5 Key Differences in PCB Board Wire Connectors

Choosing the right connector for your PCB is crucial, as it can significantly impact the performance of your electronic systems. Understanding the difference between board-to-board and pcb board to wire connectors is essential. Board-to-board connectors directly link two PCBs, making them ideal for compact designs. On the other hand, pcb board to wire connectors are used to attach wires to a PCB, facilitating the integration of external components. Each type serves its specific purpose, whether for power or data transmission. By familiarizing yourself with these distinctions, you can select the connector that best meets your requirements.

Key Takeaways

Understand the two main types of connectors: board-to-board connectors link two PCBs directly, while wire-to-board connectors attach wires to a PCB.

Choose board-to-board connectors for compact designs where space is limited, as they facilitate fast data sharing without extra wiring.

Opt for wire-to-board connectors when integrating external components, as they provide secure connections for power and data transmission.

Consider the design features of connectors, such as locking mechanisms and materials, to ensure durability and reliable performance.

Regular maintenance of connectors, including cleaning and checking for damage, can significantly enhance the longevity and efficiency of your electronic systems.

Selecting the right connector early in the design process can prevent performance issues and save costs in the long run.

Evaluate your project's specific needs, including strength, signal quality, and ease of installation, to make an informed connector choice.

Functional Purpose of PCB Board to Wire Connectors

Connectors are important for building and fixing electronics. Each connector type has a special job to help devices work smoothly.

Board-to-Board Connectors

Board-to-board connectors join two PCBs directly. They allow fast data sharing between boards without extra wires. Their small size is great for tight spaces, like in phones or cars.

These connectors come in different shapes, such as straight or U-shaped. Some have features like press-fit designs that don’t need soldering. Others are sealed to handle tough conditions. Locking parts stop them from disconnecting by accident.

Using board-to-board connectors gives strong links and fast data transfer in small gadgets. Their flexibility makes them popular for precise and efficient uses.

Wire-to-Board Connectors

Wire-to-board connectors connect wires or cables to a PCB. They’re used for power, sensors, and data connections. These connectors stay secure with locks or latches.

They come in types like crimp connectors or terminal blocks. Crimp ones hold wires tightly, while terminal blocks let you adjust easily without soldering. This makes them useful for machines needing regular fixes or upgrades.

Wire-to-board connectors can be installed using press-fit methods or soldering parts together. Adding these connectors improves how well your electronics work and last longer.

Structural Design of Board-to-Board and Wire-to-Board Connectors

The design of connectors decides how they work and fit. Knowing their features helps you pick the right one for your PCB.

Board-to-Board Connectors

These connectors link two PCBs directly. They have pins or contacts arranged neatly. Types include stacking, mezzanine, or edge-mount designs. Each type is made for specific needs like saving space or strong connections.

Their small size fits tight spaces like phones or car electronics. Many have locks to stop them from disconnecting by mistake. Some advanced ones use press-fit technology, so no soldering is needed.

Strong materials make these connectors last long and work well. Gold-plated contacts help with better conductivity and prevent rusting. Picking the right connector ensures good communication between PCBs in a compact design.

Wire-to-Board Connectors

Wire-to-board connectors join wires or cables to a PCB. They usually have a housing, terminals, and locks for secure connections.

Crimp connectors are common and hold wires tightly for strong links. Terminal blocks let you connect wires without soldering, making repairs easier. This is helpful when frequent changes are needed.

Their small size fits tight spaces but still works efficiently. Many models include extra locks to keep them stable. Using these connectors makes adding external parts to your PCB simple and reliable.

Electrical Performance in PCB Board to Wire Connectors

Electrical performance is key when picking connectors for your PCB. It affects how well power and data move, keeping your electronics reliable.

Board-to-Board Connectors

Board-to-board connectors send data fast and transfer power strongly. They work well in industries like medical tools, smart homes, and factories. Their small size reduces signal loss and keeps connections steady.

Gold-plated contacts improve conductivity and stop rusting over time. The pin layout helps smooth data flow, even at high speeds. These features make them great for devices needing exact communication.

Wire-to-Board Connectors

Wire-to-board connectors link cables to PCBs securely with locks. They handle both power and data, making them useful in many areas.

Crimp technology ensures tight electrical connections with low resistance. This boosts performance while staying easy to install or remove during repairs. These connectors are perfect for systems needing regular updates or fixes.

Picking the right connector improves your PCB’s performance, keeping it efficient and dependable.

Installing and Taking Care of Wire-to-Board Connectors

Installing connectors the right way makes electronics last longer. Knowing what each connector needs helps them work their best.

Board-to-Board Connectors

Putting in board-to-board connectors needs careful work. These connectors have pins that must match up perfectly between two PCBs. If they don’t line up, power or data may not flow well. Many of these connectors have locks like clips to keep them tight. Locks stop them from coming loose if the device shakes or moves.

Taking care of these connectors means checking for damage often. Dust can build up and block electricity flow. Use a soft brush or air to clean them for better performance. Some advanced types let you replace parts without soldering, making fixes easier.

