How to Make Secure Connections with Wiring Connector Types

Safe wire connections are very important for safety and performance. Good wire connections lower accident risks, which account for 58% of issues related to wires and tools. They also help wires last longer and function better by preventing problems. Choosing the right wiring connector types is key to achieving these benefits. Wire connectors come in various types, each designed for specific jobs and applications. Understanding these wiring connector types helps you make informed choices, ensuring that your connections are safe and effective.

Key Takeaways

Choosing the right wiring connector is crucial for safety and performance, reducing the risk of accidents and extending the lifespan of your electrical systems.

Familiarize yourself with common connector types—wire nuts, crimp connectors, push-in connectors, and solder connectors—to select the best option for your specific project needs.

Always consider the intended use, wire size, and environmental conditions when selecting connectors to ensure safe and effective connections.

Follow proper techniques for using each connector type, such as twisting wires for wire nuts and ensuring a secure fit for push-in connectors, to enhance connection reliability.

Prioritize safety by turning off power, wearing protective gear, and avoiding wet conditions when working with electrical connections.

Testing connections with a multimeter and ensuring proper insulation can prevent short circuits and enhance the overall safety of your electrical systems.

Understanding Wiring Connector Types

Definition and Importance

Wiring connectors are very important in electrical systems. They help signals move well between parts. Knowing about these connectors helps you make safe connections. Each type has a special job, like for sound, video, or data. For example, Ethernet connectors are used for data, and RCA connectors are for sound and video. Picking the right connector makes your electrical work better and safer.

Common Types of Wiring Connectors

Wire Nuts

Wire nuts are popular wire connectors. They join two or more wires. They come in different sizes and colors for different wires. Gray nuts are for small wires, yellow ones for two or three 12 AWG or 14 AWG wires. Twist the wires and screw the nut on. This makes a safe and covered joint.

Crimp Connectors

Crimp connectors join wires well. Use a crimping tool to press the connector on the wire. This makes a strong link. They are used in cars and factories. Crimp connectors hold cables tight, even if they shake. They are good when movement might loosen other connections.

Push-In Connectors

Push-in connectors make joining wires easy. Put the stripped wire in, and it locks. They are easy to use and save time. Push-in connectors are good for home and business wiring. They make a safe link without twisting or crimping, which is handy for many uses.

Solder Connectors

Solder connectors make a lasting bond. Heat melts solder around the wires for a strong joint. This way is best for a long-lasting connection. Solder connectors are used in electronics and pro audio. They make high-quality links, great for important setups.

Picking the Right Connector

Choosing the right connectors is important for safe connections. Think about a few things to pick the best one.

Things to Think About

Use

First, think about what you need it for. Different jobs need different connectors. For car electronics, you need ones that handle shaking and heat. For home projects, use simple ones like wire nuts. Knowing what your project needs helps you pick the right connector.

Wire Size

Next, think about wire size. The wire size tells you which connector to use. If the connector doesn't fit the wire, it can be unsafe. For example, wire nuts come in different sizes for different wires. Always check the connector size to match your wires.

Environment

Lastly, think about where you will use it. Some places need strong connectors. Butt splices are strong and good for tough spots. They hold wires tight even in hard places. If there is water, heat, or chemicals, pick connectors that can handle these. This keeps your connections working well.

By thinking about these things, you can pick the best connectors for your project. This keeps everything safe and working right.

How to Use a Wire Connector

Learning to use wire connectors right makes safe connections. Follow these steps for secure and good connections.

Getting Wires Ready

Before connecting, get wires ready. This is important for safety.

Taking Off the Cover

First, take off the wire cover. Use a wire stripper to remove half an inch. Be careful not to hurt the wire. Bare wire connects better.

Twisting Wires (if needed)

Next, twist the wires together. This is needed for some connectors, like wire nuts. Twisting keeps wires together, making it easy to connect.

Crimping Wires and Other Ways

Use the right way for each connector. Here’s how to crimp wires and other methods.

Using Wire Nuts

For wire nuts, put twisted wires in the nut. Twist the nut until tight. This keeps wires safe inside.

