Discover Reliable Automotive Electrical Connectors Types

Reliable automotive electrical connectors are crucial in vehicles. They facilitate seamless communication and power distribution among components. These connectors link power sources to data systems within cars. Various automotive electrical connectors types perform distinct functions, such as managing high power loads or ensuring secure connections. Factors like temperature and power influence their performance. A new model can predict potential connector failures by analyzing heat and vibration, highlighting the significance of connectors for automotive safety and performance.

Understanding Automotive Electrical Connectors Types

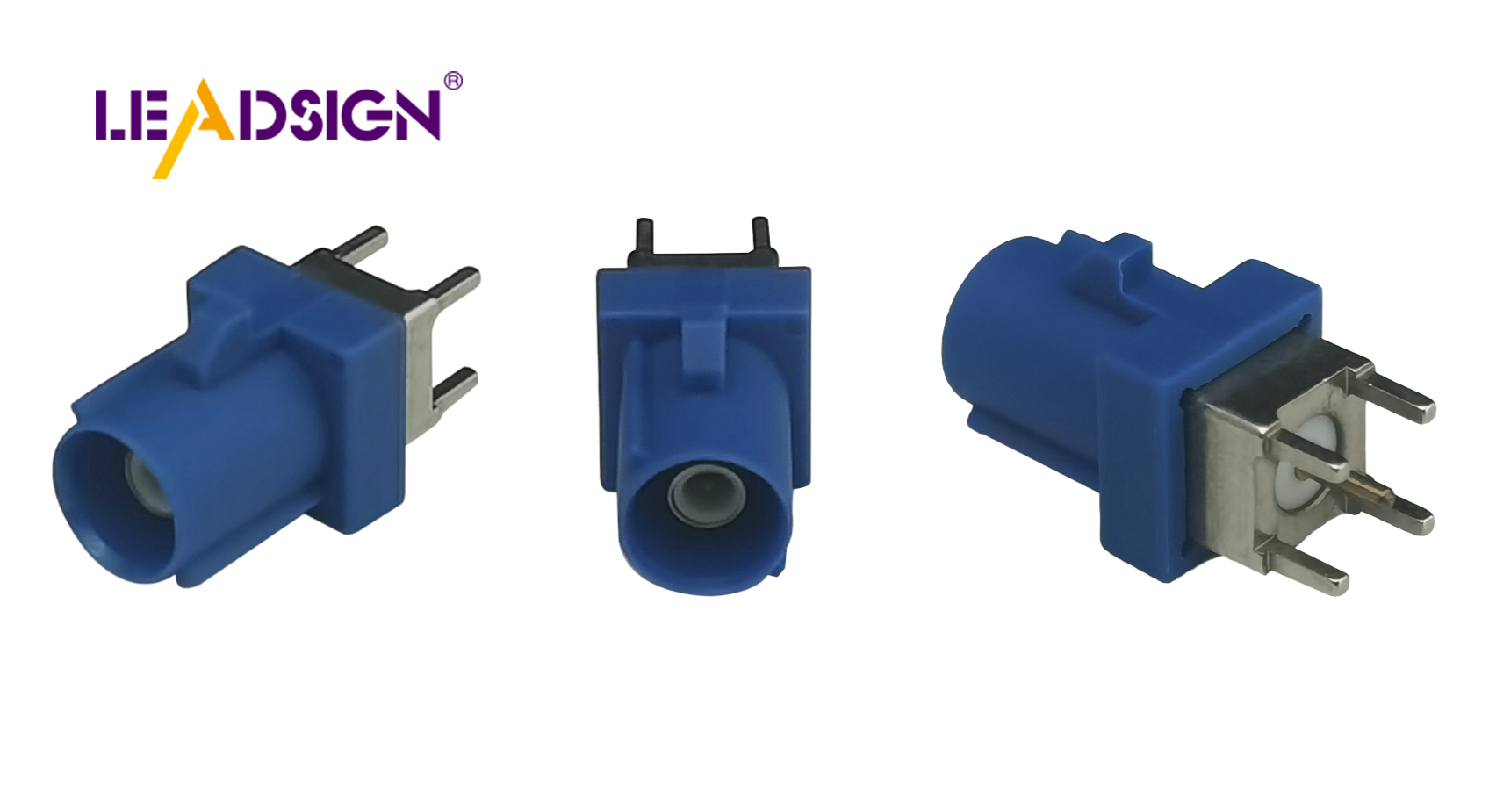

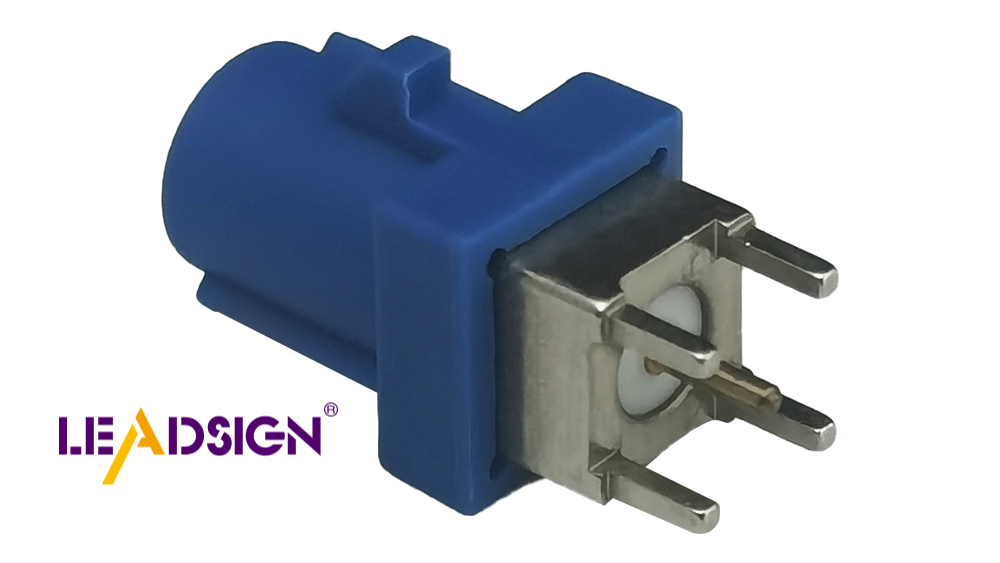

FAKRA Connectors

FAKRA connectors are used for high-frequency tasks in cars. They connect radio antennas, GPS, and infotainment systems. These connectors also help with mobile communication and RF Bluetooth. Their design works well even in tough conditions.

Specific uses in automotive applications

FAKRA connectors are great for many car uses. They link radio antennas to get clear signals. GPS needs them for accurate directions. Infotainment systems use FAKRA for smooth audio and video. They also help with mobile and Bluetooth connections, making cars more connected.

Advantages of FAKRA connectors

FAKRA connectors have many benefits. They meet strict car industry rules. A special coding system stops wrong connections. Locking systems make them safe to assemble. These connectors are strong and last long, saving space with quick plug-in options. Different housings fit specific needs.

Cable Connectors

Cable connectors are important in car systems. They join parts together for good power and data flow. Different cable types meet various needs, adding flexibility to car uses.

Types of cable connectors

Cars use different cable connector types. Straight and angled ones allow easy fitting. Waterproof ones work well in bad weather. High-speed ones support things like 5G and self-driving features.

