Selecting Automotive Wire Connectors Types for PCB Projects

Choosing the right connectors for PCB projects is crucial. It ensures that your project operates effectively and remains safe. Poor connector selections can lead to weak links or project failure. PCB board to wire connectors are essential components of your electronic design, facilitating strong and reliable connections. Making informed choices helps prevent issues and enhances the durability of your product. The right connectors also simplify assembly and boost system reliability.

Key Takeaways

Choosing the right automotive wire connectors is essential for ensuring strong and reliable connections in PCB projects.

Consider the current and voltage ratings of connectors to prevent overheating and system failures; always match them to your project's requirements.

Durability and material quality are crucial; select connectors made from strong materials to withstand harsh conditions and frequent use.

Environmental resistance is key; opt for connectors with appropriate IP ratings to protect against moisture, heat, and vibrations.

Ensure compatibility with your PCB design by selecting connectors that fit well and align properly to avoid weak links.

For high-current applications, use connectors like ring terminals and pin/socket connectors to ensure safe and efficient power distribution.

Regularly check connectors for damage and perform proper installation techniques, such as crimping and soldering, to enhance connection strength.

Types of Automotive Wire Connectors

When doing PCB projects, picking the right connectors is very important. It helps make sure connections are strong and work well. Below is a simple guide about common automotive wire connectors, their features, and uses.

Blade Connectors

Features and Common Uses

Blade connectors have flat blades that fit into slots tightly. They work like plugs fitting into sockets, making them easy to use. These are often found in cars or gadgets needing quick, reliable links.

Their flat shape makes them great for small spaces in vehicles. Blade connectors are used in wiring harnesses, fuse boxes, and systems needing frequent plugging and unplugging.

Advantages and Limitations

Blade connectors have many good points:

Easy to attach or remove without special tools.

Provide steady and secure links.

Small size fits crowded areas easily.

But they might not work well where there’s lots of shaking unless locked firmly. Also, their flat blades can wear out if unplugged too much.

Ring and Spade Terminals

Features and Common Uses

Ring terminals make strong connections that stay tight for a long time. They have a round ring that goes around bolts or posts. After tightening with a nut, the connection stays firm. You can connect several wires using one ring terminal, which is useful for grounding or power systems.

Spade terminals look like forks and are quicker to use since you don’t need to fully remove bolts. These are common in car or factory setups where speed matters.

Advantages and Limitations

Ring and spade terminals offer:

Great strength against loosening.

Work well with high-power needs.

Can connect multiple wires easily.

However, ring terminals take more time because nuts must be removed first. Spade terminals save time but may not hold as tightly in shaky places.

Butt Connectors

Features and Common Uses

Butt connectors are tube-shaped parts joining two wires end-to-end securely. They’re popular in cars or sound systems for smooth wire connections. To use them, put stripped wire ends into each side of the connector then crimp it tight.

These connectors fix broken wires or extend circuits quickly. Their simple design works for both temporary fixes or permanent setups.

Advantages and Limitations

Butt connectors provide:

An easy way to join two wires together.

Fit different wire sizes well.

Keep moisture away when paired with heat-shrink tubing.

Still, they aren’t good if you need to disconnect often. If crimped poorly, the connection might become weak over time.

Pin and Socket Connectors

Features and Common Uses

Pin and socket connectors are useful in many car and electronic projects. They have a pin (male) that fits into a socket (female) to make a strong connection. These connectors work well even when there’s shaking or movement.

You often see pin and socket connectors in PCB projects needing strength and accuracy. They are used in wiring harnesses, control systems, and sensor links. These connectors can carry both power and signals, making them very flexible.

Advantages and Limitations

Pin and socket connectors have many benefits:

Create strong, steady connections.

Easy to put together or take apart.

Work for both small and large currents.

But they need careful alignment when installed. If not lined up right, they may fail or break. Also, frequent plugging in or out can wear them down over time.

High-Speed Data (HSD) Connectors

Features and Common Uses

High-Speed Data (HSD) connectors send fast data in cars and electronics. They are great for things like USBs, Ethernet, or other quick data transfers.

HSD connectors have special features like:

Locks to keep connections tight.

