How PCB Board Wire Connectors Are Transforming Car Wire Connector Types

PCB board to wire connectors are transforming how car wiring is done. They make car designs smaller and stronger. These connectors simplify wiring, making it easier to build and fix cars. They also support new tech like electric cars and smart driving systems. This helps connect modern technology with car electronics easily. As technology grows, these connectors help improve the auto industry.

Key Takeaways

PCB board to wire connectors are revolutionizing car designs by making them smaller, lighter, and more efficient.

These connectors enhance electrical performance, ensuring reliable power and data flow for advanced car technologies like electric vehicles and smart driving systems.

The compact design of PCB connectors allows for more connections in limited spaces, facilitating the integration of modern features without compromising performance.

Durability is a key advantage; PCB connectors withstand harsh conditions, reducing the need for frequent repairs and replacements.

Simplified wiring systems lead to faster assembly and easier repairs, saving time and costs for manufacturers and mechanics alike.

As technology evolves, PCB connectors are adaptable, ready to support future innovations like 5G and AI in automotive applications.

The growing demand for electric and smart cars is driving the need for efficient, reliable PCB connectors, shaping the future of the automotive industry.

Understanding PCB Board to Wire Connectors

What Are PCB Board to Wire Connectors?

Definition and basic functionality

PCB board to wire connectors are important in modern electronics. They connect wires or cables directly to a PCB, allowing parts of a system to work together. These connectors help move power and data between device parts. They ensure systems work properly in cars and other industries.

Key features, such as compact design and high performance

These connectors are small but work very well. Their size fits tiny devices where space is tight. They allow many connections on one PCB, saving space. Built tough, they handle heat and shaking, making them great for cars.

Key features include:

Compact size: Fits small devices with many connections.

High performance: Keeps data flowing smoothly.

Durability: Handles heat and shaking easily.

Advantages of PCB Board to Wire Connectors

Miniaturization and space-saving benefits

Smaller devices need smaller connectors like these. They save space on PCBs, which helps make lighter cars more efficient. These connectors also let manufacturers add more functions into smaller spaces.

Enhanced electrical performance and reliability

These connectors provide steady power and data flow without losing signals. They lock securely so they don’t disconnect by accident. Their fast data speeds are perfect for car tech like smart driving systems.

Compatibility with high-speed data transmission

Modern systems need fast data transfer, which these connectors provide. They work well with USBs, Ethernet, and other advanced tech. This makes them useful for smarter cars and better communication tools.

Industry Trends in Printed Circuit Board Connectors

Miniaturization and High-Speed Connectivity

Development of smaller connectors with increased pin counts

Smaller printed circuit board connectors are now being made for compact devices. These connectors save space but still work very well. Industries like cars and phones need more connections in tiny spaces. Makers now design high-density connectors that fit small layouts. They also keep signals strong, helping create lighter and smarter electronics.

Role in supporting 5G, IoT, and AI technologies

New tech like 5G, IoT, and AI needs fast data sharing. The pcb connector market helps by making reliable connections between parts. For example, 5G needs faster data speeds, while IoT uses small tough connectors to stay connected. AI systems need quick data handling, so these connectors are key for modern tools.

Innovations in PCB Manufacturing Technologies

Advanced materials and designs for durability

Today’s pcb technology trends use better materials to last longer. These materials resist heat, shaking, and stress from the environment. This makes printed circuit board connectors work well even in tough places like cars or factories. Stronger connectors mean fewer replacements are needed over time.

Integration of flexible and scalable solutions

Flexible circuits have changed how connectors are designed today. Flexible ones bend to fit different shapes in complex gadgets easily. Scalable designs let makers adjust them for special uses too. This helps meet new tech demands while staying useful for future needs.

Growth of the PCB Connector Market

Projected market growth and demand drivers

The pcb connector market is growing fast due to new tech needs everywhere. Experts expect steady growth as industries want smaller yet powerful connectors more often now. Cars, health tools, and telecoms lead this rise by needing better designs.

Applications in automotive, medical, and telecom industries

In cars, printed circuit board connectors make wiring easier for smart features like self-driving systems. Medical tools depend on them for small but accurate setups that work well always. Telecoms use these for fast data speeds with strong links too.

