Step-by-Step Instructions for Replacing Auto Harness Connectors

Auto harness connectors are important for your car's safety and use. Bad connectors can cause shocks, fires, or car problems. Fixing them yourself saves cash and teaches useful skills. With easy steps and proper tools, it’s simple and fun.

Key Takeaways

Get tools like wire cutters, crimpers, and pliers first. Using proper tools helps make the work simple and safe.

Unplug the car battery before fixing any wires. This stops shocks and keeps the car's wiring safe.

Check connectors often for any damage. Spot rust, breaks, or loose wires early to keep your car safe.

Tools, Materials, and Preparation

Tools needed for replacing wire harness plug connectors

Before fixing a broken connector, gather all the tools you need. The right tools make the job easier and safer. Here’s what you should have:

Wire Strippers: These remove the plastic cover on wires. Clean wires are important for a strong connection.

Crimpers: Use these to attach the new connector tightly to the wire. A tight crimp keeps it secure and working well.

Pliers: These help hold or adjust wires and connectors while you work.

Soldering Iron (Optional): This tool makes the connection stronger. It’s not required but adds extra strength.

Having these tools ready will save time and avoid stress during the repair.

Materials required for repair or replacement

The materials you pick are as important as the tools. Good-quality parts keep your wiring safe and long-lasting. Here’s a list of what you’ll need:

Material | Description |

|---|---|

Wires | These carry power and signals. Use strong car wires for better results. |

Connectors and Pigtails | These join wires and parts. They allow easy removal if needed. |

Terminals | These are the metal parts inside the connector. Replace broken ones for better contact. |

Protective Sleeves | These cover wires to stop damage. Replace any that look worn out. |

Using the right materials for your car is very important for success.

Safety precautions to follow before starting

Safety is the most important step when working on car wiring. Follow these tips to stay safe:

Unhook the battery before starting. This stops shocks and protects your car’s system.

Work in a bright, open space. A clean area helps you focus and avoid mistakes.

Wear gloves and safety glasses. These protect your hands and eyes from sharp wires or sparks.

Check your car’s wiring diagram. Knowing where each wire goes prevents errors.

By following these steps, you’ll stay safe and finish the repair easily. With the right tools, materials, and care, you’re ready to fix the problem!

Step-by-Step Guide to Replacing Auto Harness Connectors

Disconnecting the battery and preparing the workspace

Before starting, unhook the car battery to stay safe. This stops shocks and protects the car’s system. Take off the negative terminal first, then the positive. After disconnecting, set up your workspace.

Here are tips for a safe and easy setup:

Use connectors with covers to stop wires from catching.

Make sure the area is bright for clear visibility.

Keep tools and materials close to avoid reaching too far.

Watch out for sharp edges that might harm wires.

Use marks or guides to align connectors properly.

A good workspace helps make the job easier and safer.

Finding and checking the damaged connector

To find the broken connector, start by looking closely. Check for rust, cracks, or worn-out covers. Use a multimeter to test for electrical problems like weak signals. Damage signs include rust, wear, or bad wiring.

After spotting the issue, check your car’s wiring diagram. This helps you reach the damaged part without disturbing other wires.

Taking out the old connector

Removing the broken connector needs care. Follow these steps:

Use pliers to loosen the connector gently.

Cut wires near the broken plug with cutters.

Strip wire ends to show clean copper using a stripper.

Be gentle to avoid damaging the wires further.

