How to Ensure Quality in Automotive Harness Connectors

When talking about automotive harness connectors, quality is very important. Bad connectors can cause big problems like overheating or water damage. They might even make systems stop working. You wouldn’t want your car’s lights to go out or the engine not to start. Picking good automotive harness connectors keeps your car safe, reliable, and working well for a long time.

Key Takeaways

Pick strong materials like stainless steel and nylon for connectors. These materials stop rust and damage, making them last longer.

Make sure connectors fit your system's voltage, current, and environment. This keeps them safe and working well in all conditions.

Choose connectors with certifications that follow industry rules. Certifications like USCAR 2 prove they are safe and good quality, preventing problems later.

Key Factors for Choosing the Right Connectors

Material Quality and Strength

The material of connectors is very important. It should handle wear and stay strong. Beryllium copper and stainless steel are good choices. They conduct electricity well and resist rust. Plastic connectors, like polycarbonate or nylon, are light and tough. These work well in most cars. Metal connectors are better for heavy machines like tractors or bulldozers.

Material | Key Features |

|---|---|

Stainless Steel | Resists rust, very strong |

Polycarbonate (PC) | Tough, heat-resistant, good for electrical use |

Nylon | Flexible, resists wear, and stable with chemicals |

Bronze | Very elastic and strong |

Matching Wiring Harness Needs

Not all connectors fit every system. The connector must match the voltage, current, and wire size. Weather also matters. Sealed connectors are good for wet places. Non-sealed ones work better in dry spots.

Factor | Details |

|---|---|

System Needs | Match voltage, current, signal type, and wire size to the system. |

Weather Conditions | Think about heat, moisture, dust, and shaking that may affect the connector. |

Long-Term Use | Pick connectors that last long and need little fixing. |

Easy to Use | Choose connectors that are simple to install and maintain. |

Handling Tough Environments

Car connectors face harsh conditions. They deal with heat, water, and chemicals like brake fluid. Stainless steel and nylon are great because they resist damage. Sealed connectors are best for wet or dirty areas.

Environmental Challenge | Details |

|---|---|

Extreme Heat or Cold | High or low temperatures can hurt connector performance. |

Water | Moisture can cause rust and failure. |

Chemicals | Fluids like antifreeze can harm connectors. |

Electrical Performance and Safety

Good connectors keep power and data flowing smoothly. Bad ones can cause power loss or fires. Copper is a great material for safety and conductivity. Use connectors made for your system’s voltage and current.

Good connectors stop power loss and voltage drops.

Copper materials make connectors strong and safe.

Smart designs reduce energy waste and improve safety.

Easy to Install and Fix

Connectors should be simple to install. Features like locks and strain relief help. Some have color codes to avoid mistakes. Pick connectors that save time during setup and repairs.

Design Feature | Explanation |

|---|---|

Strong Build | Locks and strain relief keep connectors secure during movement. |

Connection Type | Methods like soldering or crimping affect how easy it is to connect wires. |

Flexibility | Using common connectors makes replacements faster and easier. |

Testing and Quality Assurance for Automotive Harness Connectors

Visual Inspection for Defects

Checking connectors by sight is the first quality step. Look for wear, rust, or damage on the surface. A microscope can help find tiny problems. Follow these steps to inspect properly:

Hold the connector steady with a fixture.

Shine a light to see the surface clearly.

Check carefully for any flaws or damage.

Common issues include loose parts, burn marks, or damaged threads. Sunlight or stress can also harm connectors. Finding these problems early prevents bigger troubles later.

Electrical Testing for Conductivity and Resistance

Electrical tests check if connectors work well under pressure. Conductivity tests ensure smooth power flow. Resistance tests find weak spots that may cause overheating. These tests keep wiring safe and reliable.

Environmental Testing for Durability

Connectors face tough conditions, so durability tests are needed. These tests mimic real-life challenges like heat and moisture. For example:

Thermal Cycling: Tests if connectors handle big temperature changes.

