Step-by-Step: Using Automotive Wire Connectors Types in Projects

Selecting the appropriate automotive wire connectors types is crucial for car projects. You require robust connections to ensure safety and effectiveness. Automotive wire connectors are designed to withstand challenging conditions such as heat and vibrations. They provide secure, watertight, and vibration-resistant connections. Utilizing the correct connectors prevents electrical issues and enhances your vehicle's performance. This guide educates you on various connector types, enabling you to make informed decisions for your projects. Familiarizing yourself with these connectors empowers you to tackle any automotive wiring task with confidence.

Tools and Materials Needed

To work with automotive wire connectors, you need the right tools. These help make strong and safe connections in your projects.

Essential Tools

Wire Strippers

Wire strippers take off the plastic from wires. They do this without hurting the metal inside. You only need to show enough wire for a good connection. Pick a stripper that fits your wire size. This tool makes work easy and accurate.

Crimping Tools

Crimping tools attach connectors to wires tightly. They squeeze the connector for a snug fit. A good crimper gives you more power, making strong connections simple. Choose one that feels good in your hand and works with your connectors.

Heat Guns

Heat guns shrink tubing around connections. This keeps out water and rust. The gun heats evenly so tubing shrinks right. It’s useful for keeping connections safe.

Required Materials

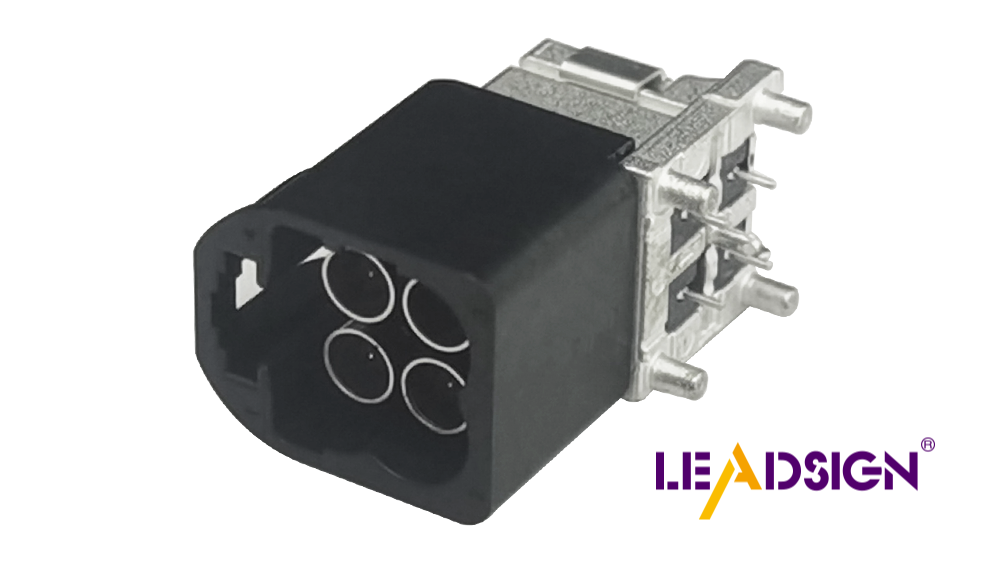

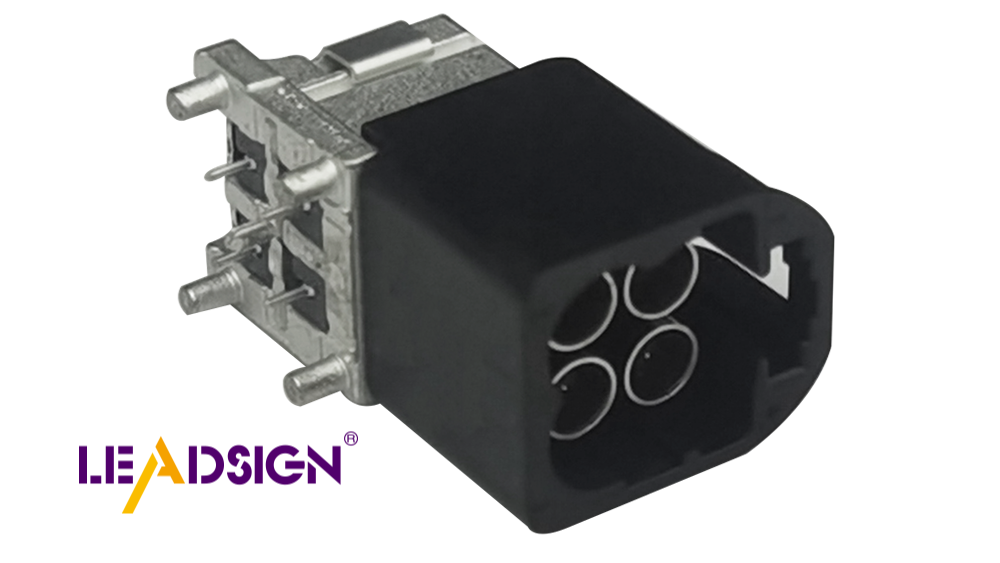

Different Types of Wire Connectors

You need different wire connectors like butt, ring, and spade terminals. Each has its own use, so having options helps. Pick ones that fit your wire size and needs. Electrical Connectors should be easy to put together and hold wires tight.

