Real User Experiences with FAKRA PCB Connectors and Automotive Wire

Custom automotive wire harness manufacturers play a crucial role in the automotive industry, especially with the increasing reliance on FAKRA PCB connectors and car wires in modern vehicles. These components are essential for the efficient operation of the advanced electronic systems found in today's cars. FAKRA connectors are known for their durability, reliability, and ease of assembly, making them a preferred choice for automotive applications. Additionally, custom wire harness manufacturers develop specialized wires to enhance the performance and safety of vehicles, meeting the evolving requirements of the automotive sector. These innovations contribute significantly to the seamless functionality and safety standards of modern cars, aligning with the changing landscape of the automotive industry.

Understanding FAKRA PCB Connectors

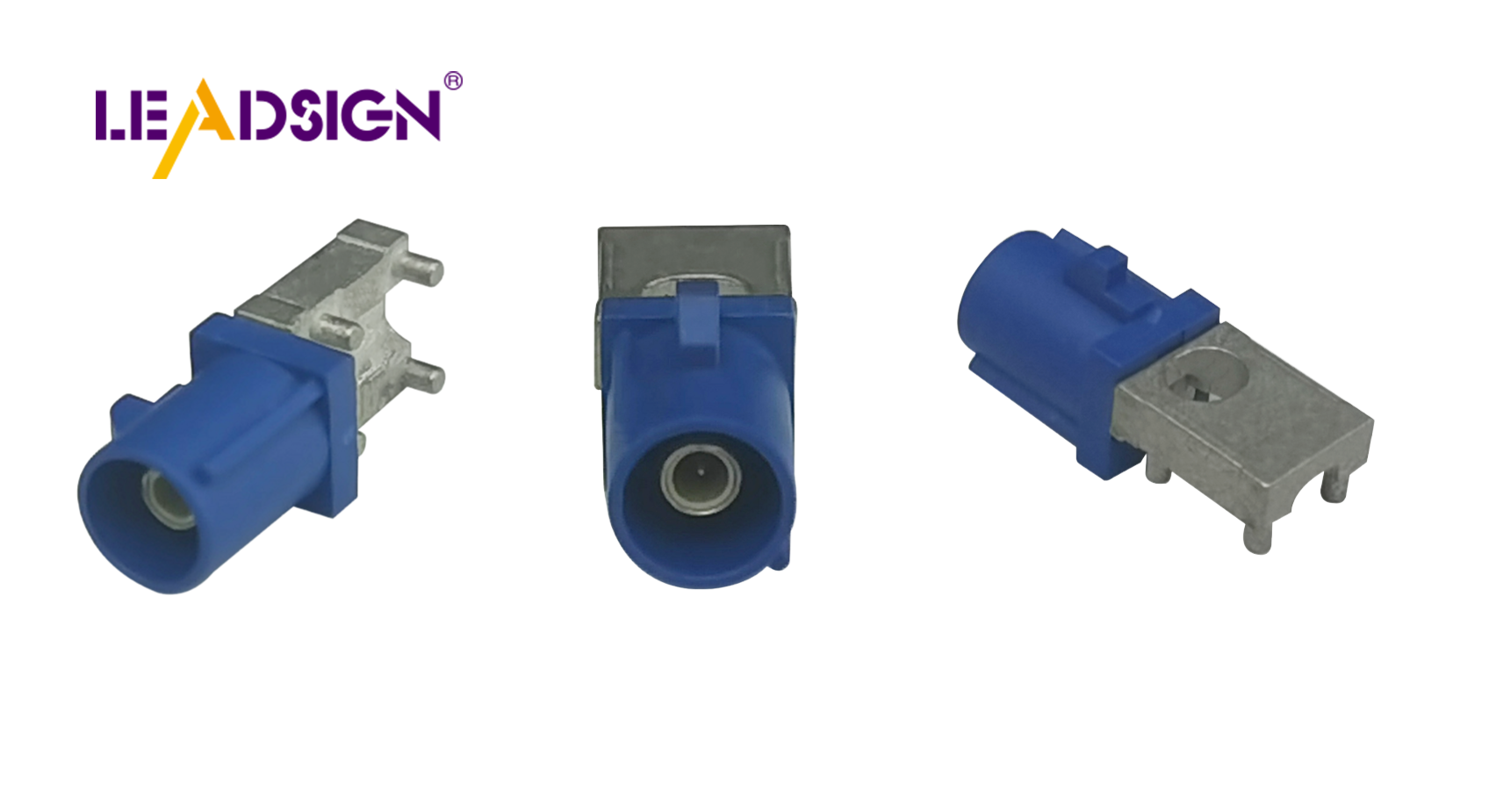

What are FAKRA PCB Connectors?

