Tips for Preventing Corrosion in Automotive Electrical Connector Plugs

Car connector plugs are important for your car to work well. These small parts help electrical connectors communicate properly. Rust can break this connection and cause problems or costly fixes. You can stop damage by protecting connectors when storing or using them.

Key Takeaways

Keep car plugs dry to stop rust. Water can harm them.

Clean plugs often with safe tools. This keeps them working well.

Buy good-quality plugs. They last longer and cost less in the end.

Causes and Risks of Corrosion in Automotive Electrical Connectors

Exposure to Moisture and Humidity

Water is a big problem for car connectors. When water, humidity, or salty air gets inside, it reacts with the metal. This creates rust that blocks electricity and makes it harder to work. Over time, this can cause signals to stop or wires to short out. Short circuits might blow fuses or even start fires in bad cases. Humid places make it worse because materials soak up water and stop working well. Keeping connectors dry is very important to avoid these problems.

Accumulation of Dirt and Debris

Dirt and dust can also damage connectors. Tiny particles can get into the pins, even with protective covers. This weakens the connection and makes it unreliable. If dirt mixes with water, it can rust the surface faster, causing more issues. Cleaning your connectors keeps them working and safe from harm.

Use of Low-Quality Materials

Cheap materials in connectors don’t last long in tough conditions. Extreme heat, brake fluid, or antifreeze can break them down quickly. This makes them rust and fail faster. Picking good-quality connectors helps them resist damage and last longer.

Neglecting Regular Maintenance

Skipping maintenance is a common mistake that causes rust. Over time, connectors wear out or get dirty. Without care, this can lead to bad connections or total failure. Checking and cleaning them often helps you spot rust early and stop it from spreading.

Tips for Preventing Rust in Car Connector Plugs

Clean Connectors with the Right Tools

Cleaning car connectors stops rust from forming. Use proper tools to clean dirt and dust. A pink eraser or eraser pencil works well for cleaning. For pins, use an emery board and contact cleaner. A brass brush can help with tough grime. After cleaning, add grease or fluid film to protect them. Clean connectors often to keep them working properly.

Use Dielectric Grease for Protection

Dielectric grease keeps water and air away from connectors. It creates a barrier that slows rust and stops tiny movements from causing damage. This grease repels water and stays in place for a long time. Adding it to connectors protects them from rust and wear.

Choose Sealed or Weatherproof Connectors

Sealed connectors block water, dust, and chemicals. They keep connections safe and prevent rust. Waterproof connectors also stop high resistance from forming. Using these connectors makes your car’s electrical system last longer.

Store Connectors the Right Way

Store connectors carefully to avoid damage. Keep them in a safe spot to stay organized. Use airtight containers to block water and dust. Label each connector for easy finding. Check stored connectors often to make sure they’re still good. These steps keep connectors in great shape.

Don’t Overload Electrical Systems

Overloading can harm connectors and cause rust. Make sure your car’s system isn’t overworked. Check the load often and replace broken parts. Keeping the system balanced helps connectors last longer.

Maintenance Tips to Keep Connectors in Good Shape

Check for Corrosion Early

Look at your car's connectors often for rust or damage. Finding problems early can save money on repairs. Watch for:

Loose or broken connectors.

Wires that are damaged.

Bent or rusty parts.

Copper turns green or white when it rusts. Iron parts get brown or red rust. Spotting these signs early helps you fix them before they get worse.

Change Broken Connectors

Replacing bad connectors keeps your car working well. Follow these steps:

Put wires into the connector.

Tighten the connector.

Test if it works.

Clean connectors with a soft cloth and mild soap first. Add a rust-proof coating after replacing to stop future rust.

Use Safe Cleaning Products

The right cleaners keep connectors clean and safe. Don’t use strong chemicals that might harm them. Use special cleaners made for car connectors. These remove dirt without damage. Cleaning often stops rust from forming.

Plan Regular System Checks

Regular checks keep your car’s electrical system working well. Have a professional check it every 1–3 years. Older cars or those in tough weather need more checks. These checks find hidden problems and keep things running smoothly.

Tip: Label connectors when storing them. This makes finding them easier later.

Importance of High-Quality Automotive Electrical Connectors

Benefits of Corrosion-Resistant Materials

Using corrosion-resistant materials makes connectors last longer. Plastic is light and strong, perfect for many uses. For tougher jobs, metal connectors are stronger. Stainless steel resists water, salt, and rust very well. Special alloys like nickel-aluminum bronze work great in wet or chemical-filled places. These materials keep connectors safe and working properly over time.

Identifying Reliable Brands and Products

Pick connectors with the right features for your car. Check if they handle your car’s current and voltage needs. High-density connectors with many contacts improve signals and allow upgrades. Choose ones made for tough conditions like water or shaking. Good connectors have strong locks and strain relief to stay connected. Plastic or metal housings should fit your needs. Low-resistance materials help keep signals clear.

