Simple Tips to Protect Custom Automotive Wiring Harness

Maintaining automotive harness connectors keeps your vehicle safe and reliable. Ignoring harness care may cause electrical problems and costly repairs. Regular checks stop damage and make connectors last longer. Being careful protects your car and prevents delays from bad wiring.

Key Takeaways

Clean and inspect your car's wiring connectors often. This stops dirt and finds issues early. It can save you money on repairs.

Apply proper lubricants to keep connectors safe from damage and rust. A small amount helps connections work well and avoids electrical problems.

Use waterproof connectors and covers to guard wires from water and heat. This keeps your car's electrical system working properly.

Understanding Automotive Harness Connectors

What Are Wire Harness Connectors?

Wire harness connectors are important parts of your car's electrical system. They connect the wiring harness to circuits and power sources, helping electricity and data flow smoothly. These connectors have male and female ends that fit together securely to carry electricity. They also keep wires in place so your car's electronics work properly.

Main parts of automotive harness connectors include:

Part | What It Does |

|---|---|

Connectors | Join wires from the harness to circuits and power sources. |

Casing | Protects the inside parts and keeps the connector stable. |

Terminals | Made of metal pins that transfer electricity and data. |

Knowing these parts helps you understand how connectors improve your car's performance.

Role of Connectors in Protecting Wire Harnesses

Automotive harness connectors are key to keeping your car safe and working well. They provide steady electrical connections for systems like engine controls, airbags, and lights. For example:

Engine controls need connectors to avoid problems with the engine.

Airbags depend on good connections to work during accidents.

Lights stay bright and don’t flicker with reliable connectors.

ABS and traction systems get steady power to work correctly.

These connectors shield the wire harness from harm, helping your car run smoothly in different conditions.

Common Causes of Connector and Harness Damage

Many things can harm automotive harness connectors and wire harnesses. Extreme heat or cold, constant shaking, and power surges are common causes. Water and rust can also weaken connectors over time. Problems like squished wires, misaligned connectors, and too much pressure can break connections.

Other issues include bad environments, factory mistakes, and wrong wiring. Poor designs, mismatched parts, or cheap materials can also cause failures. Cleaning and checking connectors often can catch problems early, saving money and keeping your car dependable.

Daily Wire Harness Care Tips

Cleaning and Checking Automotive Harness Connectors

Keeping connectors clean helps them work properly. Dirt can block connections, so clean them often. Try these simple tips:

Blow away dirt with compressed air or use a soft brush.

Wipe connectors with a clean cloth or alcohol pad.

Add a small amount of grease to protect from water and rust.

Check connectors often for damage. Look for rust, wear, or misalignment. Follow your car's manual for proper care steps. These habits stop dirt buildup and make connectors last longer.

Using Lubricants for Connector Care

Lubricants are important for keeping connectors in good shape. They make plugging in easier and reduce wear from shaking. This stops damage to the connector surfaces.

Lubricants also protect against rust and keep electricity flowing well. A thin layer of lubricant prevents sparks and shields the parts. Using the right lubricant keeps connectors working smoothly and reliably.

Spotting and Fixing Wear and Tear

Daily use can wear out your connectors. Look for cracks, color changes, or loose parts. Broken connectors can cause electrical problems. Fixing them quickly avoids bigger issues.

Replace damaged parts with good-quality ones to keep things working. Tighten loose parts gently to avoid breaking wires. These tips help you find problems early and keep your wiring in great condition.

Preventing Damage to Wire Harnesses

Keeping Connectors Safe from Water and Rust

Water can harm connectors and cause rust, breaking connections. Follow these easy tips to stop rust and water damage:

Use waterproof connectors to keep water out.

Add heat-shrink tubing for better water protection.

Pick materials that resist rust to avoid damage.

Sealing tools like o-rings and potting compounds also block water. These steps help connectors stay strong and last longer.

Best Practice | What It Does |

|---|---|

Rust Resistance | Use rust-proof materials and add protective coatings. |

Strong Sealing Methods | Use o-rings and potting compounds to stop water from getting inside. |

Protecting Connectors from Heat and Sunlight

Heat and sunlight can damage wire harness insulation. Sunlight makes materials weak and easy to crack. Long UV exposure can ruin insulation and lower performance.

