PCB Board to Wire Connectors Types Explained for Beginners

PCB board to wire connectors are key parts of electronics. They link circuit boards to wires for power and signals. Without them, devices would not work well. These connectors are important in many things, like gadgets and machines. They help send electrical signals to keep systems working properly. Picking the right connector helps your projects last longer and work better.

Key Takeaways

Understand the different types of PCB board-to-wire connectors, such as screw-in, plug-in, and soldered connectors, to choose the right one for your project.

Consider the specific needs of your project, including power requirements and environmental factors, to ensure a reliable connection.

Start with beginner-friendly connectors like JST or terminal blocks, which are easy to use and perfect for small projects.

Always check the pitch size and current/voltage limits of connectors to ensure compatibility with your PCB and prevent overheating.

Utilize datasheets and manufacturer advice to make informed decisions about connector specifications and best practices for installation.

Plan for future growth by selecting connectors that allow for easy upgrades and compatibility with evolving project needs.

Prioritize quality materials in connectors to enhance durability and performance, especially in challenging environments.

Overview of PCB Board-to-Wire Connectors

What are PCB board-to-wire connectors?

PCB board-to-wire connectors join a PCB to wires or cables. They help send power, signals, or data between parts of a system. These connectors come in different types for specific needs. For instance, crimp connectors use metal to make strong connections. This makes them great for tough and long-lasting uses. They make it easy to attach wires to PCBs while keeping devices reliable.

Common uses and applications in electronics

You can find these connectors in most electronic devices today. They are used in gadgets, cars, machines, and communication tools. For example:

In small gadgets, board-to-board connectors save space and transfer data fast.

In cars, they connect sensors, cameras, and entertainment systems securely.

In factories, they work well even in rough conditions to send power.

These connectors help electronic systems run smoothly no matter where they are used.

Benefits of using PCB board-to-wire connectors

There are many good reasons to use these connectors. First, they keep wires connected safely without coming loose easily. Second, they make fixing or upgrading parts simple without needing soldering skills. Third, modular designs let you build or expand projects quickly. For example, board-to-board connectors allow easy upgrades in powerful computers like servers. Finally, these connectors make your projects last longer by staying stable even under tough conditions.

Types of Connectors by How They Connect

When attaching wires to PCBs, the way they connect matters. It affects how strong and easy the connection is. Below are some common connector types based on their connection methods.

Screw-in connectors

Screw-in connectors are very secure for connecting wires to PCBs. These use screws to hold wires tightly in place. They work well where shaking or movement might loosen other connections. For example, terminal blocks use screws to grip wires firmly. This keeps the connection steady in tough places like factories or cars.

One good thing about screw-in connectors is their flexibility with wire sizes. You can tighten or loosen the screw for thick or thin wires. This makes them useful for many projects. Also, they can be reused without harming the wire or connector.

Plug-in connectors

Plug-in connectors make connecting wires to PCBs quick and easy. They have two parts that fit together, like a plug and socket. These are common in electronics because they’re simple and modular. For instance, board-to-board connectors often use this design to join two PCBs.

The best part about plug-in connectors is how easy they are to use. No tools are needed, so assembly is faster and simpler. They also allow upgrades without needing new wiring. But you must align them correctly when plugging in to avoid mistakes.

Spring-loaded connectors

Spring-loaded connectors use springs to keep wires held tightly. These are great when you need to connect and disconnect often. Some wire-to-board designs use springs for easier setup while staying reliable.

The spring gives steady pressure, keeping the connection strong even if there’s movement or shaking. These work well in flexible setups like testing equipment or temporary systems. Plus, no screws or soldering are needed, making them beginner-friendly.

Soldered connectors

Soldered connectors make a strong, lasting link between wires and PCBs. This is done by melting solder, a metal mix, to attach wires to PCB pads. It creates a firm electrical and physical bond, perfect for tough uses.

One big benefit of soldered connectors is handling high power. The solder joint lowers resistance, improving how electricity flows. This makes them great for power circuits or devices needing steady signals. For instance, many board-to-board connectors use soldering to work well in small electronics.

