Discover Reliable Automotive Electrical Connectors Types

Reliable automotive electrical connectors are crucial in vehicles, ensuring seamless communication between various car components, thereby enhancing overall performance. Automotive electrical connectors types, such as pigtail connectors and terminal blocks, maintain robust connections and withstand harsh conditions. The market for these connectors is projected to reach US$117.12 billion by 2028, highlighting their growing significance. The industry demands durable connectors to ensure safety and functionality in vehicles. Understanding these connectors helps us appreciate their role in advancing automotive technology.

Types of Automotive Electrical Connectors

Automotive electrical connectors types are important for cars to work well. They help send electricity and signals between parts. Knowing about different connectors helps pick the right one.

Pigtail Connectors

Description and Applications

Pigtail connectors are key in car systems. They have a short wire with a connector, making them easy to add to wires already there. These are used in engine wires like GM Vortec engines such as TBI and LS series. Their design fits many engines, so car makers like them.

Key Features and Benefits

Color-Coded for Easy Identification: Pigtail connectors use GM colors, making setup simple.

Versatile Applications: They work with many engines, which is useful for cars.

Durability: Built tough for harsh car conditions, they last long.

Terminal Blocks

Description and Applications

Terminal blocks connect many wires safely, helping share power and signals. They're used in cars to keep wiring neat. Terminal blocks make fixing things easy, so they're very useful.

Key Features and Benefits

Ease of Use: Terminal blocks make connecting wires simple.

Safety: They give safe connections, lowering electrical problems.

Flexibility: Come in different styles for various wiring needs.

Specialty Terminals

Description and Applications

Specialty terminals are made for specific car uses with special features. These include waterproof coaxial connectors needed for smart car systems like ADAS. The JAE’s MX66 Series shows these well with top waterproofing that works with FAKRA interfaces.

Key Features and Benefits

Waterproof Design: Works well even in tough places like ADAS systems.

Compatibility: Fits easily into current car systems, adding flexibility.

Advanced Performance: Gives high-quality links meeting strict standards for safety.

Knowing these automotive electrical connectors types helps makers choose the best ones for safety and performance in vehicles.

