Solutions for High-Speed PCB Design Using Best Automotive Wire

High-Speed PCB Design is crucial in modern electronics, especially with the increasing demand for fast data transmission like 5G. The importance of PCBs capable of handling high-speed signals has significantly increased. Designers face challenges such as maintaining signal integrity and reducing interference. Incorporating High-Speed PCB Design in automotive electronics enhances signal clarity, strengthens connections, and minimizes signal loss. Implementing this design approach in fast electronic systems ensures robust and efficient performance, meeting the evolving requirements of today's technology landscape.

Understanding High-Speed PCB Design

Key Parts for Fast Design

Top Frequency and Data Speed

High-speed PCBs need careful planning. They must handle fast signals. These signals help send data quickly, like in 5G. Designers focus on these to make devices work well.

Rise Time and Signal Clarity

Rise time is important for clear signals. Quick voltage changes can mess up signals. Designers fix this by adjusting rise time. This helps avoid mistakes and makes systems better.

Challenges in High-Speed PCB Design

Part and Path Density

More parts fit on PCBs now. This needs smart ways to connect them. Designers must fit many parts in small spaces without losing quality.

Interfaces and PCB Tech

Different interfaces change how PCBs are made. Picking the right one is key for good performance. Knowing these helps designers build strong PCBs for many uses.

Challenges in Fast PCB Design

Signal strength is key in fast PCB work. Designers make sure signals stay clear and strong. They do this by planning how lines carry signals.

Controlling Impedance and Using Two Wires

Keeping impedance steady helps signals stay clear. Designers match trace impedance with source and load. This stops echoes and keeps signals sharp. Using two wires makes signals clearer too. It cuts noise and boosts performance.

Weak Signals and Cutting EMI

Signals can weaken over distance. Designers fix this with good materials and methods. EMI can mess up signals too. To cut EMI, they use shields and grounding. These tricks keep high-speed PCBs working well.

Picking Materials and Placing Parts

Choosing the right stuff and putting parts in the right spots matter for fast PCBs. These choices affect how well the PCB works.

Why Low Dk Stuff Matters

Low Dk materials are best for fast PCBs. They help keep signals strong and quick. Designers pick low Dk to make things work better. This choice helps signals move fast across the board.

Tips for Placing Parts Right

Where parts go affects signal paths a lot. Designers follow tips to place them well. They keep traces short and don’t cross paths. Good placement cuts interference and keeps signals strong, which is super important for fast PCBs.

Solutions for High-Speed PCB Design

Using HSD Connectors in Cars

High-Speed PCB Design uses HSD connectors in cars. These connectors are flexible and support many protocols. They are great for modern car electronics.

Flexible and Protocol-Friendly

HSD connectors support USB, LVDS, and Ethernet. This flexibility lets designers add many functions to one PCB. It improves car systems' performance. By supporting different protocols, they help parts talk easily. This is key for fast data transfer.

Meeting Standards and Safety Rules

Following standards is important in High-Speed PCB Design. HSD connectors meet strict rules, ensuring safety in cars. They can handle tough conditions like heat changes and shaking. By following these rules, designers know their PCBs will work well.

CAD Software's Role in PCB Layout

CAD software helps make better PCB layouts. It's crucial in High-Speed PCB Design by offering simulation tools.

Testing with Simulation Tools

CAD software like Allegro X lets designers test signals and power before finishing the layout. This testing finds problems early, saving money on mistakes later. By checking designs first, they ensure PCBs work well at high speeds.

Predicting Layout Choices

Predicting layout effects is vital in High-Speed PCB Design. A single software suite helps design, test, and share data safely. Doing all tasks together helps manage projects well and see how choices affect the product. This planning makes sure PCBs meet tough standards while reducing production issues.

Picking the Right Car Wire for Fast PCBs

Choosing the right car wire is key for fast PCBs. The wire choice affects how well the PCB works, especially in tough car conditions.

Things to Think About When Choosing Wires

Voltage, Current, and Density

When picking wires for fast PCBs, think about voltage, current, and density. These decide if wires can handle power without overheating or messing up signals. Wires with high current ratings are needed for strong power. Density affects how easy it is to fit wires on the PCB.

Why Ferrules Are Good

Ferrules help a lot in fast PCB design. They make connections strong and stop wires from fraying. This keeps electric contact steady. Ferrules are great for cars because they handle shaking well.

Trends and New Ideas

European Rails in Industry

European rails are big in industry now. They show why standard solutions that fit well are important. This means car wires need to meet strict rules to work everywhere.