Changes in Car Wire Connector Types

Smaller and Lighter Wiring Systems

Moving to tiny, lightweight connectors

Modern cars are smaller and use less energy. This is because of lighter, smaller connectors in car wiring. These connectors, like PCB ones, make wires take up less space. They help car makers build lighter cars that save energy. Tiny connectors also let more parts fit into small spaces for advanced tech.

Helping electric and hybrid cars

Electric cars need smaller connectors even more. EVs use complex wires for power and data flow. PCB connectors fit tight spaces and keep connections strong. Their small size makes EVs lighter, improving battery life and driving range. As EVs grow popular, these connectors will stay important.

Stronger and More Reliable Connectors

Standing up to heat, shaking, and weather

Cars face tough conditions like heat or constant movement. PCB connectors are built to handle these challenges well. They don’t break easily under stress or bad weather. This strength makes them perfect for car wiring systems that must work all the time.

Longer-lasting wiring systems

Strong connectors make car wires last longer too. High-quality PCB connectors stop problems caused by wear or damage. This means fewer fixes or replacements over time, saving money. For EVs, reliable wiring is key for batteries to work well long-term.

Supporting New Car Technologies

Working with smart driving systems

Smart car features need fast data sharing between sensors and cameras. PCB board connectors allow quick connections for things like lane-keeping or crash alerts. These fast links help smart systems run smoothly as cars get smarter.

Helping EV batteries charge better

Good battery management is vital for electric vehicles' performance. PCB connectors move power and data inside EV batteries efficiently. They track battery health, temperature, and charging levels accurately too. These connectors also support quick charging systems for faster recharges as more people buy EVs.

Easier and Lighter Wiring Systems

Making wiring less complicated and lighter

Modern cars use lots of electronics, but old wiring adds weight. PCB connectors make things simpler by using fewer wires. This creates a cleaner design without messy, heavy cables. It saves space and makes cars lighter, helping them use less fuel.

With PCB connectors, many functions fit into one spot. This means fewer wires are needed, making systems easier to handle. For electric cars, this is very helpful. Lighter wires improve battery life and let cars drive farther. As more people buy electric cars, these connectors will help improve their designs.

Faster building and easier repairs

Simpler wiring also speeds up how cars are made. With fewer parts to put together, factories work faster and better. Cars with PCB connectors often have fewer mistakes during assembly. This lowers costs and can make cars cheaper for buyers.

Fixing your car becomes quicker too. Mechanics can find problems easily without dealing with tons of wires. PCB connectors keep everything neat, so repairs are simple. This saves you time and money while keeping your car running well.

“As vehicles get smarter, connectors now work better and last longer.” These changes make wiring systems simpler and easier to use.

Effects on the Car Industry

Better Performance and Efficiency

Quicker data sharing for smart cars

Modern cars need fast data to work well. PCB connectors help sensors, cameras, and controls share information quickly. These connectors make sure systems like navigation or safety features run smoothly. As technology improves, data sharing will get even faster.

Improved energy use in electric cars

Electric cars need good power management to perform well. PCB connectors move energy between batteries and motors efficiently. They reduce wasted power and help batteries last longer. This means electric cars can drive farther without charging often.

Saving Money and Time

Lower costs with simple designs

Simpler designs cost less to make. PCB connectors replace old soldering methods, making production easier. Their easy-to-use design speeds up assembly, saving time and money. Automation in factories makes this process even better.

Faster building and repairs

PCB connectors make car assembly quicker by simplifying wiring setups. Fixing problems is also easier since mechanics can swap parts fast without dealing with messy wires. This saves time and keeps your car working longer.

Preparing Cars for the Future

Ready for new technologies

As tech changes, cars must keep up too. PCB connectors allow makers to add new features like 5G or AI easily. These flexible designs ensure your car stays updated with future trends.

Adjusting to new rules

Car standards change often for safety and efficiency reasons. PCB connectors adapt easily to these updates without needing big system changes. This helps cars stay modern while meeting all rules.

"New connector tech is shaping how future cars are made." These upgrades improve performance while keeping vehicles affordable and eco-friendly.

PCB connectors are changing car technology in big ways. They help create smaller and stronger designs for vehicles. These connectors also support advanced systems like electric cars and smart features. Wiring becomes easier, making cars work better and last longer.

"More electric and smart cars mean higher demand for PCB connectors," say experts.

