Exploring the Types and Uses of PCB Board to Wire Connectors

PCB board-to-wire connectors play a crucial role in modern electronics by connecting wires to circuit boards, ensuring seamless power and signal transmission. These connectors are essential for maintaining the proper functionality of electronic systems, whether in gadgets or machinery. Their robust design ensures reliability and durability, making them ideal for demanding and precise applications. With advancements in technology, the demand for smaller and more intelligent pcb board to wire connectors continues to grow, enhancing device performance and energy efficiency.

Key Takeaways

PCB board-to-wire connectors are essential for ensuring reliable power and signal transmission in modern electronics.

Choosing the right connector type—such as pin headers, terminal blocks, or IDC connectors—depends on the specific needs of your device and environment.

Crimp style connectors offer durability and ease of use, making them ideal for applications requiring strong and efficient connections.

High-Speed Data (HSD) connectors are crucial for fast data transfer in automotive and telecommunications, enhancing device performance.

In industries like medical and consumer electronics, small and reliable connectors are vital for maintaining accuracy and efficiency in compact designs.

Using the appropriate PCB connectors can significantly improve assembly speed and reduce maintenance needs in industrial settings.

As technology advances, PCB connectors are evolving to become smaller and smarter, catering to the growing demands of IoT and wireless applications.

Types of PCB Board-to-Wire Connectors

Picking the right connector is important for electronics to work well. Below are some common types of PCB board-to-wire connectors, their features, and uses.

Pin Header Connectors

Features and Benefits

Pin header connectors are very useful in many ways. They come in different styles like surface mount, right-angle, and straight designs. You can find them with various pin sizes and numbers. This makes them fit into many circuit board setups. They are cheap and dependable, so they are used a lot.

Some main benefits include:

Work for both board-to-board and wire-to-board connections.

Many size options make designing easier.

Fit easily into small electronic devices.

Common Use Cases

Pin header connectors are found in gadgets, machines, and cars. Their flexibility makes them great for secure connections between parts.

Terminal Block Connectors

Features and Benefits

Terminal block connectors connect wires to circuit boards simply and quickly. They use screws or snaps, so no extra tools or steps are needed. These connectors are light and easy to set up.

Advantages include:

Quick wire connection without much effort.

Strong design that lasts long.

Saves time during assembly work.

Common Use Cases

You’ll see terminal block connectors in factories and power systems. They’re perfect where wires need frequent changes or fixes.

IDC (Insulation Displacement) Connectors

Features and Benefits

IDC connectors make connecting wires fast by skipping insulation removal. This saves time when putting things together. They are small but strong, fitting tight spaces well.

Key features include:

Easy setup process.

Small size helps save space.

Reliable connections with little work needed.

Common Use Cases

IDC connectors are used in phones, electronics, and data systems. They handle fast data speeds, making them great for modern devices.

Crimp Style Connectors

Features and Benefits

Crimp style connectors securely join wires to circuit boards. They use crimping to attach wires to metal contacts. This method creates strong connections without needing soldering. It also makes assembly faster and easier.

Main benefits are:

Durability: Crimped connections handle vibration and stress well, lasting long.

Ease of Use: Crimping is simple and saves time during setup.

Versatility: These connectors work with many wire sizes and types.

Common Use Cases

Crimp style connectors are used where strength and efficiency matter most. They are common in cars, factories, and electronics. For example:

In cars, they stay secure even with constant shaking.

In factories, they connect heavy-duty machines reliably.

In electronics, they help create small but effective designs.