Soldered connectors are also good in places with shaking or movement. Unlike screw-in or spring-loaded types, they stay tight over time. This makes them useful in cars, machines, and airplanes. But soldering takes skill and care. You need the right heat to avoid weak joints or damage.

When using these connectors, pick the right solder and flux. Lead-free solder is common but needs more heat to melt. Flux cleans surfaces so the bond stays strong and secure. Good preparation helps you make a solid connection every time.

PCB Connector Types by Design and Use

Male and female connectors

Male and female connectors are very common in electronics. The male connector has pins that fit into the female socket. This pairing creates a strong and steady connection between parts. They are often used in wire-to-board systems for easy attachment. Wires connect to either side using solder or mechanical methods.

These connectors work well in many electronic setups. For example, they are key in board-to-board connectors for smooth communication between PCBs. Their simple design makes them beginner-friendly and quick to install. When choosing these connectors, check the pin count and spacing to match your PCB.

USB connectors

USB connectors are everywhere in modern devices today. They offer a standard way to share data or power gadgets. USB types include USB-A, USB-B, and USB-C for different uses. USB-C is popular because it’s reversible and supports fast data transfer.

These connectors are great for projects needing frequent plugging in or out. You’ll see them in phones, laptops, cameras, and more. They also support various functions, making them flexible for many tasks. Before picking a USB connector, ensure it fits your device’s needs for power or data.

JST connectors

JST connectors are small but dependable for tiny projects. Named after Japan Solderless Terminal (JST), they’re used in robotics, drones, and LED lights. Their compact size helps them fit tight spaces without losing efficiency.

There are different JST types like PH, XH, or SH series based on power needs. For example, PH is good for low-power tasks while XH handles higher currents better. These plug-and-socket designs make connections simple yet secure. Always choose the right type of JST connector based on your project’s electrical demands.

Terminal blocks

Terminal blocks are a simple way to connect wires to PCBs. They use screws to hold wires tightly, making them secure. These connectors are used in machines and home systems too. You can link many wires to one PCB with terminal blocks. This makes them great for projects needing lots of wiring.

A big benefit is their ability to fit different wire sizes. You can use them for small or large projects easily. They are also reusable, so you can disconnect and reconnect wires without harm. This is helpful for projects that need changes or fixing often.

Make sure the screws are tight when using terminal blocks. Tight screws keep connections safe and improve how electricity flows. If you want something easy and long-lasting, terminal blocks are a smart choice.

