DIY Tips for Replacing Auto Wiring Harness Kits Safely

Replacing auto harness connectors keeps your car safe and working. Broken connectors can mess up the electrical system and cost money. Doing it yourself saves cash and teaches useful skills. With proper tools and care, you can do this job well.

Key Takeaways

Disconnect the car battery first to avoid shocks or sparks.

Use proper tools, like wire cutters and crimpers, for safety.

Pick good-quality parts to stop future problems and make repairs last.

Tools and Materials for Wiring Harness Repair

Tools You Need for Fixing Auto Harness Connectors

Using the right tools makes repairs easier and faster. To fix wiring harnesses, you’ll need some basic tools. First, get a wire stripper and cutter. These help remove old insulation and cut wires to size. A crimping tool is also important. It attaches new connectors to wires securely. Make sure it matches your connector type.

A multimeter is useful for checking if wires work properly. Heat guns are needed to shrink tubing and seal connections. Keep needle-nose pliers and a small flathead screwdriver for detailed work. Lastly, use special connector repair tools for cars. These tools make removing and installing connectors simple and quick.

Materials for Strong and Safe Repairs

Good materials make repairs last longer and safer. Heat shrink tubing is important. It keeps wires safe from dirt and water while looking neat. Use PVC or nylon conduits to protect wires from damage. Braided sleeving is flexible and protects wires that move often.

For wrapping and bundling, use vinyl or silicone tapes. Molded shapes and grommets stop wires from rubbing against surfaces. Choose strong insulation like PTFE or ETFE. These materials resist heat, chemicals, and wear, making them great for cars.

Material | Why It’s Durable |

|---|---|

Polytetrafluoroethylene (PTFE) | Flexible, resists water, oil, heat, and chemicals; works in -73° to +204° Celsius. |

Ethylene Tetrafluoroethylene (ETFE) | Stronger and more bendable than FEP; hardens with irradiation. |

Polyvinylidene Fluoride (PVDF) | Resists heat, chemicals, weather, and fire; affordable and widely used. |

With the right tools and materials, you can fix wiring harnesses confidently and get great results.

Getting Ready for the Repair

Unplugging the Battery for Safety

Before fixing your car’s wiring, unplug the battery. This stops shocks or short circuits. Follow these steps to do it safely:

Turn off the car and make sure it’s not running.

Open the hood and find the battery.

Look for the positive (+) and negative (-) terminals.

Use a wrench to remove the negative terminal first. This lowers the chance of sparks.

Push the cables away from the battery to keep them safe.

These steps protect you and your car’s electrical system while you work.

Checking and Noting Wiring Harness Damage

Look closely at the wiring harness before starting repairs. Check for problems like dim lights, broken accessories, or engine trouble. Also, look for frayed wires, melted parts, or exposed metal.

Write down or take pictures of any damage you see. This helps you remember what to fix and keeps you organized. Learn how the circuit works and match wire sizes to their jobs. This avoids power problems and ensures the harness works well after repairs.

Setting Up Tools and Workspace

A clean workspace makes repairs easier and safer. Use shelves, cabinets, or wall storage to organize tools.

Keep the floor clear by putting tools away after use. This prevents accidents and keeps things neat. Arrange tools in the order you’ll need them. This saves time and helps you focus on fixing the harness.

Step-by-Step Guide to Fix Car Electrical Connectors

Taking Out Broken Wires or Connectors

Start by carefully removing damaged wires and connectors. Follow these steps to stay safe:

Gently pull the wires out of the harness.

If a wire is stuck, remove it slowly to avoid damage.

Never yank wires, as this can break parts or connectors.

Bend wires and connectors softly to prevent cracks or breaks.

Being patient during this step helps avoid new problems while fixing car connectors.

Adding New Connectors and Securing Them

After removing broken parts, install the new connector. Crimping is the best way to make a strong connection. Here’s how to do it:

Use a crimping tool that fits the wire and connector size.

Replace any broken connector covers before attaching the new part.

Match the wire size to its job to avoid power issues.

Cover the crimped area with heat shrink tubing for protection and strength.

A good crimped connection is strong and lasts a long time.

Testing and Finishing the Repair

Once the new parts are in place, test the wiring to ensure it works. Use these simple checks:

What to Do | |

|---|---|

Move wires gently to find loose or bad connections. | |

Tug Test | Pull wires lightly to check they’re tight and clean. |

Also, look for damaged insulation or bad crimps. Use a continuity tester to confirm electricity flows through the wires. These checks make sure your repair is complete and your car’s electrical system works well.

By following these steps, you can fix car connectors and keep your vehicle running safely.

