Signal Integrity Challenges in High-Speed Auto Wiring PCB Design

Signal integrity is crucial in high-speed PCB design for cars. It plays a vital role in ensuring that electrical signals remain reliable and accurate as they traverse through a car's systems. With the increasing sophistication of automotive technology and higher electricity usage in vehicles, maintaining clear signals becomes even more critical. However, achieving this can be challenging due to the harsh conditions that cars are exposed to, such as heat, vibrations, and signal interference. High-speed designs may encounter issues like signal bending and reflection, which can negatively impact the overall performance if not addressed properly. Therefore, addressing these challenges is essential for advancing car technology.

Understanding Fast PCB Design

Important Features

What It Means and Key Points

Fast PCB Design is about making circuit boards that send data quickly. These designs need careful planning to keep signals clear. Important things to consider are trace width, spacing, and how layers are stacked. The material's dielectric constant also matters because it changes signal speed. Managing these helps reduce signal problems like distortion and reflections, which often happen in fast circuits.

Fast vs. High-Frequency

People mix up fast and high-frequency designs, but they focus on different things. Fast design is about quick digital signals, while high-frequency deals with analog signals at high frequencies. In fast PCB design, the main goal is keeping signals clear over long distances and through parts. This needs special tools and careful routing to handle issues like signal loss and crosstalk.

Complexity Challenges

Parts Density and Routing

Fast PCB design gets harder with more parts on a board. More parts make routing tricky. Designers must keep traces short to avoid delays and interference. Good layer management is key for multiple layers to keep signals clear. This means placing power and ground planes smartly to lower impedance.

Interface Types Add Complexity

Different interfaces make fast PCB design more complex too. Interfaces like USB, Ethernet, and LVDS need special designs to work well. Each has its own needs for keeping signals clear, like matching impedance or using differential signaling. Designers must know these needs to make strong designs that work right. Advanced tools help improve these interfaces for reliable use.

Keeping Signals and Power Strong

In fast PCB design, keeping signals and power strong is key. These help devices work without problems. Designers focus on two things: controlling impedance and using differential signaling.

Controlling Impedance

Why It's Important

Controlling impedance is crucial in fast designs. It helps signals move smoothly without issues. If not controlled, signals can bounce back, causing trouble. This matters a lot in fast designs where signal precision is needed. Special tools predict and fix these problems for smooth device operation.

Ways to Reduce Signal Loss

Designers use tricks to cut signal loss. They pick materials with the right properties for steady impedance. They also adjust trace width and space to stop reflections. Software helps find and solve problems before making boards. These steps keep signals clear in fast PCB design.

Differential Signaling

Advantages and Uses

Differential signaling has big perks in fast PCB design. It sends two opposite signals on separate paths, cutting interference and boosting signal strength. It's used in USB, Ethernet, and LVDS to keep data clear even when conditions are tough.

How to Do It Right

Doing differential signaling needs planning. Traces must be equal length to avoid timing issues. Keeping them spaced evenly stops crosstalk too. Using connectors with special features improves signal strength further. By following these tips, designers make sure differential signaling works well in fast PCB design.

Material and Part Choices

Picking Materials

Dielectric Constant and Signal Speed

In fast PCB design, materials matter for signal quality. The dielectric constant shows how quickly signals move through a material. Lower constants mean faster signals, less delay, and fewer problems. Designers pick materials with the right dielectric to keep signals strong. They must balance speed with cost and availability.

Heat Expansion and Trustworthiness

Heat expansion is also key when choosing materials. As it gets hotter or colder, materials change size, which can hurt the PCB's trustworthiness. Fast designs make more heat, so managing it is important. Materials that don't expand much help keep the board strong and signals clear. Picking these helps PCBs last longer.

Placing Parts

Rules for Best Performance

Putting parts in the right spots keeps signals good in fast designs. Designers should follow rules to do this well. Parts should be close to shorten paths and cut signal loss or noise. Grouping similar parts helps with routing and makes signals clearer. Keeping power planes near each other boosts power strength too.

Effect on Signal Quality

Where parts go affects signal quality a lot. Bad placement can cause crosstalk or reflections that mess up signals. Designers need to think about how parts interact and leave space between them to stop problems. Tools like Altium Designer help check part placement for good results in fast PCB designs.

Tools and Techniques for Fast PCB Design

In fast PCB design, picking the right tools is key. These tools help make sure designs work well and signals stay strong.

CAD Tools and Simulation

Why They Matter

CAD tools are super important in fast PCB design. They let designers see and fix layouts before making them. This helps find problems early on. With CAD tools, designers can test how signals will act on the board. This testing helps stop issues like signal loss or noise.

What They Can Do

Altium Designer and Cadence Allegro are top CAD tools used today. They have great signal checking features needed for fast PCB design. These tools give exact tests so designers can fix signal problems early. Key things they offer include:

Fast and Accurate Tests: Important to spot issues in quick designs.

Dependability: Strong enough to handle tricky designs without failing.

Worth the Price: Offers many features that make it a good buy.

Smooth Process: Helps from start to finish, from drawing plans to testing.