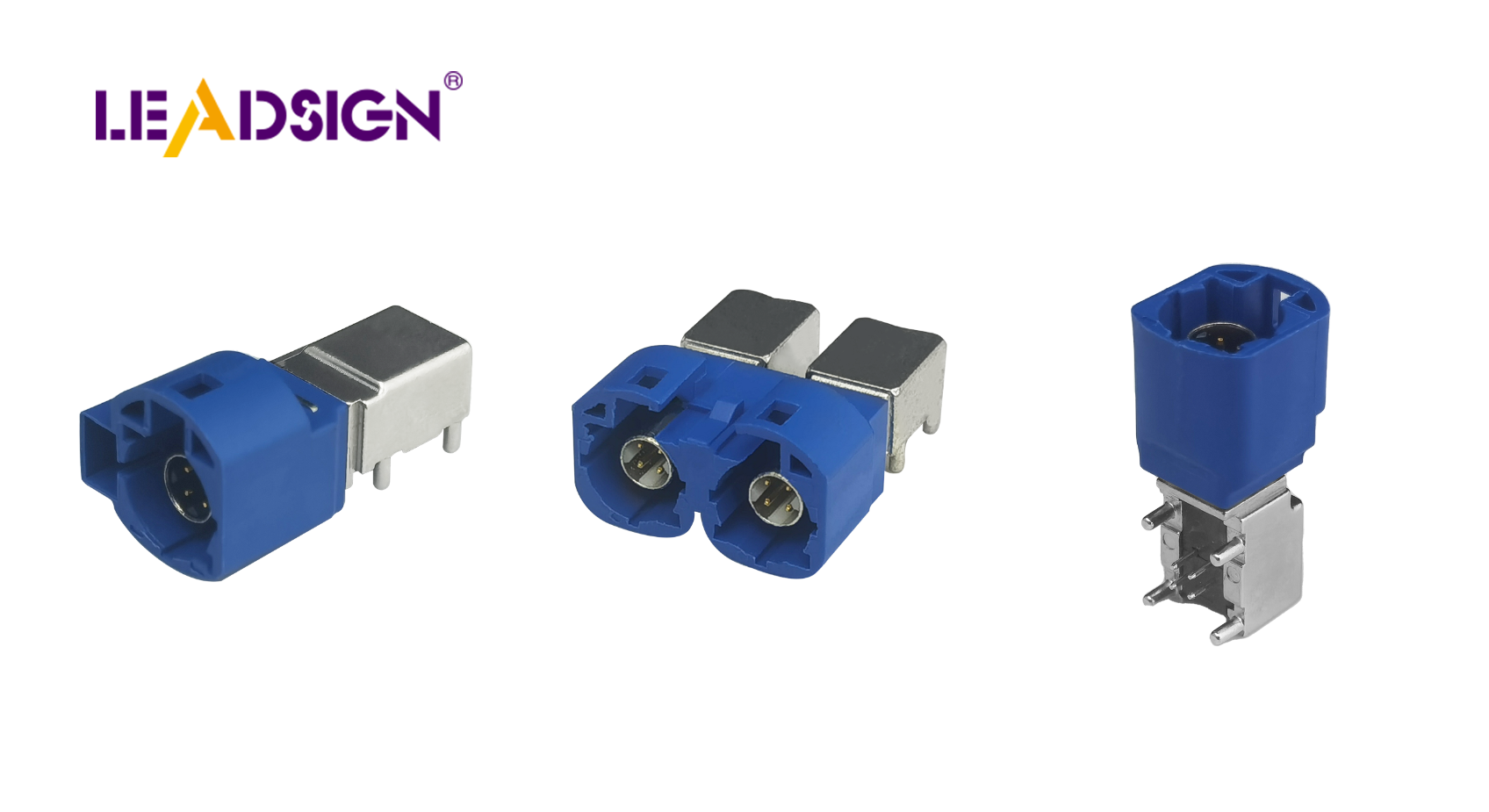

High-Speed Data (HSD) connectors

HSD connectors send data quickly and reliably between devices. They are used in cars, entertainment systems, and telecom tools. These connectors keep signals strong even at high speeds, which is important for modern gadgets.

HSD connectors have locks that keep them steady during movement or shaking. Their crimp design holds cables firmly, making them very durable. They also prevent mistakes during setup with their coding system.

You’ll see HSD connectors in USB 3.0, Ethernet, and LVDS setups. They work well for projects needing fast data transfer or advanced tech compatibility. If your project needs speed and accuracy, HSD connectors are a good pick.

IDC (Insulation Displacement Connector) connectors

IDC connectors make connecting wires easy by skipping insulation removal steps. Sharp metal parts cut through the wire cover to create a connection quickly. This makes them popular among beginners and experts alike.

They’re useful where quick assembly is needed, like ribbon cable setups in small devices. IDC connectors allow repeated connections without trouble, perfect for flexible projects.

Before pressing wires into place, align them correctly to avoid issues. Proper alignment ensures strong connections that improve project performance. IDC connectors save time while keeping your wiring neat and reliable.

FPC/FFC (Flexible Printed Circuit/Flexible Flat Cable) connectors

FPC/FFC connectors link flexible circuits to PCBs. They work with flat, thin cables, making them great for small devices. You’ll see them in phones, laptops, cameras, and other portable gadgets.

These connectors have many benefits. First, their slim design saves space in tight spots. This is helpful where regular wire connectors are too big. Second, they ensure stable connections for complex systems. Third, their light weight helps keep devices easy to carry.

FPC/FFC connectors come in different styles for various needs. Some have locks to hold cables securely and avoid disconnects. Others use soldering for stronger and lasting connections. When picking one, check the pin count and lock type to match your project.

