A Guide to Selecting PCB Board Wire Connectors for Beginners

PCB board to wire connectors play a crucial role in modern electronics. They ensure secure and efficient connections between wires and the PCB. These connectors simplify the process of linking components, often reducing the need for extensive soldering. As electronic designs become more advanced, pcb board to wire connectors offer compact and durable solutions. Whether you're working with a PCB cable or a custom assembly, selecting the right connector is essential for enhancing the performance and longevity of your project.

Key Takeaways

Understand the importance of PCB board-to-wire connectors for secure and efficient connections, which simplify setup and repairs.

Choose the right type of connector based on your project's specific needs, such as header connectors for simple setups or IDC connectors for tight spaces.

Always check the current and voltage ratings of connectors to ensure they can handle your project's power requirements safely.

Consider environmental factors like temperature and moisture when selecting connectors to ensure durability and reliability in harsh conditions.

Prioritize ease of assembly and maintenance by opting for solder-free connectors, which are beginner-friendly and reduce the risk of mistakes.

Test connectors with your PCB and cable assembly to confirm proper fit and functionality before finalizing your project.

Start with reputable brands like Molex, JST, and LEADSIGN to ensure quality and performance in your connector choices.

What Are PCB Board-to-Wire Connectors and Why Are They Important?

Definition and Purpose

PCB board-to-wire connectors are important parts of electronics. They connect wires to the PCB securely, allowing electricity to flow well. These connectors replace direct soldering, making setup and repairs simpler. Using them helps improve how devices work and last longer.

Knowing how to choose the right connector is very important. Each type has a job, like sending power or data signals. Their designs fit many PCB layouts, making them easy to use in systems. Whether for simple circuits or complex cables, they make things easier and work better.

Common Applications in Electronics Projects

PCB board-to-wire connectors are used in many industries. Their flexibility makes them useful for cars, telecoms, and digital gadgets.

Automotive Electronics (e.g., HSD Connectors for High-Speed Data Transmission)

In cars, connectors must handle tough conditions like heat or vibrations. HSD connectors are great for fast data transfer in vehicles. They support cameras, USBs, and other systems needing low-voltage signals. Electric cars also use these to move power between batteries and motors. They are strong enough for safety systems like engine controls or entertainment units.

Digital Infotainment Systems

Infotainment systems need connectors for smooth audio, video, or data flow. Compact ones save space while working well. For example, wire-to-board types like JST PH Series give cheap but reliable connections. These are perfect where small size and good performance matter most.

Telecom Industries (e.g., Radio Base Stations)

In telecoms, connectors keep signals clear with less interference. They’re used in radio stations or Ethernet setups often under tough conditions. HSD connectors manage high-speed data streams reliably even under stress or harsh environments.

Types of PCB Board-to-Wire Connectors

Picking the right PCB connector is very important. It ensures your project works well and stays reliable. Different connectors have different uses, so knowing their features helps you decide.

Header Connectors

Header connectors are simple and common in electronics. They have rows of pins that link cables or parts to the PCB. These connectors come in single-row or double-row designs for flexibility.

They are great when you need a small and easy solution. Wire housings often pair with them to keep connections secure. In cable assemblies, they hold wires tightly to the PCB. Their ease of use makes them popular for many projects.

Terminal Blocks

Terminal blocks connect wires directly to the PCB securely. They use screws or springs to hold wires firmly in place. This makes it easy to add or remove wires when needed.

These blocks work well for high-current tasks or frequent wiring changes. They prevent loose wires and keep everything organized on the PCB. Terminal blocks are strong and perfect for industrial or power-heavy projects.

Crimp Connectors

Crimp connectors make strong links by pressing contacts onto wires. This keeps them from disconnecting due to movement or stress.

They are used where reliability matters, like cars or telecom setups. Crimp connectors handle fast data transfer and low-voltage signals well. They fit many cable types, making them useful for various projects.

IDC (Insulation Displacement) Connectors

IDC connectors let you connect wires to PCBs quickly. You don’t need to strip or solder the wires. These connectors cut through wire insulation when pressed in place. This creates a strong and safe electrical link. They are perfect for projects needing speed and ease.

Use IDC connectors with ribbon cables or multi-wire setups. Their small size fits tight PCB spaces easily. This makes them great for crowded designs. They provide steady connections, lowering mistakes during assembly. For beginners, they make wiring simple and reliable, even in tricky projects.

Other Specialized Connectors

Molex Connectors

Molex connectors are flexible and used in many electronics tasks. They connect wires to PCBs while keeping signals clear and stable. These come in single-row or double-row layouts for different needs.

