Why PCB Board to Wire Connectors Matter

PCB board to wire connectors are important in electronics today. They make sure electrical connections work well between parts. These connectors help put wires into PCB designs easily. This process keeps things efficient and simple. They provide strong and stable links, improving device durability. Their flexibility helps designers build systems that can grow or change. This meets the needs of many industries. The global PCB market was worth $81 billion in 2022. These connectors are key for innovation and reliability in technology.

Key Takeaways

Wire-to-board connectors simplify the assembly process, eliminating the need for complex soldering skills and reducing assembly time.

These connectors offer flexibility and modularity, allowing for easy upgrades and replacements without overhauling the entire system.

Their robust design ensures reliable connections even in harsh environments, enhancing the durability and performance of electronic devices.

Using wire-to-board connectors can lead to cost savings by streamlining assembly and reducing the need for skilled labor.

Consider the specific needs of your project, such as space constraints and environmental factors, when selecting the right type of connector.

Wire-to-board connectors are essential for high-speed data applications, ensuring clear and steady signal transmission in modern technology.

Regular maintenance and careful selection of connectors can prevent wear and ensure long-lasting performance in demanding applications.

What Are Wire-to-Board Connectors?

Definition and Functionality

Wire-to-board connectors are key parts of modern electronics. They connect outside wires to a PCB securely. These connectors act like bridges, moving power or data between the PCB and devices like sensors or power supplies. Crimping technology helps make strong connections. This process attaches terminals to wires, which fit into a housing.

There are different types of wire-to-board connectors, each for specific uses:

Pin Headers: Simple and common, used in low-power tasks.

Terminal Blocks: Great for factories, using screws for high-power needs.

IDC Connectors: Easy to assemble, often used with ribbon cables.

These connectors save money while keeping signals clear and reliable.

Role in PCB Designs

Wire-to-board connectors help link PCBs to other parts easily. They connect PCBs to things like screens, motors, or communication tools. Their modular design lets you swap parts without much work. This makes designs flexible and easy to upgrade.

These connectors also make PCBs stronger. They handle stress and tough environments well, keeping connections steady. They manage both power and data transfer, making them useful in cars, gadgets, and factory systems.

"Wire-to-board connectors link outside wiring to PCBs as bridges."

Adding these connectors improves flexibility, strength, and efficiency in your electronic projects.

Pros of Using Wire-to-Board Connectors

Easy to Assemble

Attaching wires to a PCB can be tricky. Wire-to-board connectors make this job much easier. You don’t need hard soldering skills or lots of time. These connectors use crimping, which makes strong and safe wire links.

Without soldering, you don’t need highly trained workers. This saves time and reduces mistakes during assembly. The simple design lets you connect and remove parts quickly. This speeds up the whole process.

Flexible and Modular

Wire-to-board connectors are very flexible and easy to upgrade. You can replace old parts without changing the whole system. This is helpful in fast-changing industries like cars or electronics.

These connectors work for small projects or big ones too. They let you build systems that grow or change over time. This makes them great for projects with changing needs.

Strong and Reliable

Good connections are important in electronics, and these connectors deliver that. They keep electrical links steady even in tough conditions. Unlike soldered joints, they stay strong under stress.

Their solid design prevents loose or bad connections from happening. This is key for things like cars or factory machines where movement happens often. Using these connectors makes your designs last longer and work better, giving you confidence in your system’s performance.

Flexible Design

Wire-to-board connectors are very flexible for many uses. You can change them to fit small gadgets or big systems. They easily fit into designs needing accuracy and speed.

In places with shaking or movement, like cars or factories, they work well. Their strong build keeps connections tight, avoiding breaks or signal problems. This makes them great for projects needing steady performance. Adding these connectors makes your PCB designs tougher and better, even in hard conditions.

Saving Money in Some Uses

Wire-to-board connectors save time and money when building things. Soldering takes skill and effort, but these connectors make it easy. Crimping helps create fast and safe links so you can focus on other tasks. This saves time and lowers costs.

Complicated wiring can cost more and confuse designs. These connectors fix that by making simple links between PCBs and parts outside them. Their design cuts the need for tricky wiring, helping save money on tight budgets. Picking these connectors lets you use resources wisely without losing quality or function.

Cons of Using Wire-to-Board Connectors

Cost Issues

Wire-to-board connectors can cost more than soldering. They need special parts, which raise project costs. Strong and reliable connectors are even pricier. Although they save time during assembly, the upfront cost might not fit all budgets. For tight-budget projects, this could be a problem.

Tip: Think about your project's future needs. Spending more now on good connectors can prevent expensive fixes later.

Space Problems

Wire-to-board connectors use more room on a PCB. Their design includes housings and terminals, taking up space. Small devices like wearables may struggle to fit these connectors. Limited space on a PCB can make designing harder.