Salt Spray Test: Checks how well connectors resist rust in salty air.

Humidity and Corrosion Tests: See how connectors deal with water and chemicals.

Test Type | Description |

|---|---|

Thermal Cycling | Exposes connectors to extreme temperatures to test strength. |

Humidity and Corrosion | Tests how connectors resist water and harmful substances. |

Certification Standards for Quality Assurance

Certifications prove connectors meet strict rules. Look for standards like USCAR 2 for electronic connectors. QC/T 1067 and USCAR 21 focus on durability and crimping. These certifications ensure high-quality connectors for cars.

Standard | Description |

|---|---|

QC/T 1067 | Lists tests and rules for car wiring connectors. |

USCAR 2 | Sets rules for electronic connectors in cars. |

USCAR 21 | Focuses on crimping performance of terminals. |

Tools and Techniques for Testing Connectors

Special tools make testing faster and more accurate. Automated systems check force, strength, and resistance. These tools use precise sensors and easy software for quick results. Common methods include:

Thermal Cycling Testing: Mimics temperature changes to test reliability.

Vibration and Shock Testing: Ensures connectors stay strong under stress.

Durability Testing: Tests how connectors perform after repeated use.

Using these tools and methods keeps connectors strong and safe for a long time.

Recommended Automotive Harness Connectors and Suppliers

Overview of Common Connector Types

Automotive harness connectors come in different types for specific uses. Here are some common ones:

Flat Connectors: Best for small spaces needing a slim design.

Round Connectors: Good for outdoor use, like car lights, as they resist weather.

Square Connectors: Used for engine sensors since they handle many wires.

Rectangular Connectors: Found in control units for managing complex setups.

Each type has a special job. Picking the right one helps your system work well.

Benefits of Using OEM-Grade Connectors

OEM-grade connectors are reliable and meet strict rules. They last long and need fewer replacements. These connectors fit perfectly with custom wire harnesses, making setup simple. Choosing OEM-grade connectors ensures safety and good performance over time.

Trusted Brands and Suppliers in the Market

Choosing a trusted supplier is important for quality connectors. Top brands include:

Aptiv: Known for creative and eco-friendly products.

Nexans: A global leader in wiring harnesses.

Motherson: Provides full services from design to support.

Yura Corporation: Focuses on quality and has grown worldwide.

Kyungshin: A well-known name in the automotive field.

These brands are reliable and deliver great products.

Tips for Sourcing Reliable Connectors

Finding good connectors can be easy with these tips:

Search online for the exact connector you need.

Use keywords like "automotive connector" to narrow results.

Read reviews to learn how the product works in real life.

Check for certifications that prove quality standards.

Look at delivery options to get connectors on time.

Don’t skip checking environmental needs or testing performance. Research helps you find the best connectors for your system.

Good connectors help keep your car safe and working well. Materials, fit, and testing are very important for quality. Always pick trusted brands and certified products for better results. Using top-quality connectors means your car lasts longer and works better. Take your time to choose the right ones for your car!

FAQ

What do automotive harness connectors do?

These connectors link wires in cars. They help systems like lights, sensors, and radios work properly by keeping power and signals steady.

How can I tell if a connector is good quality?

Look for certifications such as USCAR 2. Check if it’s made from strong materials, sealed well, and can handle heat, water, and chemicals.

Can I put connectors in by myself?

Yes, you can if you follow the steps closely. Pick connectors with simple features like color codes or locks to make it easier.