Heat Shrink Tubing

Heat shrink tubing covers and protects connections. It gets smaller when heated, sealing wires well. This stops water and dirt from messing up connections. Choose tubing that fits over connectors snugly.

Electrical Tape

Electrical tape adds extra safety to connections. Wrap it around wires for more insulation. It’s not as good as heat shrink but adds protection too. Keep some tape handy for quick fixes.

With these tools and materials, you're ready for wiring projects in cars. Each item helps keep connections strong, safe, and lasting long.

Understanding Automotive Wire Connectors Types

When you work on car projects, knowing wire connectors is key. Each type has a special job to keep connections strong. Let's look at some common types and how to pick the right one.

Types of Connectors

Butt Connectors

Butt connectors join two wires in a line. Put each wire in and crimp it tight. They are great for fixing or making wires longer. These connectors keep the electric path smooth.

Ring Terminals

Ring terminals have a round end for bolts or screws. Use them to attach wires to posts. They’re good for grounding or secure spots. The ring keeps the wire steady, even if it shakes.

Spade Terminals

Spade terminals, or fork terminals, slide under screws easily. They make quick connections simple to change. Use them where space is tight and you need easy access.

Expert Testimony: Draper Spark!Lab tested these connectors for different uses.

Choosing the Right Connector

Picking the right connector means thinking about a few things.

Factors to Consider

Environment: Think about where you’ll use it—wet, hot, or shaky places? Pick ones that handle these well.

Current Load: Make sure it can carry the electric load safely.

Ease of Use: Some are easier than others based on your tools and skills.

Connector Material and Size

The material and size matter a lot. Most are made from copper or brass for good flow of electricity. Match the size with your wire gauge to avoid problems.

Knowing this helps you choose safe and strong automotive wire connectors types for your project.

Step-by-Step Guide to Using Wire Connectors

When you work on car projects, using the right wire connectors is important. This guide helps you make safe and strong connections.

Preparing the Wires

Stripping the Wire Insulation

First, take off the plastic from wires. Use a wire stripper to show some metal. This step is important for a good connection. Be careful not to hurt the wire strands. A clean strip helps the connector hold tight.

Selecting the Correct Connector

Next, pick the right connector type. Think about wire size and what you need it for. Butt connectors join two wires; ring terminals attach wires to posts. Choosing well makes sure connections last long.

Connecting the Wires

Inserting Wires into Connectors

After stripping wires and picking connectors, put wires in connectors. Make sure they touch metal inside for a good path. Proper insertion stops loose connections and problems.

Crimping the Connector

Use a crimping tool after putting in wires. Squeeze tight so connectors grip well. A strong crimp handles shakes and stress well. Good crimping keeps your connections reliable.

Securing the Connection

Applying Heat Shrink Tubing

Slide heat shrink tubing over connectors for protection. Use a heat gun to seal it around wires and connectors tightly. This keeps out water and rust, which is very important in cars.

Using Electrical Tape for Extra Security

Wrap electrical tape around connections for more safety. It adds insulation and keeps things stable too. Tape isn’t as strong as tubing but helps quickly when needed.

Follow these steps to use wire connectors well, making safe car connections that last long.

Extra Tips and Tricks

When using automotive wire connectors, make sure your connections are strong. Here are some tips to help you do that.

Making Strong Connections

Checking the Connection

After connecting, always test it to see if it's secure. Use a multimeter to check if electricity flows well. If there's a break, recheck your work. Testing stops future problems and keeps your project working well.

Avoiding Mistakes

Mistakes can happen, but you can avoid them with care. First, strip the wire insulation correctly. Too much or too little is bad. Also, pick the right connector for your wire size. A wrong match makes weak connections. Lastly, double-check crimps because loose ones fail.

Comparing Connector Types

Knowing different connector types helps you choose the best one.

Pros and Cons of Each Type

Butt Connectors: Great for joining two wires straight. They connect cleanly but can be big in tight spots.

Ring Terminals: Strong for posts or bolts but need more space.

Spade Terminals: Easy to use in small spaces but less secure than rings.

Expert Insight: Draper Spark!Lab says choosing the right connector is key for durability and easy assembly.

Best Uses

Butt Connectors: Good for making wires longer or fixing breaks.

Ring Terminals: Best for grounding or securing wires to posts.

Spade Terminals: Perfect when you need to disconnect often.

By knowing these pros and cons, you can pick the best automotive wire connectors types for your needs. This helps make projects efficient and effective.

Good wire connections are very important in car projects. They keep things safe and make them work better. By using the steps in this guide, you can handle any wiring job easily. Each project helps you get better at it.

In Spark!Lab, people make smart connectors for special tasks, showing how cool new ideas can be.

Picking the right connectors changes your car projects a lot. It's not only about joining wires; it's about making them stay joined. Keep trying new ways and improving what you do. Your hard work will make things more reliable and work well.

See Also

An In-Depth Look at HSD Connectors for Autos

A Thorough Overview of HSD Connectors

Discovering the Advantages of Fakra Car Connectors