PCB Board to Wire Connectors What You Need to Know

PCB board to wire connectors are key in modern electronics. They connect wires and circuit boards smoothly and reliably. These connectors help send signals, power, and data accurately. They are very important in cars to improve performance. In gadgets, they make sure devices work properly. These parts make connections easier and lower mistakes during setup. If you design circuits or build devices, knowing them is important. They help create strong and efficient electronic systems.

Key Takeaways

Understanding the different types of PCB board-to-wire connectors, such as screw terminal blocks and IDC connectors, is crucial for effective electronic design.

Choosing the right connector type based on your project's specific needs, like current ratings and environmental conditions, ensures reliable performance.

Mechanical features like locking mechanisms and wire holders enhance the durability and stability of connections, especially in dynamic environments.

Pay attention to pitch size, as it affects the fit and functionality of connectors in your designs; smaller pitches are ideal for compact devices.

Always test connectors in real-world scenarios to confirm their compatibility and longevity before finalizing your design.

Avoid common mistakes, such as overlooking voltage limits or environmental factors, to prevent overheating and connector failure.

Selecting the appropriate connector not only improves device performance but also extends the lifespan of your electronic systems.

Types of PCB Board-to-Wire Connectors

When building electronic systems, knowing connector types is important. Each type has a special use and unique benefits. Below are three common PCB board-to-wire connectors explained simply.

Screw Terminal Block Connectors

Screw terminal block connectors are simple and very reliable. They hold wires tightly with screws for a strong connection. You don’t need special tools to attach wires, so they’re easy to use. This makes them great for quick setups.

Key Features:

Screws hold wires firmly in place.

Easy to handle in tough environments.

Perfect for stable connections.

These connectors are used where many wires need managing. Their design helps assemble them quickly, making them useful in factories and control panels.

Pin Header Connectors

Pin header connectors are basic but very useful in electronics. They have rows of pins that connect straight to the PCB. These come in different sizes, like 1.27mm or 2.54mm, for various needs.

Advantages:

Simple to add to circuit designs.

Available as single-row or double-row pins.

Work well with molex connectors for better links.

Pin headers connect one board to another easily. They work in many devices like home gadgets and factory machines because they’re flexible.

IDC (Insulation Displacement Connectors)

IDC connectors make wiring faster and easier. You don’t need to remove insulation; they cut through it directly to touch the wire inside. This saves time and avoids mistakes during setup.

Why Choose IDC Connectors?:

Fast wire connection without stripping insulation.

Great for tight spaces with lots of wires.

Compatible with molex connectors for smooth use.

IDC connectors are found in small devices where space is tight. They can handle several wires at once, which is helpful in modern electronics.

Wafer Connectors

Wafer connectors are small and work well with many wires. Their thin shape is great for places with little space. They keep connections neat and dependable in tight areas.

Key Features:

Small size fits tight spaces on PCBs.

Connects several wires in one piece.

Ensures strong and safe electrical links.

These connectors are used in gadgets, machines, and cars. Their design lets you put them together fast, making them good for crowded wiring setups.

FPC/FFC (Flexible Printed Circuit/Flexible Flat Cable) Connectors

FPC/FFC connectors are made for bendable circuits and flat cables. They fit perfectly into small devices where regular connectors won’t work. These connectors give light and flexible links without losing quality.

Advantages:

Thin and light for small designs.

Works with flexible circuits and flat cables.

Best for portable items like phones or tablets.

You’ll see these in laptops, cameras, and wearable tech. They handle bendable cables well, helping to make slim and handy devices.

Ejector Header Connectors

Ejector header connectors make unplugging wires from PCBs simple. They have a built-in part that helps remove them easily without harm. This makes them great for things needing frequent wire changes.

Why Choose Ejector Headers?:

Built-in tool makes removal easy.

Protects wires and boards during unplugging.

Good for setups needing regular fixes or updates.

They’re found in servers, factory machines, and test tools. Their design is tough yet easy to use, perfect for tricky systems professionals manage often.

Key Details and Features of PCB Connector Types

Current and Voltage Ratings

It's important to know current and voltage ratings. These show how much electricity a connector can handle safely. For instance, wafer connectors have different sizes like 1.0mm or 2.54mm. These sizes affect how much current they can carry. Picking the right rating avoids overheating or damage.

