Unlocking the Secrets of Rigid Coax in Cars

You may ask why semi-rigid coax cables are important in cars. These cables are known for being reliable and stable. They help send RF signals well. They have solid copper tubes and PTFE inside, which makes them strong and long-lasting. Knowing how these cables work in cars shows why they matter. They keep the same length even when it gets hot or cold. This makes them perfect for high-frequency uses. By learning about rigid coax, you can see why they are key in today's cars.

Understanding Semi-Rigid Coaxial Cables

Basic Structure

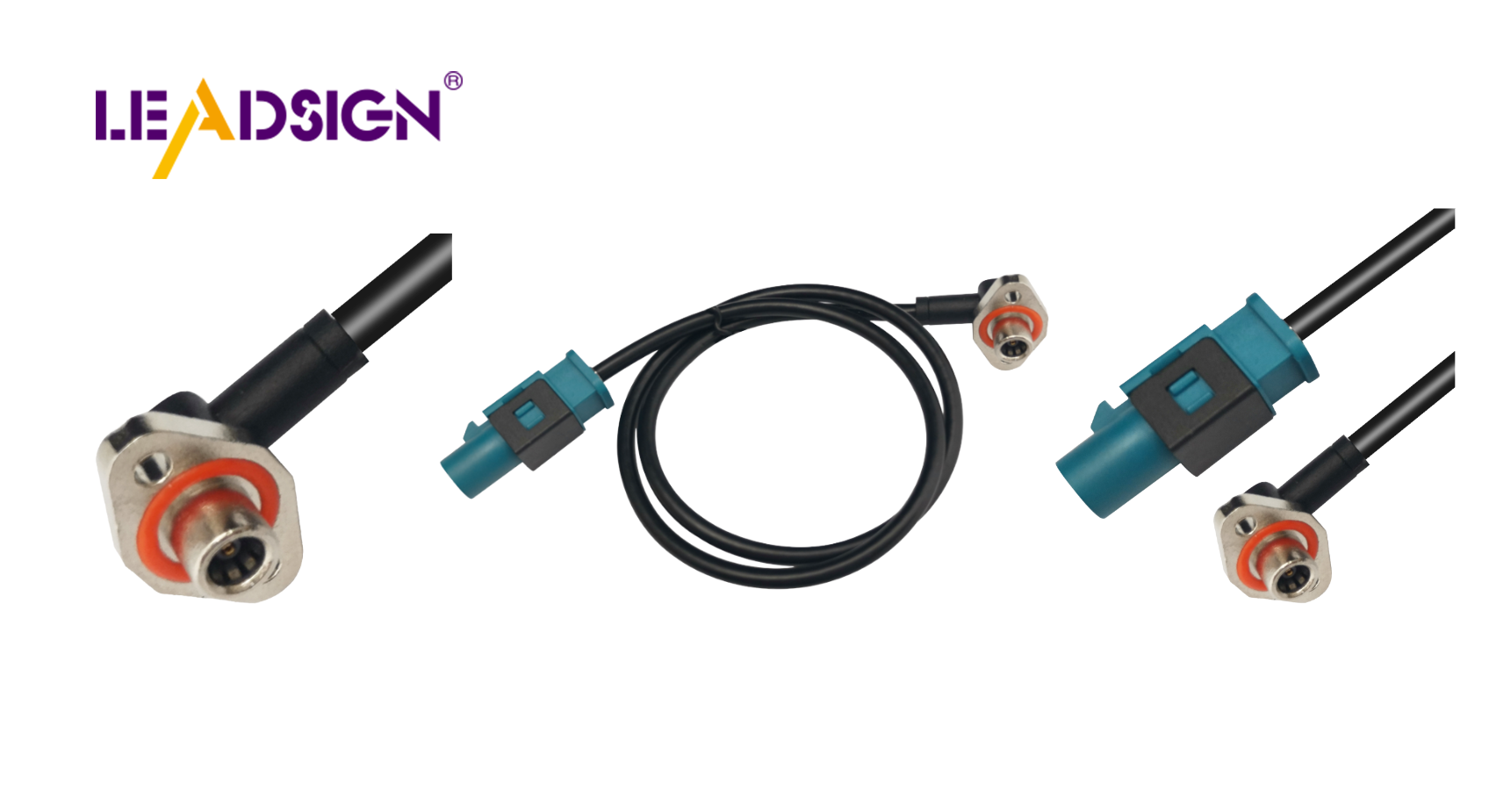

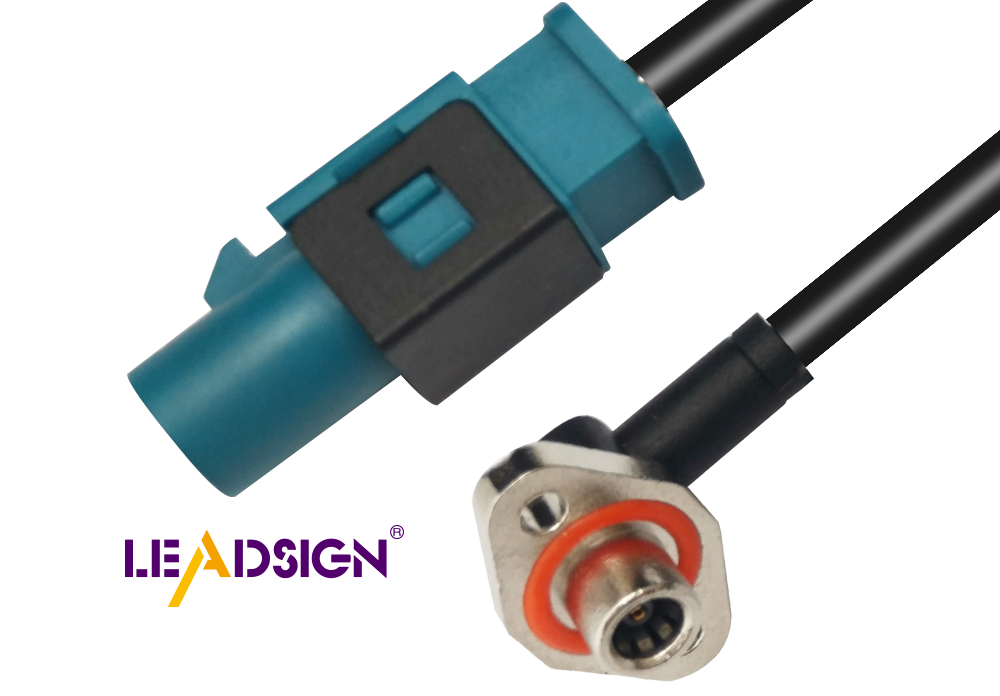

Semi-rigid coax cables are important in cars. They have a special design that makes them work well. These cables have three main parts: a center wire, an insulating layer, and a metal cover. The center wire is usually copper and carries signals. The insulating layer, often PTFE, wraps around the center wire to keep it safe and in place. The metal cover, made of copper or aluminum, protects the signal from outside noise.

These cables send signals very well over long distances. This makes them great for things like car GPS and radios. Their strong design keeps signals clear with little loss. Knowing how these cables are built helps you see why they matter in cars today.

Key Materials

The materials in semi-rigid coax cables help them work better. Copper is often used because it conducts electricity well and bends easily. Sometimes steel covered with copper is used to make them last longer while still working well.

The insulation is also important for these cables to work right. PTFE is a common choice because it insulates well and holds the center wire steady inside the tube. This steadiness keeps the cable's electrical performance good.

By looking at what these cables are made of, you can understand why they are chosen for cars. They use top-quality materials to meet tough car needs, ensuring reliable signal sending.

