How to Replace Faulty Automotive Wire Connectors Types

Maintaining the functionality of automotive wire connectors is crucial for safety. Faulty connectors can lead to electrical issues, accounting for 45% of high-voltage connector problems. These issues result in lengthy repairs and increased costs. Pigtail connectors are prevalent in vehicles and play a vital role in ensuring smooth operation. Regular inspections can prevent unexpected failures, such as brake system malfunctions. Understanding the various automotive wire connectors types aids in easily identifying and repairing faulty ones.

Finding Bad Automotive Wire Connectors Types

Knowing how to find bad automotive wire connectors is key. It helps keep your car's electrical system working well. Let's look at the signs and tools you need for checking.

Signs of Bad Connectors

Electrical Problems

Bad connectors often cause electrical troubles. You might see flickering lights or gadgets not working right. These happen when connectors can't keep a steady electric path. Use a multimeter to check if electricity flows smoothly with no blockages. This tool shows where the issue is.

Physical Harm

Physical harm is another sign of bad connectors. Look for broken or cracked parts that can show wires and cause shorts. Rust is also common. Unplug all connectors and check for rust, like green or white powder on metal ends. This check tells if you need new ones.

Tools Needed for Checking

Multimeter

A multimeter is vital for finding electrical problems. It measures voltage, current, and resistance. With this tool, you can make sure connections work right.

Looking Tools

Looking tools are important for spotting physical harm. Use magnifying glasses or mirrors to see hard spots. These help find any wear or damage that may affect how the connector works.

By knowing these signs and using the right tools, you can find and fix issues with automotive wire connectors types easily. Regular checks keep your car safe and running well.

Getting Ready to Replace

Before you change bad automotive wire connectors, collect the needed tools and items. This makes sure the replacement goes smoothly and quickly.

Collecting Needed Tools and Items

To change wire connectors well, you need certain tools and items. Here's what you should have:

Wire Strippers: These help take off the cover from wires without hurting them. Good stripping is important for a strong connection.

Crimping Tools: A good crimper tool is a must-have. It helps attach male and female pins to wires easily. The ratchet makes sure it's done right and lets go when finished. If fixing many wires or sensors, this tool is very useful.

Replacement Connectors: Keep extra connectors ready. These include both male and female pins. They are key for fixing motor, sensor, or extension wires. Instead of throwing away a good motor because of a broken pin, fix it with these cheap parts.

Safety Steps

Safety comes first when working with car electrical systems. Follow these steps to stay safe:

Disconnecting the Battery: Before starting any work, unplug the car's battery. This stops accidental shocks and keeps the car's system safe from harm.

Wearing Protective Gear: Always wear safety gear like gloves and glasses. This protects you from dangers like sharp wires or sparks.

By getting the right tools and following safety steps, you're ready to replace bad automotive wire connectors successfully. This not only keeps you safe but also makes fixing easier and better.

Executing the Replacement Process

Replacing bad car wire connectors is easy. Follow these steps to fix them and keep your car's wires working well.

Removing the Bad Connector

Cutting the Wire

First, find the bad connector. Use cutters to cut the wire near it. Leave enough wire to add a new connector. Cut carefully to avoid more damage.

Stripping the Insulation

Next, use strippers to take off the wire cover. Remove about half an inch to show bare wire. This helps make a strong link with the new connector. Be careful not to hurt the wire strands.

Installing the New Connector

Choosing the Right Connector Type

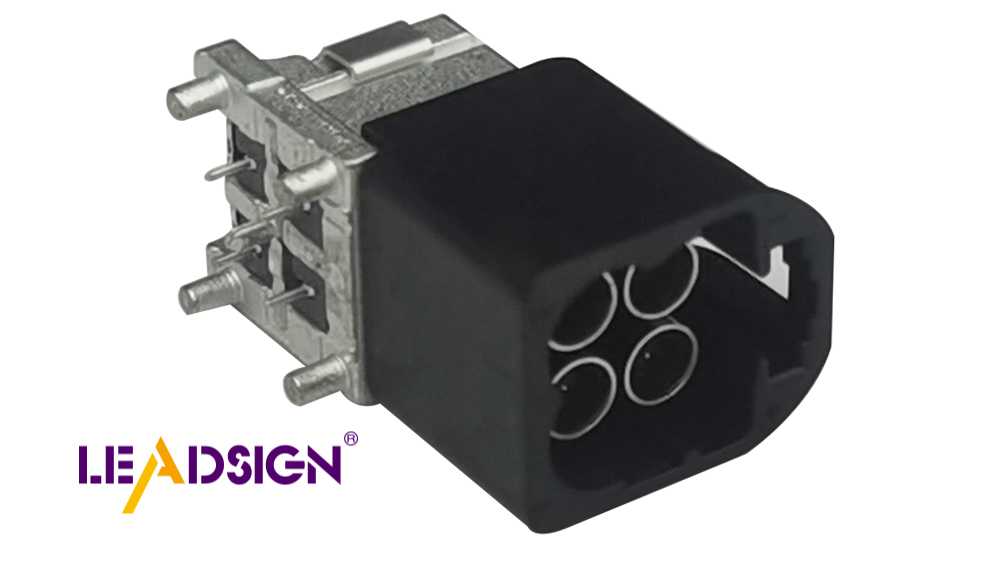

Pick the right connector for your car. Think about pins, shape, and if it fits your car's system. The right type makes sure it stays connected well.

Crimping the Connector

Put the bare wire into the connector end. Use a crimper tool to hold it tight. Press hard so it doesn't slip out and works well.

Testing the Connection

After adding the new connector, test it out. Reconnect your battery and turn on electric parts in your car. Look for problems like flickering lights or things not working right.

By doing these steps, you can change bad connectors easily. This saves time and money and keeps your car safe and running better.

Tips and Things to Think About

When working with car wire connectors, know when to fix or change them. Here are some tips to help you.

Fixing or Changing

Checking the Damage

First, check how bad the damage is. Look for rust, broken parts, or melted plastic. If it's not too bad, you might just fix it. You can take out the old parts and put in new ones without cutting wires. This helps stop rust later.

Thinking About Costs

Think about how much fixing or changing costs. Sometimes, getting a new connector saves money over time if the old one breaks a lot. Compare the price of new parts with future repair costs.

Handy Tips for Replacing Well

Making Sure It's Connected Right

A good connection is key for car wire connectors to work well. When putting in a new one, take pictures of where wires go. Change one wire at a time so you don't mix them up. Push pins until they click to make sure they're in right. Doing this stops mistakes and makes sure it works well.

Not Making Common Mistakes

Don't rush when working on wires. Carefully take off the cover and attach wires to the new part right. Being careful now means fewer problems later. Use a tool to push each pin all the way in. Do this for all wires so everything works like new.

By using these tips, you can handle car wire connectors easily. This keeps your car's electric parts safe and working well.

Replacing bad car wire connectors is simple. It helps your car's electric system work well. Checking them often is important. Experts say, "Check and fix pigtail connectors regularly to stop problems." This keeps your car running well and avoids surprises.

If you find it hard or feel unsure, ask for help. Professionals know how to do it right. They keep your car safe and working great.

See Also

Exploring HSD Connectors in the Automotive Sector

Navigating Fakra Connectors in Honda Cars

Significance of FAKRA Connectors in Auto Uses