Applications in automotive systems

Cable connectors are used all over cars. They help spread power efficiently between parts. Data moves smoothly through these links for good communication between components. Safety systems use them to keep the car stable and working right.

PCB Connectors

PCB connectors are key in car electronics, linking circuit boards for signal transfer and power sharing.

Features of PCB connectors

PCB connectors have cool features like supporting fast data rates for quick communication, handling stress from movement or vibration, and matching global standards so they fit different car setups.

Use cases in automotive electronics

In cars, PCB connectors link sensors that detect things to boost safety, make infotainment work better with sound/video delivery, and keep control systems steady.

Custom Solutions

Automotive electrical connectors types have changed to fit new cars. Custom solutions make designs that match special car needs, making them work better and last longer.

Why Customize?

Customizing car connectors has many good points. First, they fit perfectly in the car, using space well. This perfect fit stops loose connections and keeps systems stable. Second, custom connectors can have special features like strong locks or extra support, which makes them tough and safe. These are important for high-performance where stress and shaking happen a lot.

Custom solutions also bring in new tech. For example, fast connectors for 5G and self-driving can be made to send signals well. This personal touch makes sure connectors meet today's car needs like safety and smart tech.

Custom Connector Examples

There are examples of good custom car connectors. Deutsch DRC Series Connectors show lots of pins and choices for different uses in cars. They handle tough conditions but stay connected well.

Another example is connectors with extra locks that follow global rules. These keep working great without losing function, perfect for jobs needing high trust and accuracy.