Wire-to-Board Connectors

Wire-to-board connectors make it easy to connect wires to PCBs. They often come with locks like latches to hold wires firmly in place. When installing, use tools like crimpers or soldering irons to secure wires tightly. Crimp connectors grip wires well, so they stay connected safely. Terminal blocks don’t need soldering and let you change wires quickly.

To take care of these connectors, check for loose wires or broken insulation regularly. Tighten screws on terminal blocks if needed for a strong connection. Clean the parts to avoid rust that could harm performance later on. Doing this keeps your wire-to-board connectors working well and lasting longer.

Where and How Connectors Are Used

Knowing how connectors are used helps you choose wisely. Each type has a special job to make devices work well.

Board-to-Board Connectors

These connectors link two PCBs directly for small, powerful devices. They are great for fast data sharing and steady power flow. You’ll see them in cars, medical tools, and gadgets at home.

In cars, they connect control systems smoothly in tight spaces like dashboards. In medical machines, they send accurate data for tools like monitors or scanners.

Developers like these connectors because they’re flexible and strong. They come in different shapes to fit various needs. Their durability makes them perfect for advanced tech that needs quick signals.

Wire-to-Board Connectors

Wire-to-board connectors join wires to PCBs easily. They’re common in phones, factory machines, and home electronics.

In telecom setups, they connect cables to stations for stable signals. Machines use them for power or sensors without coming loose from shaking.

These connectors are easy to fix or change when needed. Crimp ones install quickly, while terminal blocks let you adjust wires without soldering. This makes them useful for systems needing regular updates or repairs.

Experts say choosing the right connector early is smart planning. Picking the best one helps your device last longer and work better over time.

Knowing the five main differences in connectors helps you choose better. Board-to-board connectors are great for small spaces. Wire-to-board connectors work well with external parts. Pick the right one by thinking about your project’s needs. Look at things like strength, durability, and signal quality. Also, think about design, how easy it is to install, and cost. Planning early makes sure everything fits and works well later. Choosing the correct connector improves how your electronics work and last longer.

FAQ

What are PCB connectors and why are they important in PCB design?

PCB connectors link parts in electronic devices. They make sure electricity flows between modules, external gadgets, or other PCBs. These connectors make it easy to put together, fix, or replace parts. Without them, making and fixing electronics would be much harder.

Why is selecting the right PCB connector critical for electronic devices?

Picking the right PCB connector helps your device work well. The type you need depends on size, power use, and where it will be used. A wrong choice might cause bad performance or even break your device.

How do PCB connectors contribute to the efficient operation of electronic devices?

PCB connectors keep connections strong and steady for smooth working. They help parts talk to each other so the device works properly. They also allow small designs by linking different pieces neatly.

What role do PCB connectors play in ensuring optimal functionality?

PCB connectors help parts work together as one system. This makes your device run better and perform its tasks smoothly. They are very important for high-performing electronics.

What key features should you consider when selecting PCB connectors?

When choosing a connector, think about how strong it is and how well it works with electricity. Check if it fits your device’s needs like handling heat or carrying enough power. A good choice keeps your device running longer.

Why must PCB connectors meet the design needs of your device?

The connector must match your device’s design to work right. If not, it could cause weak links or trouble during setup. Picking a matching connector makes building easier and improves performance.

What is the significance of PCB connectors in various applications?

PCB connectors are used in many fields like cars, phones, and factories. They adjust to different jobs easily because they’re flexible and reliable. This makes them key tools in modern technology.

How do PCB connectors simplify maintenance and repairs?

PCB connectors let you remove or attach parts without breaking anything else. This saves time when fixing things or replacing wires using tools like crimpers or blocks.

Why are PCB connectors crucial for modern electronic systems?

In today’s tech world, these connectors join parts securely so devices work well. From phones to medical machines, they ensure everything runs smoothly without problems.

What happens if you choose the wrong PCB connector?

A wrong connector can lead to weak links or broken devices. It might also make fixing harder later on. Choosing correctly from the start avoids issues and saves money over time.

