Why PCB Board Wire Connectors Are Essential for Reliability

PCB board to wire connectors help power, signals, and data move smoothly. They make strong electrical connections needed for devices like laptops and phones. These connectors keep connections safe and steady to avoid problems. They also shield circuits from damage and prevent short circuits. Their job is to make devices last longer and work better. This makes them very important in building electronic systems.

Key Takeaways

PCB board to wire connectors are crucial for ensuring stable and reliable electrical connections in electronic devices, preventing issues like short circuits.

These connectors come in various types, such as pin headers, terminal blocks, and coaxial connectors, each designed for specific applications and environments.

Durability is a key benefit of PCB connectors, as they are made from strong materials that withstand harsh conditions, extending the lifespan of devices.

Ease of maintenance is enhanced by connectors that allow for quick assembly and disassembly, making repairs and upgrades faster and more efficient.

Advancements in connector technology, including smaller sizes and improved safety features, cater to the needs of modern compact devices and enhance user safety.

Industries such as consumer electronics, automotive, industrial automation, and medical devices rely heavily on these connectors for optimal performance and reliability.

Choosing the right type of PCB connector can significantly improve device performance and longevity, making them essential components in electronic systems.

Understanding PCB Board to Wire Connectors

What Are PCB Board to Wire Connectors?

PCB board to wire connectors are key parts of electronics today. They link wires and PCBs, helping power, signals, and data flow easily. These connectors join outside wires with a device’s internal circuits. This connection allows devices to work properly without issues.

There are many types of these connectors for different uses. For example, wire-to-board connectors include crimp-style, insulation-displacement, and solder types. Each type works best for certain tasks or industries. Their wide use makes them important in electronics, cars, and factories.

These connectors are built to last and work well. Many use strong materials that resist heat, rust, and damage. This helps them perform even in tough places like space or military settings. Their strength shows how they keep devices working reliably.

Primary Functions of Circuit Board Wire Connectors

Establishing Stable Electrical Connections

These connectors make sure electrical connections stay steady and safe. They stop power or signals from being interrupted in devices. For example, terminal block connectors connect wires securely without needing soldering. This is helpful in factories where stability is very important.

They also lower the chance of short circuits or failures happening. Using good materials like flame-resistant ones improves safety and trust in them. That’s why they’re used where reliable performance matters most.

Facilitating Communication Between Components

Connectors help different parts of a circuit board talk to each other well. They let signals move smoothly so all parts can work together as one system. For instance, flex PCB connectors are great for bending or twisting designs in devices. They keep communication stable even when the design is complex.

Some have features like EMI shielding to block outside interference with signals. This is very useful for sensitive tools like medical machines or telecom devices.

Enabling Modularity and Ease of Assembly

These connectors make building and fixing electronics easier by design. You can connect or remove parts without needing soldering tools at all times! Repairs become faster this way while saving effort too!

For instance, ruggedized connectors handle rough conditions but still stay strong over time! Their design makes adding them into systems simple yet effective overall! Industries like oil fields value this flexibility greatly!

Lastly compact versions such as miniature wire-to-board connectors save space inside gadgets! Portable tech benefits from smaller sizes fitting tight spaces better!

Types of Wire-to-Board Connectors and Their Uses

Wire-to-board connectors link outside wires to circuit boards. Each type has a special job to ensure devices work well. Let’s look at some common types and how they are used.

Pin Headers and Socket Connectors

Pin headers and socket connectors are very common in electronics. They are used where flexibility and easy assembly are needed. These connectors have pins (male) and sockets (female) that fit together tightly.

Pin headers are great for projects needing frequent setup changes. For example, they’re found in Arduino or Raspberry Pi boards. You can connect or remove parts without harming the board. They also come in different styles like single-row or angled designs.

Socket connectors pair with pin headers for strong connections. Together, they keep devices working even with movement or shaking. This makes them useful in cars and factory machines.

Terminal Blocks

Terminal blocks hold wires firmly using screws or clamps. They work well when connecting many wires to one board.

You’ll see terminal blocks in factories and power systems often. They last long, even under tough conditions like heat or dust. In factories, they make wire repairs faster during upgrades.

A big plus of terminal blocks is handling high power safely. They’re perfect for heavy-duty tasks needing strong connections. Their design also lets you add more wires easily if needed.

Wire-to-Board Connectors

Wire-to-board connectors come in styles like crimp, IDC, or solder types. Each style fits specific needs to make devices run better.