Molex is helpful for power delivery and data transfer jobs. Their tough build works well in hard conditions. Beginners like them because they’re easy to put together for custom projects.

JST Connectors

JST connectors are tiny, light, and fit small devices well. They’re common in gadgets, robots, and hobby projects. These connectors hold wires firmly to PCBs for steady performance.

If your design needs space-saving parts, choose JST connectors. Their simple style is beginner-friendly too! Use them for low-power tasks like sensors or small motors.

HSD Connectors (For Cars and Telecoms)

HSD connectors send fast data in cars or telecom systems. They handle low-voltage signals like USBs or cameras well. Built tough, they survive heat, cold, and stress easily.

Use HSD connectors where quick data transfer matters most. In cars, they help with safety tools or entertainment systems. In telecoms, they keep signals strong even under tough conditions.

Important Features to Look for in a Connector

Picking the right pcb connector is key for good performance. Each feature helps it fit your pcb design and project needs.

Current and Voltage Limits

Check the current and voltage rating of a pcb connector. This ensures it matches your project's power needs. The current rating shows how much electricity it can handle safely. For high-power machines, choose connectors with higher ratings. Voltage limits show the highest voltage it can take without damage.

For small gadgets like battery devices, use compact connectors like JST connectors. They work well for low-power tasks and stay reliable. Always match the connector's power ability with your pcb design to avoid problems.

Pin Spacing and Connector Size

Pin spacing, or pitch size, affects the size of a pcb connector. Smaller pitches are better for tight spaces on pcb designs. For example, IDC connectors are great in small areas since they connect many wires easily.

Connector size also changes how your pcb layout looks. Low-profile ones like the JST KRD Series, at 9 mm tall, fit tiny devices well. They make wiring easier with features like friction locks and daisy chaining. Think about space limits when picking a connector for your board.

Build Material and Strength

The material decides how strong a pcb connector is against wear or weather changes. Good materials help them survive stress, heat, or moisture without failing. In cars or factories, tough conditions need durable connectors.

Connectors like the JST KRD Series use strong materials that last long under pressure. Their special U-slot tech improves connections in hard environments too. Pick sturdy materials to keep your board working longer and better over time.

Environmental Factors (e.g., temperature, moisture, mechanical stress)

The environment affects how well a pcb connector works. Check where your project will be used to pick the right connector. Things like heat, water, and movement can harm your pcb design.

Hot temperatures can weaken materials or make them break. For hot places like cars, use connectors that resist heat. Water can cause rust or short circuits in electronics. If your pcb is in wet areas, choose waterproof connectors with good seals. Vibrations or bumps can loosen connections over time. Strong connectors like IDC connectors or JST KRD Series Wire-to-Board IDC Connectors work best here. They stay secure even when shaken or hit.

By thinking about these conditions, you’ll keep your pcb design working longer and better.

Ease of Assembly and Maintenance

Easy setup and repair are important for choosing a pcb connector. A good connector makes building and fixing simple and quick. Beginners should use solder-free ones like IDC connectors, which need no special tools.

The JST KRD Series Wire-to-Board IDC Connectors are beginner-friendly with features like friction locks and daisy chaining. Their small size fits tight spaces on a pcb design easily. Some have polarized headers to stop wrong connections during assembly.

Pick easy-to-use connectors for your pcb design to save time and avoid mistakes.

Compatibility with PCB Thickness and Design

A connector must match your board’s thickness for it to work well. Different types fit different sizes of boards, so check before buying one.

For instance, the JST KRD Series Wire-to-Board IDC Connectors work with 26 AWG and 28 AWG wires. They also come in through-hole or surface-mount styles for various setups. Their 9 mm height makes them great for small devices needing space-saving parts.

Choosing the right connector ensures it fits securely on your board without issues.

Signal Integrity and Reducing Crosstalk

Signal integrity is important for your pcb to work well. Bad signals can cause data loss, noise, or device failure. To keep signals strong, pick connectors that lower crosstalk and other issues.

Crosstalk happens when one cable's signal affects another, creating noise. This problem is worse in fast data setups or crowded pcb designs. The right connector can help fix this. For example, IDC connectors give steady connections without soldering. Their design keeps performance reliable in tight pcb spaces.

When designing a pcb, think about the connector’s features. Shielding and good pin spacing reduce crosstalk a lot. The JST KRD Series Wire-to-Board IDC Connectors use great insulation displacement technology. Their twin U-slot design makes secure links while keeping signals clear. These connectors also allow daisy chaining for easier complex cable assembly setups.

The type of cable used with the connector also matters. Ribbon cables work well with IDC connectors, cutting interference in multi-wire systems. Their layout reduces electromagnetic problems and keeps signals steady on your pcb.