See Also

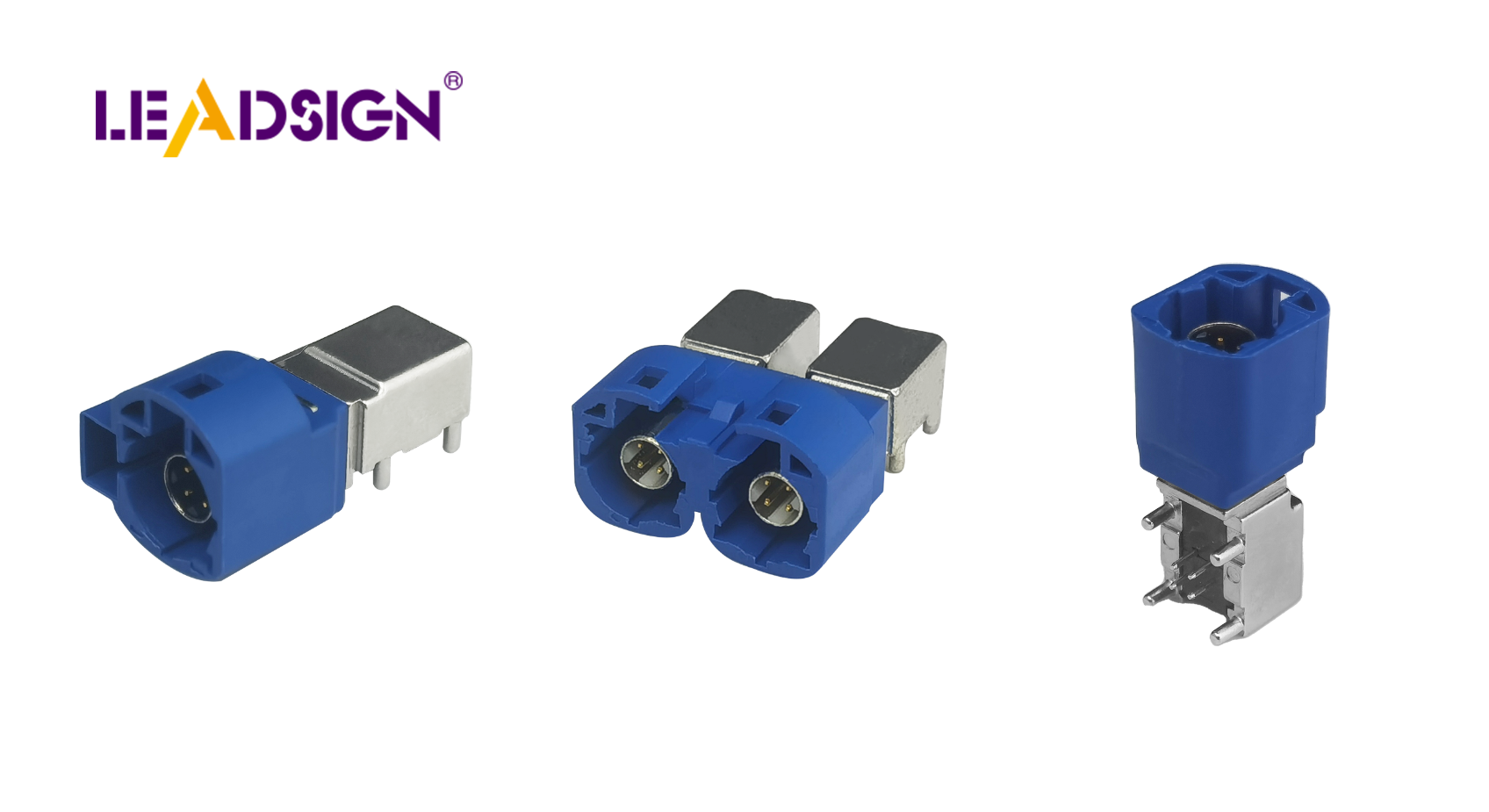

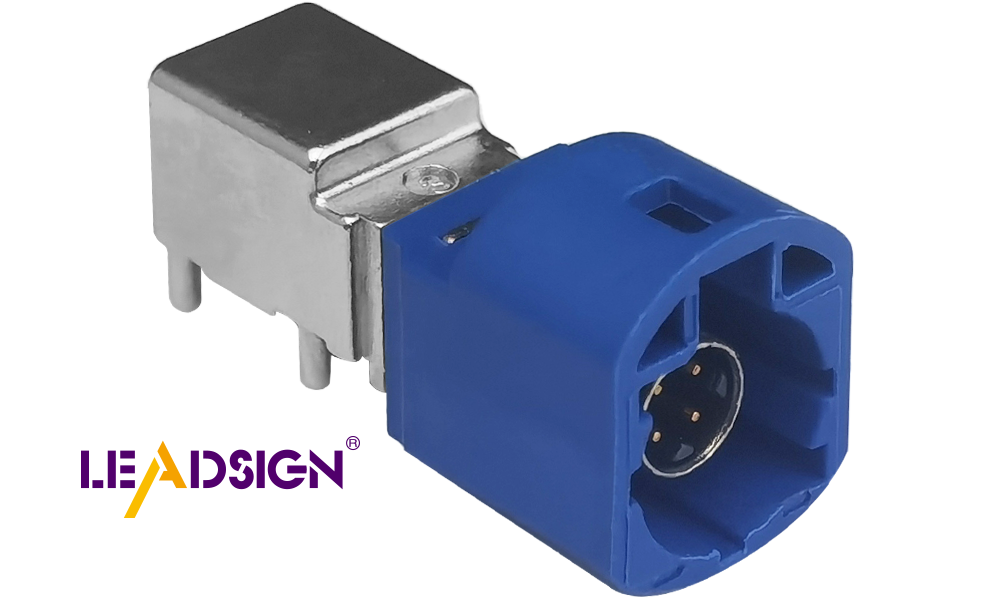

Exploring FAKRA Connectors for Automotive PCB Solutions

Why FAKRA PCB Connectors Are Essential for Automotive Use

Key Benefits of FAKRA PCB Mount Connectors in Automotive and RF

Utilizing FAKRA PCB Connectors for Enhanced Automotive Performance

Significance of FAKRA PCB Connectors in Automotive Communication