To protect connectors:

Keep them out of direct sunlight when possible.

Use materials that block UV rays to prevent damage.

Cover them with heat-resistant shields to handle high temperatures.

These tips keep connectors strong and safe from harsh conditions.

Using Covers and Sleeves for Extra Protection

Covers and sleeves protect wires from heat, wear, and weather. They are made from materials like:

Heat shrink tubing to block weather and insulate wires.

Fiberglass sleeves for very hot areas.

Woven sleeves that are easy to install and maintain.

PVC tubing for great insulation and voltage safety.

Pick the right cover for your car's needs. These covers add extra safety and keep wires in good shape.

Best Practices for Installing Wire Harness Connectors

Proper Handling During Installation

Handle connectors carefully to make sure they work well. Always line up connectors before plugging them in. Misaligned connectors can break pins or terminals. Use the correct tools for the job. For example, crimping tools made for cars prevent weak connections. Never pull wires to connect or disconnect them. Hold the connector housing instead to avoid wire damage.

Common mistakes during installation include:

Not checking wire direction, which can cause short circuits.

Skipping strain relief, which may lead to broken wires.

Forgetting to test or inspect, leaving errors unnoticed.

Using wrong tools, which can harm the connectors.

Paying attention to these steps ensures proper installation and fewer repairs later.

Securing Connectors to Prevent Loosening

Loose connectors can mess up your car’s electrical systems. Secure them well to avoid this problem. Use nylon lock nuts to keep threads tight. Safety wires can hold fasteners in place to stop loosening. Threadlockers like Loctite keep threads secure and resist shaking. SpiralockⓇ fasteners are great for areas with lots of vibration.

For extra safety, try castle nuts with clips or retainer pins. These methods keep connectors tight even in tough conditions. Secured connectors mean fewer repairs and better performance.

Avoiding Over-Tightening or Stressing Wires

Over-tightening can crush or harm wires inside connectors. Tighten just enough to hold them securely without too much force. Bending wires sharply or pulling them too tight can break them. Use strain relief parts to spread tension evenly and protect wires.

Check wires after installation to ensure they aren’t pinched or stretched. These steps keep the wiring harness safe and prevent future problems.

Troubleshooting and Repairing Wire Harness Connectors

Finding Common Problems in Automotive Harness Connectors

Car connectors can have problems as they get older. Spotting these early helps keep your car’s electrical system working well. Look out for these common issues:

Intermittent connectivity: This causes uneven signals or data disruptions. Loose wires or bad connections are often the reason.

Corrosion and oxidation: Moisture can cause rust or buildup on connectors, changing their color.

Physical damage: Cracks, bent pins, or broken wires happen from rough handling or tough conditions.

Improper wiring: Wires in the wrong place or crossed can lead to short circuits.

Check connectors often for worn wires, rust, or other damage. Fixing these problems quickly keeps your car running smoothly and avoids expensive repairs.

Fixing Broken Connectors

Fixing connectors needs care and the right steps. Follow these to fix them:

Look for dirt, rust, or damage on the connector.

Clean it well with brushes or alcohol pads to remove buildup.

Take out broken wires and pins from the connector.

Replace them with new ones by opening locks and using tools to secure them.

These steps make your connectors last longer and work better.

When to Ask for Expert Help

Some connector problems need a professional to fix. If you see heavy rust, badly damaged wires, or repeated failures, call an expert. They have the tools and skills to solve hard problems and protect your wiring. Getting help keeps your car safe and reliable.

Taking care of wire harness connectors helps them last longer. Clean and check them often to stop dirt and find problems early. Adjust your care based on weather, like heat, cold, or wet conditions. Protect them from sunlight and use the right tools to install them safely. These steps keep your car working well and trouble-free.

FAQ

How should you clean automotive harness connectors?

Blow away dirt with air or use a soft brush. Clean them with an alcohol pad. Add a little grease to stop rust.

Tip: Cleaning often keeps connectors working well and dirt-free. 🧹

How often do wire harness connectors need checking?

Check connectors every three months or after tough driving conditions. Look for cracks, rust, or loose parts to fix issues early.