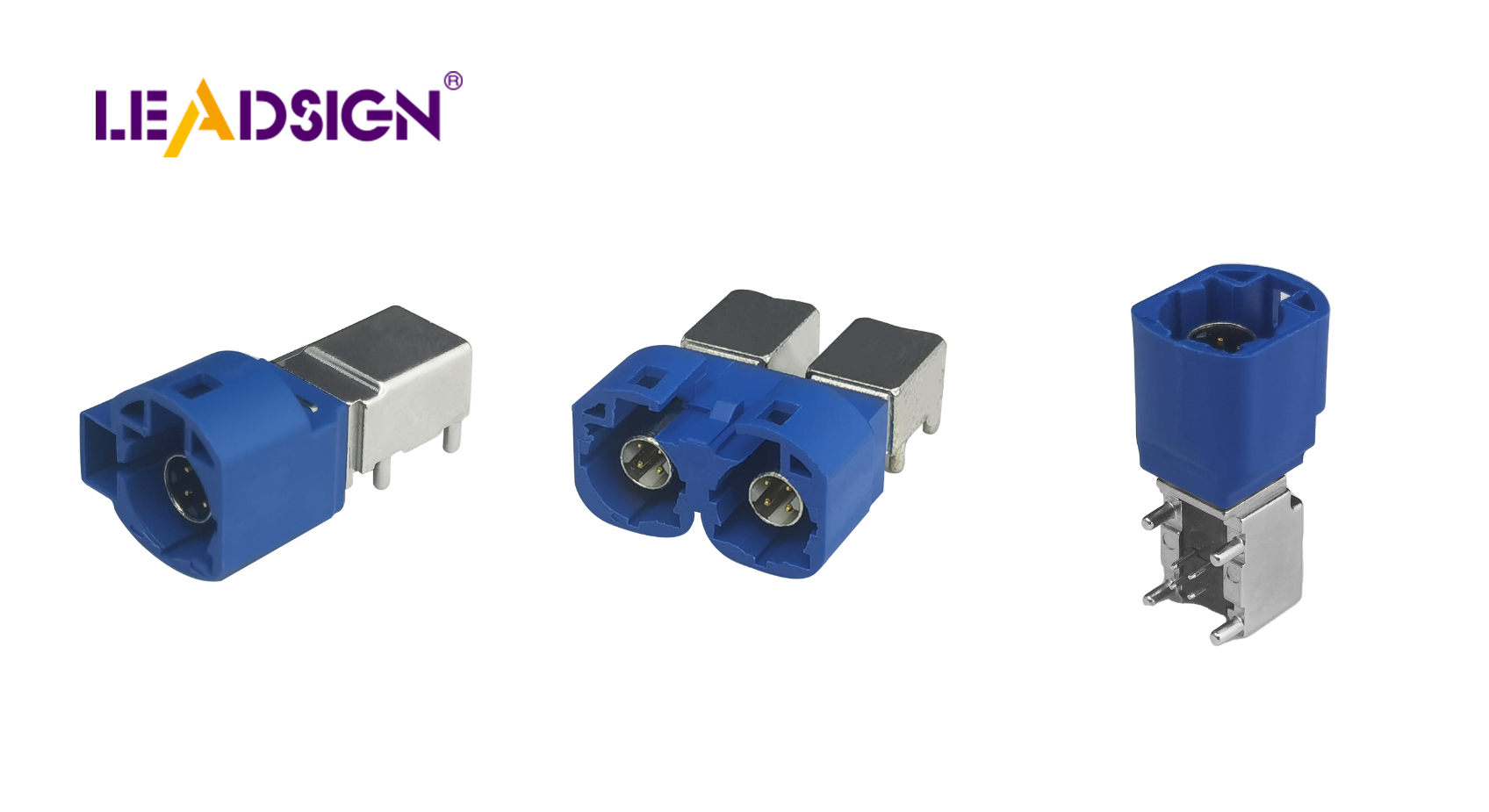

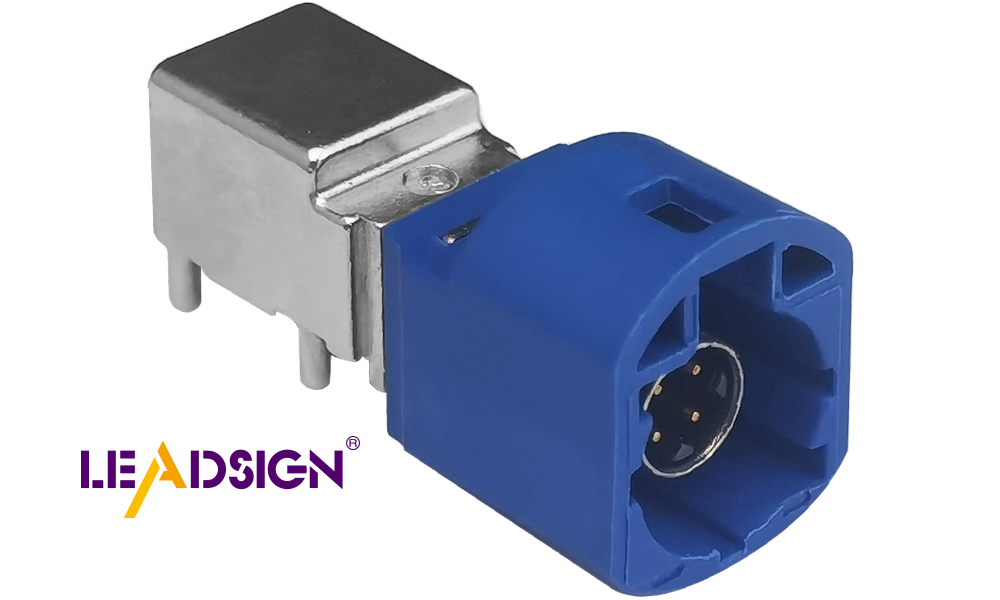

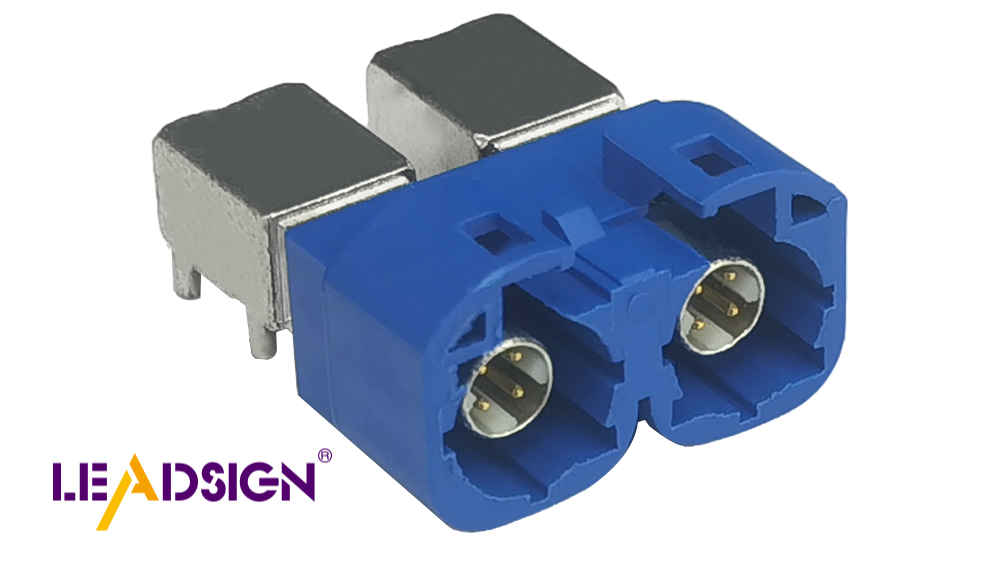

High-Speed Data (HSD) Connectors

Features and Benefits

High-Speed Data (HSD) connectors move data quickly for advanced systems. They are small but tough, working well in hard conditions. Their locking features keep cables safely attached.

Key features include:

High Coding Efficiency: Different codes stop wrong connections during assembly.

Strong Cable Retention: Cables stay firmly connected under pressure or movement.

Compatibility: These support USB, Ethernet, and other data standards.

Common Use Cases

HSD connectors are needed for fast data transfer jobs. You’ll find them in:

Automotive Electronics: Used in cameras and entertainment systems inside cars.

Telecommunications: Found in radio stations and network setups.

Consumer Electronics: Help connect USB devices or Ethernet systems quickly.

These connectors ensure smooth communication between modern devices everywhere.

Applications of PCB Board-to-Wire Connectors

Industrial Automation

Needs in Factories

Factories need connectors that work in tough conditions. These places have high heat, shaking, and dust or water. Wire-to-board connectors must stay strong during these challenges. They should last long and keep machines running smoothly. Fast data transfer and power sharing are also very important.

Benefits of Using PCB Board-to-Wire Connectors

PCB board-to-wire connectors make building factory systems easier. Their strong design means they last a long time with less fixing needed. They also let you swap parts quickly when needed. Using these connectors makes machines work better and faster, helping factories run without problems.

Medical Devices

Why Precision Matters

Medical tools need to be exact and dependable. Connectors must send signals clearly and correctly every time. These tools often work in clean spaces, so the connectors can’t cause interference. Small designs are key to fit into tiny medical machines while still working well.

How These Connectors Help Medicine

PCB board-to-wire connectors are crucial for medical devices to work right. They help parts talk to each other perfectly, which is vital for things like scanners or monitors. Because they’re small but reliable, they’re great for medical use. With them, data stays accurate, keeping medical tools safe and effective.

Transportation and Automotive

What Vehicles Require

Cars and buses need connectors that handle hard conditions like heat or shaking. Chemicals can also be a problem, so the connectors must stay secure under stress. Safety is very important; good connections stop accidents from happening. Modern cars also need fast data-sharing features.

How These Connectors Improve Cars

Automotive connectors, like High-Speed Data (HSD) connectors, make vehicles better by sending information quickly between parts like cameras or screens. Their tough build keeps them working even in rough situations. Adding these connectors makes cars safer, smarter, and more efficient on the road.

