Understanding Applications of Semi-Rigid Coaxial Cables for Types of Wire Connectors Automotive

Semi-rigid coaxial cables are important in car wire connectors. They help car systems work well by improving electrical performance at high frequencies. These cables have better insulation than flexible ones, making them great for high-frequency use. They are strong and can withstand environmental changes, so they are very useful in cars. Knowing how they are used helps us see why they matter in today's vehicles.

Overview of Semi-Rigid Coaxial Cables

Special Features and Benefits

Strong Structure

Semi-rigid coaxial cables are very strong. They have a center wire inside a hard PTFE piece, all in a metal tube. This keeps them from bending, so they stay the same length. The solid build lets them work in many places, even in vacuums. This makes them great for jobs needing exactness and trust.

Good at High Frequencies

These cables work well with high frequencies because of their good materials. Semi-rigid coaxial cables can handle more power than bendy ones, so they're good for big microwave tasks. They're used in radar, satellites, and amplifiers. The solid parts help send signals clearly at high frequencies, making them the best for precise jobs.

Benefits in Cars

Tough and Trustworthy

In cars, semi-rigid coaxial cables are very tough and reliable. Their solid build handles rough conditions well over time. Unlike bendy cables, they don't wear out fast, lasting longer in car systems. Solid wires and PTFE make them strong enough for car use.

Resist Weather Changes

Semi-rigid coaxial cables resist weather changes well. They work fine in hot or cold places and can handle wetness too. This means they keep working right in different car spots like engines or outside parts. Their ability to stay good makes them a top pick for car wire connectors where keeping signals clear is key.

Comparing Coaxial Cable Types

Flexible Coaxial Cables

Bending vs. Staying Still

Flexible coaxial cables can bend and twist easily. This makes them good for places where they need to move. Semi-rigid coaxial cables stay in one shape because of their hard metal cover. This helps them work better with electricity, but they can't bend often.

Best Uses in Cars

In cars, flexible cables fit in small spaces and move with the car. Semi-rigid coaxial cables are best for parts that don't move much but need strong signals. They are great for important car systems.

Rigid Coaxial Cables

How They Work Differently

Rigid coaxial cables are like semi-rigid ones but bigger and less bendy. They work well with high frequencies but take up more space.

Cost and Setup Thoughts

Rigid cables cost more and need more room to install since they don't bend. Semi-rigid coaxial cables are cheaper and easier to set up than rigid ones, making them a smart choice for many car uses.

Integration with Automotive Wire Connectors

Types of Wire Connectors in Cars

Common Connector Types

Cars need different wire connectors for good electrical links. Some common ones are:

