The Most Popular Automotive Wire Connectors You Need to Know

Automotive wire connectors types play a crucial role in vehicles, ensuring the electrical system functions efficiently. These connectors facilitate the smooth flow of electricity, maintaining the car's safety and optimal performance. Choosing the right automotive wire connectors types prevents electrical issues caused by poor connections. Advances in materials have enhanced the reliability and performance of these connectors. Understanding the various automotive wire connectors types is essential for maintaining a robust car electrical system.

Types of Automotive Wire Connectors

Crimp Connectors

Definition and Uses

Crimp connectors are often used in cars. They work by folding a metal piece around a bare wire. This makes a strong link that lasts. There are different kinds like bullet, butt splices, and wire joints. These connectors keep the car's wires working well.

Advantages and Disadvantages

Crimp connectors have many good points. They make strong links which are important for cars. You can put them on fast without special tools. But if done wrong, they might not connect well. Once crimped, it's hard to take them off without breaking the wire.

Solder Connectors

Definition and Uses

Solder connectors join wires by melting solder on them. This makes a lasting bond for steady power flow. They are used where shaking is common, needing strong connections.

Advantages and Disadvantages

Solder connectors make tough links that resist shaking and bad weather. But soldering takes more time and skill than crimping does. You need certain tools and must be careful to do it right. Also, you can't easily undo soldered links.

Push-On Connectors

Definition and Uses

Push-on connectors let you join or separate wires quickly. Just push the wire into place to connect it. They're handy in cars where wires need frequent changes.

Advantages and Disadvantages

Push-on connectors are easy to use without tools, great for regular checks or fixes. But they might not hold as tightly as crimp or solder types do. Over time, they can get loose causing problems with electricity.

Other Popular Automotive Wire Connectors

Ring Terminals

Ring terminals are very common in cars. You use them by placing the terminal over a bolt and tightening it with a nut. This makes a strong connection, important for cars. They work well where you need a lasting link that handles shaking and tough conditions. Their design is easy to install and remove, so many car fans like them.

Butt Connectors

Butt connectors join two wires end-to-end simply. Put the wire ends into each side of the connector and crimp them together. They are great for fixing or extending car wires. These connectors make sure electricity flows without stopping. Many people use butt connectors because they are simple and effective. They help when you need to join wires without changing the original setup.

Molex Connectors

Molex connectors are useful and strong, often used in cars. They connect many wires neatly together in one place. These connectors have a plug and socket, making it easy to connect or disconnect wires. Molex connectors handle high power well, good for both small and big jobs in cars. Their design keeps connections secure, so they don't come apart easily by accident. You see them often in car lights, music systems, and other electronics.

Things to Think About When Picking Wire Connectors

When picking car wire connectors, think about a few things. This helps your car work well and stay safe.

Material and Strength

Why Good Material Matters

Good materials make connectors work better. They last long and don't rust. Look for connectors made of strong metals like copper or brass. These are good for carrying electricity.

Weather Concerns

Weather is important when choosing connectors. If your car faces tough weather, pick strong ones. They should handle heat, cold, and wet conditions. This keeps the connection safe from water and dirt.

Electrical Needs

Power Levels

Know the power levels of connectors. Each type has limits for different uses. Pick ones that fit your car's needs to stop overheating.

Fit with Car Systems

Make sure connectors fit your car's systems. Not all work with every model. Choose ones that match your car’s wiring to avoid problems.

Easy to Install

Needed Tools

Different connectors need different tools to install. Crimp types need special tools. Check what you need before starting.

Skill Level Required

Your skills matter too. Solder types need more skill and care. If you're new, try easy ones like push-on types needing fewer tools.

Picking the right wire connectors means checking material quality, weather strength, electrical fit, and how easy they are to install. Doing this keeps your car’s electric system working well.

Common Uses of Wire Connectors in Cars

Knowing where to use wire connectors helps your car work better. Let's look at some usual uses.

