How to Replace Automotive Wiring Connector Types Safely

Taking care of car wiring is very important, especially when dealing with different automotive electrical connectors types. Bad wiring can cause small problems or big dangers like fires. Loose wires, rust, and broken wires are common issues. These happen because connectors wear out as cars get older. Fix these problems quickly to keep your car safe. Be precise and safe with car electrical connectors. Handle them carefully to avoid more damage and keep connections strong.

Getting Ready and Staying Safe

Collecting Needed Tools

Before changing car wiring connectors, get the right tools. Right tools make the job easy and fast.

Important tools for the job

Wire Strippers: These take off wire covers to show metal.

Wire Cutters: Use these to cut wires to needed size.

Soldering Iron: This tool joins wires securely together.

Wire Connectors: These link circuits for smooth electricity flow.

Extra tools for better work

Pick Set: Opens plastic connectors without breaking them.

Multimeter: Checks if electricity flows properly and measures voltage.

Heat Gun: Shrinks tubing to protect wire connections.

Safety First

Be safe when working with car wiring. Safety keeps you and your car protected.

Personal safety gear

Safety Glasses: Keep eyes safe from flying bits and sparks.

Gloves: Protect hands from sharp wires and hot items.

Insulated Tools: Prevent shocks with insulated handle tools.

Car safety steps

Disconnect the Battery: Unplug battery before starting work to avoid shocks.

Secure the Vehicle: Make sure car is stable and brake is on while working.

Learning Wiring Diagrams

Wiring diagrams are key when fixing car electrical systems. They show how parts connect together.

Why wiring diagrams matter

Diagrams show how circuits are set up in your car, helping find which wires go where, making fixes easier.

Reading diagrams step-by-step

Identify Symbols: Know symbols for parts like batteries or switches.

Follow the Lines: See how electricity moves through lines in a circuit.

Check Connections: Use diagrams to ensure all connections are right and spot any issues.

By getting ready well and knowing safety steps, you can change car wiring connectors safely and well.

Finding and Checking the Problem

Usual Wiring Connector Problems

Knowing common wiring connector problems helps keep your car's electrical systems working well. Connectors help send electrical signals between parts, letting them work together for smooth driving.

Signs of Wear and Damage

Check your car's wiring connectors often for wear and damage signs. Look for:

Corrosion: Rust or color change can stop electricity.

Frayed Wires: Broken wires mean possible electrical dangers.

Loose Connections: Shaky connectors can cause power issues.

Spotting these early stops bigger problems later.

Finding connector problems

Finding connector problems needs a step-by-step method. Start by:

Checking for Continuity: Use a multimeter to check if electricity flows.

Inspecting for Physical Damage: Look for cracks in the connector cover.

Testing Functionality: Make sure connected parts work right.

By finding issues correctly, you decide to fix or replace the connector.

Checking How Bad the Problem Is

After spotting a problem, check how bad it is to choose what to do next. This helps save money on car repairs.

Visual Check Techniques

Do a careful look-over using these steps:

Examine Connector Pins: Make sure pins are straight and clean.

Assess Wire Insulation: Look for cuts on wire covers.

Observe Connector Fit: Ensure connectors fit tight without too much force.

Looking closely gives clues about your connectors' state.

Using Diagnostic Tools

Diagnostic tools make checking connector problems easier. Try using:

Multimeters: Measure voltage and current to check electric work.

Circuit Testers: Find open or short circuits fast.

OBD-II Scanners: Get error codes about electric faults in new cars.

These tools find problems exactly, saving time and money instead of changing all wires. By finding and checking wiring connector issues well, you keep your car safe and running smoothly.

Taking Out, Fixing, or Swapping Connectors

Taking Out the Old Connector

First, take out the old connector. Be careful not to break other parts.

Cutting Power Safely

Turn Off the Car: Make sure the car is off to stay safe.

Unplug the Battery: Take off the battery's negative end. This stops electric shocks.

Safe Removal Tips

Know Your Connector: Each connector locks differently. Learn how each works for safe removal.

Use Right Tools: Use a pick set or small screwdriver to unlock tabs gently.

Be Gentle: Wiggle it free slowly. Too much force can break wires or connectors.

Fixing or Swapping Connectors

After removing, decide if you fix or swap based on damage.

Fixing Small Problems

Look for Little Issues: Find tiny cracks or loose pins that don’t need full replacement.

Solder Loose Wires: Use a soldering iron to secure any loose wires.