Design and Functionality

FAKRA connectors are key parts in car electronics. They have strong bodies that handle tough conditions. Colors and keys stop wrong connections, keeping them secure. They send data fast, important for safety systems like brakes and lane warnings. These features make them vital for new cars.

Common Applications in Vehicles

FAKRA connectors work in many car systems. They help with radios, GPS, and car computers. Safety systems need them for sending data reliably. They connect antennas, sensors, and controls easily. This makes them a top choice for car makers.

User Feedback on FAKRA Connectors

Performance and Reliability

People like FAKRA connectors for being reliable. They stay connected even with shakes or heat changes. Their strong build lasts long and meets car standards. Users say they keep signals clear, making cars safer. They also work well with high-speed tasks.

Installation Challenges and Tips

Installing FAKRA connectors can be tricky. Aligning them right is very important to avoid mistakes. Handle them carefully to not break anything. Colors help you match parts correctly, cutting down errors. Follow the maker's steps for best results. Use the right tools to make sure they fit tight.

Exploring Automotive Wire

Types of Automotive Wire

Standard vs. Custom Wiring

Car wires are standard or custom. Standard wires fit basic needs. Custom wires are made for special uses. They improve car safety and work better. Many people like custom wires because they fit well.

Material Considerations

The wire material is important. Copper wires are good at carrying electricity and bend easily. Aluminum is lighter but not as good as copper. Insulation keeps wires safe from heat and water. Picking the right material makes wires last longer.

Real User Experiences with Automotive Wire

Durability and Longevity

People say car wires last a long time. Good wires handle tough weather for years. Some use old harnesses for decades, showing they last long if made well. Taking care of them helps them stay strong.

Common Issues and Solutions

Finding certain wires can be hard. Multi-colored ones are tricky to get. People suggest places like Waytek for more choices. Old harnesses can be reused cheaply from auto shops, which keep them handy.

Integrating FAKRA Connectors with Automotive Wire

Best Practices for Integration

Ensuring Compatibility

Pick connectors and wires that fit system needs. Check each part's details. Make sure FAKRA connectors match the wire's electric and physical traits. Think about where they will be used. TE Connectivity makes strong connectors for tough places. Choose ones that meet these standards for good integration.

Safety and Compliance

Follow safety rules and standards. Use connectors that follow car laws. Check connections to ensure they fit right and are secure. Regular checks stop problems and make systems reliable. The need for good FAKRA connectors shows why rules matter. Ensure all parts have needed approvals.

Case Studies and Examples

Success Stories from Top Companies

Leading automotive manufacturers use FAKRA connectors with car wires well. They see better electronic system performance. This helps driver assistance and entertainment features work better. Smaller, lighter FAKRA connectors fit new industry needs, saving space without losing function.

Lessons Learned from Real-World Applications

Real uses give helpful lessons. Training and tools cut down mistakes in setup. Careful assembly keeps connections strong over time. FAKRA’s role in driver systems boosts market growth. Learning from these helps future plans improve by adapting to new tech.

Role of Custom Car Wire Makers

Why Custom Solutions Matter

Benefits of Customization

Custom car wire makers create special wires for cars. These wires improve how cars work and keep them safe. Each wire fits the car perfectly, helping it run well. Special designs handle tough weather and tight spaces. They make wires strong and reliable.

Picking the Right Maker

Choosing a good maker needs careful thought. Check their experience and skills. Look for a good history in making wires. Ask smart questions about their design and fixing methods. Make sure they use top materials and follow safety rules. A smart choice means better car performance.

Tips from Wire Makers

Industry Trends

Makers see important trends in car parts. Light materials are popular because they save fuel. New tech needs more complex wiring systems. Safety and strength are always key goals. Wires must fit easily in cars for simple setup.

Future Ideas

Future ideas focus on smart tech in cars. Makers look at adding sensors and data tools to wires. This helps cars talk better with each other. New materials will be bendy yet strong, leading to better wires that meet new car needs.

Important Points from User Experiences:

FAKRA connectors are strong and last long in cars.

Special car wires make cars work better and safer.

Helpful Tips for Picking and Using FAKRA Connectors and Car Wires:

Pick connectors that fit your car's needs well.

Line them up right when putting them in to avoid mistakes.

Use copper for good electricity flow.

Extra Resources to Learn More:

Check out TE Connectivity for safe car connections.

Look at online chats for user stories and setup help.

See Also

Exploring the Benefits of FAKRA PCB Connectors in Auto Industry

Discovering the Advantages of FAKRA PCB Connectors in Auto Sector

Uncovering the Advantages of Fakra Auto Connectors

The Significance of FAKRA PCB Connectors in Auto Connectivity