To use them right, line up the cable carefully with the contacts. Misaligned cables can cause bad connections or damage parts. For projects needing frequent changes, pick ones with simple locking systems to save time.

These connectors are useful because they’re small, strong, and easy to use. They’re a top choice for modern electronics like portable gadgets. Knowing how they work helps you add them confidently to your projects.

Important Things to Check When Picking a Wire to PCB Connector

Pitch (space between pins)

Pitch is the space between two nearby connector pins. It’s important because it shows if the connector fits your PCB. Small pitch sizes are good for tight spaces like phones or smartwatches. Bigger pitches work better for high power or voltage uses. They also lower the chance of electrical problems.

Always check pitch details in the connector's datasheet. For instance, JST connectors have different pitches, like 2.0mm or 2.54mm, for various needs. Matching your connector’s pitch with your PCB design ensures a strong and proper connection.

Current and voltage limits

Current and voltage ratings show how much electricity a connector can handle safely. Going over these limits can cause overheating or damage to devices. For example, USB-C connectors support high power, making them great for charging gadgets and moving data quickly.

Choose a connector based on your project’s power needs. High-power projects need connectors with strong current and voltage ratings. For smaller tasks, tiny connectors like JST PH series might be enough. Always pick connectors that handle more than your project’s maximum power to stay safe.

Strength and material quality

Good materials make connectors last longer and work better. Gold-plated contacts stop rusting and keep electricity flowing well. Strong housings, like those in male and female connectors, protect against damage during use.

For tough environments like cars or factories, pick durable connectors. Features like locks in HSD connectors stop accidental unplugging even when there’s movement or shaking. Always check if the connector is built well enough for what you need it to do.

Environmental factors (e.g., temperature, moisture resistance)

The environment affects how well a wire to PCB connector works. Think about things like heat, water, and tough conditions when picking one. These can change the connector's materials and design.

Hot temperatures can damage connectors over time. For example, weak materials might break in hot places like factories or cars. To prevent this, use connectors made of heat-safe plastics or metals for high-heat jobs.

Water is another big problem. Moisture can cause rust that harms the connection. Connectors with gold-plated parts resist rust and keep working well. Sealed connectors or waterproof ones (like IP67) are great for wet areas like outdoors or near water.

Dust and dirt also cause trouble by blocking connections. In places like construction sites, covered connectors stop dirt from getting inside. For instance, male and female connectors often have strong covers to protect them from dust.

By checking environmental needs, your connector will work better in its setting. Always read the datasheet for details on heat limits, water safety, and other features.

Ease of installation and maintenance

Easy setup and care are important for beginners or changing projects. A good connector makes assembly simple and avoids mistakes.

Connectors like plug-in connectors are easy to use without tools. Just match the plug with the socket to connect them quickly. This saves time and reduces errors for fast setups or modular designs.

For systems needing regular care, reusable connectors work best. Terminal blocks, for example, let you tighten screws without harming wires. This makes them great for repairs or updates.

Small connectors like JST connectors fit tight spaces easily. Their tiny size helps in gadgets like drones where space is limited. Bigger ones with locks, such as HSD connectors, stay secure but are still easy to unplug when needed.

Pick a connector that’s simple to install and maintain so your project stays smooth to manage as it grows.

Tips for Picking the Right PCB Board to Wire Connectors for Beginners

Understand your project’s needs

Before picking a connector, think about what your project requires. Decide the type of connection you need. If plugging and unplugging often, use plug-in connectors or molex connectors. For a strong, lasting link, soldered connectors work better.

Check the power needs like current and voltage ratings. High-power projects need stronger connectors, while small tasks can use JST connectors. Also, consider the environment. If there’s moisture or dust, pick sealed or waterproof connectors. Knowing these details helps you choose the best connector for your project.

Start with easy-to-use connectors (e.g., JST or terminal blocks)

If you’re new to this, start with simple options first. JST connectors are small and easy to handle, great for beginners. They’re good for tiny projects like drones or LED lights. Their plug-and-socket design makes them secure without needing special skills.

Another beginner-friendly choice is terminal blocks. These hold wires tightly using screws and are reusable too. They’re perfect for setups with many wires like control panels or machines. Their design allows quick changes when needed.