To fix this, plan your layout carefully. Use smaller connector types if space is tight. Balancing size and function is very important for compact designs.

Maintenance Issues

Wire-to-board connectors can wear out over time. Frequent use might weaken their parts, causing problems later. In tough places with dust or vibrations, keeping them working is harder. Bad connections in such spots can hurt your system's performance.

To avoid this, pick strong connectors with good locks or grips. Regular checks and care will help them last longer and work better.

When to Use Wire-to-Board Connectors in PCB Designs

When Easy Upgrades Are Needed

Wire-to-board connectors are great for easy upgrades. You can change parts without messing up the whole system. This is helpful in fast-changing industries like electronics and factories. For example, in factories, you can quickly replace old sensors or motors. In gadgets, these connectors let you add new parts to stay updated.

These connectors also help when projects grow bigger. If your design needs more features, you can add them easily. This makes wire-to-board connectors a good choice for flexible and lasting designs.

For Projects Needing Regular Fixes

Wire-to-board connectors make fixing things easier and faster. You can take apart and put back parts without much trouble. This is useful for cars and medical devices where repairs happen often.

In cars, they keep systems like cameras or music players connected well. During repairs, workers can remove and reattach parts safely. In medical tools, these connectors allow regular checks or part changes while staying reliable.

"Wire-to-board connectors make maintenance simple for frequent repair needs."

For Complex Wiring Jobs

Wire-to-board connectors are helpful with tricky wiring setups. They organize many connections neatly and reduce mistakes. This keeps the system working better overall.

Big systems like telecom towers or factory machines benefit from this feature. In telecom towers, they handle many power and data lines while keeping signals clear. In factories, they simplify messy wiring so fixes are easier.

They also work well with special circuit boards (FPCBs). ZIF connectors connect these boards gently without damage. They protect delicate circuits while keeping power and data steady. These features make them perfect for high-tech projects needing accuracy and strength.

High-Speed Data Uses

Fast data tasks need strong and efficient connections. Wire-to-board connectors, like HSD connectors, work well for this. They help send data smoothly between parts, making them very important in modern tech.

Examples include HSD connectors in cars for USB and Ethernet.

HSD connectors are key in car electronics. They handle fast data for USB, Ethernet, and LVDS uses. These connectors link cameras, music systems, and driver-assist tools (ADAS). Their tough design keeps them working even with shaking or heat changes in vehicles.

Crimping technology makes HSD connectors more reliable. This method secures wires to terminals tightly, stopping signal loss. Extra locks also keep the connection steady during use.

Good for digital entertainment and balanced networks.

Digital entertainment systems depend on wire-to-board connectors. HSD connectors connect screens, speakers, and maps easily. They keep signals clear so users enjoy smooth entertainment and accurate directions.

Balanced networks also gain from these connectors. In such setups, even data flow is crucial. HSD connectors ensure steady links for high-speed tasks like FireWire or LVDS.

"Wire-to-board connectors like HSD ones are vital for fast data jobs."

These connectors also make building and fixing easier. Their simple design helps quick setup or part swaps, saving time and money. Adding wire-to-board connectors to your PCB designs boosts speed and reliability for fast data needs.

PCB to wire connectors are important for today's electronics. They make linking outside parts to PCBs easy and reliable. These connectors help send power and data without problems. Their flexible design allows simple upgrades and fixes when needed. They also protect circuits by handling stress in shaky or moving places. Though they can cost more and take up space, their usefulness is worth it. Knowing how to use them helps you build better PCB designs that fit your needs.

FAQ

What are wire-to-board connectors used for?

Wire-to-board connectors join outside wires to PCBs. They act like bridges, moving power or data between the PCB and devices such as sensors or power supplies. These connectors make sure connections stay strong, even in tough conditions.

Expert Insight: "Wire-to-board connectors help link a PCB with external devices like sensors or power supplies."

How do wire-to-board connectors improve PCB designs?

These connectors make assembly easier and designs more flexible. You can quickly connect or remove parts, which helps with upgrades or repairs. Their strong build keeps electrical connections steady, even in hard environments.

What types of wire-to-board connectors are available?

There are many kinds of these connectors for different uses:

Pin Headers: Used for small tasks needing low power.

Terminal Blocks: Best for factories needing high-power links.

IDC Connectors: Great for ribbon cables and quick setups.

HSD Connectors: Made for fast data jobs in cars and tech systems.

Each type fits specific needs in electronic designs.

Why are wire-to-board connectors better than soldering?

These connectors skip soldering, saving time and effort during assembly. They let you replace parts without harming the board. Crimping makes their connections strong and less likely to fail compared to soldered joints.

Can wire-to-board connectors handle high-speed data?

Yes, they can! HSD connectors work well for fast data tasks like USB or Ethernet. They keep signals clear and steady, making them great for car electronics and digital systems.

