Exploring the Role of Auto Electrical Connectors Plugs in Vehicles

Vehicle connectors are essential for linking wires in vehicles. They facilitate the transmission of power, signals, and data between various components. This integration allows systems such as the engine and sensors to operate in harmony. These connectors are robust and designed to withstand challenging conditions, ensuring that your car runs safely and smoothly.

Key Takeaways

Automotive electrical connectors are crucial for linking various car systems, ensuring they operate smoothly and safely under challenging conditions.

Choosing the right connector involves considering factors like current and voltage ratings, environmental conditions, and the type of termination to ensure reliability and longevity.

Strong connectors are designed to withstand heat, moisture, and vibration, which helps prevent electrical failures and enhances vehicle safety.

Types of Vehicle Connectors

Shapes and Sizes of Connectors

Vehicle connectors come in many shapes and sizes. Each type has a specific use. Below are common examples:

Description | |

|---|---|

Simple, round design for basic circuits like stereo systems. | |

Scotch Locks | Join wires quickly without stripping or soldering. |

Flat Connectors | Fit tight spaces without blocking other parts. |

Round Connectors | Good for outdoor use, often in exterior lights. |

Square Connectors | Handle multiple wires, used in engine sensors. |

Rectangular Connectors | Allow many pins, used in control units and modules. |

The shape and size affect how they work. For example, bullet connectors are great for audio systems because they disconnect easily. Square connectors are better for engine sensors since they handle more wires.

Connectors for Different Car Systems

Different car systems need specific connectors. Here are some examples:

Vehicle System | Connector Type |

|---|---|

Engine Management System | Rectangular or Square |

Lighting System | Round and Flat |

Audio and Entertainment Systems | Bullet or Rectangular |

Round connectors work well for lights because they resist weather. Rectangular connectors are used in engines for complex circuits.

Materials Used in Connectors

Connectors are made from strong and durable materials. Plastic is light and works for most uses. Metal is stronger and used in tough conditions.

Material Type | Common Materials | Reasons for Selection |

|---|---|---|

Insulation Material | PA66, PBT, ABS, PC | Lightweight and fits many uses. |

Contact Material | Brass, phosphor bronze, beryllium copper, copper nickel silicon | Conducts electricity well and resists rust, good for high power. |

Housing Material | Plastic, Metal | Plastic is cheap and light; metal is strong and shields better. |

Plastic connectors are popular because they are cheap and flexible. Metal ones are better for tough jobs, offering strength and protection.

Key Features of Automotive Electrical Connectors

Built to Last

Automotive electrical connectors are made to be strong and durable. They can handle heat, shaking, and interference from other signals. This helps your car's systems work well, even in tough places. For example, they are tested to survive bad weather and rough roads.

Important durability features include:

Current rating: Handles electricity without getting too hot.

Voltage rating: Stops sparks and system problems.

Mechanical strength: Locks and holds tight during shaking.

Material selection: Uses plastic or metal to avoid damage.

These features keep connectors working for a long time and prevent problems.

Protection from the Environment

Connectors face water, heat, and rust challenges. To fix this, makers use special materials and seals. Rubber parts like gaskets or o-rings block water. Many connectors have IP ratings, like IP67 or IP68, showing they resist dust and water.

Connectors are also made to:

Work in temperatures from -65 to 200 degrees Celsius.

Resist rust in salty air for at least 48 hours.

Handle wet conditions for a long time.

These protections help connectors work well in hard conditions.

Keeping Connections Strong

Good connections are important for cars to work right. Loose or rusty connectors can stop electricity and cause issues. New connectors are built to handle shaking, water, and extreme heat. Picking the right connector for the job makes them last longer.

Strong connections help your car run safely and smoothly.

Uses of Car Electrical Connectors

Car electrical connectors are important for many car systems. They help systems share power and information, making cars safer and better.

Engine Systems

Connectors are key for engine systems. They link parts like sensors and actuators to work together.

Powertrain control uses connectors to stay connected to Engine Control Units (ECUs).

9-hole connectors help sensors and actuators talk, saving fuel and cutting pollution.

CPA connectors stop breaks in the system, keeping the engine running well.

Lights and Signals

Lights and signals need connectors to work properly. These include headlights, brake lights, and turn signals.

Connectors keep lights working so drivers can show their moves.

Broken connectors can cause light problems, making accidents more likely.

