Are All PCB Board Wire Connectors the Same?

PCB board to wire connectors are essential in electronic systems. However, not all connectors are the same. Each type has a specific use and differs in quality. They also vary in performance and price. For example, USB connectors are great for data transfer and power. High-speed connectors work well for tasks needing fast data, like 5G. They are also used in car entertainment systems. Choosing the right connector means understanding what you need. Factors like strength, signal quality, and fit are crucial for your device to function effectively.

Key Takeaways

Understand the different types of PCB connectors, such as pin headers, terminal blocks, and wire-to-board connectors, to choose the right one for your project.

Consider material strength and durability when selecting connectors; metal connectors are stronger, while heat-resistant plastics are ideal for high-temperature environments.

Always check the current and voltage limits of connectors to prevent overheating and ensure safe operation in your electronic devices.

Choose connectors that fit your PCB design perfectly, paying attention to size, pin configuration, and mounting options to avoid compatibility issues.

Use high-quality crimp tools for secure connections; proper crimping is essential to prevent loose wires and ensure reliable performance.

For tough environments, opt for connectors with waterproof seals and rust-proof coatings to enhance longevity and reliability.

Balance cost and performance by selecting premium connectors for high-power or fast data needs, while affordable options can suffice for simpler projects.

What Are PCB Board Wire Connectors?

PCB board to wire connectors help connect parts of a circuit. They link things like sensors or power supplies to the PCB. These connectors make sure devices work well by carrying power and data.

Definition and Purpose

These connectors join wires or cables to a PCB. They act as bridges between the outside world and the circuit inside. They let different parts of a system talk to each other. For example, they connect power sources, sensors, or gadgets to your PCB. Their job is to keep connections strong and safe from damage.

Common Applications in Electronics

You can find these connectors in many electronics:

Power Supply Connections: They bring electricity from an external source into the PCB.

Data Transmission: USB connectors move data quickly between devices.

Sensor Interfaces: Sensors use them to send information for processing.

Consumer Electronics: Phones and gaming systems need these connectors.

Automotive Systems: Cars use high-speed ones for entertainment and safety systems.

Types of PCB Board Wire Connectors

There are different types of these connectors for various uses.

Pin Headers

Pin headers have rows of metal pins. They're used in simple projects or low-power tasks. You can solder them onto a board or pair them with female plugs.

Terminal Blocks

Terminal blocks securely attach wires to a board. They're good for high-power tasks. Screws hold the wires tightly, making strong connections.

Wire-to-Board Connectors

These connect wires directly to a board. They're used for power sources or gadgets like audio jacks. Brands like amphenol make many types that handle different needs.

Wire-to-Wire Connectors

These join two wires without using a board. They're helpful when extending wiring or needing removable links. Amphenol makes strong options for cars and factories.

Key Things to Think About When Picking a Connector

When choosing a connector for your PCB, consider important factors. These help ensure the connector works well and fits your needs.

Material Strength and Durability

The material of a connector affects how long it lasts. Strong materials like metals or heat-proof plastics last longer. Plastic connectors are light and cheap, while metal ones are stronger. If you connect and disconnect often, pick durable connectors. This keeps them working even with heavy use.

Some connectors resist heat, water, or rust better than others. These types work well in tough places like cars or factories. Always choose connectors with strong outer parts to avoid breaking early.

Current and Voltage Limits

Connectors have limits on how much power they can handle safely. Going over these limits can cause overheating or damage. For high-power needs, pick connectors with higher ratings to stay safe.

If using crimp connectors, make sure they’re attached properly. Use good crimp tools for tight connections that don’t loosen easily. A proper tool is key for safe use in high-power situations.

Size and Shape

The size of a connector matters for fitting into your PCB design. Small ones work best for tiny devices like phones or smartwatches. Bigger ones may be needed for more pins or power.

Check your PCB layout before picking a connector size. Make sure it fits without blocking other parts on the board. Crimp connectors come in different sizes to match wires and layouts well. Using the right tool ensures they fit tightly and work properly.