Using these common connectors helps you focus on learning without extra difficulty.

Plan for growth and compatibility

Think ahead when choosing a connector for your project. Pick ones that allow upgrades later on if needed. For example, board-to-board connectors let you connect multiple PCBs easily as projects grow more complex.

Make sure the connector fits your PCB specs like pin count and pitch size too. Standard types like molex connectors make finding replacements easier in the future.

Planning ahead keeps your project flexible and ready for changes later on.

Use datasheets and manufacturer advice

When picking a PCB board-to-wire connector, use datasheets and advice. These tools give important details to help you choose the right one.

Why are datasheets helpful?

Datasheets explain what a connector can do and its limits. They include:

Electrical ratings: The most current or voltage it can handle.

Pitch size: Space between pins to fit your PCB design.

Material composition: Details like gold-plated parts that stop rusting.

Environmental tolerances: How it handles heat, moisture, or tough conditions.

For example, IDC connectors are easy to install without soldering. But their datasheet might say they don’t work well in shaky places. This helps you decide if they’re good for your project.

Why follow manufacturer suggestions?

Manufacturers make connectors for specific uses. Their tips show where each type works best. For instance:

Terminal blocks are great for factories needing secure wire setups. Makers suggest them for machines or control panels because they’re simple to use.

HSD connectors are perfect for fast data transfer in cars or telecoms. Their special locks stop errors during setup, as makers often highlight.

Using these tips ensures your connectors last longer and work better.

Steps to use these resources

Know your needs: Think about power, size, and environment requirements.

Match specs: Compare project needs with datasheet info like current limits.

Check fit: Make sure the connector matches your PCB’s pin layout.

Follow instructions: Use assembly guides to avoid loose wires or damage.

"Picking the right connector makes systems reliable," say experts.

Taking time with datasheets and advice avoids mistakes later on. It saves effort and keeps projects running smoothly over time.

PCB board-to-wire connectors help make strong connections in electronics. Knowing the different types and their features helps you pick the best one. Whether you need something flexible, tough, or small, learning about these connectors helps your devices work better. Look for more information or ask experts to learn more and choose wisely. Picking the right connector improves how your project works and keeps it reliable for a long time.

FAQ

What do PCB board-to-wire connectors do?

These connectors link PCBs to wires or cables. They are found in gadgets like phones, cars, and machines. They help move power, signals, or data so devices work well.

How can I pick the right connector?

Think about wire size, current needs, and contact numbers. Check the pitch to match your PCB design. If used in tough places, consider heat or moisture resistance. Always read the datasheet for details.

What is pitch and why does it matter?

Pitch is the space between two pins on a connector. It shows if the connector fits your PCB. Small pitches are good for tight spaces; large ones handle more power.

Are there connectors for fast data transfer?

Yes, High-Speed Data (HSD) connectors are made for quick data moves. They keep signals strong and steady. These work well with USB 3.0, Ethernet, and car systems.

Can one connector handle both power and data?

Some connectors like USB connectors can do both tasks. But check their limits for current and voltage first. Using them wrongly can cause overheating or failure.

Why are IDC connectors easy for beginners?

IDC connectors skip wire stripping steps during setup. Sharp parts cut through insulation to connect wires quickly. This saves time and avoids mistakes for new users.

How does the environment affect connectors?

Heat, water, or dust can harm a connector’s performance over time. Gold-plated contacts stop rusting while sealed designs block water or dirt damage.

What’s good about spring-loaded connectors?

Spring-loaded types hold wires tightly using springs for pressure. They stay stable even when moved often or shaken around.

Why does material quality matter in connectors?

Good materials make them last longer and work better too! Gold stops rusting while strong covers protect against damage in harsh conditions.

How can I install a connector properly?

Follow instructions from the maker carefully during setup steps! Align pins right with PCBs before securing screws tightly if needed.

See Also

Understanding Fakra Connectors: Types, Uses, and Fundamentals

Fakra Connectors Explained: Benefits, Uses, and Setup Advice

All You Need to Know About HSD Connectors