Fixing or replacing the connector

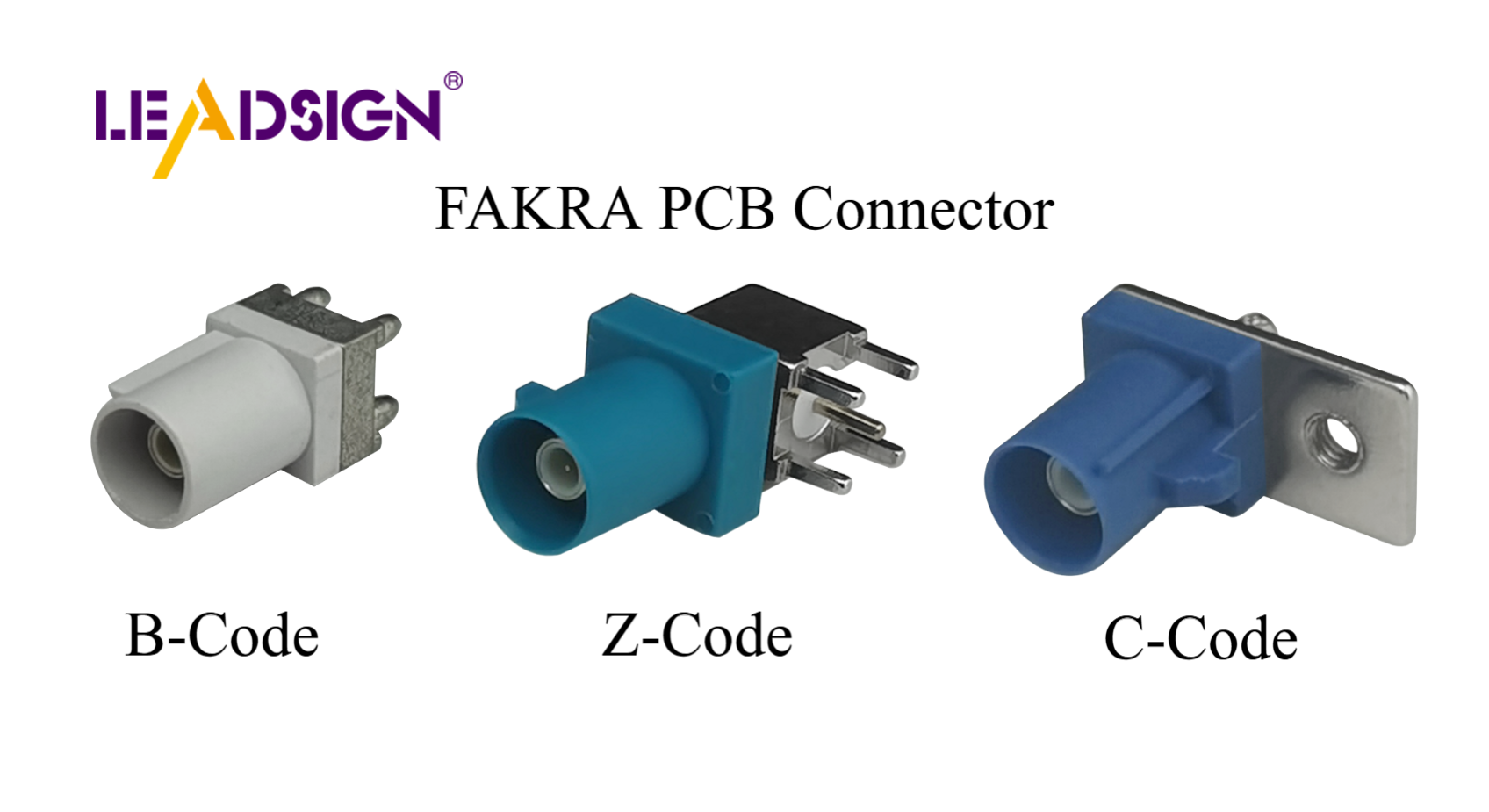

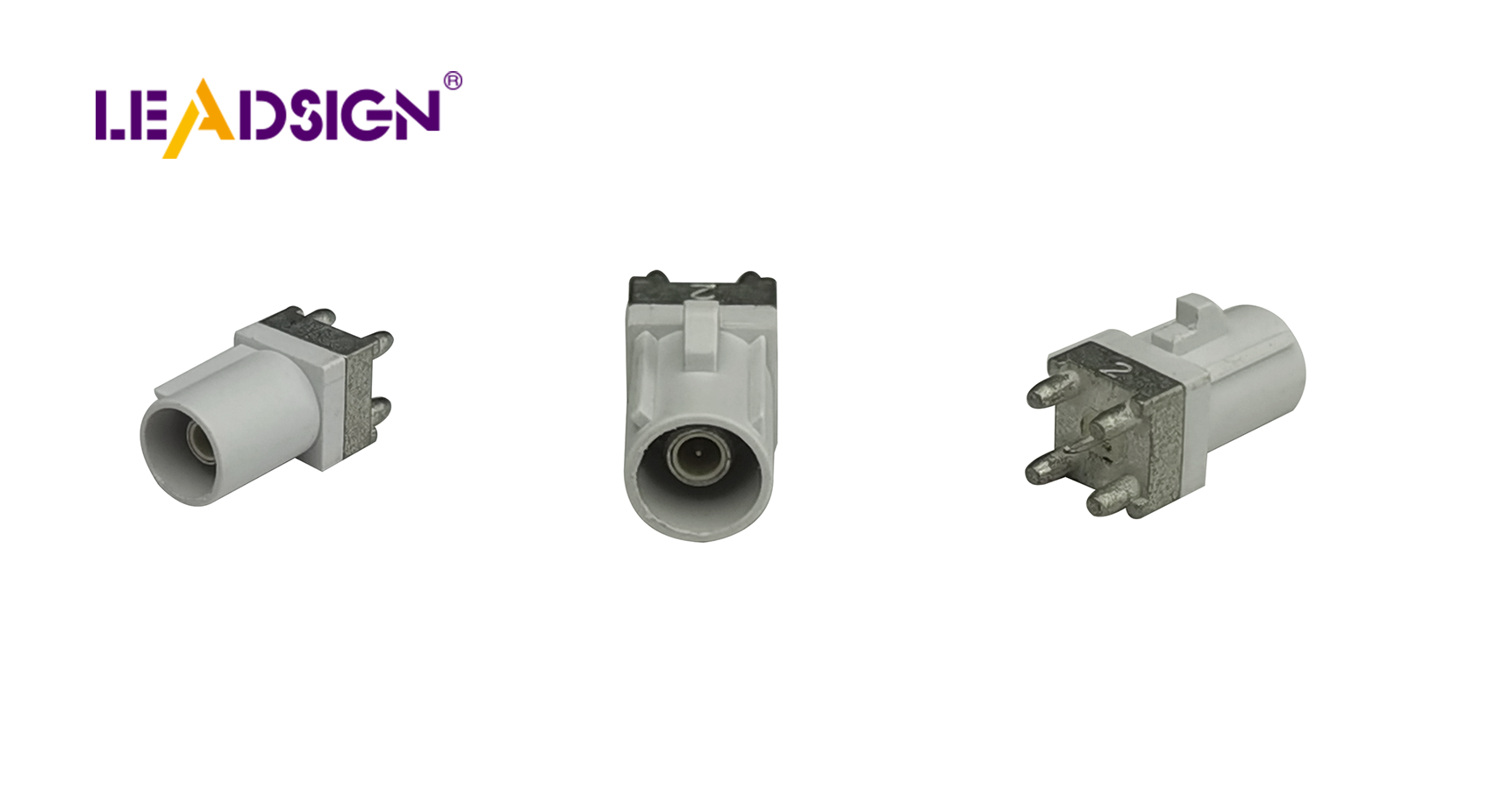

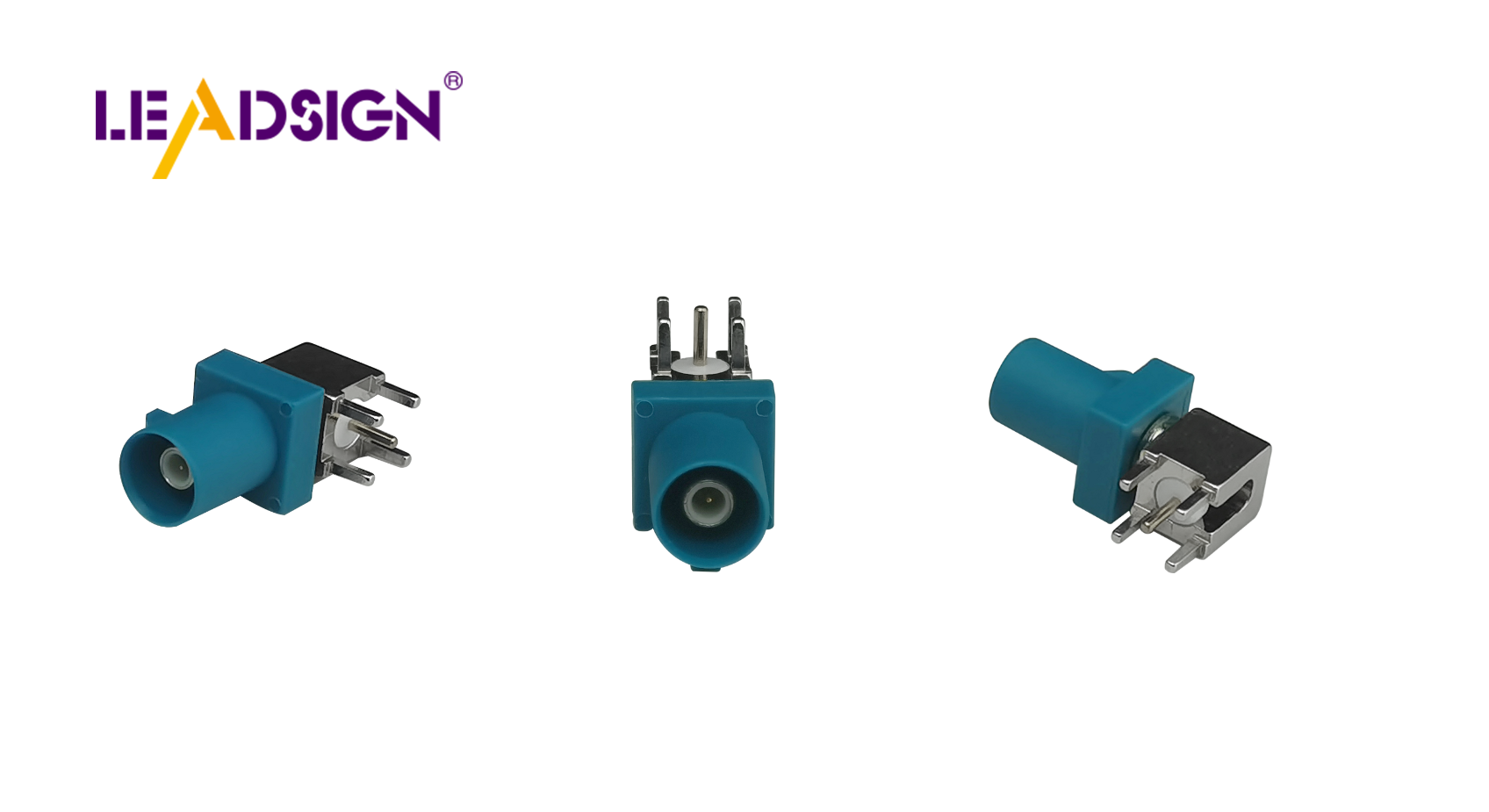

If fixable, replace broken parts like terminals or covers. For full replacement, pick a strong connector like a FAKRA type. These are tough and work well in cars. Attach the new connector to the wires with a crimper. Make sure it’s tight for a good connection.

Securing and testing the new connector

Once the new connector is attached, lock it in place. Push it until it clicks to ensure it’s secure. Reconnect the battery and turn on the car to test. Check if the system works properly. If not, check the wires and alignment again.

Putting everything back and final checks