Consumer Electronics

Needs for Small and Effective Designs

Consumer electronics need small and efficient designs to work well. Gadgets like phones, laptops, and gaming consoles need tiny parts. These save space but still perform at a high level. PCB connectors are key in making this possible. They create strong electrical links in tight spaces, which is vital for today’s devices.

These connectors are made to handle fast data transfer and power sharing. For example, flex PCB connectors reduce signal problems and block interference. This keeps data moving smoothly, which is important for smart home gadgets or wearable tech.

Connectors’ Importance in Modern Devices

Connectors link different parts of modern devices together easily. They help circuit boards talk to outside parts, enabling fast charging or wireless features. Cable to board connectors make connections simple while staying tough and dependable.

Connectors also improve how users experience their gadgets. Devices with FFC connectors are easier to build and design better. These connectors skip cable stripping steps, speeding up assembly time. Because of them, products become smaller yet very reliable.

Telecommunications

Demands and Advantages

Telecom systems depend on connectors for smooth operations. These systems need parts that manage fast data flow while handling heat or shaking well. PCB connectors meet these needs by offering secure and lasting links.

Using these connectors brings big advantages in telecom setups. They keep data moving without breaks even during heavy use times. For instance, AMP connectors are great at managing strong power flows and boosting signals in radio stations or hubs.

Real-Life Uses

Connectors play a big role in telecom workspaces. In radio stations, high-speed data connectors support smooth device communication. Ethernet systems use them for quick internet speeds without issues. Plus, header connectors give safe but easy-to-remove links for fixing equipment faster.

By adding advanced connectors into telecom networks, you get better data flow and stronger system performance overall. These parts not only improve connections but also make communication tools more trustworthy today.

PCB board to wire connectors are very important in electronics. They are used in factories, medical tools, and cars. These connectors help send power and signals smoothly. They also stay strong in tough conditions. Their small size fits the need for tiny gadgets today.

In the future, they will get stronger and smarter for IoT use. These changes will make them work better, helping create smarter electronic systems.

FAQ

What are PCB board-to-wire connectors used for?

PCB board-to-wire connectors link wires to circuit boards. They help send power and signals between devices. You can find them in phones, machines, medical tools, and cars. These connectors keep devices working properly by ensuring smooth communication.

How do I choose the right PCB board-to-wire connector?

Pick a connector based on your device’s needs. Think about what it will carry (power or signals) and where it will work (hot, shaky, or wet places). For example, high-speed data connectors suit cars and telecoms. Crimp-style ones are great for tough conditions with lots of movement.

Why are PCB connectors important in consumer electronics?

PCB connectors make gadgets smaller and more efficient. They connect parts inside phones, tablets, and gaming systems easily. Flex PCB connectors save space while stopping signal problems. This makes them perfect for today’s advanced devices.

Can PCB board-to-wire connectors handle harsh environments?

Yes, many can survive tough conditions like heat or shaking. Automotive ones, like High-Speed Data (HSD) connectors, resist chemicals too. This makes them useful in cars, factories, and telecom setups.

What are the common types of PCB board-to-wire connectors?

Common types include pin headers, terminal blocks, IDC connectors, crimp styles, and high-speed data ones. Each has special uses: terminal blocks connect wires fast; IDC skips stripping insulation during setup.

How do PCB connectors improve medical devices?

PCB connectors make medical tools accurate and reliable. Their small size fits tight spaces like monitors or scanners. They ensure safe signal flow for better patient care.

Are PCB connectors evolving with technology?

Yes! Connectors now get smaller but faster at sending data. They’re also more reliable for IoT gadgets and wireless tech. These changes make them better for modern needs.

What industries rely on PCB board-to-wire connectors?

Many industries depend on these connectors—like electronics, cars, factories, medicine, and telecoms. They provide strong links that keep everything running smoothly.

How do PCB connectors support telecommunications?

In telecoms, they move data quickly without breaks or errors. Ethernet networks use them to stay fast and steady during heavy use times.

What makes high-speed data connectors unique?

High-speed data ones send information super fast without losing connection strength. They fit USBs or Ethernet cables perfectly while staying secure under pressure.

See Also

Exploring FAKRA Connectors for Automotive PCB Solutions

Key Benefits of FAKRA Connectors for Automotive Use

FAKRA PCB Mount Connectors: Advantages for Automotive and RF

Why FAKRA PCB Connectors Are Essential for Automotive

Significance of FAKRA PCB Connectors in Automotive Communication