Cover with Heat-Shrink Tubing: Protect fixed spots with tubing from future harm.

Putting in a New Connector

Pick Right Connector: Choose one like the old type and size.

Strip Wire Ends: Remove 1/4 inch of cover from wire ends.

Connect Wires Securely: Put wires in new connector and lock them safely.

Testing New Connection

Test after installing to make sure it works right.

Checking Installation

Fit Check: Ensure connector fits tight and secure in its spot.

Lock Check: Make sure locking tabs are clicked in place to stop disconnection.

Running Function Tests

Reconnect Battery End: Attach battery’s negative end again.

Check Electrical Parts Work: Turn on car and see if parts work fine.

Use Multimeter Tool: Measure voltage and current for stable connection check.

Experts say good wire connectors are key for cars to work well and be safe too! Follow these steps for strong connections, keeping your car running great and safely!

Understanding Automotive Electrical Connectors Types

Overview of Connector Types

Automotive electrical connectors are important for your car's electric system. They help parts talk to each other, making your car work well. There are many connector types, each with a special job.

Different types and their uses

Crimp Connectors: Easy to use by squeezing metal onto wires. They make strong joins and are good for fast fixes.

Weather Pack Connectors: Made for tough weather, they keep out water and dirt. Perfect for outside use in any weather.

Deutsch Connectors: Very strong, used in hard jobs like off-road cars. They protect well from bad weather.

Molex Connectors: Used in many car parts, great for low-power areas like lights inside the car.

Butt Connectors: Join two wires end-to-end easily and safely. Good choice for simple wiring jobs.

Bullet Connectors: Quick to connect or disconnect, good for things you unplug often like trailer wires.

Product Information: Real automotive connectors keep cars safe and working well. Cars need different connectors based on their type and age.

Selecting the right connector for the job

Picking the right connector is key to keeping your car's electric system working right. Think about these when choosing:

Application: Know what you need it for; Weather Pack is best outdoors because it seals tight.

Environment: Think about where it will be used; Deutsch is best in rough places because it's strong.

Compatibility: Make sure it fits your car's type and year so it works well.

Ease of Use: Pick ones that are easy to put in; Crimp and Butt connectors are simple choices for quick fixes.

Knowing about different automotive electrical connectors helps you choose wisely when fixing or changing wires in your car, keeping it safe and running smoothly.

Changing car wiring connectors safely needs a few steps. First, get the right tools. Next, find problems and gently take out old connectors. Then, put in new ones. Regular checks stop big electric issues that cost a lot to fix. As cars get older, connectors might break and cause trouble. Fixing them fast helps your car work well. If things are too hard, ask an expert for help. Doing this saves time and money, making sure your car stays safe and works on the road.

