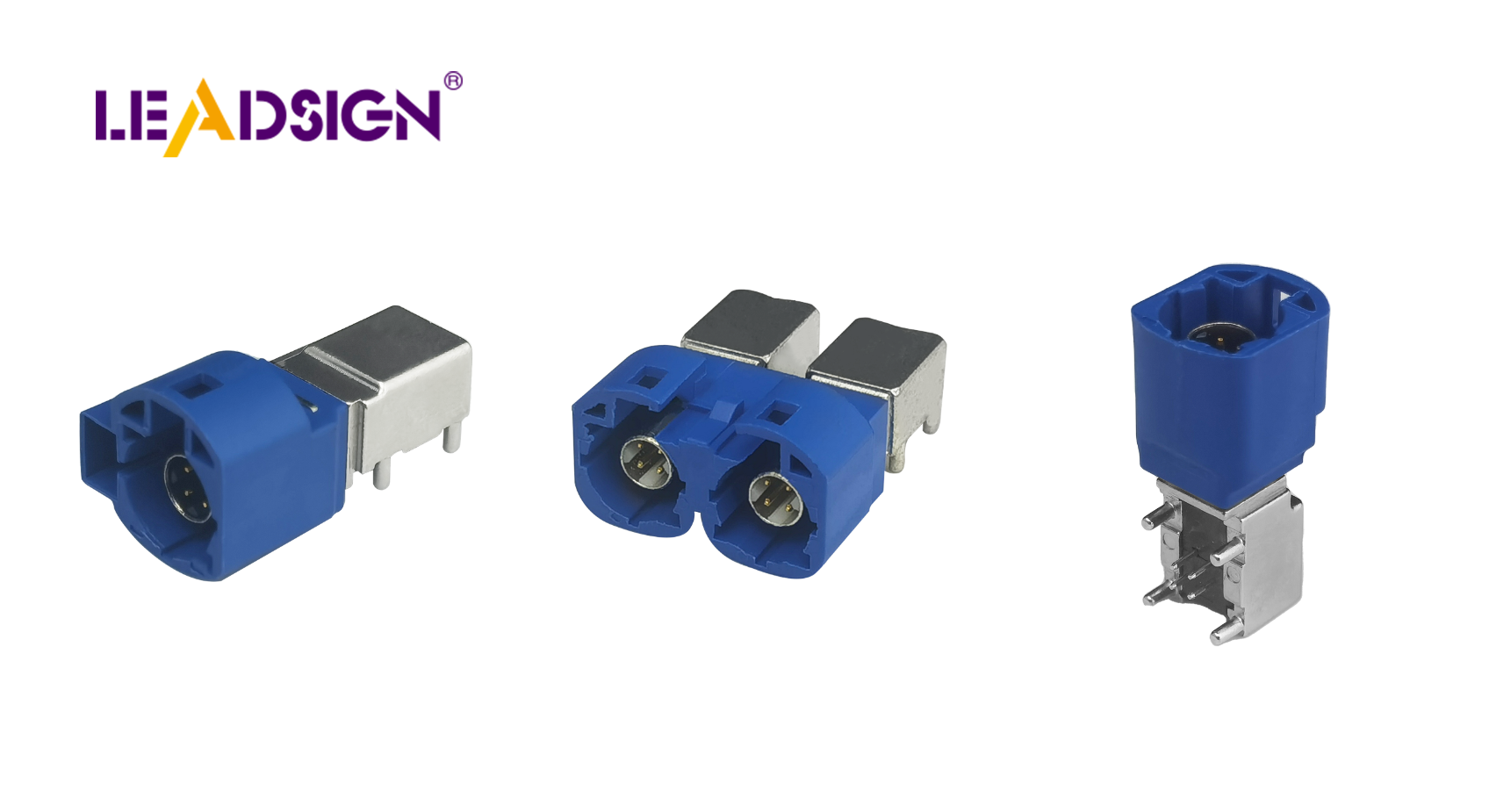

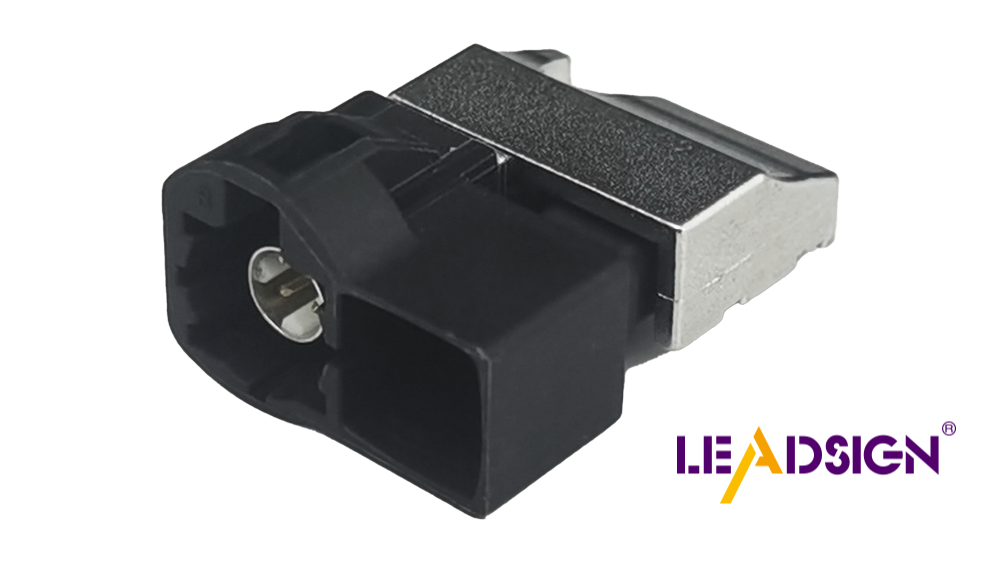

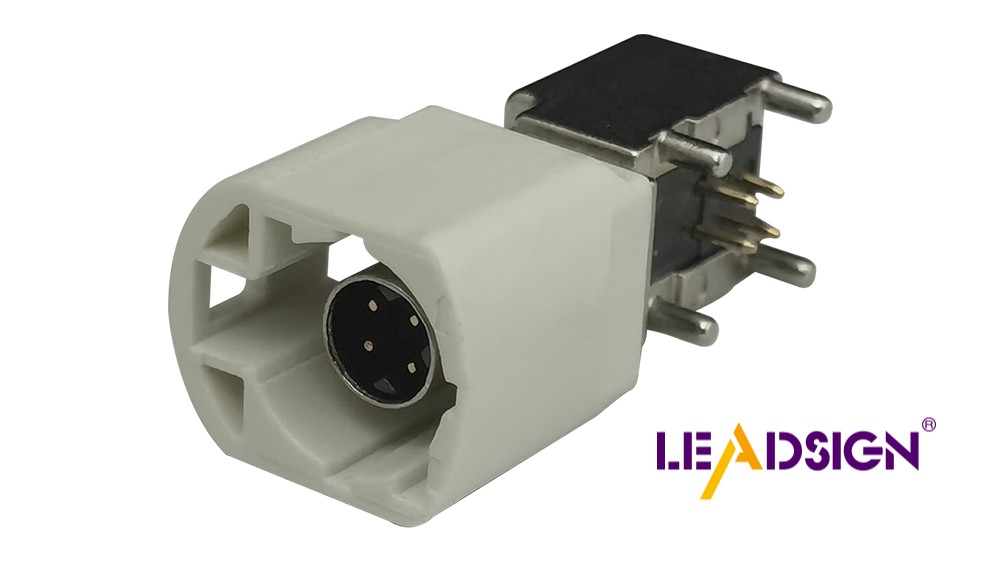

Exploring Benefits of Mini FAKRA Connectors for Vehicles

Why Fakra Connectors Matter for Today's Automotive Designs

Boosting Data Transfer with High-Speed Automotive Connectors