Strong connectors fight weather damage, keeping lights working in all conditions.

Entertainment Systems

Modern cars use connectors for entertainment systems like radios, screens, and GPS.

HDMI connectors stay in place and handle shaking.

Type E connectors combine media features for steady performance.

Fast data connectors keep GPS and communication tools running smoothly.

Safety Systems (e.g., Airbags, ABS)

Safety systems like airbags and ABS need strong connectors to work well.

CPA connectors make sure airbags connect and work in emergencies.

Good connectors help ABS and traction systems work without stopping.

These connectors keep passengers safe and cars steady on the road.

How to Pick the Right Car Terminals and Connectors

Picking the right car terminals is very important. It helps your car's systems work well and stay reliable. Think about certain factors, the environment, and expert advice to choose wisely.

Things to Think About

When picking car terminals, check some key things. These make sure they fit and last long.

Factor | What It Means |

|---|---|

Current rating | Terminals must handle the system's current to stop overheating. |

Voltage rating | They should match the system's voltage to avoid sparks. |

Number of contacts | More contacts allow many connections, making them more useful. |

Terminals should survive heat, cold, water, and dirt. | |

Mechanical factors | Look for locks and features to handle shaking and movement. |

Type of termination | Pick soldering, crimping, or screw-on types for strong links. |

Material | Plastic is light, but metal is stronger for tough jobs. |

These tips help you find the right terminals for your car.

Why the Environment Matters

The environment affects how well car terminals work. Terminals need to handle tough conditions like heat, water, and chemicals.

Terminals with high IP ratings block dust and water.

Good seals keep them working in wet places.

Materials must handle temperatures from -40°C to 120°C.

Choosing the right terminals makes them last longer and work better.

Ask Experts or Suppliers for Help

If you're not sure which terminals to pick, ask experts or suppliers. They can help based on your car, system needs, and challenges. They also follow rules like USCAR-20, which tests for stress and shaking. Their advice saves time and avoids mistakes.

Car connectors are important for keeping your car safe and working well. They help systems like ECUs, airbags, and ABS stay connected. This prevents problems that could make driving unsafe. Good quality connectors last long and handle tough conditions. Always pick reliable brands with certified products for your car's needs.

What are car terminals, and why do they matter?

Car terminals link wires in a car's system. They make sure parts work by keeping electrical connections strong.

How can you pick the right connectors for your car?

Think about things like power, voltage, and weather conditions. Choose connectors that fit your car's wiring and needs.

Why are strong connectors important in cars?

Strong connectors last a long time. They handle heat, shaking, and water, helping car parts work well and stay reliable.