Crimping for extra strength.

Strong cables that handle vibrations well.

These connectors are found in car electronics, infotainment systems, and telecom networks. They’re also used where keeping signal quality is important.

Advantages and Limitations

HSD connectors offer several good points:

Send fast data with little interference.

Built tough for harsh conditions.

Work with USB 1.0 to 3.0, Ethernet, etc.

However, they need gentle handling during setup to avoid damage. Their advanced design can also make them costlier than regular options.

Key Selection Criteria

When picking automotive wire connectors for PCB projects, knowing what to look for helps them work well and last long. Here are the main things to think about.

Current and Voltage Ratings

Why Matching Ratings Matters

Make sure the connector's current and voltage ratings fit your project. If they don’t match, it can cause overheating or even system failure. For example, using a low-current connector in a high-current setup may overheat and damage everything. Always check the manufacturer's details to ensure it works with your design.

Problems from Wrong Ratings

Using a connector with too low voltage capacity can cause sparks or insulation problems. For instance, a 12V connector might fail in a 24V system, damaging both the PCB and connector. Properly rated options like HSD connectors handle specific signals like USB safely and efficiently.

Durability and Material Quality

Withstanding Wear Over Time

Connectors in cars need to survive tough conditions and frequent use. Strong materials help them stay reliable over time. For example, pin header/socket connectors are built to handle repeated plugging without breaking down.

Why Good Materials Matter

In vehicles, connectors face vibrations, heat changes, and chemicals. Picking ones made of strong metals or plastics ensures they last longer. Wire-to-board connectors, such as pin headers, provide secure links perfect for car setups needing durability.

Environmental Resistance

Fighting Moisture, Heat, and Vibration

Car wire connectors must resist water, heat, and shaking. Water causes rust; heat weakens materials; vibration loosens connections. Connectors like HSD connectors are designed to handle these issues with features like strong crimping.

Understanding IP Ratings

IP ratings show how well a connector blocks dust or water. An IP67-rated connector keeps out dust fully and handles short water dips safely. This makes it great for outdoor or engine-area uses. Always pick connectors with suitable IP ratings for your project’s needs.

Compatibility with PCB Design

Ensuring Proper Fit and Alignment

Picking the right connector for your PCB is important. If it doesn’t fit well, it can harm the board or cause weak links. Choose connectors that match your board’s design and layout. For instance, pin header/socket connectors are flexible and work for many setups. They come in different styles like surface mount or right-angle to suit your needs.

Good alignment helps connector pins touch PCB pads securely. Misaligned parts may interrupt signals or stop power flow. Always check the connector's details against your PCB plan to avoid problems. This step ensures strong connections and makes your project more reliable.

Connector Size and Layout Considerations

Connector size matters when designing a PCB. Smaller ones save space, lower costs, and make layouts simpler. For example, HSD connectors are small but powerful, perfect for fast data transfer in tight spots. Their design keeps signals clear with little interference.

Think about where you place connectors on the board too. If they’re too close to other parts, assembly becomes harder. Leave enough room around them for easy handling during setup or repairs. Also, choose the right orientation—right-angle might fit some designs better than straight ones.

Mechanical Considerations

Locking Mechanisms and Reinforced Housings

Connectors need to stay steady in places with lots of movement or shaking. Locks keep them secure so they don’t disconnect by accident. For example, HSD connectors have strong locks that hold even in tough conditions, making them great for cars or factories.

Strong housings protect connectors from damage caused by bumps or weather changes. Look for durable options if using them in rough environments like engines or outdoors.

Importance of Cable Retention Force and Coding Efficiency

Cable retention force means how well a connector holds onto a cable under tension or vibration. Strong retention prevents cables from slipping out easily. HSD connectors are excellent at this, keeping cables firmly attached even when moved around.

Coding efficiency helps ensure correct connections without mistakes during setup. Some connectors like HSD connectors have coded housings to prevent mismatches during assembly. This feature improves safety while making projects more dependable.

By focusing on these mechanical features, you can pick stable and user-friendly connectors that help your project work perfectly.