As their use increases, these connectors will improve future car designs. They bring better performance, save money, and adapt to new ideas. By using this tech, car makers build smarter and greener cars for everyone.

FAQ

What do PCB board to wire connectors do in cars?

PCB connectors join electronic parts in cars. They help move power and data between systems like cameras, sensors, and controls. These connectors are key for modern car tech, including electric cars (EVs) and smart driving systems.

How do PCB connectors make electric cars better?

PCB connectors improve EVs by managing power and batteries well. They simplify wiring, making EVs lighter and use less energy. Their small size fits tight spaces, connecting important parts like motors and chargers easily.

For instance, TE Connectivity made a connector in 2022 for EV battery systems, showing how innovation matters here.

Why are smaller connectors useful in today’s cars?

Smaller connectors save space and make wires lighter. This is important for small car designs and lightweight EVs. With these connectors, car makers can add more features without losing efficiency or performance.

Can PCB connectors handle tough conditions in vehicles?

Yes, PCB connectors are made to survive hard car conditions. They resist heat, shaking, and moisture. This strength makes them work well even in rough environments, ensuring long-lasting wiring systems.

How do PCB connectors help smart car features?

PCB connectors allow fast data sharing for smart car tools. They link cameras, sensors, and controls so features like lane-keeping or crash alerts work smoothly. Their speed is vital for modern car innovations.

Are PCB connectors good for the environment?

PCB connectors help eco-friendly car designs by cutting wiring weight and saving energy. In EVs, they boost battery life for longer drives with less power use. Simpler wiring also supports greener manufacturing methods.

Where else are PCB connectors used besides cars?

PCB connectors are used in telecoms, medical devices, and gadgets too. They support quick data transfer and strong connections while fitting into small spaces—making them useful beyond just vehicles.

How do PCB connectors make building cars easier?

PCB connectors simplify wiring setups during production. Their easy design removes tricky soldering steps to save time when building cars. This lowers costs while speeding up factory work with fewer mistakes.

Will PCB connectors keep up with future car tech?

Yes! PCB connectors can adjust to new technologies like 5G or AI tools easily. Their flexible designs let them stay useful as smarter features get added to future vehicles.

Why is there more demand for PCB board wire connections now?

More people want EVs and smarter cars today than before. These vehicles need compact yet powerful connections that work reliably all the time—driving growth in this field through constant improvements.