Crimp-style connectors: Wires attach by crimping into the connector housing securely.

Insulation-displacement connectors (IDC): Wires connect without removing insulation, saving time.

Solder connectors: Wires need soldering for permanent use in tough jobs.

These connectors save space while working well in tight gadgets or machines. Their ability to adjust to different uses makes them key for modern electronics everywhere!

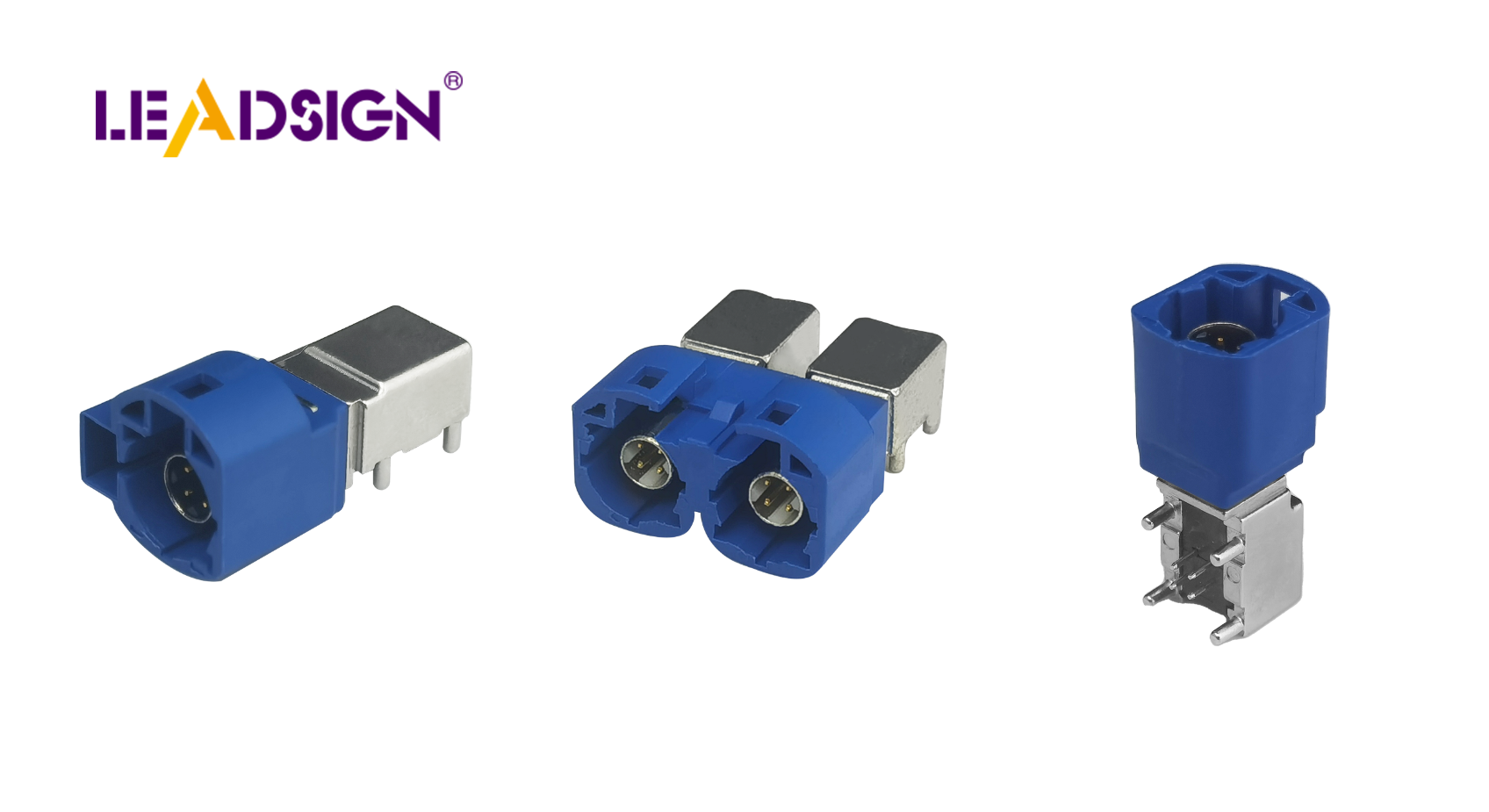

Coaxial Connectors

Coaxial connectors help send high-frequency signals smoothly and clearly. They have a center wire, an insulating layer, and an outer shield. These parts work together to reduce signal loss and interference. You see them in places needing accurate signals like telecoms, broadcasting, or data systems.