Application Scenarios

High-Current Applications

Connectors for power distribution tasks

In systems needing high current, connectors are very important. They help safely and efficiently share power. Ring terminals and blade connectors are often used here. Ring terminals give strong, lasting connections, perfect for batteries or grounding wires. Blade connectors are small and easy to use, making them great for fuse boxes.

For higher current needs, pin and socket connectors work well. These handle both power and signals, making them flexible in cars. Their sturdy build keeps the connection strong under heavy electrical loads.

Important tips for high-current setups

Safety is key in high-current systems. Use connectors rated higher than your system's load to avoid overheating or damage. Keep enough space between PCB traces to prevent electrical problems like sparks.

Choose good-quality materials like copper or brass for better conductivity and strength. Strong housings and locks keep connections steady, even with constant shaking or vibrations.

Signal Transmission Applications

Connectors used for data transfer lines

Signal transmission needs special connectors to keep signals clear. High-Speed Data (HSD) connectors are great for fast data transfer in USBs or Ethernet systems. They handle low-voltage signals well, ideal for car cameras or infotainment setups.

Another option is pin and socket connectors, which align precisely to avoid signal loss. For simpler tasks, butt connectors can join signal wires securely without much effort.

How to reduce interference issues

Interference can mess up signals badly. To stop this, pick shielded connectors like HSD ones that block electromagnetic noise (EMI). Installing them correctly also helps maintain clear signals.

Plan your PCB layout wisely by keeping signal lines away from high-power parts. Small-footprint connectors like HSD make it easier to design clean paths while reducing noise risks.

Harsh Environment Applications

Connectors built for tough conditions

Connectors in harsh places must resist water, heat, and shaking well. HSD connectors are strong enough for these jobs with tight cable grips. They’re common in car electronics and outdoor tools.

Ring terminals and spade terminals also work well in rough areas like engines due to their solid build. Waterproof designs using heat-shrink tubing or IP-rated casings add extra protection when needed.

Features that boost durability in tough settings

Durability matters most in extreme environments. Look for reinforced housings with locks that stop accidental disconnections or damage from bumps. Materials resisting rust or heat last longer too.

IP ratings show how much protection a connector offers against dust or water damage. An IP67-rated connector blocks all dust and survives short dips in water—perfect outdoors or near engines where conditions get rough.

Digital Infotainment and Networking Applications

Using HSD connectors for USB, Ethernet, and LVDS

In today’s car electronics, High-Speed Data (HSD) connectors are important. They send data quickly, making them perfect for USB, Ethernet, and LVDS uses. These connectors keep signals clear even with electrical noise around.

HSD connectors work well in USB ports from USB 1.0 to 3.0. They give fast and steady data transfer for multimedia systems or charging devices in cars. For Ethernet, they provide strong links for in-car networks like cameras or sensors. In LVDS setups, such as displays or cameras, they ensure accurate signals with little interference.

Key Insight: PCB traces must match voltage needs to avoid problems like sparks. HSD connectors handle specific voltages safely for smooth operation.

Why high-speed data is useful in car electronics

Fast data speeds have improved how car electronics work and feel. With HSD connectors, parts can communicate faster for things like ADAS, infotainment, or maps.

Here’s why fast data helps car systems:

Better Multimedia: HSD connectors make video and audio stream smoothly.

Improved Navigation: Quick updates help maps stay accurate during trips.

Easy Device Connections: Phones or tablets link easily to the car system.

Less Signal Noise: Shielding stops interference so data stays clear.

Adding HSD connectors to your projects makes systems more reliable and advanced. These connectors meet modern vehicle demands while handling tough conditions effectively.

Tips for Proper Installation

Getting Wires and Connectors Ready

Stripping and Cleaning Wires

Preparing wires correctly makes connections strong and dependable. First, remove the plastic covering from wire ends with a wire stripper. Only expose enough metal to fit inside the connector. Too much bare wire can cause short circuits or accidents.

Next, clean the exposed wire tips. Dirt or grease can weaken the connection. Use a soft cloth or alcohol cleaner to wipe them clean. Clean wires carry electricity better and make stronger connections.

Checking Connectors for Damage

Before using connectors, check them carefully for problems. Look for cracks, bent parts, or rust spots. Broken connectors can cause weak links or system failures. Also, check if locks and covers are working properly.