Specific Examples of Connectors

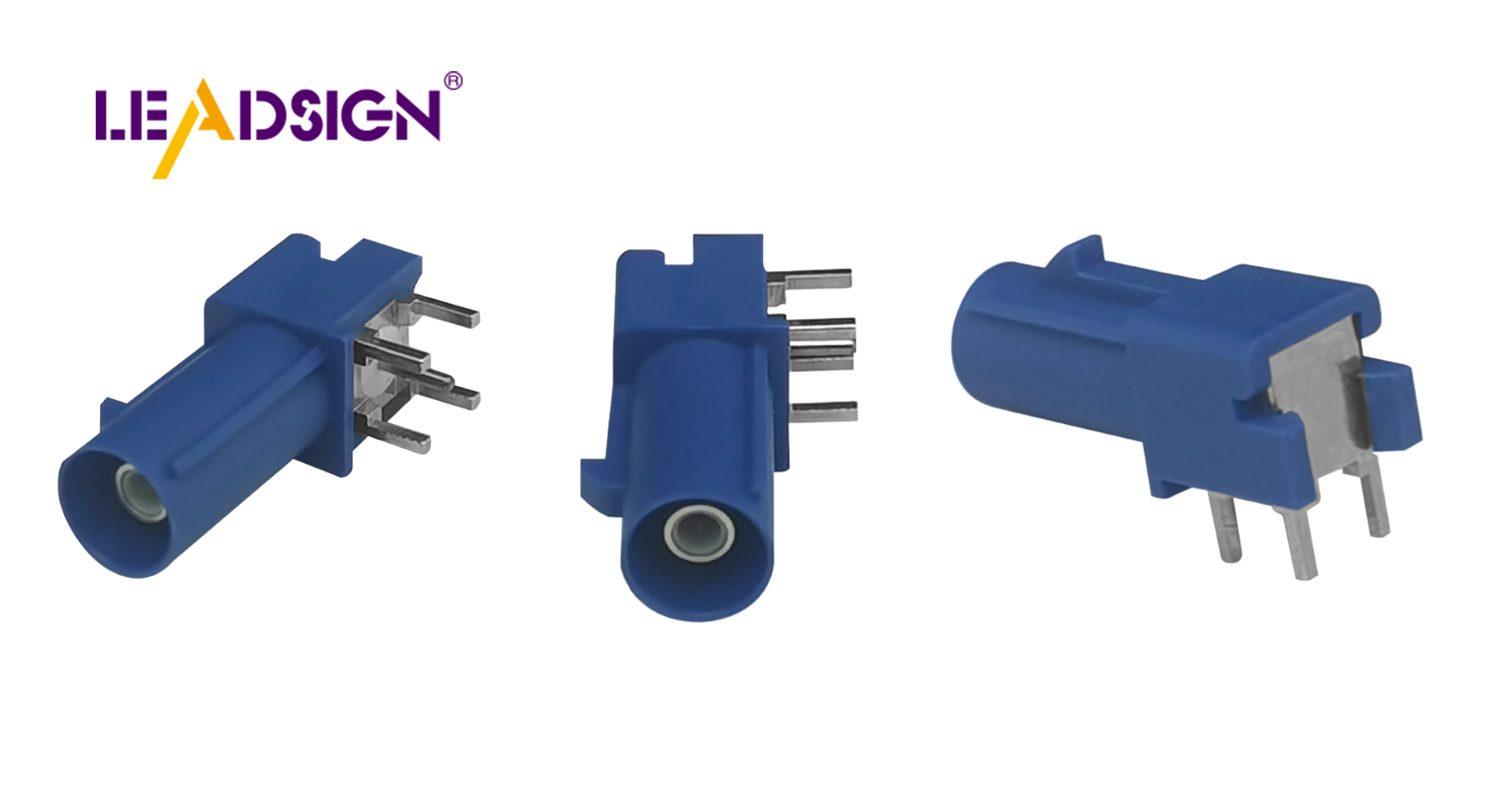

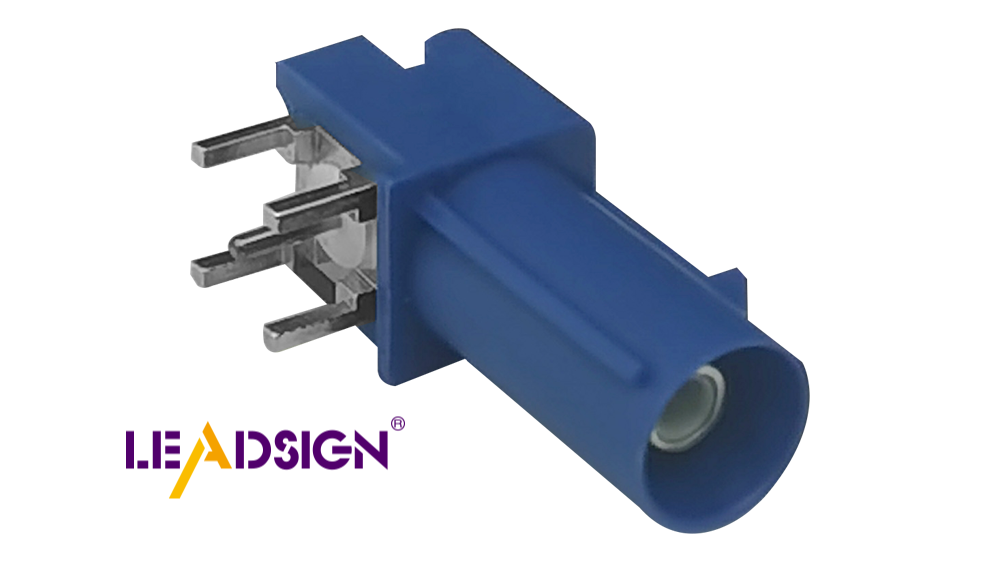

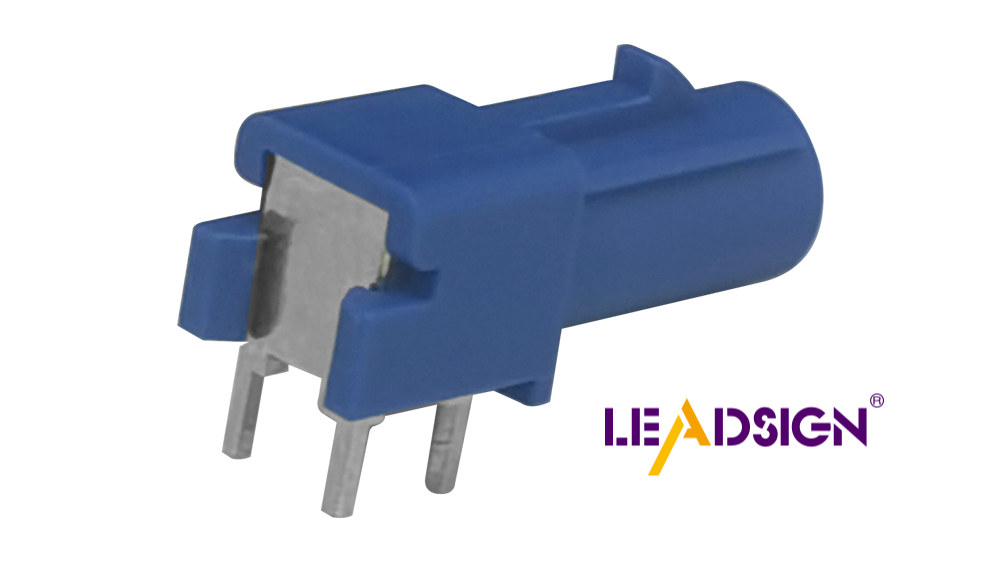

FAKRA connectors

Features and Benefits

FAKRA connectors are special for cars. They work well with radio signals and stay connected. These connectors have plastic covers with colors to tell them apart easily. This helps people connect parts without mistakes. FAKRA connectors work up to 6 GHz, which is very good for cars. They handle high voltage and are great for many car uses. Their strong build makes them easy to put together in factories.

Applications in Automotive Electronics

FAKRA connectors are used a lot in car electronics. They help GPS systems work, so you know where you are going. In phones, they keep calls clear while driving. For music and video, they make sure everything sounds and looks good inside the car. They also help Bluetooth and Wi-Fi work better in cars. Because they do many things well, car makers like using them.

Crimp Connectors

Features and Benefits

Crimp connectors are important too. They are simple but strong for connecting wires in cars. You squeeze them onto wires to hold tight against shaking or weather changes. No need to melt metal, so putting them on is fast and easy. Crimp connectors let electricity flow well, stopping problems from happening.

Applications in Automotive Electronics

In cars, crimp connectors do many jobs. They join wires all over the car safely, keeping the electric system working right. For batteries, they give steady power without trouble. Crimp connectors can handle tough spots like near engines too. By making sure connections stay safe, they help cars run better.

Technical Details and Rules

Car connectors must follow rules to be strong and last long. These rules keep cars safe and working well.