A key feature is handling high-frequency signals without losing quality. This makes them perfect for antennas, cable modems, and satellites. Their strong design keeps signals steady even in tough environments like factories or outdoors.

Coaxial connectors are easy to use and assemble quickly. You can attach or remove them fast without special tools. This makes repairs and upgrades simple and saves time. Their small size also fits well into tight spaces in modern devices.

When choosing coaxial connectors, think about frequency range and strength. These features ensure they work for your specific needs. For example, better shielding works well where there’s lots of interference around.

Key Benefits of Circuit Board Wire Connectors

Reliability and Stability

Circuit board wire connectors keep devices working without interruptions. They ensure power and signals flow smoothly, avoiding problems in systems. For example, wire-to-board connectors like crimp-style or IDC types stay secure even with movement. This makes them very useful in cars and factory machines.

These connectors also lower the chance of short circuits or failures. They are made from strong materials that resist heat, rust, and damage. This strength helps devices work well in tough conditions. Whether for home gadgets or medical tools, these connectors improve system performance.

Durability and Longevity

Circuit board wire connectors are made to last a long time. Strong materials help them survive harsh environments easily. For instance, coaxial connectors used in broadcasting keep signals clear even at high frequencies. Their tough design means they don’t need replacing often.

These connectors work well for demanding tasks too. Systems needing fast data transfer rely on them to handle high-frequency signals efficiently. Their durability increases device life while cutting down repair costs, making them a smart choice for long-term use.

Ease of Maintenance and Repair

Circuit board wire connectors make fixing devices simple and quick. You can connect or remove parts without soldering tools needed every time! For example, terminal blocks allow easy wire changes in factories with little delay.

Compact designs like miniature wire-to-board connectors fit into small spaces perfectly. This is great for modern gadgets where space is tight! Snap-on features in MCX coaxial connectors also make assembly faster during repairs.

Picking the right connector improves maintenance speed and keeps devices running longer with fewer issues.

Applications of PCB Board to Wire Connectors in Different Industries

Consumer Electronics

In gadgets, pcb board to wire connectors are very important. They help parts connect so power and signals flow easily. Devices like phones, laptops, and gaming consoles depend on them to work well.

These connectors are small, saving space in slim devices. Miniature wire-to-board connectors fit into tiny gadgets, making them portable. They also make repairs simple by letting you replace parts without harm. Picking the right ones helps devices last longer and perform better.

Automotive Systems

In cars, connectors create strong and safe links between parts. They connect sensors, cameras, and systems to the main board. This keeps your car running smoothly with all parts working together.

High-speed data connectors send information from cameras or USB ports fast. They are tough and handle vibrations or heat easily. These features make cars safer and more efficient for drivers.

Industrial Automation

In factories, pcb connectors keep machines reliable by linking systems together. They let control systems talk to mechanical parts for smooth operations. Their strength makes them perfect for tough factory jobs.

Terminal blocks are common here because they hold many wires securely. This makes setting up or fixing machines easier and faster. Their durability reduces downtime while improving factory productivity overall.

Medical Devices

PCB wire connectors are very important in medical devices. They make sure parts connect well, keeping devices safe and working right. These connectors help machines give accurate results for tests and treatments.

Medical tools need small, strong connectors because of their tight designs. Miniature wire-to-board connectors fit into tiny gadgets like health trackers. Their small size saves space but still keeps connections strong for easy-to-carry devices.

In advanced tools like MRI machines, connectors handle high signals without problems. Coaxial connectors stop signal loss and keep communication clear between parts. This helps imaging systems and robots work better for patients.

Durability is crucial in medical equipment like ventilators or pumps. These connectors must last through heavy use and cleaning with harsh chemicals. Strong materials prevent damage, making them reliable during important procedures.

Easy repairs also make PCB connectors helpful in healthcare settings. Quick-connect designs let workers fix or replace parts fast to avoid delays. Terminal blocks organize wires neatly, making upgrades or fixes quicker too.

Picking the right PCB wire connector makes medical devices last longer and work better. These connectors not only improve device performance but also help keep patients safe and healthcare efficient.