Long-Term Value of Investing in Quality Connectors

Buying good connectors saves money over time. They handle heat, water, and shaking without breaking. These connectors keep electrical connections steady, avoiding problems. Easy-to-use designs make installation faster and simpler. They also cut maintenance costs by lasting longer. Durable connectors keep your car’s electrical system running well.

Tip: Look for industry standards like ASTM testing to ensure quality.

Knowing what causes rust helps protect your car’s connectors. Cleaning and checking them often stops damage and keeps them working. Good-quality connectors are stronger and last a long time. Store connectors safely and follow these tips to make them last longer and save money on repairs.

FAQ

How should you clean rusty connectors?

Use a contact cleaner and a soft brush to clean. Don’t use strong chemicals. After cleaning, add dielectric grease to stop future rust.

How often should car connectors be checked?

Check connectors every three months or after wet or dusty trips. Regular checks find rust early and save on repairs.

Does dielectric grease help connectors last longer?

Yes, dielectric grease blocks water and dirt from connectors. It lowers damage and helps connectors last much longer.

See Also

Enhancing Data Transfer in Vehicles With Advanced Connectors

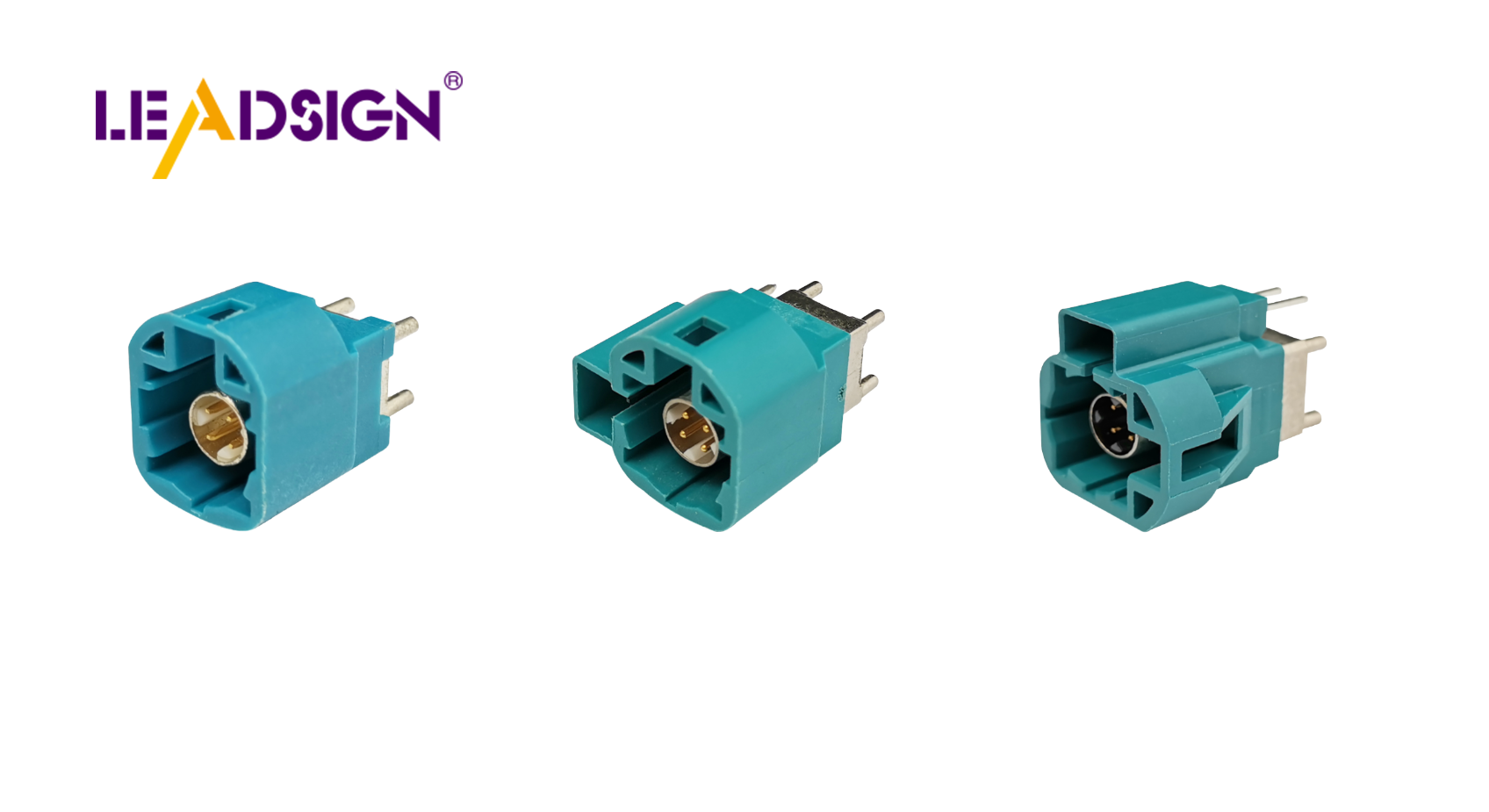

Why FAKRA Connectors Are Crucial for Automotive Systems

Benefits of FAKRA PCB Connectors for Automotive Use