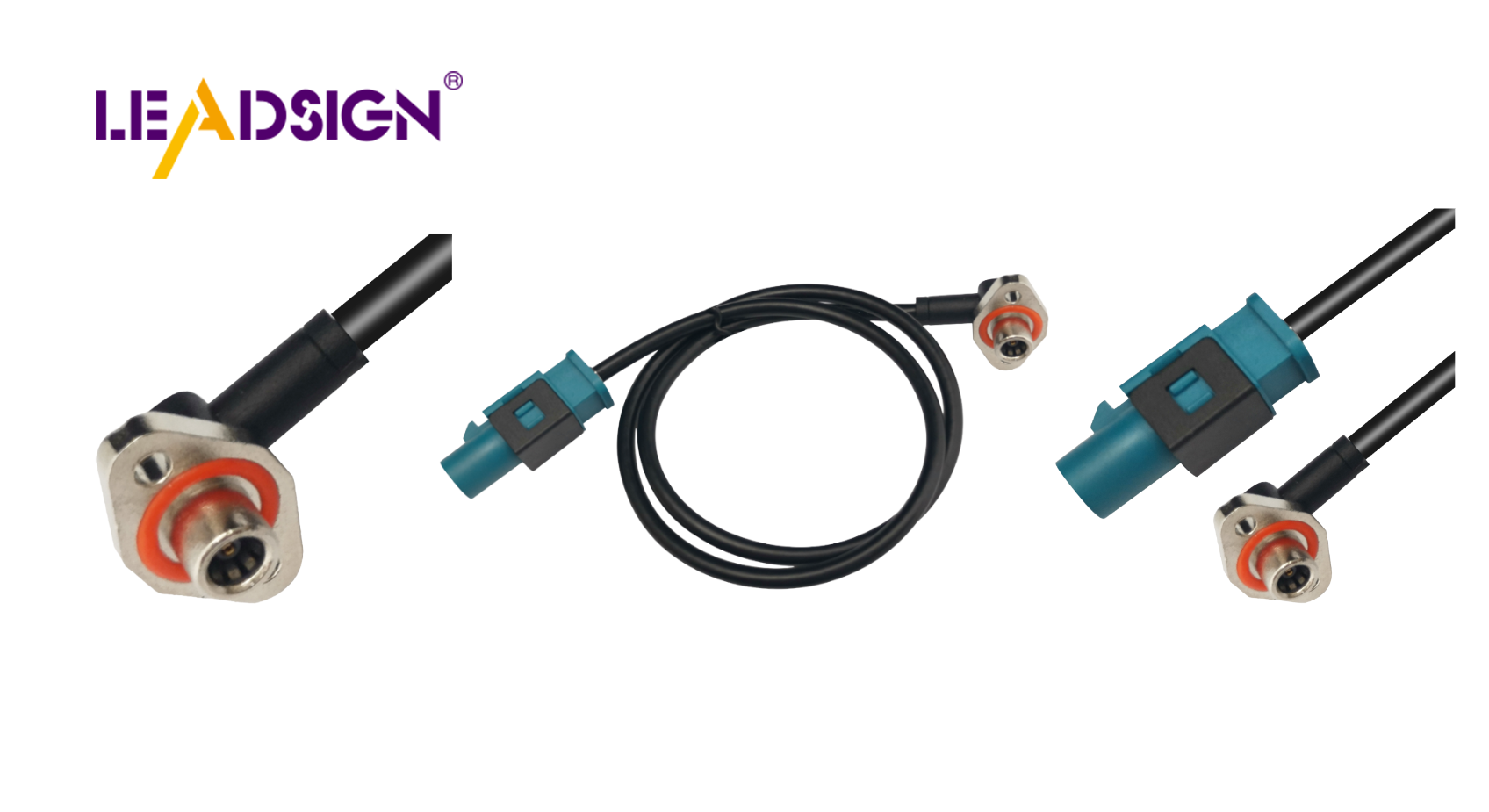

FAKRA Connectors: Used in high-frequency places like GPS and radios. They stop wrong connections and keep signals strong.

Blade Connectors: Simple for joining wires to parts, best for low frequencies.

Ring Terminals: These attach wires to screws or studs, making tight connections.

Each type has a job to keep the car's electric system running well.

Specific Uses for Semi-Rigid Cables

Semi-rigid coaxial cables are key where stability is needed. They work great for:

GPS and Radio Antennas: Good at high frequencies, they send clear signals.

Infotainment Systems: They give top audio and video quality, improving user fun.

Vehicle Sensors: They ensure sensors send data correctly.

These uses show why semi-rigid cables are vital in cars.

Installation and Compatibility

Ensuring Proper Fit and Function

Installing semi-rigid coaxial cables right is crucial. Installers should:

Follow Maker's Rules: Stick to bending guides to avoid harm.

Use Right Tools: Use tools that prevent bends from breaking the cable.

Check Compatibility: Make sure connectors fit the car's system well.

These steps help keep cables working long in cars.

Challenges and Solutions

Putting semi-rigid coaxial cables in cars can be tricky because:

Limited Flexibility: Hardness makes tight space installs tough. Automated benders help bend without harm.

Environmental Factors: Extreme heat or shakes can hurt them. Pick cables that resist these issues for reliability.

Cost Considerations: Though pricier than flexible ones, their strength justifies the cost over time.

By solving these problems, designers can use semi-rigid coaxial cables better, boosting car performance overall.

Practical Considerations and Trade-offs

Cost vs. Performance

Budget Limits in Car Design

Car designers often have tight budgets for parts. They need to balance cost and performance. Semi-rigid cables cost more than flexible ones but work better at high frequencies. Designers should check the system's frequency. If it's under 3kHz, cheaper cables might work. For strong microwave tasks, semi-rigid cables are best because they handle more power.

Long-term Gains of Semi-Rigid Cables

Buying semi-rigid cables can save money later. They last long and don't need replacing often, cutting costs over time. These cables keep signals clear and steady, making them a smart pick for important car systems where good performance is key.

Environmental and Operational Factors

Heat and Shake Resistance

Semi-rigid cables do well in tough places. They handle heat and shaking, so they're good for cars. Their solid build keeps them working well even when things get rough. This makes them last longer in vehicles.

Care and Lifespan

Strong semi-rigid cables need little care. They resist wear and tear, lasting longer than others. This means fewer replacements, saving money too. By picking these cables, car makers ensure systems work well for a long time.

Semi-rigid coaxial cables are great for cars. They are very stable and work well, especially for GPS and entertainment systems. Their strong build makes them last long, even in tough places. These cables keep signals clear when it really matters. Car designers should use these cables in new cars to make them better and more reliable. This way, cars can stay advanced and work well for a long time.

See Also

Why FAKRA Coaxial Cables Matter for Automotive Use

Benefits of HFM RF Connectors in Auto Tech

Harnessing FAKRA Coaxial Connectors for Maximum Efficiency