Advancements in Wire-to-Board Connector Technology

Better Materials for Stronger Performance

New wire-to-board connectors use better materials to work well. These materials resist heat, rust, and damage over time. This makes them last longer in tough places like factories or cars. For example, strong plastics and metals make connectors durable and reduce replacements.

These materials also keep electrical connections steady and safe. Flame-resistant and non-conductive parts lower the chance of short circuits. This is very important for devices in healthcare or space systems. With these upgrades, devices can handle hard tasks without problems.

Smaller Sizes for Modern Devices

As gadgets shrink, connectors are getting smaller too. Tiny designs fit into tight spaces but still work great. This helps portable devices like phones, laptops, and smartwatches stay slim and light. Small connectors save room on circuit boards for better designs.

Tiny connectors are also easier to use during repairs or assembly. They fit well into small areas while staying strong and reliable. For example, miniature connectors are perfect for today’s compact electronics where every bit of space matters.

Safer Features for Better Use

Safety is key in new connector designs today. Many now have locks to stop accidental unplugging during movement or shaking. This keeps connections secure in cars or factory machines.

Some connectors block interference from outside signals with special shields. This helps sensitive tools like medical devices work properly without errors. Insulated parts also protect users from electric shocks when handling them.

With these safety upgrades, modern connectors are more dependable and secure to use anywhere—from home gadgets to critical systems at work!

PCB board to wire connectors are very important for devices. They keep power and signals steady, helping devices work better. These connectors last a long time, even in tough places like factories. They make fixing and upgrading devices quicker and easier too. With new technology, these connectors improve to meet modern needs. From gadgets to medical tools, they are key for building strong and reliable systems.

FAQ

What are PCB board to wire connectors used for?

PCB board to wire connectors join wires to circuit boards. They help power, signals, and data move smoothly in devices. You can find them in electronics, cars, and medical tools. Their job is to keep devices working well and reliably.

How do PCB connectors improve device reliability?

PCB connectors make strong and steady electrical connections. They stop power or signals from breaking, preventing problems like short circuits. Many are made from tough materials that resist heat and rust. This helps them last long even in hard conditions.

What types of PCB board to wire connectors are available?

There are different types of these connectors:

Pin headers and socket connectors: Easy to use and flexible.

Terminal blocks: Hold many wires firmly together.

Wire-to-board connectors: Come in crimp, IDC, or solder styles.

Coaxial connectors: Send high-frequency signals clearly.

Each type is made for specific jobs, from small gadgets to big machines.

Why is material selection important for PCB connectors?

The materials used decide how strong the connector will be. Good materials resist heat, rust, and wear over time. For example, flex PCB connectors with heat-resistant parts work better under stress. Picking the right material makes sure they last longer.

How do advancements in connector technology benefit users?

New designs include locks, smaller sizes, and safety upgrades. Locks stop plugs from coming loose by accident. Smaller designs fit into tiny devices easily. Safety features protect people and gadgets from electric shocks or damage.

Can PCB connectors handle high-speed data transmission?

Yes! Some PCB connectors are built for fast data transfer needs. High-speed ones like HSD connectors send data quickly without losing quality. They’re great for cars, USB ports, or digital systems where speed matters most.

How do PCB connectors simplify maintenance and repairs?

PCB connectors let you fix parts without needing soldering tools every time! Terminal blocks make changing wires faster in factories too. This saves time during repairs or when upgrading systems.

Are there connectors suitable for compact devices?

Yes! Miniature wire-to-board ones work well in small gadgets like phones or watches. They save space but still keep connections strong so devices stay reliable.

What industries rely heavily on PCB connectors?

Many industries need these important parts:

Consumer electronics: Phones, laptops, gaming consoles.

Automotive systems: Cameras, sensors.

Industrial automation: Factory machines.

Medical devices: MRI machines or health trackers.

These industries depend on their strength and flexibility daily.

How do safety features in PCB connectors enhance performance?

Safety features like grounding or shielding stop electric shocks or interference issues. Grounding keeps users safe while shielding blocks outside signal problems. These features make them perfect for sensitive tools like medical equipment or telecom systems.

See Also

Why FAKRA PCB Connectors Matter for Vehicle Communication

Exploring FAKRA Connectors' Advantages in Automotive PCB Use

Key Benefits of FAKRA PCB Connectors for Automotive Use

HSD Connectors: Essential Components for Automotive Technology

HSD Connectors: Crucial for Today's Technological Advancements