Example: HSD connectors help cars link cameras with infotainment tools smoothly.

Are wire-to-board connectors suitable for harsh environments?

Yes, they are built tough! These connectors resist shaking, stress, and bad weather. This makes them perfect for industries like car-making or factories where reliability is key.

How do wire-to-board connectors save costs?

They cut costs by making assembly simple. Crimping avoids hiring skilled workers and reduces mistakes when setting up. Their design also simplifies wiring in big projects, saving time and money overall.

What industries benefit most from wire-to-board connectors?

Many industries use these helpful tools:

Automotive: For connecting cameras or music systems.

Telecommunications: In radio towers and network gear.

Consumer Electronics: For gadgets that need easy upgrades.

Factories: To manage power in machines efficiently.

Their wide use shows how important they are across fields!

How do I choose the right wire-to-board connector for my project?

Think about these points before picking one:

What will it be used for—power, data, or both?

Will it face dust, heat changes, or vibrations?

Does it fit your PCB’s space limits?

Do you need fast data transfer? If yes, pick HSD ones.

Choosing carefully ensures your project works well!

Can wire-to-board connectors be used for modular designs?

Yes! These connectors make modular designs easy by letting you swap parts without changing everything else. This flexibility helps industries adapt to new technology quickly while keeping systems scalable over time.