See Also

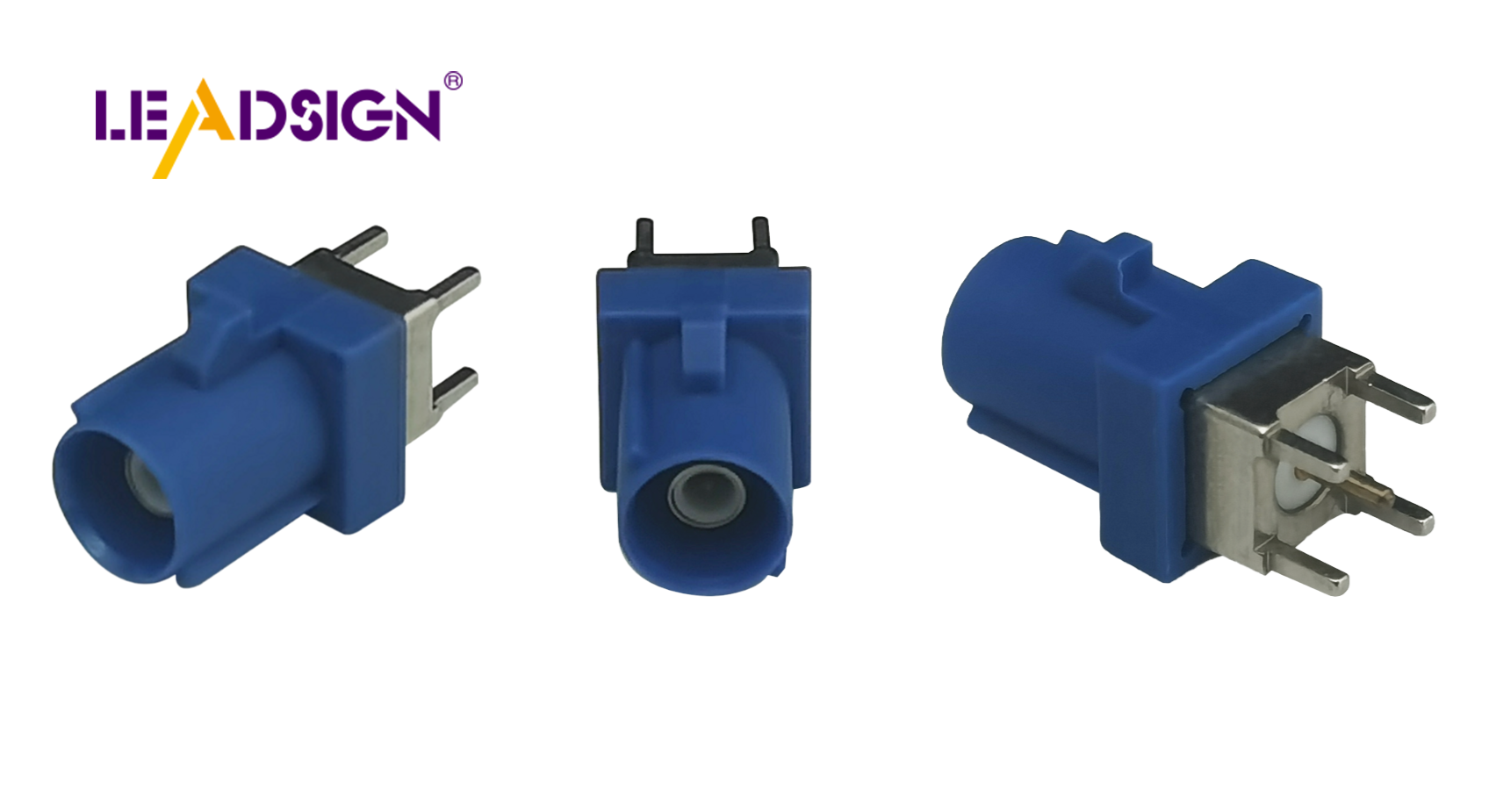

Why Fakra Connectors Matter in Today's Automotive Sector

Significance of FAKRA Connectors in Vehicle Technologies

Crucial Role of HSD Connectors in Automotive Systems

Boosting Data Transfer with High-Speed Connectors in Cars

Fakra Connectors: Essential Components for Modern Automobiles