Top Companies and Their Products

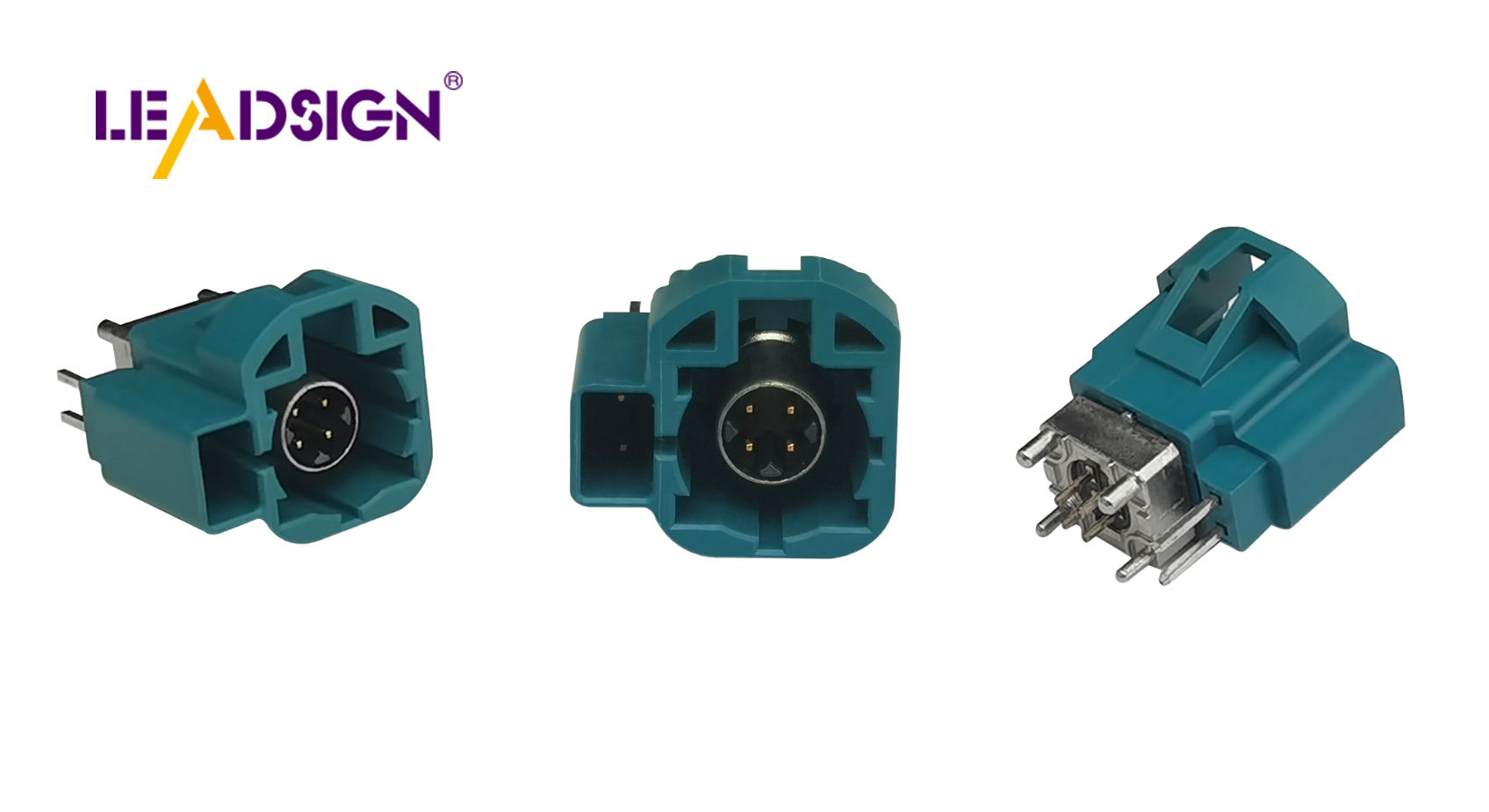

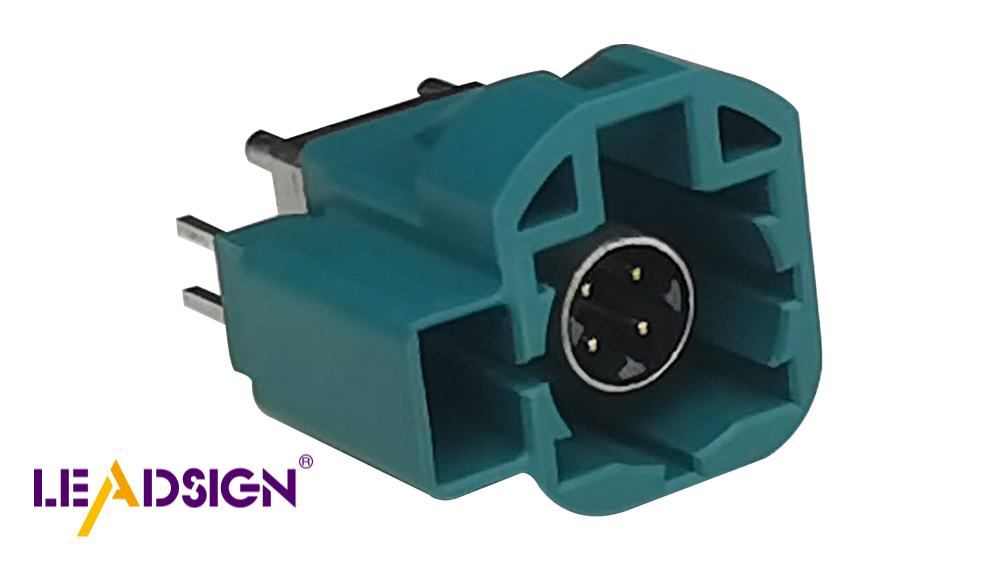

Some top companies lead new ideas in fast PCB design. They make products for today’s car needs. For example, LEADSIGN makes connectors that support USB and more. These work well in tough car places.

In short, picking the best car wire for fast PCBs needs careful thought about voltage, current, and density. By knowing trends and using new products, designers can make PCBs that work well in modern cars.

High-Speed PCB Design has many challenges. Keeping signals clear and fitting parts are tough. Designers fix these by picking good materials. They use smart CAD software to plan layouts well. Choosing the right car wire and connectors is key for strong performance in cars. As tech grows, High-Speed PCB Design gets better and greener. New trends in making PCBs will boost how they work and help the planet. This meets the needs of today’s electronics.

See Also

Improving Automotive Data Transfer Using FAKRA PCB Connectors

Enhancing Productivity with HFM Connectors for Automotive

Benefits of FAKRA PCB Connectors for Automotive Uses

Advantages of Employing FAKRA PCB Connectors in Automotive

Maximizing Automotive Data Transfer with Advanced Connectors and Cables