To improve signal strength more, check the connector’s details. Choose ones with polarized headers or friction locks like in the JST KRD Series. These stop misalignment and keep connections tight, avoiding signal loss.

By focusing on these points, you can protect signal quality and cut crosstalk in your pcb project. This ensures your design works reliably even under tough conditions.

Step-by-Step Guide to Picking the Right Connector

Step 1: Understand Your Project Needs

First, figure out what your project requires. This helps you pick a pcb connector that fits well with your design. Count how many pins you need. Pins are spots where power or signals pass between the pcb and the cable. Simple projects may need fewer pins, but complex ones might need many.

Next, think about the electrical needs. What kind of signals will your project use? It could be power, data, or both. For fast data transfer designs, choose a connector that keeps signals clear and avoids interference. Knowing these details makes choosing easier.

Step 2: Check Electrical and Mechanical Demands

After listing your needs, focus on electrical and physical requirements. Look at current and voltage ratings first. The pcb connector should handle maximum power safely without overheating. High-power projects need connectors with higher ratings for safety.

Think about movement or stress too. If there’s vibration or frequent plugging in and out, pick a durable connector like crimp connectors. They stay strong in tough places like cars or factories. Also, check for heat resistance, moisture protection, or anti-corrosion features if needed for harsh environments.

Step 3: Choose the Best Connector Type

Now match a connector type to your project’s job. Each type works best for certain tasks:

Header Connectors: Good for simple setups needing basic connections.

Terminal Blocks: Great for high-power jobs; easy to manage wires.

Crimp Connectors: Strong under stress; perfect for moving parts or tough conditions.

IDC Connectors: Easy wiring without stripping; ideal for small spaces.

Pick one that suits your project’s specific needs. For fast data transfer tasks, try IDC or HSD connectors to keep signals steady. Choosing the right type ensures your pcb works well and lasts longer.

Step 4: Check the Connector Details

When picking a connector for your pcb, check its details carefully. First, see if it is strong enough to last long. A strong connector can handle wear and tear without breaking. Look for ones that resist rust, heat, and pressure. For example, connectors in cars or factories should survive high heat and shaking.

Next, think about what it's made of. Good materials make the connector work better and last longer. Pick connectors with flameproof and safe materials to avoid fires or shocks. These are important for projects needing lots of power. If you need to connect often, choose connectors with strong locks to keep them secure.

Also, think about where your pcb will be used. If it’s in a tough place, pick connectors that block water, dust, or big temperature changes. Waterproof ones are good for wet areas like kitchens or outdoors. Heatproof connectors work well in hot places like engines. Always match the connector's features to where your design will be used.

Step 5: Test if It Works Well

Testing is the last step when choosing a connector for your pcb. First, make sure it fits your board properly. Check the pin layout and size to see if they match your board’s design. If they don’t fit right, connections might fail.

Next, test how it works with your cable assembly. Make sure it handles the needed power without getting too hot. For fast data setups, check if signals stay clear without interference or noise problems.

Finally, try putting it together with your pcb and cable physically. See if it's easy to attach and remove without trouble while staying secure once connected. Testing helps you know everything works as planned so there won’t be issues later on during use.

Helpful Tips for Beginners

Check Current and Voltage Ratings Carefully

When picking a connector, check its current and voltage limits. These show how much power it can handle safely. Ignoring these can cause overheating or damage to your PCB.

For high-power projects, use connectors made for more current. For small devices like sensors, pick connectors with lower ratings. Always match the connector’s ability to your PCB’s needs. This keeps everything safe and working well.

Make Sure the Connector Fits Your PCB

Before choosing, ensure the connector matches your PCB design. Look at pin layout and spacing first. The pins must align perfectly with the board to work right.

Also, check your PCB’s thickness. Some connectors only fit certain board sizes. Using the wrong one can cause loose connections or stress on the board. For projects with many wires, pick a connector that fits all cables neatly without crowding.

Plan for Easy Repairs Later

Think about future repairs when selecting connectors for your PCB. Choose ones that are easy to use, like solder-free designs or locking types. These make replacing parts simple if needed later.

Durability matters too for long-term use. Pick strong connectors that resist heat, water, or stress from movement. In tough places like outdoors or factories, durable connectors keep your project running longer without problems.

Begin with a Reliable Brand or Supplier

Picking a trustworthy brand or supplier is very important. Good brands make high-quality PCB connectors that work well and last long. Choosing reliable suppliers lowers the chance of problems in your project.