See Also

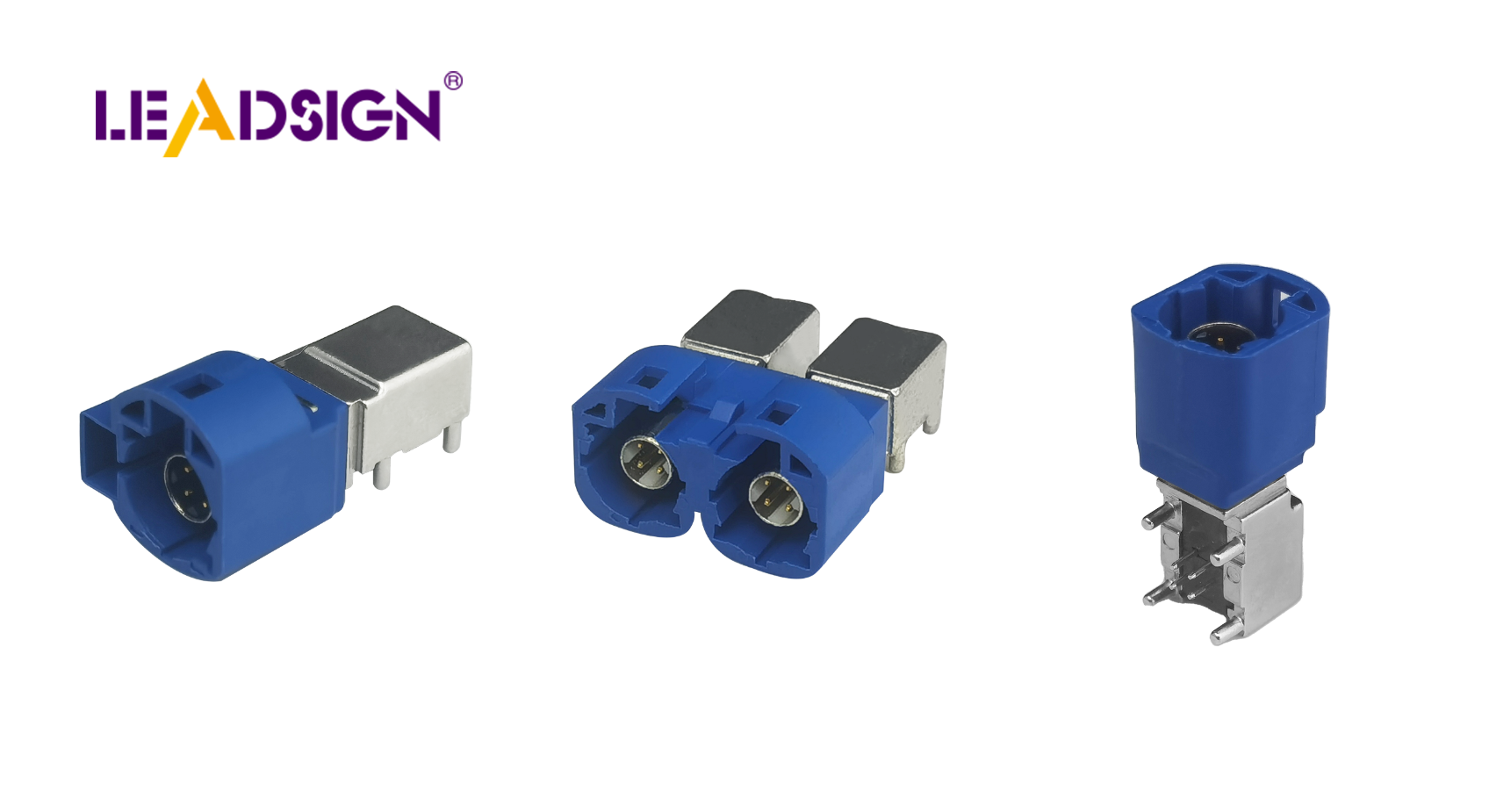

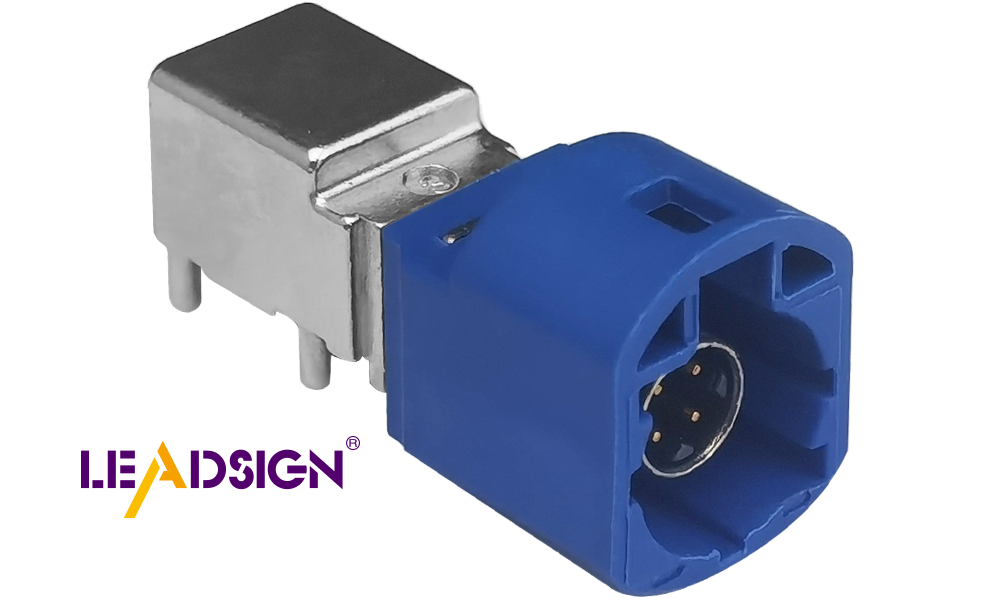

Why FAKRA PCB Connectors Are Essential for Automotive Use

Key Benefits of FAKRA PCB Connectors in Vehicles

Advantages of FAKRA Connectors for PCB in Automotive