Tip: Always check your system's needs before choosing a connector. Using the wrong one can cause problems or poor performance.

Pitch (Space Between Pins)

Pitch is the space between pins on a connector. It decides the size and fit with your PCB. Small pitches, like in FPC/FFC connectors, work well in small devices like phones. Bigger pitches, such as 2.54mm or 5.08mm, are better for tough jobs in factories.

Why It Matters:

Small pitches save space on PCBs.

Big pitches are stronger and easier to use.

Matching pitch ensures proper connection.

Think about your device size and space when picking a pitch size.

Strength and Resistance to Damage

Strength and resistance keep connectors working longer. They need to handle stress, temperature changes, water, or dust exposure well. For example, FPC/FFC connectors are flexible for small gadgets but reliable too. On the other hand, wafer connectors are strong for cars or factory machines.

Key Features to Look For:

Good materials that last longer.

Protection from water and dust.

Locks that stop wires from coming loose.

Choosing durable connectors keeps systems working even in tough conditions.

Mechanical Features (e.g., locks, wire holding)

Mechanical features are important for keeping connectors strong and lasting. These features help connectors work well under pressure or tough conditions. When picking a connector, look for things like locks and wire holders to keep connections steady.

Locking Features

Locks stop wires from disconnecting by accident. They keep the connector tightly attached to the PCB, even with shaking or movement. For example, wafer connectors often have locks that hold the pin header and housing together securely. This design lowers the chance of loose wires, which can break signals or power flow.

Why It’s Important:

Stops accidental unplugging.

Keeps steady in shaky places.

Needs less fixing over time.

Locks are very helpful in car electronics and factory machines where steady performance is needed.

Wire Holding

Wire holding means keeping wires firmly in place. A good wire holder stops wires from slipping out when pulled or bent. For instance, FPC/FFC connectors can grip flexible cables while staying secure. This is useful in small gadgets where cables need to bend often.

Main Advantages:

Protects wires from pulling damage.

Keeps connections stable in small devices.

Lasts longer by reducing wear.

When choosing PCB connectors, think about mechanical features that match your project. Whether it’s for strong machines or tiny gadgets, these features help make sure your connections stay safe and work well.

How to Pick the Right Wire-to-PCB Connector

Choosing the right wire-to-PCB connector is very important. It helps build strong and efficient electronic systems. You need to know your project needs, pick the right connector type, and avoid mistakes that can hurt performance.

Understanding Project Needs

First, figure out what your project requires. Think about how much current and voltage the connector must handle. For example, high-power projects need connectors with higher ratings to stop overheating. Check if your system faces tough conditions like heat, water, or dust. If it does, pick connectors that resist damage well.

Tip: Look at pitch size (space between pins). Small pitches save space in small devices. Big pitches are better for stronger setups like factories.

Also, think about mechanical features your project needs. Locks and wire holders are key for systems with shaking or movement. For example, car electronics often use connectors with locks to keep connections steady.

Matching Connectors to Projects

Each connector works best for certain jobs. Picking the right one makes sure everything works well. Here’s a simple guide:

Screw Terminal Block Connectors: Great for factory panels needing stable and easy setups.

Pin Header Connectors: Good for general electronics; they link PCBs easily.

IDC Connectors: Best for small devices with many wires; they save time.

Wafer Connectors: Perfect for cars or factories; they’re small but strong.

FPC/FFC Connectors: Made for tiny gadgets like phones where space is tight.

Ejector Header Connectors: Useful in tools needing wires unplugged often.

Pro Tip: Choose connectors that match data speeds and usage needs. Fast data tasks like USB 3.0 need special high-speed connectors.

Avoiding Common Mistakes

Skipping details when choosing can cause problems later on. One mistake is ignoring current or voltage limits. Using weak connectors can lead to overheating or failure. Another mistake is forgetting environmental factors like moisture or dust that may harm unprotected connectors.

Key Reminder: Make sure the connector prevents wrong connections by design. Misaligned plugs can damage both the PCB and connector.

Lastly, always test before deciding on a connector type. Try it in real situations to check if it fits well and lasts long.