If you find damage, replace the connector right away. Using broken parts can lead to poor performance or danger. Regular checks keep your project safe and reliable.

Crimping and Soldering Basics

How to Crimp Wires Correctly

Crimping is a simple way to attach wires to connectors. Use a good crimping tool made for your connector type. Place the stripped wire into the connector barrel snugly. Then press firmly with the crimper.

A proper crimp holds tightly without breaking the wire. Test it by gently pulling on the wire; it should stay in place if done right. Crimping is quick, strong, and works well in shaky conditions.

When Soldering Helps Connections Last Longer

Soldering makes connections stronger in tough environments like cars or machines. After crimping, add a little solder to secure the joint further. Let it flow evenly around both parts for better contact.

Don’t use too much solder—it could weaken or block parts of the connector. Let it cool fully before touching it again. Soldered joints last longer and resist coming loose over time.

Testing Your Work

Making Sure Connections Work Right

Testing shows whether your connections are solid and working well. Use a tester or multimeter to check electrical flow through each connection point. A steady signal means everything is fine; breaks mean there’s an issue.

Also look at how wires are attached physically—make sure they’re tight and aligned properly in their connectors so they don’t fail later on.

Using Multimeters for Extra Checks

Multimeters help confirm that all connections are good quality ones! Set yours up depending on what needs checking: resistance (low numbers = good) OR voltage output matches expectations? High-power areas need extra care since failures here hurt more often than others might otherwise do!

Choosing the right wire connectors for your PCB projects is important. They help connect wires and parts, making power and data flow smoothly. Look at things like current rating, strength, and resistance to tough conditions when deciding. Good connectors last longer and work better in harsh environments. Spending more on quality can prevent problems later. Understand what your project needs to pick the best connectors. This way, you can build strong systems that work well for modern cars.

FAQ

What do automotive wire connectors do in PCB projects?

Automotive wire connectors join wires to PCBs for smooth power and data flow. They ensure secure links in car systems like electronics, infotainment, and controls. These connectors also stay reliable in tough places like under the hood or outdoors.

How can I pick the right connector for my project?

Think about a few things when choosing a connector. Check current and voltage ratings to match your system's needs. Look at material quality to make sure it lasts long. Consider resistance to heat or moisture for harsh conditions. Finally, ensure it fits your PCB layout properly.

Why are HSD connectors special?

HSD connectors send fast data with little interference. They have strong locks, crimped connections, and hold cables tightly. These work great in car electronics, USB ports, Ethernet lines, and LVDS setups. Their design keeps them reliable even in rough environments.

Expert Insight: "Our display uses HSD connectors for signals. They handle LVDS well while keeping data clear."

Can I use the same PCB if switching from HSD to another type?

Switching from HSD to something else might need PCB changes. You may have to adjust wiring or add an adapter for compatibility. Always check both connector specs and datasheets before making changes.

Why is matching current and voltage important?

Matching ratings avoids overheating or failure of systems. Using a low-rated connector can cause sparks or damage insulation. Always confirm specs from manufacturers so your project works safely.

How can I protect connectors in tough conditions?

Use reinforced housings and high IP-rated connectors for protection in harsh areas. For example, IP67-rated ones block dust and water well. Add heat-shrink tubing or waterproof covers for extra safety. Connectors like HSD resist vibrations, heat, and moisture effectively.

What tools are needed to install connectors correctly?

You’ll need a wire stripper to remove insulation cleanly and a crimper for tight connections. A multimeter checks circuits, while soldering tools strengthen joints if needed. These tools help create strong connections that last longer.

How do I check if my connections are secure?

Test circuits with a multimeter to find any breaks or issues. Gently tug on wires to see if they’re firmly attached inside the connector. Make sure pins align properly so there’s no weak link causing problems.

Why use smaller-sized connectors?

Smaller connectors save space on PCBs and lower costs too! They make layouts simpler while reducing signal loss during transmission. For example, compact HSD connectors transfer fast data without taking up much room.

Should damaged connectors be reused?