Put the wires back neatly into the harness. Replace any covers you removed earlier. Inspect everything to ensure no damage, rust, or bad wiring. Test the system again to confirm it works fine.

By following these steps, you’ll fix your car’s wiring and keep it working well for a long time.

Fixing auto harness connectors yourself has many advantages. It makes your car safer and more reliable while saving cash. New connectors improve how wires work and last longer. Problems like rust or wrong wiring might happen, but this guide helps you solve them. You can do it—start fixing your car now! 🚗

FAQ

What is the best type of connector for automotive use?

FAKRA connectors are a top pick! They are strong, dependable, and made for high-frequency car uses like GPS, Bluetooth, and radios. 🚗

Can I replace a connector without soldering?

Yes, you can! Crimpers can tightly attach the wires. Soldering makes it stronger but isn’t always needed for a good connection.

Tip: Always check crimped wires to ensure they are tight and secure.

How do I know if a connector is damaged?

Check for breaks, rust, or loose wires. Use a multimeter to find weak signals or electrical problems. Damaged connectors often look worn out.

Note: Inspect your connectors often to catch small issues before they grow.

See Also

Understanding Ford Fakra Connectors: A Complete Overview

All You Need to Know About HSD Connectors

Fundamentals of HSD Connectors for Automotive Applications

Exploring High-Speed FAKRA-Mini Connectors for Automotive Use