Common Mistakes to Avoid in Wiring Harness Repair

Picking the Wrong or Cheap Connectors

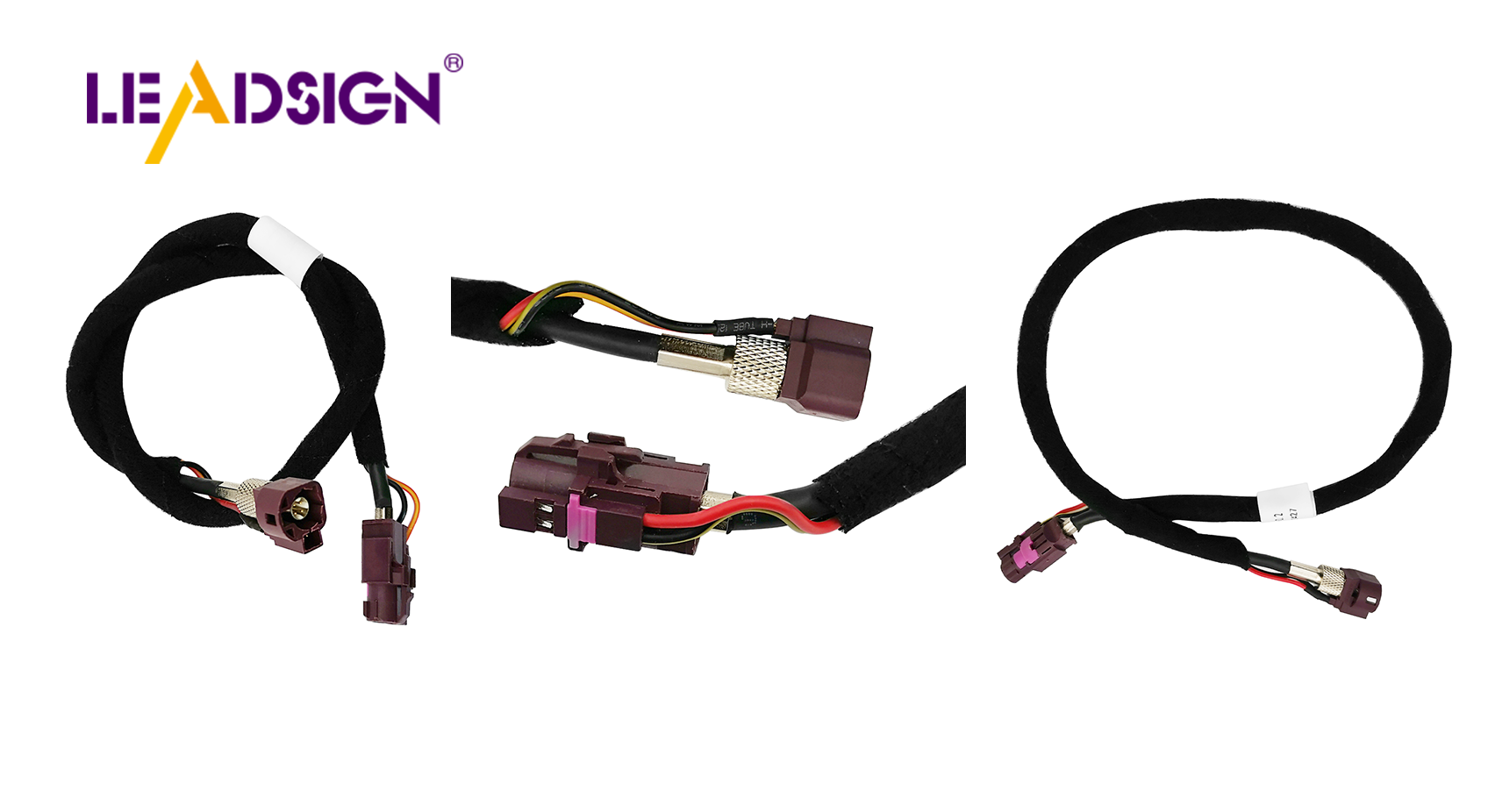

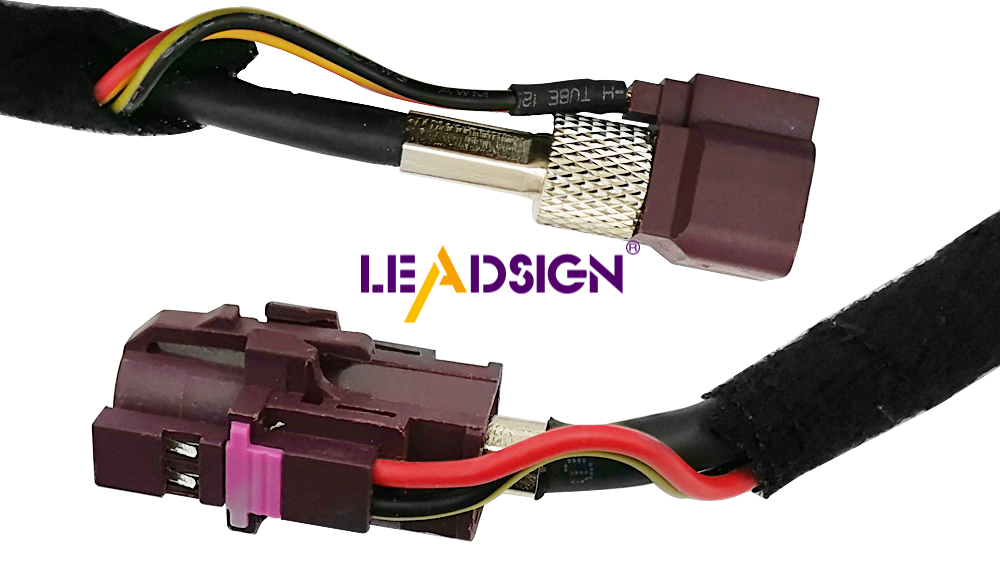

Using the wrong connectors can cause big wiring problems. Cheap connectors rust easily, leading to bad connections and electrical issues. They might overheat, melt, or even start fires. Weak connectors can loosen from car vibrations, causing shorts or broken circuits. Always choose connectors that fit your car and handle tough conditions. High-speed data connectors, like HSD connectors, are great for cars. They hold wires tightly and stay secure.

Wrong connectors can also harm your wiring system. Mismatched ones may cause shorts or stop electricity from flowing. To prevent this, check if the connectors match before installing them.

Skipping Insulation or Heat Shrink Tubing

Skipping insulation can ruin your repair. Without it, wires are open to dirt, water, and damage, which can rust connections. Heat shrink tubing is key for sealing and protecting wires. It blocks water and keeps repairs strong and neat.

If you use butt connectors, make sure they’re sealed well. Unsealed ones let moisture in, causing random problems. Always cover bare wires with heat shrink tubing or good insulation to keep your wiring safe.

Not Checking Connections Twice

Rushing repairs often leads to missed mistakes. Loose or badly crimped wires can cause shorts or stop electricity. After fixing connectors, check everything carefully. Use a multimeter to test if electricity flows properly.

Simple tests like wiggling and tugging wires can find weak spots. Move wires gently to spot loose ones, and pull lightly to ensure they’re tight. Taking time to double-check your work helps your wiring harness last longer and work better.

Avoiding these mistakes will help you fix your wiring harness right and keep your car running well.

Safety Tips for Replacing Auto Harness Connectors

Wearing Protective Gear and Following Precautions

Safety is the most important part of car wiring repairs. Wearing protective gear keeps you safe from dangers. Use insulated gloves to avoid electrical shocks. Wear safety goggles to protect your eyes from sparks or debris. If working in tight spaces, use a dust mask to avoid breathing harmful particles.