Never reuse broken or rusted connectors as they weaken links over time! Replace damaged parts immediately so your project stays safe and works well always! Regular checks help spot problems early on.

See Also

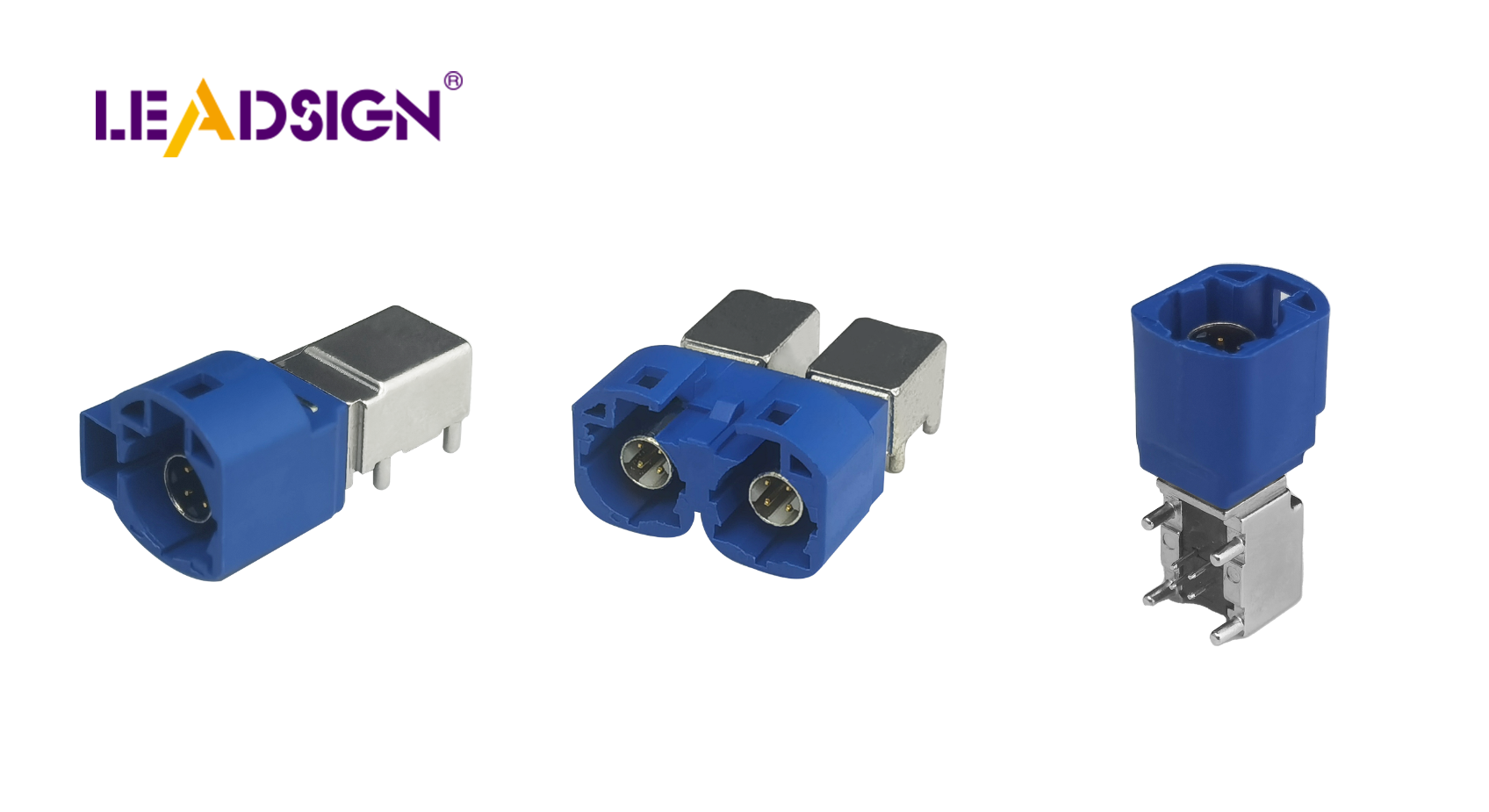

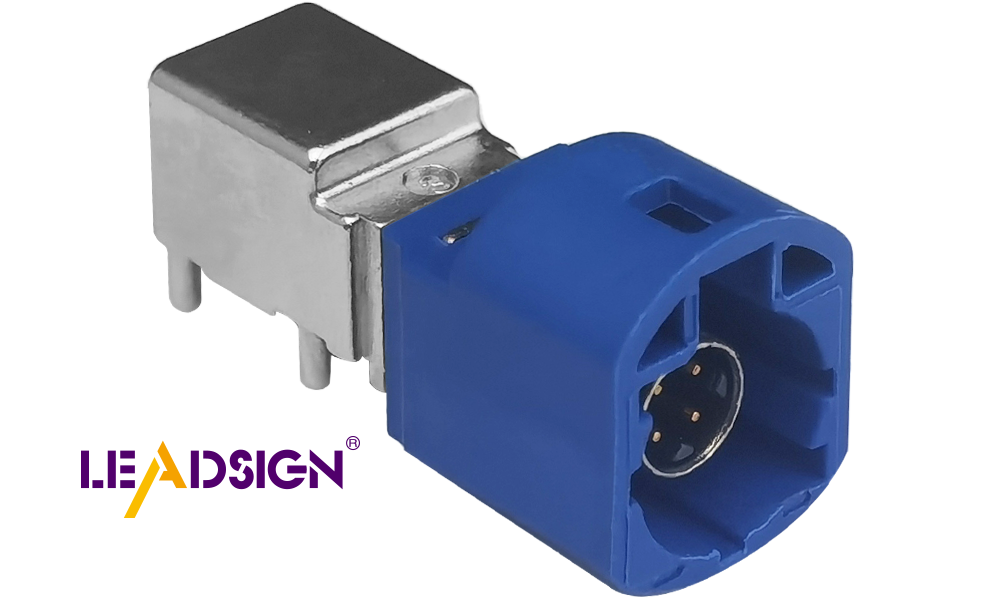