Picking Connectors

Choosing good connectors is also very important in fast PCB design. Connectors help signals move well between board parts.

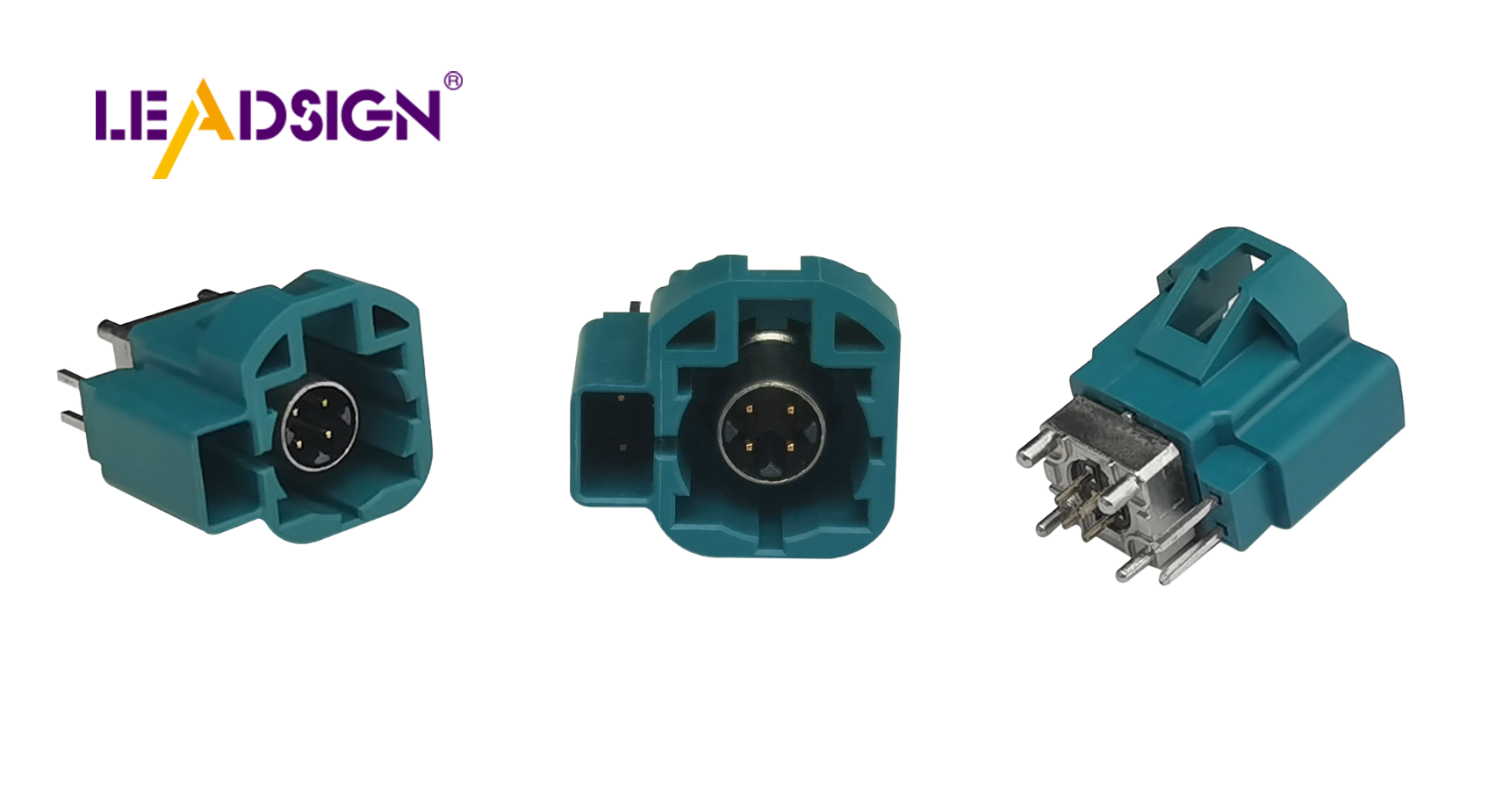

Types and Details

Connectors come in different kinds, each for special uses. In fast PCB design, connectors need to handle quick data speeds and keep signals clear. Designers pick connectors based on their build and how they work with electricity. For example, car electronics use HSD connectors, made for speedy data moves while lasting through tough conditions.

Rules and Guidelines

Following rules is key when choosing connectors. Connectors must meet certain needs to work right with others. Rules like USB or Ethernet have special guidelines that connectors must follow. By picking connectors that match these rules, designers make sure data moves well in fast PCB design.

Signal integrity in fast car wiring PCB design has many problems. Designers need to fix signal loss, interference, and where parts go. They use tricks like controlling impedance and using differential signaling to keep signals strong. Future ideas might have better materials and smarter tools for testing. These new things will make performance better and more reliable. Keeping up with research is very important. Engineers should look for new ways and tech to solve current problems. By doing this, they can make sure fast PCB designs work well in cars.

See Also

Improving Automotive Data Transfer Using FAKRA PCB Connectors

Boosting Data Transfer: The Significance of High-Speed Auto Connectors

The Vital Role of FAKRA PCB Connectors in Auto Connectivity