Using Crimp Connectors

Crimp connectors need a tool. Put the wire in and crimp it. Press hard for a strong hold. Crimping stops wires from loosening.

Using Push-In Connectors

Push-in connectors are easy. Put the bare wire in the hole. The connector holds the wire. This saves time and makes a safe link.

Using Solder Connectors

Solder connectors make a strong bond. Heat solder around wires until it melts. Let it cool for a solid link. This is great for lasting connections.

Making the Connection Safe

After connecting, make sure it’s safe and strong.

Testing the Connection

Test by gently pulling wires. They should stay put. Use a multimeter to check. This shows the connection is good.

Keeping Wire Connections Safe

Lastly, make sure connections are safe. Cover bare wires with tape or tubing. This stops short circuits and protects from damage.

By doing these steps, you can use wire connectors well. Crimp wires right and use good ways to keep connections safe and strong.

Safety Steps

Keeping wire connections safe is very important. It helps keep you safe and makes sure your electrical systems work well. Follow these safety steps to lower risks and make strong connections.

Basic Safety Tips

Turn Off Power Supply: Always turn off power before working with wires. This stops shocks and accidents.

Wear Protective Gear: Use gloves and glasses to protect from shocks or sparks. These are important when handling wires.

Avoid Wet Conditions: Never work in wet places. Water makes electrical dangers worse, so keep your area dry.

Keep Flammable Materials Away: Keep your work area away from things that can catch fire. This lowers fire risks.

Consult Professionals When Needed: If unsure about using connectors or if it's hard, ask an electrician. They know how to do tricky wiring safely.

Dinglian Ltd, experts in electrical safety, say these steps are important: "Electricity can be dangerous, so always be safe when using connectors."

Special Tips for Each Connector

Wire Nuts: Twist wires together before using a wire nut. This makes the connection stronger.

Crimp Connectors: Use the right tool to press hard. This keeps wires tight and secure.

Push-In Connectors: Make sure the wire is all the way in. This makes a safe connection without twisting.

Solder Connectors: Heat evenly to melt solder around wires. Let it cool for a strong bond.

By following these safety tips and special steps, you can make safe wire connections. Remember, being safe protects you and keeps your electrical systems working well.

Picking the right wire connector is very important. It helps make safe and strong connections. Using the right connectors makes your wiring projects safer. It also helps them last longer. Safe connections have many good points. They can carry more data and have less noise. This is why many people like wired networks. A good wiring setup is safer than wireless. It keeps your systems safe from hackers.

FAQ

What are the main types of wire connectors?

Wire connectors have different types for specific jobs. Common ones are wire nuts, crimp connectors, push-in connectors, and solder connectors. Each type helps make safe electrical links.

How do I choose the right connector for my project?

To pick the best connector, think about the job, wire size, and place. Use crimp connectors in cars where shaking happens. For home tasks, wire nuts work well. Always match connector size to wire size for safety.

Why is it important to use the correct wire connector?

Using the right connector keeps your electrical system working well. It stops accidents and helps wires last longer. Good connectors keep connections strong, lowering failure risks.

Can I use wire connectors for all types of electrical projects?

Wire connectors work in many projects. But some need special connectors. For fast data, you might need Ethernet connectors. Always check what your project needs before picking a connector.

How do I ensure a secure connection with wire connectors?

To make a secure link, follow the guide steps. Prepare wires right, use the right way for each connector, and test it. If unsure, ask an electrician for help.

What safety precautions should I take when using wire connectors?

Turn off power before working with wires. Wear gloves and glasses. Don't work in wet places and keep fire-starting things away. If unsure, get help from a pro.

Are there specific tools needed for using wire connectors?

Yes, different connectors need different tools. Crimp connectors need a crimping tool. Wire nuts might need pliers. Solder connectors need a soldering iron. Right tools make connections safe and good.

Can I reuse wire connectors?

Some connectors, like wire nuts, can be reused if okay. But it's safer to use new ones. Reusing might make connections weak.

What should I do if I'm unsure about using wire connectors?

If unsure or not comfy with wiring, ask an electrician. They know how to do tricky wiring safely. It's better to get help than risk unsafe connections.