Features and Benefits of Automotive Electrical Connectors

Durability

Car connectors need to be tough. Makers use strong stuff to make them last. They use good plastics and metals that don't break easily. These materials handle heat and shaking in cars.

Materials used for durability

Good plastics and metals keep connectors strong. Plastics like polyamide resist chemicals and heat. Metals like copper conduct electricity well. These materials help connectors work for a long time.

Testing for longevity

Makers test connectors to ensure they last long. They mimic real car conditions in tests. Tests include heating, shaking, and salt spray checks. These tests show if connectors can handle car demands.

Security

Security is key for car connectors. They must stay connected to avoid problems. This keeps the car running safely.

Secure connection mechanisms

Connectors have special locks to stay put. Locks stop them from coming apart by accident. Primary and secondary locks hold them tight, reducing loose connections.

Protection against environmental factors

Connectors need protection from weather elements. Seals keep moisture and dust out. This stops rusting inside parts, keeping them working well in different places.

Compatibility

Connectors must fit with many systems in cars. They should work smoothly with different technologies.

Compatibility with various automotive systems

Connectors link power, data, and control units together. This lets them fit with many connector types in cars, ensuring smooth operation throughout the vehicle.

Standards and certifications

Connectors follow industry rules for safety and fitment. Certifications like ISO confirm they meet global standards, ensuring reliable performance in cars.

Case Studies:

Greenconn's Customized Connector Solutions: Greenconn makes top products for specific needs, cutting costs while boosting success rates through customization.

Product Portfolio

Different Types of Connectors

Overview of product range

Car connectors come in many types. Each type is made for specific car needs. They help move power and data smoothly so everything works well. The types include FAKRA, cable, PCB, and custom ones. Each has special features for different car uses. For example, FAKRA is good for high-frequency jobs. Cable connectors are flexible with straight, angled, and waterproof styles.

Main makers and suppliers

Some big companies make most car connectors. TE Connectivity, Molex, and Amphenol are leaders with smart designs and strong products. They make sure their connectors meet tough car rules for strength and performance. These companies have lots of connector choices for different car needs. By working with them, car makers get the best connector tech to keep cars safe and efficient.

New Ideas in Connector Tech

Recent improvements

New ideas have made car connectors better and more reliable. Makers use new materials that handle bad weather like heat and shaking well. A study shows how important it is to think about heat and movement when designing connectors. This helps choose the right tests to make sure they work well in all conditions.

Future trends in automotive connectors

The future of car connectors means more new ideas as cars get smarter. Connectors need to change to support things like self-driving cars and better connections. Future changes include making connectors that can handle more data and power. Also, they will be smaller and lighter to save space in modern cars. These changes will help shape the next wave of car connector types.

Uses in Car Systems

Power Flow

Car connectors are key for power flow in cars. They link parts to the main power, helping lights, ignition, and charging work well.

Helping Power Move Well

Connectors move electricity from the battery to car parts. They keep connections steady for good system performance. By lowering resistance, they cut energy loss and boost power use.

Power Connector Examples

Many connectors help with power flow. Battery connectors join the battery to the car's system for steady power. Terminal connectors connect wires to parts, handling high currents and tough conditions.

Data Flow

In new cars, data flow is as vital as power. Connectors help systems talk by moving data signals for infotainment and driver-assist tech.

Importance in New Cars

Data connectors let info move between sensors and screens. This helps with traffic updates, GPS, and car checks. As cars get smarter, good data flow is more needed.

Data Connector Types

FAKRA connectors are used for GPS and radios. USB connectors link devices to infotainment systems for data sharing.

Safety Systems

Safety systems need car connectors a lot. They make sure airbags, brakes, and controls work right by linking sensors to control units.

Connectors in Safety Gear

Safety gear needs strong connectors. They join sensors to controls for real-time checks on car safety features like airbags during crashes.

Effect on Control Systems

Connectors affect control systems by helping parts talk well together. They aid traction control and stability programs for better safety.

Picking the right car connectors is very important. They help cars work well by connecting power, data, and safety parts. These connectors are a must-have in today's cars. As technology grows, car connectors will get better. They will focus on making cars safer and more stable. Makers keep improving them to meet tough rules. Looking into new ideas for connectors will make cars more reliable and efficient. This will help improve car technology in the future.

See Also

Exploring HSD Connectors in Automotive Sector

Significance of FAKRA Connectors in Auto Uses

Vital Role of Fakra Auto Connectors in Contemporary Cars