Note: Regular checks help avoid expensive repairs later. 🔧

Can damaged connectors be fixed at home?

Yes, small problems like rusty pins can be fixed by cleaning. For big damage, ask an expert to prevent more issues.

Reminder: Always use proper tools when making repairs. 🛠️

See Also

Streamlining Automotive Data Flow With Innovative Connectors And Cables

Boosting Data Transfer Efficiency With Fast Automotive Connectors

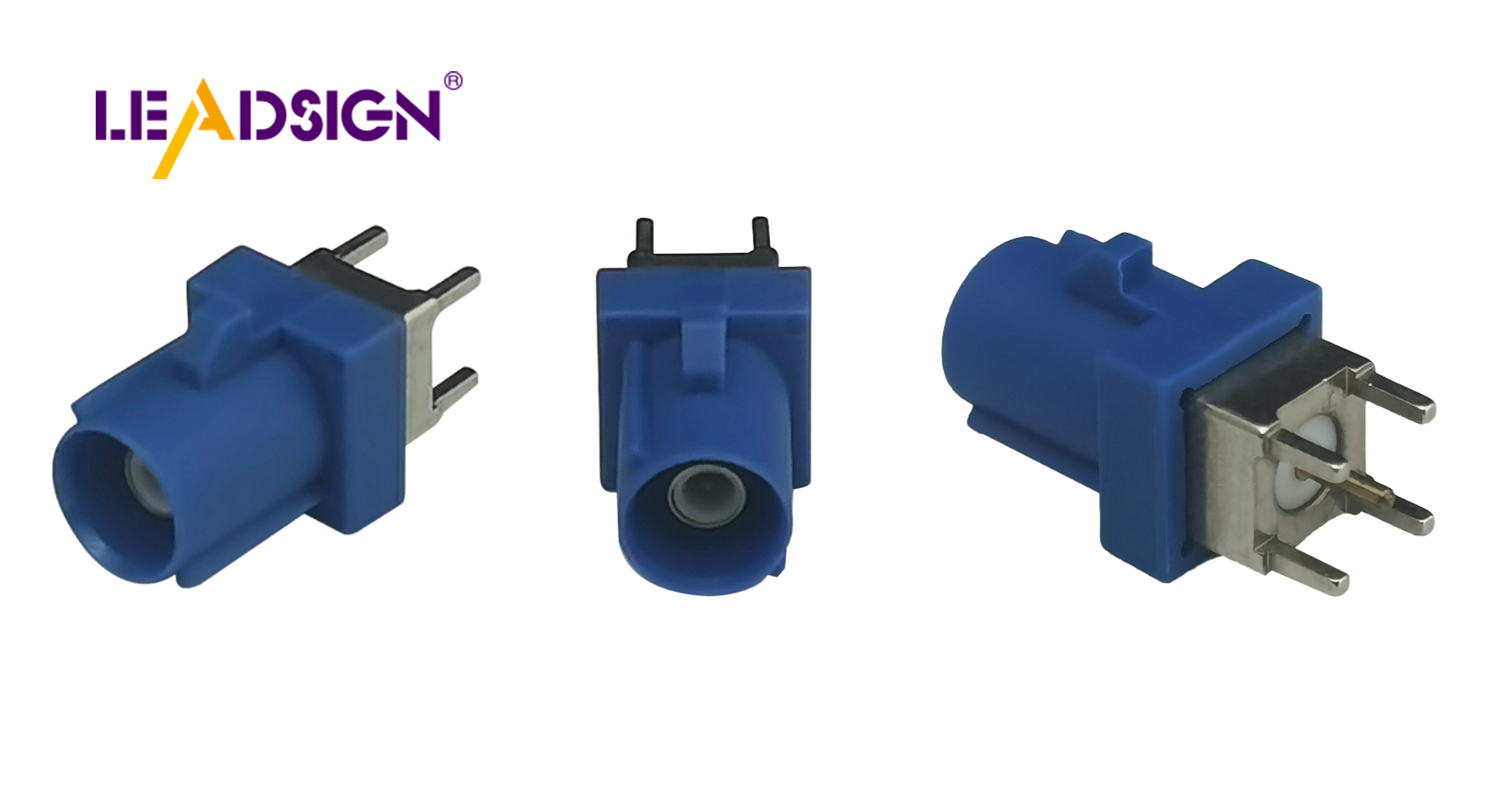

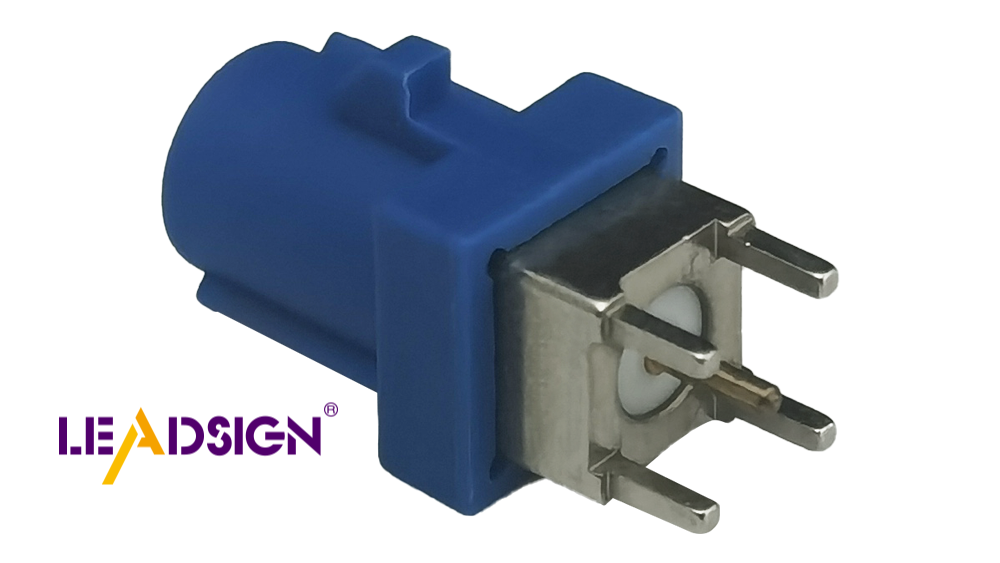

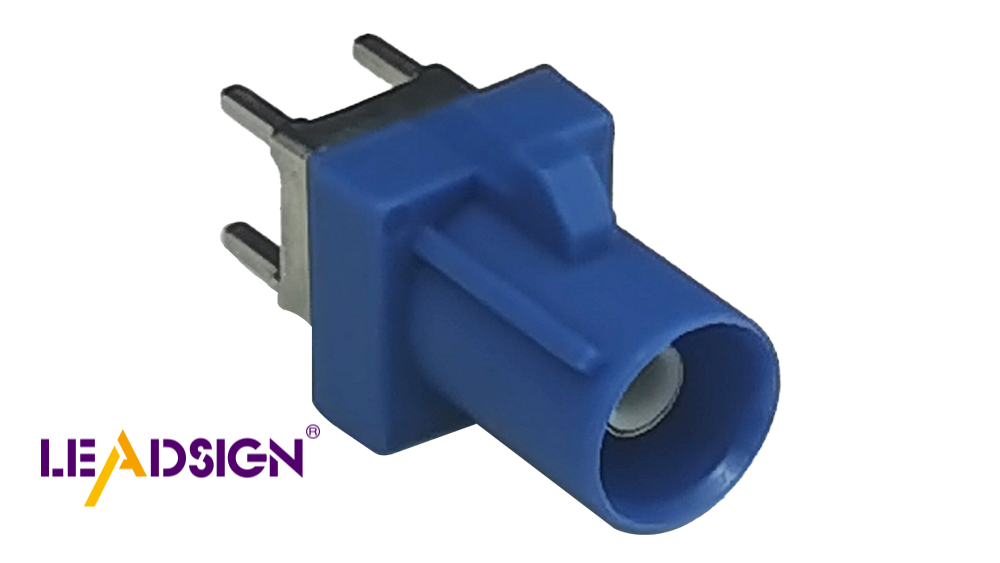

Key Benefits Of FAKRA PCB Connectors For Automotive Use

Improving Automotive Data Transfer Using FAKRA PCB Connectors