Examples: Molex, JST, LEADSIGN (HSD Connectors)

Molex

Molex is famous for making strong and precise connectors. Their products are flexible and fit many PCB uses. Whether for power or data, Molex ensures clear signals without interference. They also handle tough conditions like heat and pressure.JST

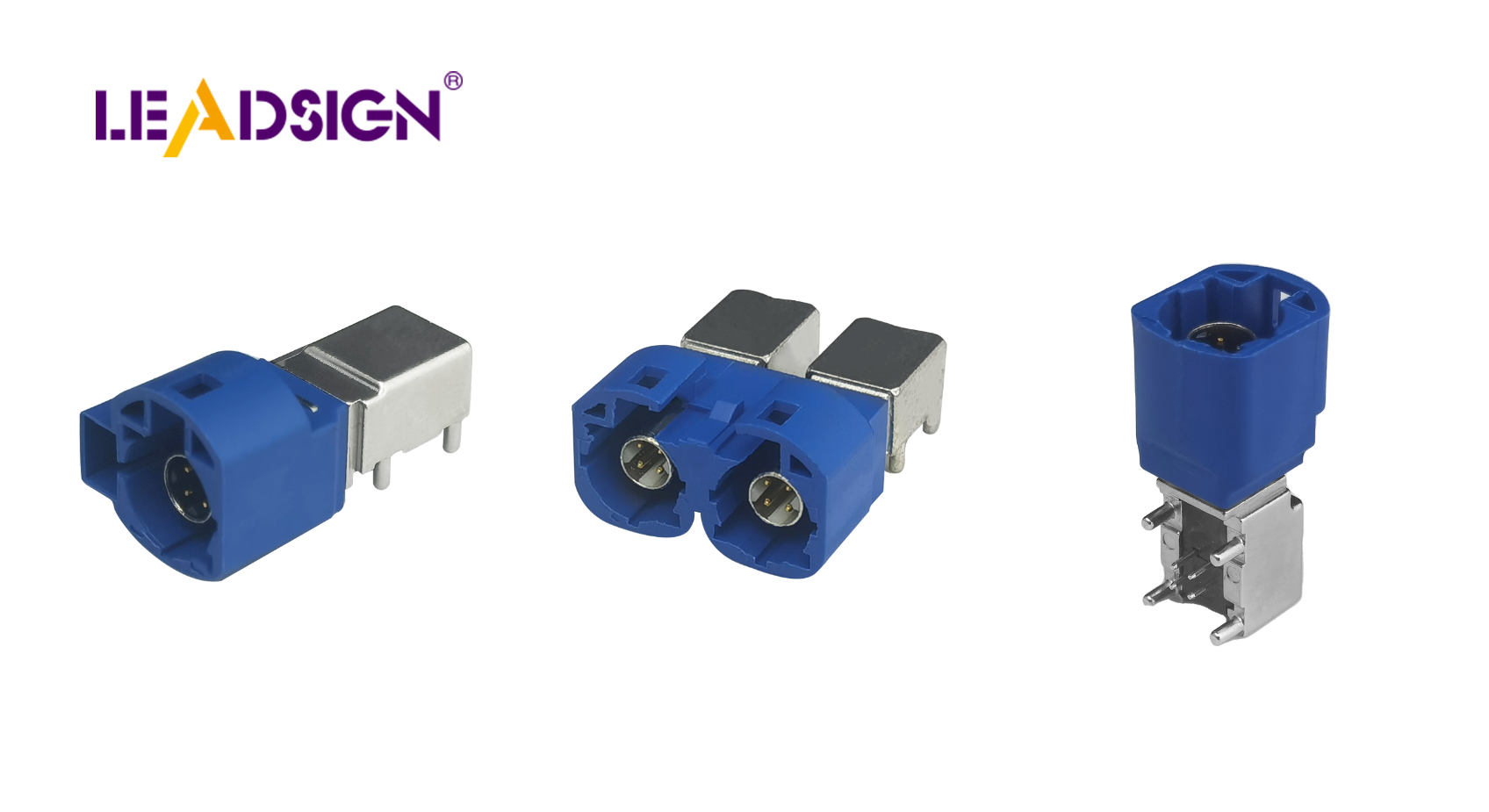

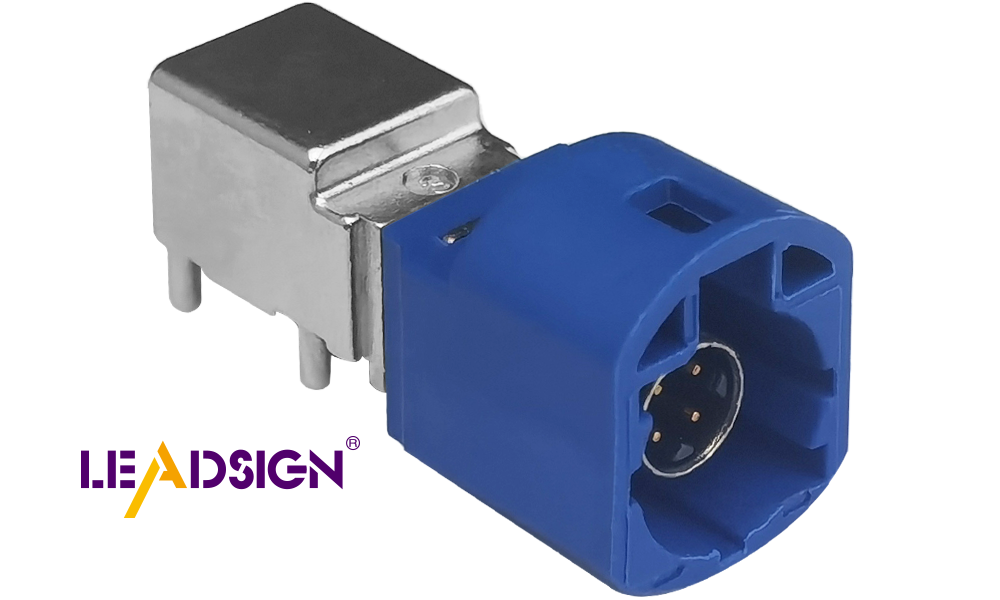

JST connectors are small but very dependable. They work great in tight spaces on small devices like gadgets or robots. These connectors stay secure even in hard situations, making them easy to use for beginners too.LEADSIGN (HSD Connectors)

LEADSIGN focuses on fast data transfer with their HSD connectors. These are used in cars, telecoms, and infotainment systems. Their connectors are strong against stress, heat, and moisture, perfect for harsh environments.

"A good connector can improve your project’s success."

When choosing a supplier, check their reputation and product details carefully. Look for certifications to ensure they meet your needs. Brands like Molex, JST, and LEADSIGN provide helpful support to guide you.

Starting with trusted suppliers gives your project a solid start. Quality connectors boost performance while cutting down on repairs later.

PCB to wire connectors are important for your project’s success. Learn about their types and features to choose wisely. Check what your project needs, like power, environment, and design limits. Picking the right one stops problems like weak signals or noise. For tricky setups, use connectors that are easy to install and fix. Test if they work well with your PCB and cables before using them. With good planning, you can create strong and effective systems.

What do PCB board-to-wire connectors do?

PCB board-to-wire connectors link wires to circuit boards. They replace soldering, making setup and repairs simpler. These connectors help send power or data reliably, improving how devices work and last.

How can I pick the right connector for my project?

First, know your project’s needs. Decide if you need power or data transfer. Check current, voltage, and environment conditions. Crimp connectors are strong for tough places. IDC connectors are quick to use in small spaces. Match the connector to your task for better results.