By knowing your project needs, picking matching types, and avoiding errors, you’ll create reliable connections in your electronic systems.

PCB board-to-wire connectors are important for making strong electronics. They make connections easier, lower mistakes, and improve how devices work. Different types like screw terminal blocks and FPC/FFC connectors have special uses. Knowing their differences helps you pick the right one. Always check what your project needs, like power limits and tough conditions. Choosing the correct connector makes your designs last longer and work better.

FAQ

What is a PCB board-to-wire connector?

A PCB board-to-wire connector joins wires to a circuit board. It helps send signals, power, or data between parts. These connectors are important for making strong and efficient electronics.

How do I choose the right PCB board-to-wire connector?

Think about what your project needs. Check things like current limits, voltage ratings, and how tough it must be. For example, locks on connectors help in shaky setups. Picking the right type makes it last longer and work better.

Why is pitch size important in connectors?

Pitch size is the space between pins on a connector. It shows if it fits your circuit board and design. Small pitches save space in tiny gadgets. Big pitches are stronger for factory machines. Always pick the right size for your project.

Can I use any connector for high-speed data transfer?

No, not all connectors handle fast data well. For things like USB 3.0 or Ethernet, you need special ones made for speed. These keep signals clear and make sure everything works smoothly.

What happens if I use the wrong connector?

The wrong connector can cause overheating or system problems. A weak one might fail in high-power jobs. Always choose one that matches your system’s needs to avoid issues.

Are locking mechanisms necessary for all connectors?

Locks aren’t needed everywhere but help in moving systems. They stop wires from unplugging by accident and keep things steady. Cars often use locked connectors to stay secure during movement.

How do I ensure my connector lasts longer?

Pick strong materials that fit your environment’s needs, like heat or water resistance. Clean them often and check for damage to make them last longer.

What is the role of mechanical features in connectors?

Mechanical features like locks stop wires from slipping out accidentally. Wire holders keep cables steady under stress or bending. These are helpful in tough conditions with lots of movement.

Can one connector type fit all applications?

No, each type has its own job. Screw terminal blocks are good for factories, while FPC/FFC ones work best in small devices like phones. Choose based on what your project requires.

What makes board-to-board connectors different?

Board-to-board connectors link two boards directly without wires between them. They save space and work well where tight connections are needed.

