Step-by-Step Guide to Installing Car Connector Plugs

Knowing how to put in a car connector plug is important. It helps keep your car working well. A good connection makes sure the car's electric parts are safe. Bad plugs can cause problems with airbags and brakes. Learning to do it yourself saves money. It also lowers the chance of accidents from bad plugs. With the right tools, you can do a great job. This makes your car work better.

Key Takeaways

Understanding the different types of car connector plugs, such as blade, bullet, and butt connectors, is essential for making the right choice for your vehicle's electrical system.

Choosing the right connector involves considering the application, environment, and current/voltage requirements to ensure safety and functionality.

Having the right tools, including wire strippers, crimping tools, and heat guns, is crucial for a successful installation of car connector plugs.

Follow a step-by-step process: prepare the wires, connect them securely, and protect the connections with heat shrink tubing and electrical tape to ensure durability.

Regularly check your car's connectors for wear and damage, using a multimeter to test electrical flow and ensuring all connections are tight to prevent issues.

Replacing any faulty connectors promptly is vital for maintaining your car's safety and performance, so always have suitable replacements on hand.

By learning to install car connector plugs yourself, you can save money and enhance your vehicle's reliability, contributing to safer driving.

Understanding Car Connector Plugs

Car connector plugs are important for your car's electrical system. Knowing the types and picking the right one helps your car work better and stay safe.

Types of Car Connector Plugs

There are different car connector plugs, each with a job. Let's look at some common ones:

Blade Connectors

Blade connectors are flat and slide into slots. They are simple and reliable. You see them in fuse boxes and other parts.

Bullet Connectors

Bullet connectors are round and fit into sockets. They are good for connecting and disconnecting wires often, like in lights.

Butt Connectors

Butt connectors join two wires end-to-end. They are great for making wires longer or fixing broken ones. They help connect wires smoothly.

Ring and Spade Terminals

Ring and spade terminals connect wires to screws or studs. The ring is a circle, and the spade is open-ended. They are used in battery and grounding connections.

Choosing the Right Connector for Your Needs

Picking the right car connector plug depends on a few things. Think about these when choosing:

Application: Know what you need the connector for. If it's for high-frequency things like GPS or radio, use special connectors like the FAKRA Connector.

Environment: Check where the connector will be used. If it gets wet, choose waterproof ones for strength.

Current and Voltage Requirements: Make sure the connector can handle the power needed. For example, the SAE J1772 Connector can handle up to 80 amps and 240 volts, good for electric cars.

By knowing these things and the connector types, you can make smart choices for your car's electrical system.

Tools and Materials Needed

To put in a car connector plug, you need tools and materials. These help make sure your car's electric system works well.

Important Tools

Having the right tools makes the job easier. Here are the tools you need:

Wire Strippers

Wire strippers take off wire covers without harm. They get wires ready for the plug. Pick one that fits your wire size.

Crimping Tool

A crimping tool connects wires tightly. It keeps wires from coming loose. Press hard to make a strong hold.

Heat Gun or Lighter

A heat gun or lighter shrinks tubing. This adds protection. Be careful not to burn the tubing with a lighter.

Needed Materials

Besides tools, you need materials to finish the job. These keep connections safe.