Easy to Use and Install

Picking a connector that’s easy to use is important. A good connector makes assembly simple and reduces mistakes. For example, connectors with labels or color codes help you install them correctly. This is helpful when working with tricky circuits or small spaces.

Crimping helps make strong connections between wires and connectors. To crimp well, you need good tools and accuracy. High-quality crimp tools apply the right pressure to keep wires secure. Bad crimping can cause loose wires, signal problems, or even safety risks. Always pick a tool that matches your connector for the best results.

Some connectors have snap-fit or push-lock features for quick installation. These are great for projects needing frequent assembly and disassembly. Connectors made for many uses stay strong even after being used repeatedly.

Fits Your PCB Design

The connector must fit your PCB design perfectly to work well. It should match the board layout without blocking other parts. Check details like pin setup, spacing, and how it mounts before buying.

Small devices like phones need tiny connectors that save space but still work well. High-density connectors are great because they handle lots of data in small areas. Bigger boards might need stronger connectors for more power or data transfer.

Crimp connectors work with many designs but must be done properly to fit right. Using the correct crimp tool ensures everything lines up without damage. Test the connection first to avoid fixing costly mistakes later.

Handles Tough Conditions (like heat or water)

Connectors used in tough places must resist things like heat and water. Picking the right material makes them last longer in these conditions. Plastic is cheap and light, while metal is strong and durable.

For hot areas, use heat-resistant materials like special plastics or ceramics. If moisture is an issue, pick waterproof connectors with seals for protection outdoors or in cars.

Rust-proof connectors are best for wet or salty environments since they don’t corrode easily over time. Long-lasting ones often have coatings to stop wear and tear too.

Good crimping also helps protect against tough conditions by sealing gaps where dirt or water could sneak in. Using high-quality tools keeps connections tight so they stay reliable even in harsh places.

Comparing Popular Brands and Their Models

Choosing the right PCB connectors means knowing what brands offer. Below are some well-known brands and their features.

Molex

Strengths and Weaknesses

Molex is a famous name in making connectors. Their products are strong and work in tough conditions. They have many types, like wire-to-wire or high-speed ones.

Molex connectors are easy to upgrade or fix. They follow rules that make them last longer and fit with other parts.

But Molex can cost more than other brands. This might not be good for cheap projects. Still, their quality is worth it for important uses.

Popular Models and Uses

Molex has different models for various jobs:

Mini-Fit Jr.: Great for power, handling up to 9.0A per circuit.

Micro-Fit 3.0: Small size works well in tight spaces.

Mega-Fit: Handles high power, up to 23.0A per circuit.

You’ll see Molex in cars, phones, and electronics. For example, their wire-to-wire connectors help cars run safely even in bad weather.

JST

Strengths and Weaknesses

JST connectors are small and light, perfect for tiny gadgets. They’re easy to use, which helps avoid mistakes during setup.

JST’s simple design makes swapping parts fast in electronics.

One downside is they carry less power than some others. This makes them less useful for big power needs.

Popular Models and Uses

JST has popular models like:

PH Series: Used often in small battery setups.

XH Series: Works well in everyday electronics.

SH Series: Fits into very tight spaces easily.

You’ll find JST connectors in drones, RC toys, or wearables because they’re compact and light.

TE Connectivity

Strengths and Weaknesses

TE Connectivity focuses on making reliable products that last long. Their materials resist heat, water, or rust—great for tough places.

TE follows rules that ensure their products work with many systems.

However, installing TE connectors can be harder than simpler ones. You might need special tools or training to set them up right.

Popular Models and Uses

TE offers many options:

AMP-LATCH Connectors: Good for ribbon cables.

Dynamic Series: Perfect for factory machines.

MTA-100/MTA-156: Best for connecting wires directly to boards.

TE connectors are used in factories, cars, or planes where strength matters most. For instance, their wire-to-wire types help keep machines running smoothly over time.