See Also

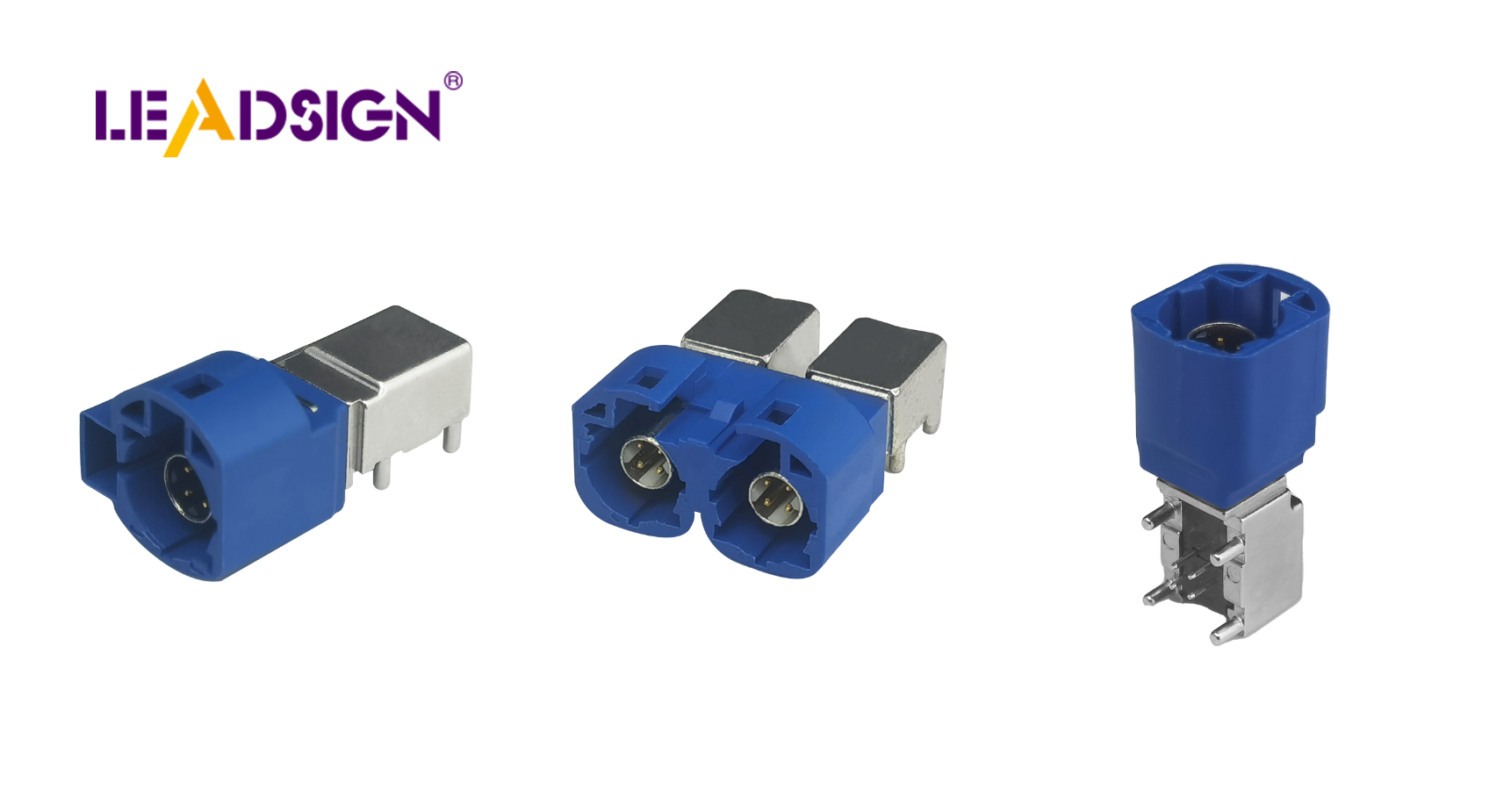

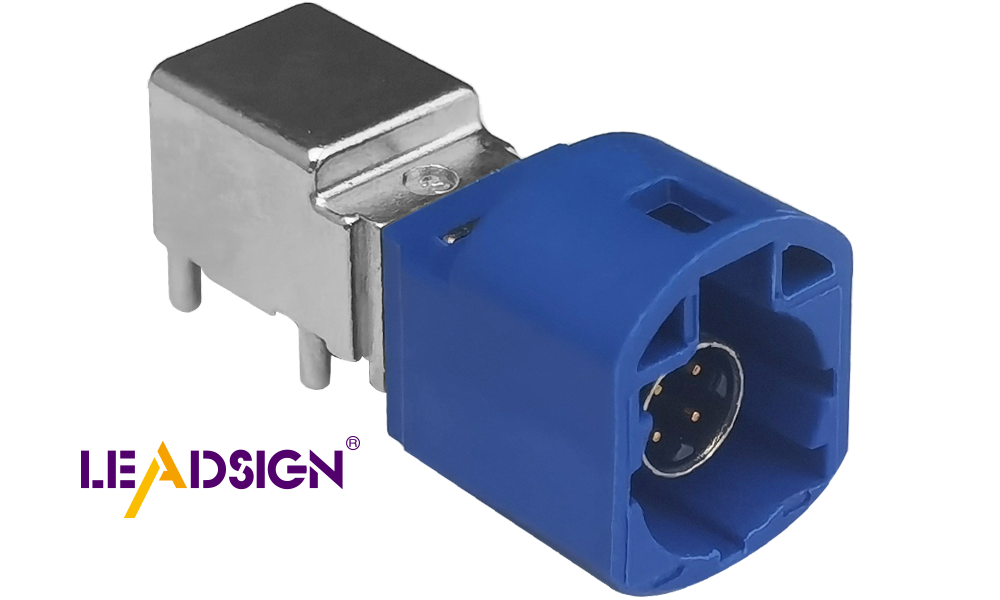

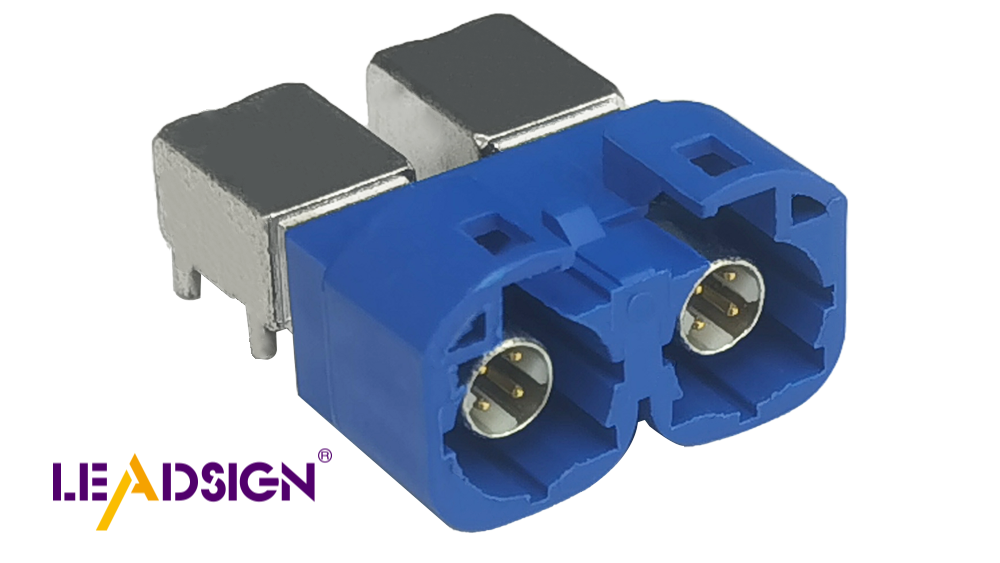

Why FAKRA PCB Connectors Matter for Car Communication

Exploring FAKRA Connectors' Advantages in Automotive PCBs

Key Benefits of FAKRA PCB Connectors for Vehicles

How FAKRA PCB Connectors Enhance Automotive Functionality

FAKRA PCB Mount Connectors: Boosting Automotive and RF Performance