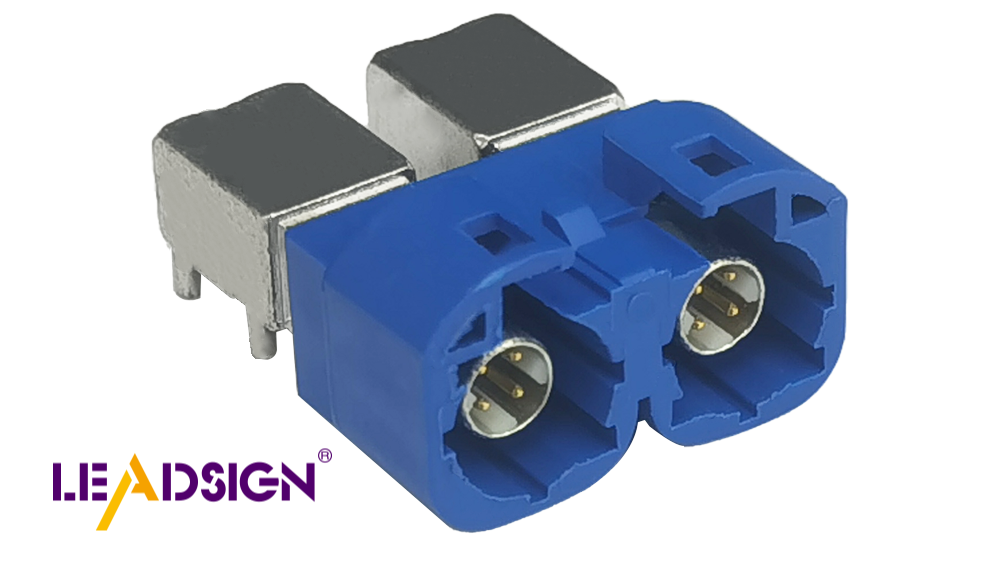

Exploring FAKRA Connectors for Enhanced PCB Automotive Use

Key Benefits of FAKRA Connectors in Automotive Systems

Why FAKRA PCB Connectors Are Essential for Automotive

FAKRA PCB Connectors: Vital for Automotive Communication

Boosting Automotive Communication Through FAKRA PCB Connectors