How do wire connectors improve the safety of electrical systems?

Wire connectors make safe links, lowering failure risks. They stop bare wires that can cause shorts or fires. Using the right connectors makes your electrical setups safer and better.

See Also

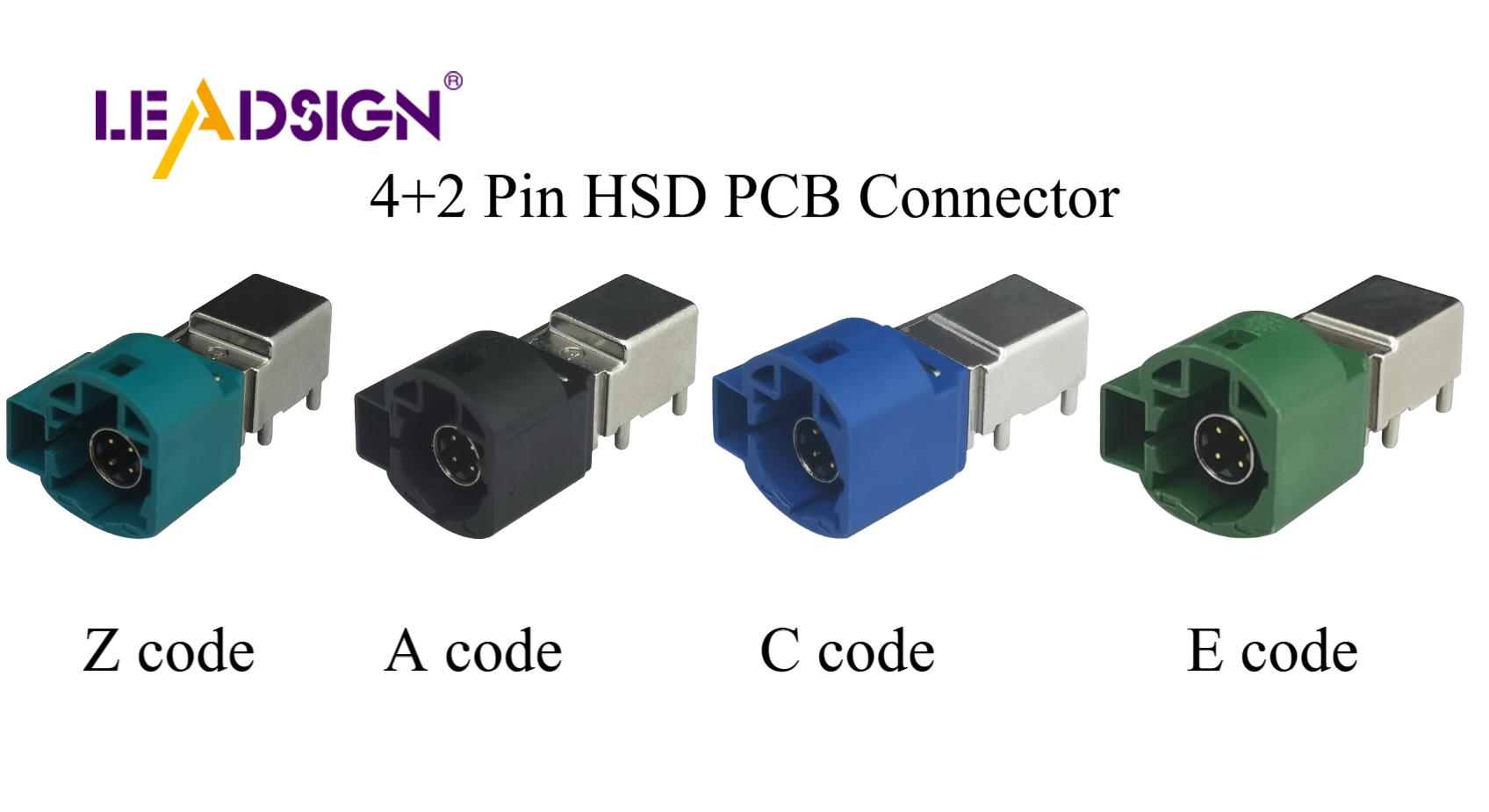

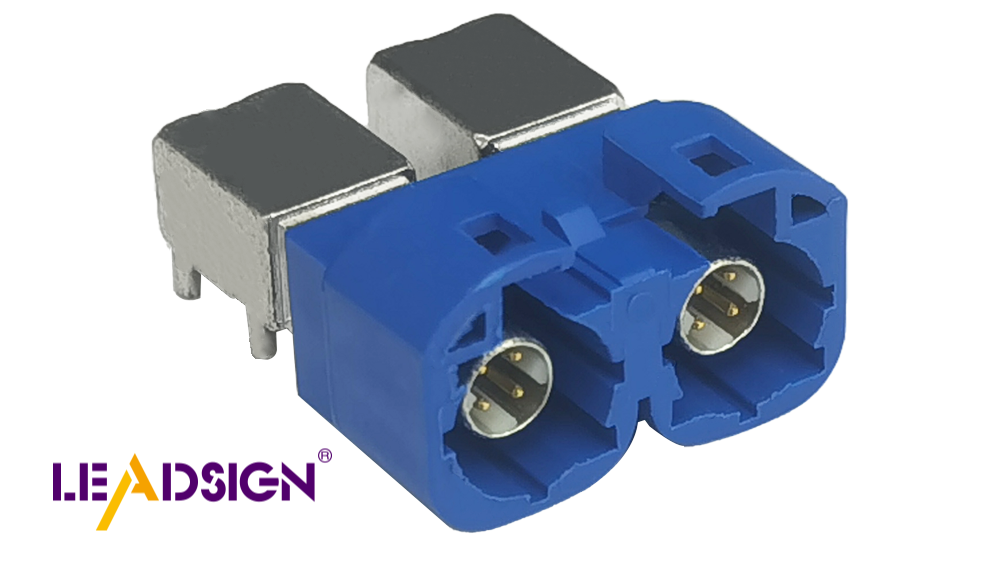

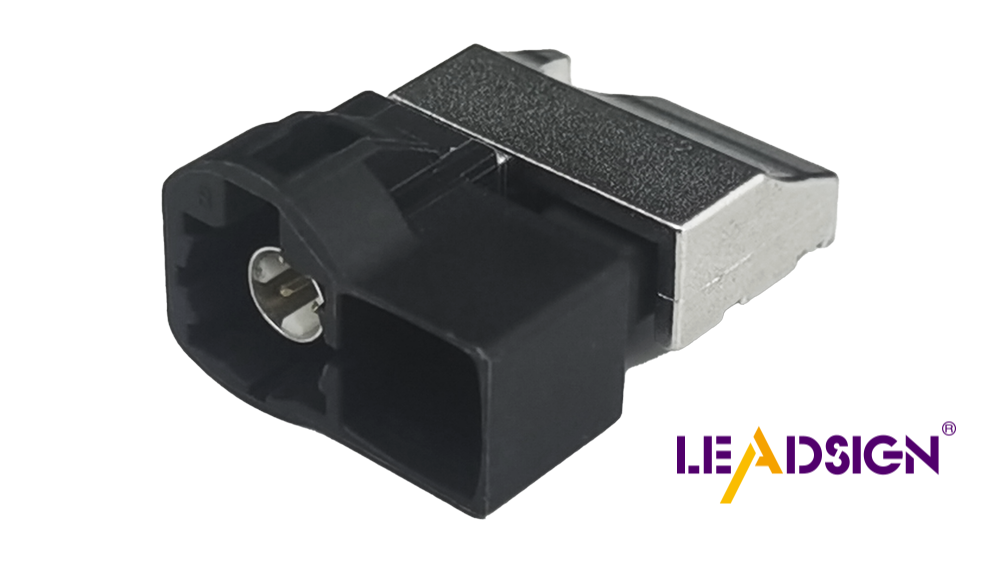

Essential Insights Into HSD Connectors For Everyone

Understanding Fakra Male Connectors: A Complete Overview

Fakra Connectors Explained: Benefits, Uses, And Setup Advice