Trustworthy Rules

Why Following Rules Matters

Following rules is key for car connectors. They make sure connectors work well in different situations. This stops problems that might break cars. By following these rules, makers promise their parts are safe and work right.

Common Rules in Car Making

Car makers use common rules for connectors. ISO 9001 checks quality, while ISO/TS 16949 is for car needs. Connectors also follow RoHS to keep the planet safe. These rules make sure car connectors are good and safe to use.

Strongness Details

What Affects Strength

Many things affect how strong car connectors are. Heat changes, shaking, and wetness can hurt them. Connectors need to handle these tough spots to work well. Picking the right stuff and design helps them stay strong longer.

Checking and Following Rules

Checking is important to see if car connectors are strong enough. Makers test them in hard times like heat or shaking tests. Passing these shows they can handle tough car places over time.

Picking the right automotive electrical connector is important for car safety and how well it works. Good connectors help car parts talk to each other, making everything work better. As more people buy cars, knowing about different connectors helps you choose wisely.

Adam at Colchester Car Connector: "Car Connector is awesome! We sold our car with Adam's help at Colchester Car Connector, and it was super easy!"

Look at different connector choices to find what suits your needs best. Talk to experts or go to car stores to see products that meet rules and make your car more reliable.

See Also

Exploring HSD Connectors' Fundamentals in Automotive Sector

Significance of FAKRA Connectors in Auto Implementations

Vital Role of Fakra Auto Connectors in Contemporary Cars