See Also

Exploring HSD Connectors in the Automotive Sector

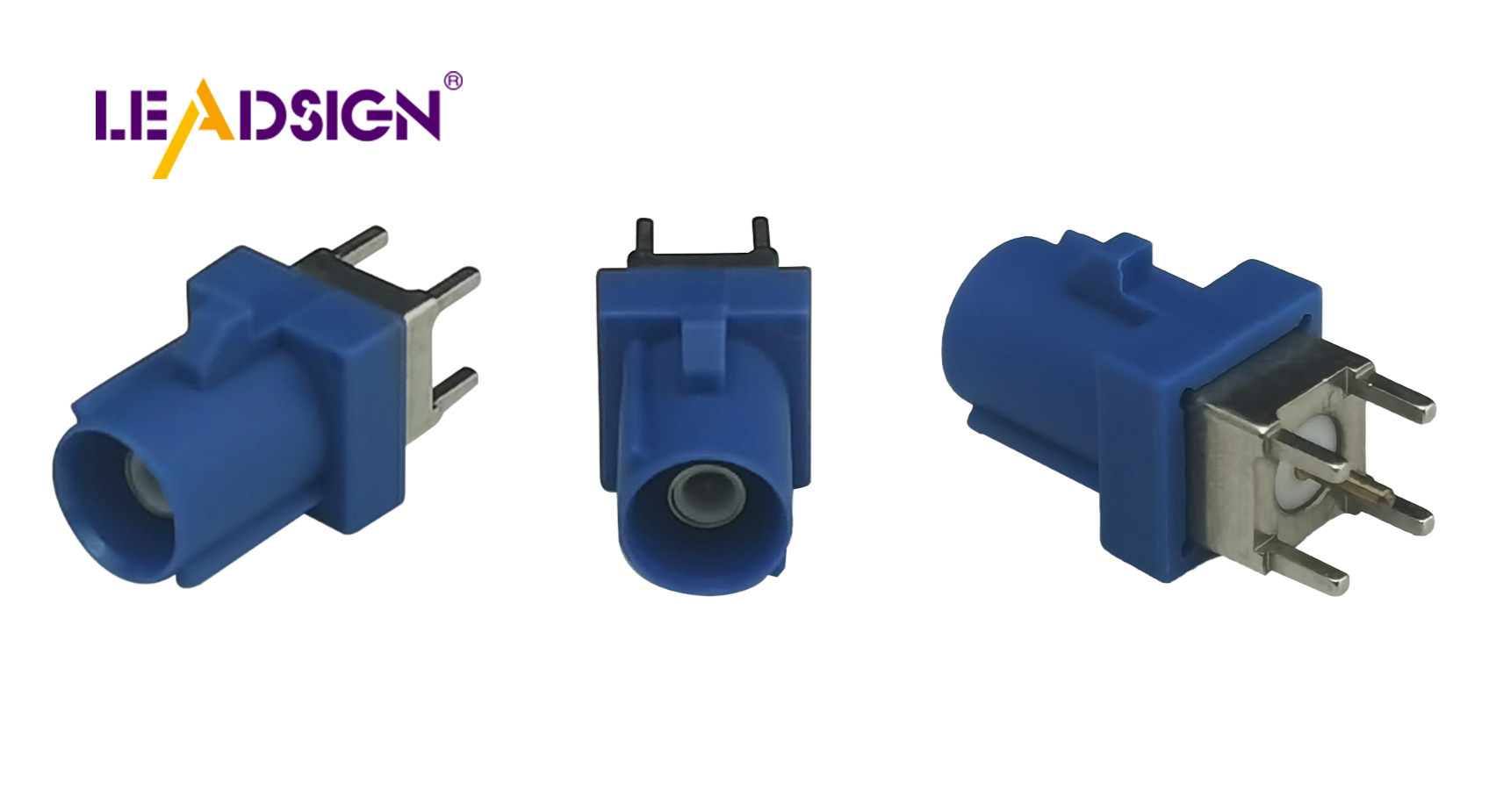

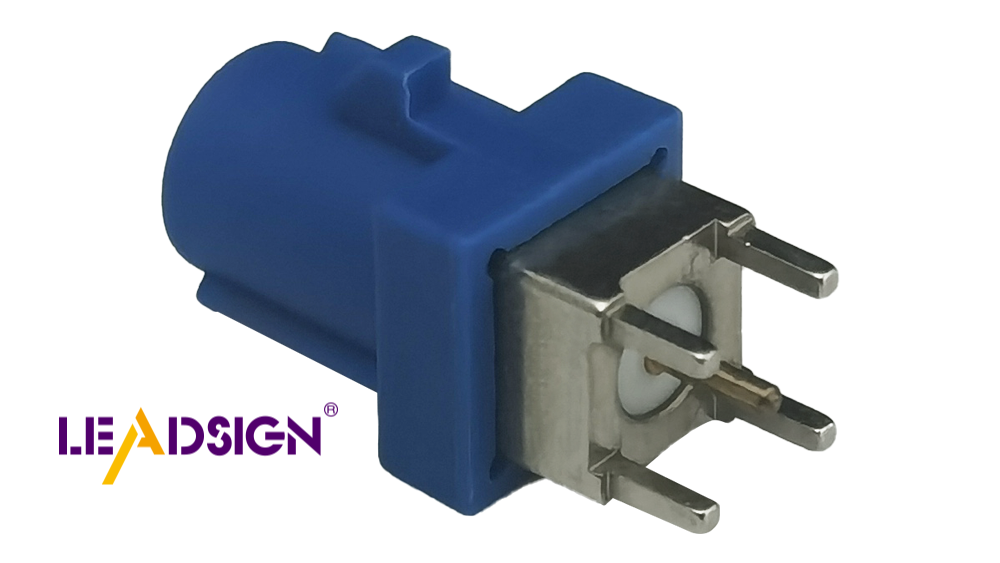

Significance of Fakra Connectors in Contemporary Cars

Critical Role of FAKRA Connectors in Auto Uses

Enhancing Auto Data Transfer: Advanced Connectors and Cables