See Also

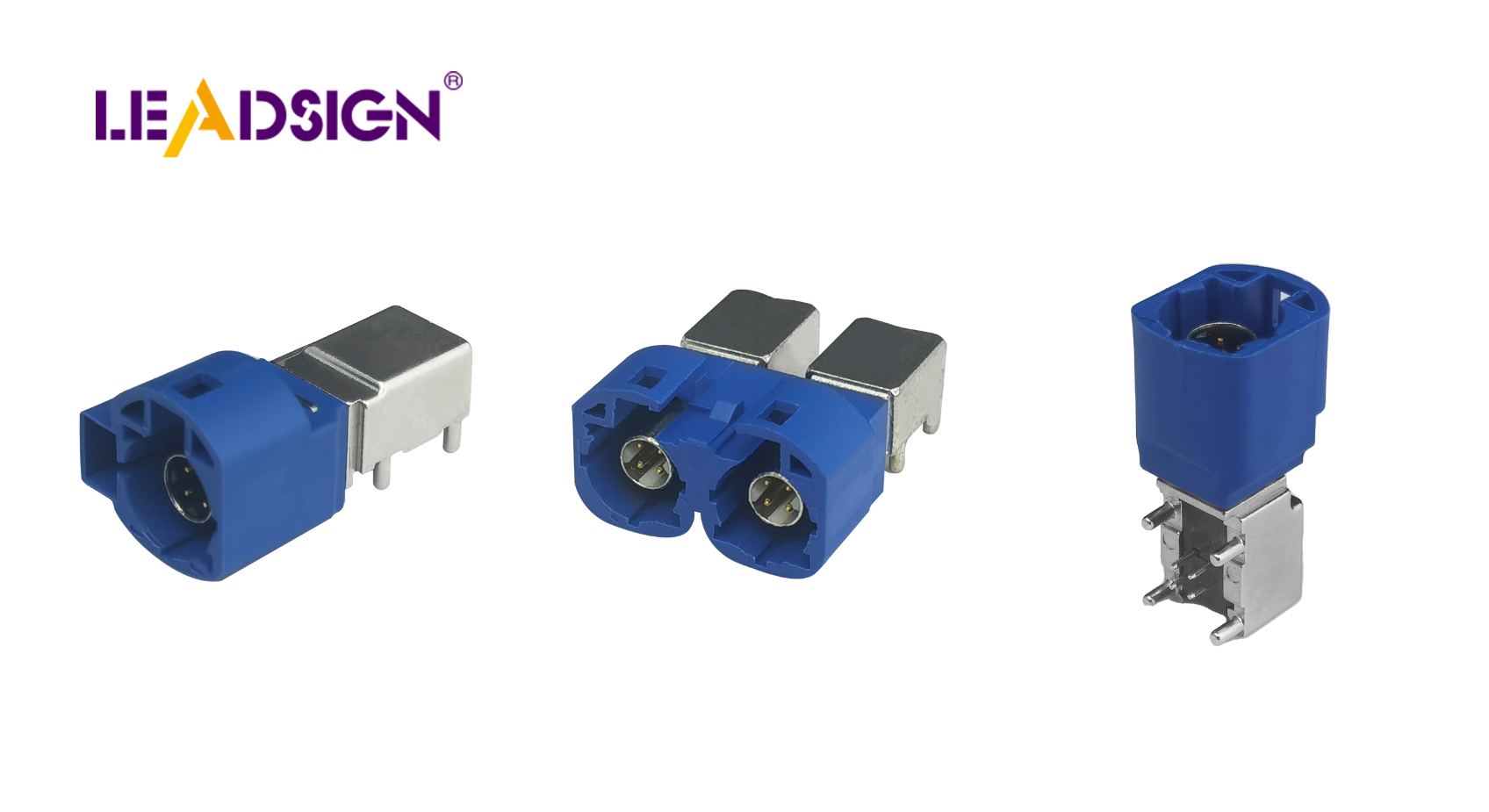

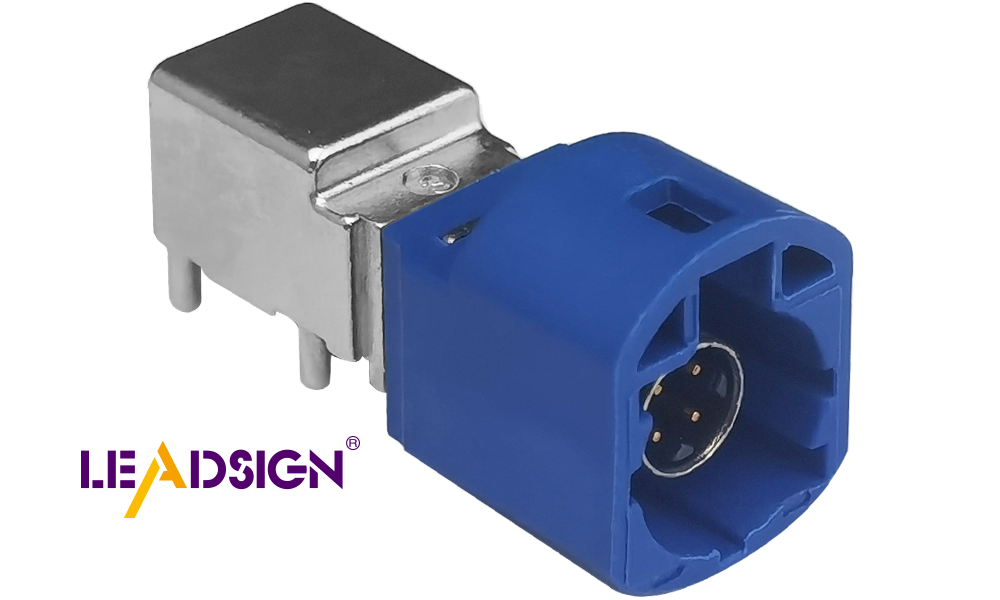

Exploring Fakra Connectors: Benefits, Uses, and Setup Advice

Understanding Fakra Connectors: Fundamentals, Varieties, and Uses

Why FAKRA PCB Connectors Matter for Automotive Communication