Engine Area

Connectors Often Found

In the engine, crimp connectors, ring terminals, and Deutsch connectors are common. They handle heat and shaking well.

Specific Use Examples

Crimp connectors hold battery cables and ignition wires tight. Ring terminals link to grounding spots for steady power. Deutsch connectors make strong links for sensors, key for engine control.

Inside the Car

Connectors Often Found

Inside, push-on and Molex connectors are used a lot. They are easy to use for different parts inside.

Specific Use Examples

Push-on connectors fit dashboard wires and audio gear, allowing quick swaps. Molex connectors keep many wires neat in infotainment systems.

Lights System

Connectors Often Found

For lights, butt and heat shrink connectors are often used. They give safe and weatherproof links.

Specific Use Examples

Butt connectors join headlight and taillight wires for steady power. Heat shrink ones guard against moisture and dirt, crucial for outside lights.

By picking the right connector for each job, your car's electric system stays safe and works well.

Knowing about car wire connectors is important for your car's electric system. These connectors help power move smoothly and keep things safe. When picking connectors, think about quality and if they fit well. Choose ones that don't rust and suit your car's needs. New connectors have many sizes, which helps car makers by being flexible. Always pick connectors that match your car to stop problems. By choosing wisely, you keep your car's electric system working well and safely.

See Also

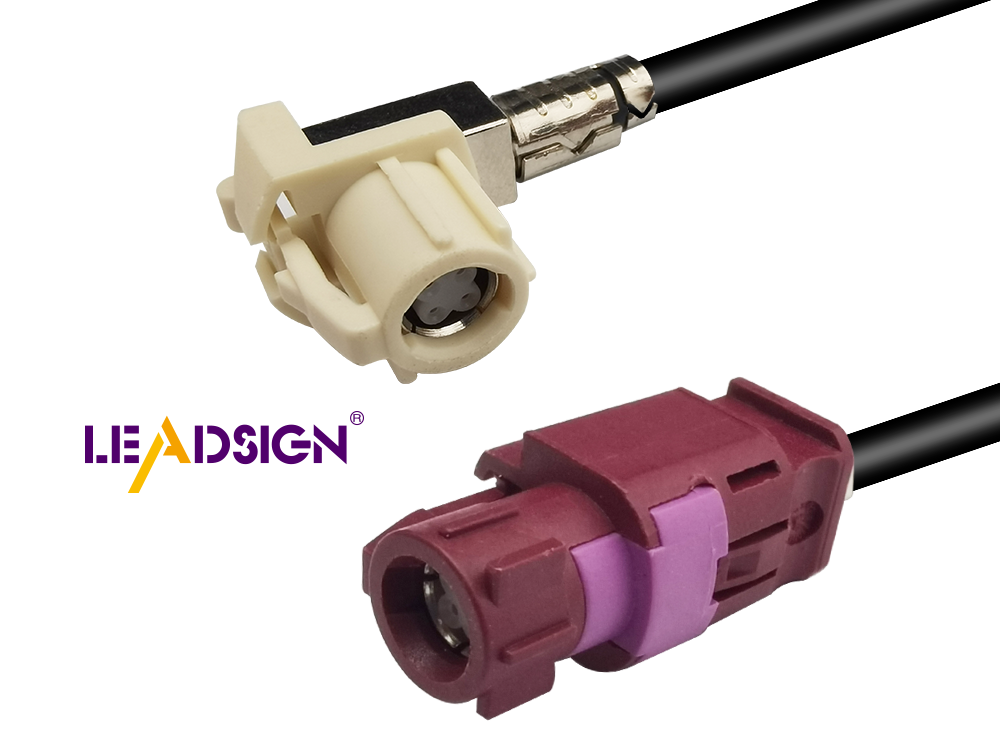

The Significance of Fakra Auto Connectors in Modern Cars

The Value of FAKRA Connectors in Auto Uses

The Role of Fakra Connectors in Auto Sector