Make sure your workspace is bright and has good airflow. Don’t wear loose clothes or jewelry that could get caught in tools. Always follow the instructions for your tools and connectors. These steps help you stay safe and focused while working.

Ensuring Proper Insulation and Moisture Protection

Good insulation protects wires and makes repairs last longer. Use heat shrink tubing to seal wires from dirt and water. Tubing with adhesive lining works best for strong protection. Automotive harness tape also creates a waterproof seal.

Avoid black electrical tape because it doesn’t handle heat or moisture well. Instead, use butt connectors with heat shrink tubing for secure connections. These steps stop rust and keep your wiring harness working properly.

Avoiding Overloading Electrical Circuits

Overloading circuits can harm your car’s electrical system. Check the wire and connector ratings before using them. Make sure they match the circuit’s power needs. Thin wires or weak connectors can overheat or cause fires.

Spread the electrical load across different circuits. Don’t connect too many devices to one circuit. If unsure, check your car manual or ask a professional. These tips keep your wiring harness safe and working well.

Having the right tools and staying safe makes repairs easier. Be careful and trust yourself to do the job well. Share your thoughts or ask for advice in the comments. Your ideas can help others and build a better community! 🚗✨

FAQ

1. How do I know if my wiring harness needs replacement?

Check for problems like dim lights or broken accessories. Frayed wires, burning smells, or exposed metal mean it’s time to replace the harness.

2. Can I use any connector for my car’s wiring harness?

No, you must use connectors that match your car’s needs. Strong connectors, like HSD connectors, work best and last longer.

3. What should I do if I’m unsure about a repair step?

Pause and read your car manual or ask an expert. Don’t guess, as errors can harm your car’s wiring system.

See Also

Maximizing Automotive Data Flow With Superior Connectors And Cables

Boosting Data Transfer: Why High-Speed Automotive Connectors Matter

Understanding HSD Connectors Within The Automotive Sector