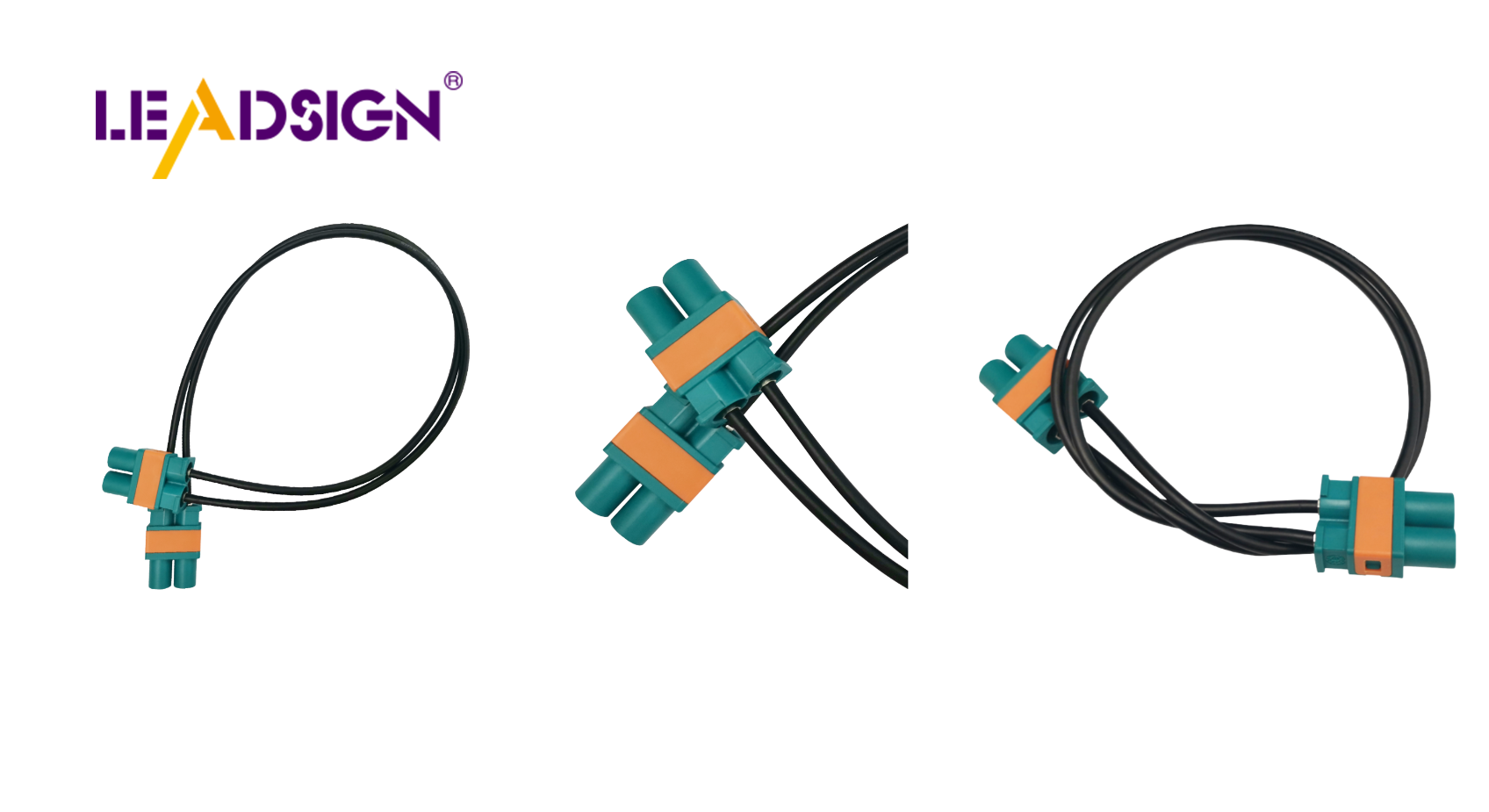

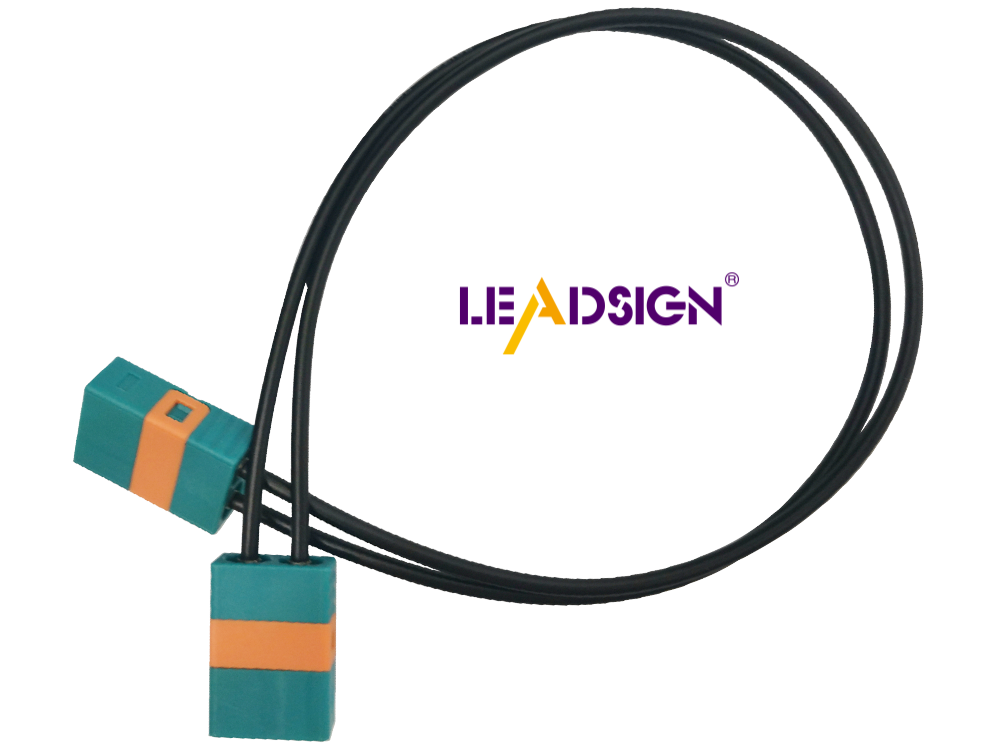

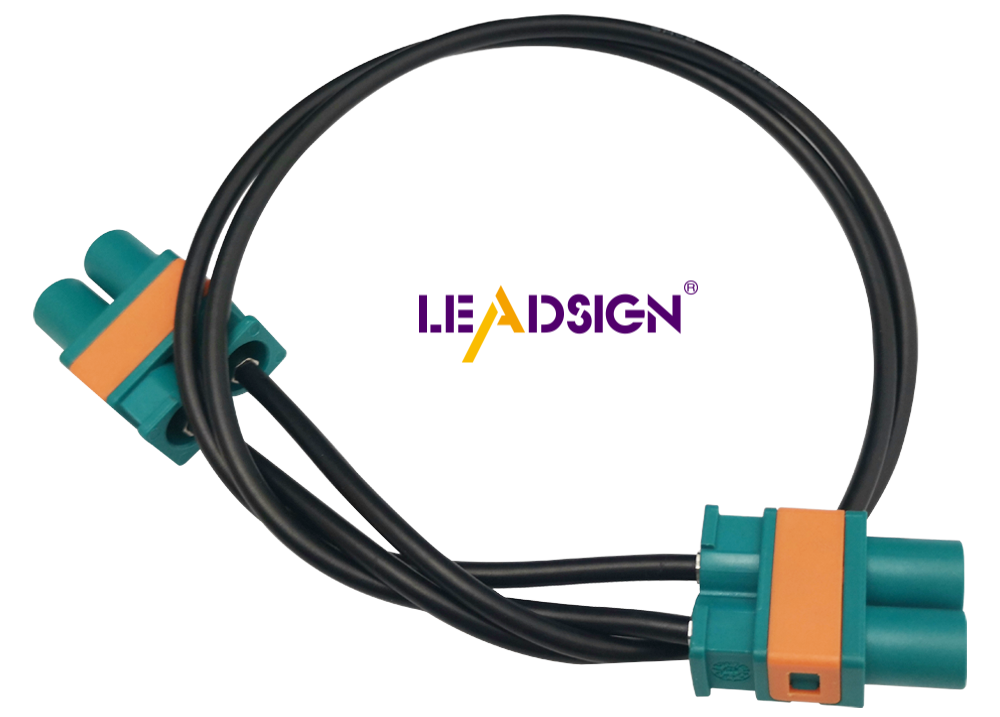

Car Connector Plugs

Car connector plugs are what you will install. Pick the right plug for your car. Make sure it fits the wires and system.

Heat Shrink Tubing

Heat shrink tubing protects wire connections. Slide it over and heat it to shrink. This keeps out water and dirt.

Electrical Tape

Electrical tape gives extra safety. Wrap it after shrinking the tubing. It adds more protection and keeps it steady.

By getting these tools and materials, you are ready to install the plug. Each part helps make a strong connection.

Step-by-Step Installation Process

Putting in a car connector plug has many steps. Each step makes sure your car's electric system works well and safely. Follow these steps to make a good connection.

Preparing the Wires

Get the wires ready before starting. This is important for a tight fit.

Cutting the Wires to Length

First, measure the wires to find the right length. Use a wire cutter to cut them. Make sure they are long enough to reach the connector without being too loose. Well-cut wires stop pulling and breaking.

Stripping the Wire Insulation

Next, take off the cover from the wire ends. Use a wire stripper to show about half an inch of bare wire. Be careful not to hurt the wire strands. Taking off the cover right helps the car connector plug fit better.

Connecting the Wires

After getting the wires ready, connect them to the car connector plug. This step is key for a strong electric link.