Why does pin spacing matter when choosing a connector?

Pin spacing shows how much room a connector takes on a board. Small spacing works well for tight designs. Bigger spacing fits boards with more space available. Picking the right size avoids crowding or misalignment.

What should I think about for harsh environments?

In tough places, choose durable connectors that resist heat and water. Waterproof ones work in wet areas, while heatproof ones suit hot spots like car engines. Strong materials keep them working under stress.

How can I keep signals clear in my design?

To avoid signal problems, use connectors that reduce noise and crosstalk. Shielding and good pin spacing help keep signals steady. For fast data tasks like HSD connectors, test them with your board to check performance.

Can one connector handle both power and data?

Some connectors manage both power and data but check their specs first. Make sure they meet your project’s power needs and data speed requirements. For example, HSD connectors are great for fast data but not high-power tasks.

Why does material choice affect connector performance?

The material decides how strong a connector is against wear or weather damage. Good materials stop rust or overheating issues in tough projects like cars or factories.

How can beginners make assembly easier?

Beginners should pick easy-to-use options like IDC connectors that don’t need soldering or wire stripping. Features like locks prevent mistakes during setup.

Why is testing important before using a connector?

Testing checks if the connector fits your board properly and works well under load without issues like overheating or loose connections.

Which brands make reliable PCB connectors?

Brands like Molex, JST, and LEADSIGN offer trusted options for different needs: Molex handles various uses; JST suits small gadgets; LEADSIGN excels at fast-data setups.

See Also

Everything You Need To Know About HSD Connectors

Exploring Fakra Connectors: Benefits, Uses, And Setup Advice

In-Depth Look At Fakra Female Connectors