See Also

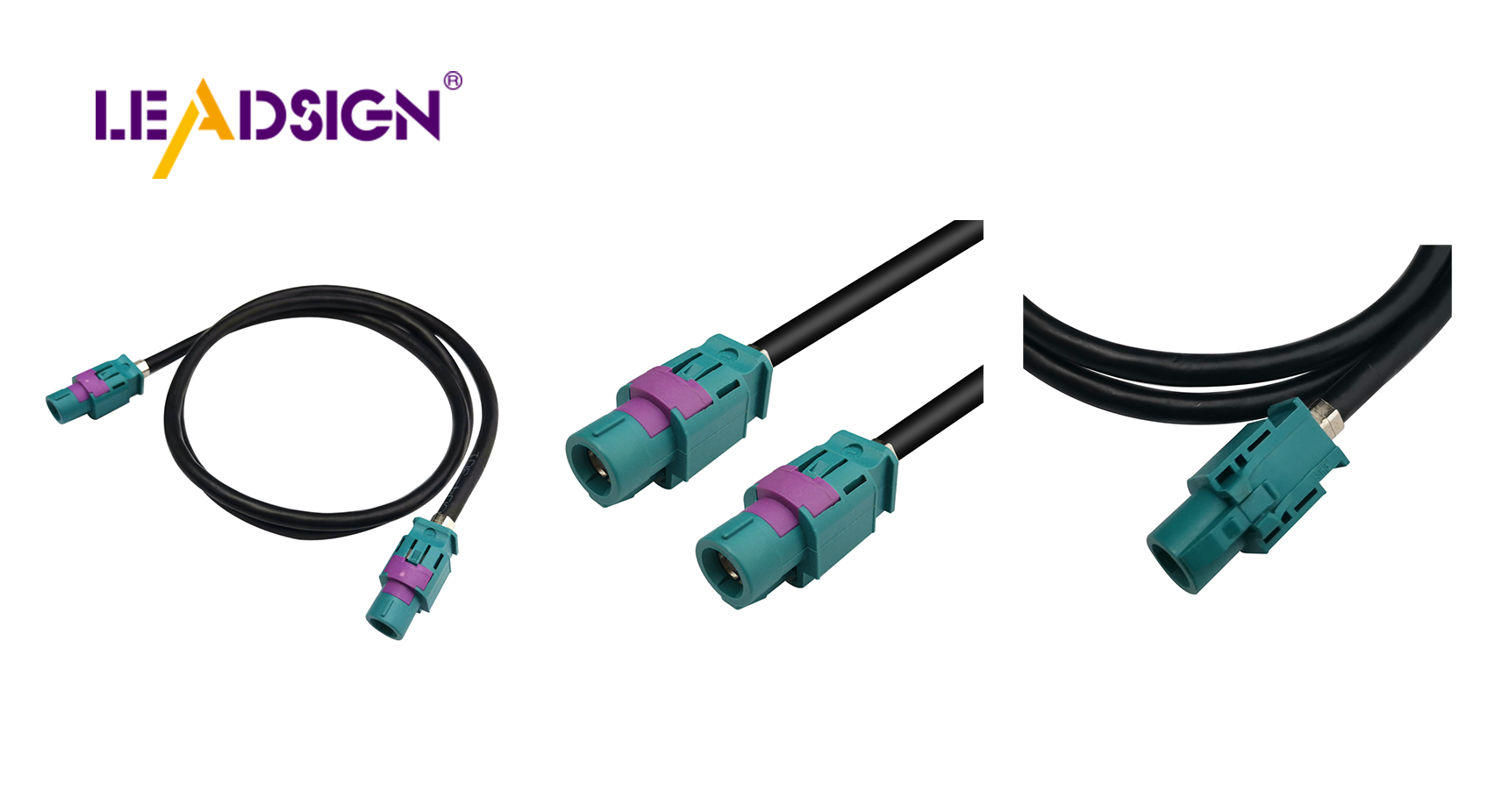

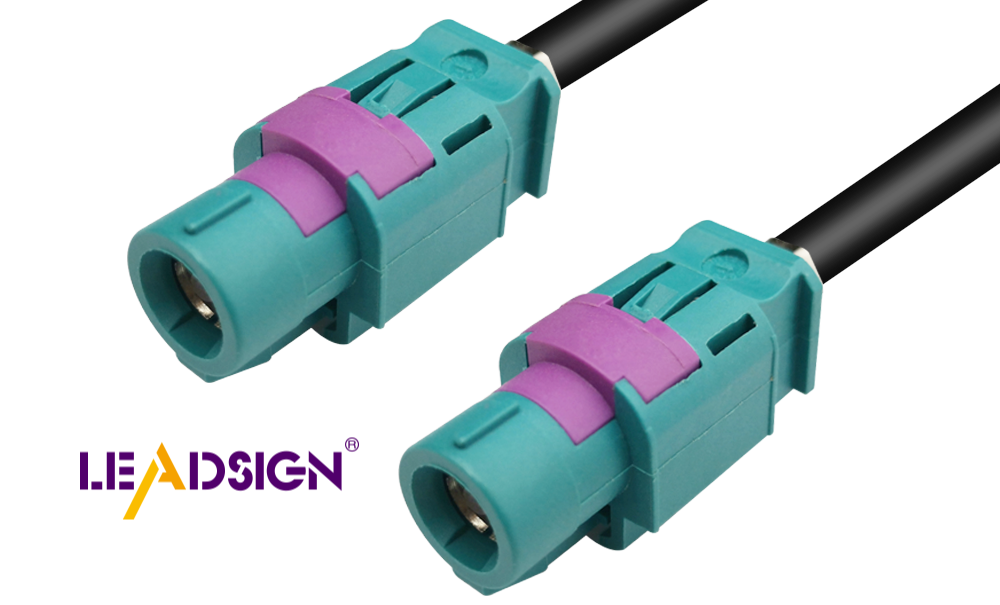

Unveiling Advantages of Fakra Connectors in Vehicles

Boosting Data Transfer: Significance of Fast Automotive Connectors

Crucial Role of Fakra Connectors in Today's Cars