Inserting Wires into Connectors

Put the bare wire ends into the right slots of the connector. Make sure each wire is in its spot. Putting wires in right stops them from being loose and helps them work well.

Crimping the Connectors

Use a crimping tool to hold the wires in the connector. Press hard to make them stay tight. A good crimp keeps wires from coming loose later. This step is important for the car connector plug to stay strong.

Securing the Connection

After connecting, keep it safe from things like water and dirt.

Applying Heat Shrink Tubing

Slide heat shrink tubing over the connection. Use a heat gun to make it fit tightly around the wires and connector. This gives extra protection from wetness and dirt, making the car connector plug last longer.

Using Electrical Tape for Extra Security

Wrap electrical tape around the connection for more safety. This adds more cover and keeps it steady. Tape helps keep the connection strong, even in tough places.

Expert Testimony: "How long a car connector works depends on putting it in right and taking care of it." This shows why following each step is important for a strong and lasting connection.

By doing these steps, you can put in a car connector plug well. This helps your car work better and stay safe.

Keeping Connections Safe and Strong

To keep your car's electric parts working well, make sure every connection is safe and strong. This means checking them and doing regular care.

Checking the Connection

Checking connections is key to make sure they are safe and work well. Here’s how you do it:

Using a Multimeter

A multimeter checks the electric flow in your car connector plug. Set it to check voltage or if the circuit is complete. Put the probes on the connector ends. A steady number means a good connection. If the number changes or shows no flow, check your connections again.

Looking for Loose Connections

Loose connections can cause electric problems. Gently pull each wire on the plug. If a wire moves, it might not be tight enough. Squeeze the connector again to make it tight. This stops problems like short circuits or system issues.

Care Tips

Regular care keeps your car's electric parts in good shape. Follow these tips to make connectors last longer:

Regular Checks

Check your connectors often for wear and damage. Look for rust, color changes, or breaks. Clean them with a soft cloth and mild soap. Use a wire brush for rusty spots. Add a rust-proof coat to stop future damage.

Changing Bad Connectors

Change any bad connectors right away. A bad connector can hurt your car's safety and work. Pick a good replacement that fits your car. Putting in a new car connector plug right makes the system work best.

Expert Insight: "Checking connectors often for wear is key to keeping them working well." This shows why regular care is important for a strong connection.

By doing these steps, you keep a safe and strong connection in your car's electric parts. This not only makes it work better but also keeps you safe on the road.

Putting in a car plug is easy. First, get your tools ready. Then, cut and strip the wires. Next, join the wires with the right connectors. After that, cover the connection with heat shrink tubing and tape. A strong connection keeps your car safe. It stops problems like misfires or electric issues. By following these steps, you can put in car plugs well. Share what you learn to help others with their projects.

FAQ

What do high-voltage connectors in cars need?

High-voltage connectors must be safe and work well. They handle lots of power without getting too hot. They also resist water, dust, and temperature changes. Good materials and careful design help meet these needs.

How strong are car connectors?

Car connectors are made to last. They can handle tough conditions like heat, shaking, and chemicals. Strong materials and good locks keep them connected. Checking them often helps them last longer.

Why pick the right car connector plug?

The right plug keeps your car safe and working well. It stops problems like short circuits. It fits your car's power needs.

Can I put in car connector plugs myself?

Yes, you can do it with the right tools and steps. Follow a guide to do it right. Prepare wires, use the right connectors, and cover them for safety.

What tools do I need to install car plugs?

You need some tools:

Wire Strippers: To take off wire covers.

Crimping Tool: To hold wires tight.

Heat Gun or Lighter: To shrink tubing.

These tools make the job easier.

How do I check if my car plug is in right?

Use a multimeter to check the electric flow. Tug the wires gently to see if they are tight. A good connection won't move.

What if I find a broken connector?

Replace it right away to avoid problems. Pick one that fits your car's needs. Put it in right for best results.

How often should I check my car's connectors?

Check them every few months. Look for wear or rust. Fix problems fast to keep them working well.

Do all cars need waterproof connectors?

Cars in wet places need waterproof connectors. They stop water from causing problems. If your car gets wet a lot, use these connectors for better performance.

See Also

Exploring Ford Fakra Connectors: A Detailed Overview

Fakra Connectors in Honda Cars: An Informative Guide

In-Depth Insights into HSD Connectors for Users

Fakra Connectors Explained: Benefits, Uses, and Setup Advice