Building Process

Simple Steps

Picking Materials

When making semi-rigid coax cables, picking good stuff is key. Choose top metals and insulators for steady electricity flow. Copper is often used for the middle wire because it carries electricity well. For the outside cover, solid copper tubes stop interference. The insulator, usually PTFE, holds the middle wire and keeps its shape. Picking these materials carefully helps the cable work well in cars.

Putting It Together

After choosing materials, you start building. Follow steps to make sure the cable works right. First, put the middle wire into the PTFE insulator. Next, wrap this with a metal tube. Be careful not to break anything while doing this. Machines bend cables without bending them too much. These steps help make a strong cable that lasts long.

Making Techniques

Careful Building

Being exact is important when making these cables. Each part must fit just right inside. This makes sure they work well all the time. Special machines help make cables fit car needs perfectly. Being exact means cables send signals reliably.

Checking Quality

Checking quality is super important when making cables. Test them to see if they work well under different conditions. Tests check how they handle electricity and tough environments like cars have. By testing carefully, you make sure cables are strong and dependable.

Benefits in Automotive Applications

Durability and Performance

Semi-rigid coax cables are very strong and work well in cars. They can handle tough weather. The copper tubes and PTFE inside make them tough against heat, water, and shaking. This strength keeps them working even when things get rough, so they're great for cars.

Scientific Research Findings: Semi-rigid coaxial cables stay the same length. They work well even when temperatures change a lot.

These cables keep signals clear too. Their design stops signal loss and noise, giving good signal flow. This is important for car GPS and radios to work right. Rigid coax helps your car's systems stay accurate and dependable.

Versatility and Adaptability

Rigid coax cables fit many car systems easily. You can use them with different car techs like music players or GPS units. They connect smoothly with other devices in the car.

Scientific Research Findings: Semi-rigid coaxial cables have a strong middle wire held by PTFE inside a metal tube.

They also help with new tech in cars. As cars get smarter, we need better parts that work well all the time. Rigid coax does this by blocking outside signals well, especially over 500 MHz frequencies. This makes sure your car can use new tech without losing performance.

Challenges and Considerations

Installation Challenges

Space constraints in vehicles

Putting rigid coax cables in cars can be hard. Cars have little space, so planning is key. You must think about the cable's size and bendability to fit it well. These cables are stiff, making them tough to place in tight spots. But they last long and work great, which is worth the trouble. Knowing space limits helps you plan better and avoid problems.

Compatibility with existing systems

Another issue is making sure these cables fit with your car's systems. Cars today have many electronic parts, so adding new cables needs careful thought. Check if the cables match the current setup without issues. This means knowing what both the cables and systems need to work together well. Doing this stops problems when installing.

Cost and Maintenance

Initial investment considerations

Buying rigid coax cables for your car costs money at first. They use top materials, so they cost more than others. But their strength and good performance make them worth it over time. Think about how they help long-term against what you pay now. This way, you choose what's best for your budget.

Long-term maintenance needs

Once set up, these cables need little care. They are strong enough for tough conditions without much fixing needed. Still, check them often to keep them working well. Look for any wear or damage and fix it fast if found. Keeping them in shape makes them last longer and work right.

Logical Reasoning: Picking the right cable needs thinking about many things like electricity, mechanics, and environment stuff.

In short, while rigid coax cables give many good things for cars, think about installation and care challenges too. By knowing these points, you get more out of these cables in your car.

Semi-rigid coax cables are important in car tech. They work well and block interference, especially over 500 MHz. Their strong build helps keep signals steady without mixing up. Knowing how they are made and used is key for best results in cars. These cables have PTFE inside and a metal tube outside, making them very reliable. Using them in your car systems gives great signal flow and lasts long, making them a must-have in today's car tech.

See Also

Discovering the Benefits of FAKRA Coaxial Connectors

Harnessing the Strength of FAKRA Coaxial Cables

Maximizing the Efficiency of FAKRA Coaxial Connectors

Significance of FAKRA Coaxial Cables in Automotive Use

Exploring the Flexibility and Advantages of FAKRA Connectors