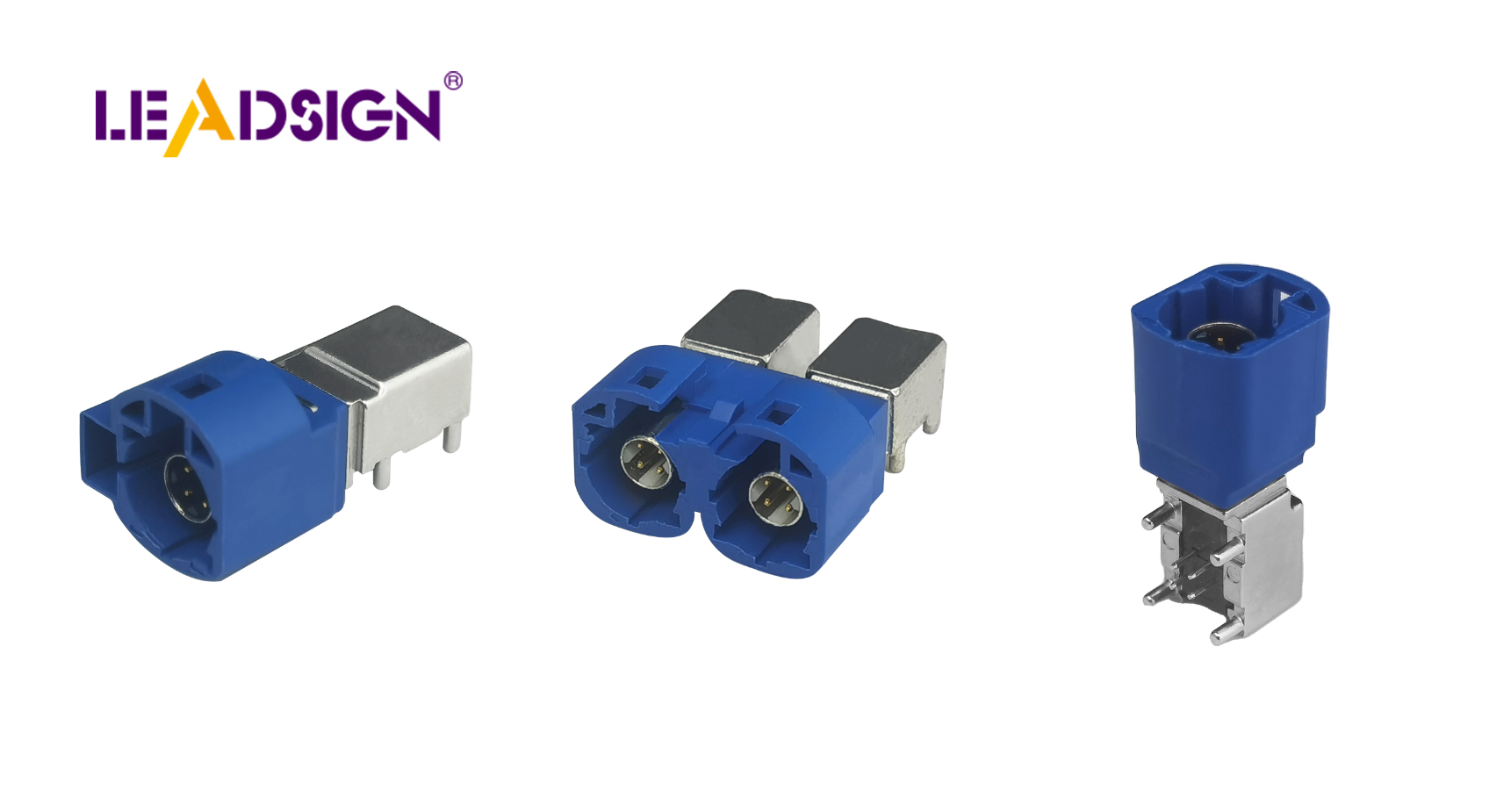

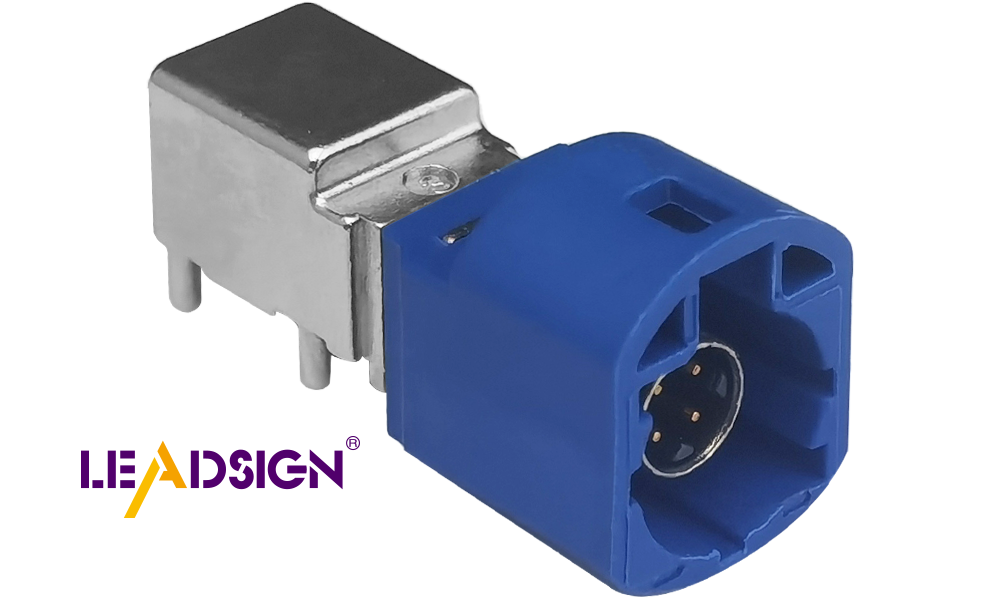

LEADSIGN

Overview of HSD Connector

LEADSIGN's HSD connector is great for fast data transfer. It works well in modern systems needing quick and steady connections. The locking system keeps it secure, preventing accidental disconnections. Its crimp design holds cables tightly, making it strong and long-lasting.

The connector also has smart coding to avoid mistakes. Different codes on the plastic housing ensure correct assembly every time. This makes installation easier and reduces errors, saving time during setup. Whether used in cars or telecom projects, this connector performs reliably.

Uses in Cars and Telecom Industries

The LEADSIGN HSD connector is useful in cars and telecom work. In cars, it handles tough conditions like heat, moisture, and shaking. It’s perfect for cameras, USB ports, and Ethernet systems in vehicles. These connectors are also key in car entertainment setups for flexible designs.

In telecoms, the HSD connector supports fast data for communication tools like radio stations. It works with USB 1.0 to 3.0 standards, FireWire, and Ethernet networks too. Its strong build ensures it lasts even in harsh environments.

Choosing the LEADSIGN HSD connector gives you a reliable option that’s affordable yet high-quality. Its sturdy design and many uses make it ideal for any project needing fast data connections.

Cost vs. Performance: Are Premium Connectors Worth It?

Picking the right connector means balancing price and performance. Knowing when to spend more can help you choose better.

How Price Shows Quality and Features

Connector cost often matches its quality and features. Expensive connectors use strong materials like tough metals or heat-proof plastics. These last longer, even in hard conditions. For example, car or factory connectors resist heat, water, and rust, which makes them pricier.

High-cost connectors also have extra features. Some lock securely or prevent wrong connections with special codes. Molex connectors are strong and reliable but harder to unplug for safety. JST connectors are small and light, great for tiny devices but handle less power than Molex.

When High-End Connectors Are Worth It

Spend more on connectors for high power or fast data needs. Molex’s Mega-Fit series handles up to 23.0A per circuit, perfect for heavy tasks. LEADSIGN’s HSD connector is great for quick data transfer in cars or telecom systems.

Choose premium ones if durability matters too. In tough places like factories or outdoors, strong crimping and good materials last longer. TE Connectivity connectors resist heat and water well in these settings.

Affordable Choices for Hobbyists

For simple projects, cheaper connectors work fine. They may lack fancy features but do basic jobs well. JST PH or XH series are cheap and easy to use, ideal for beginners.

For low-current tasks, JST-GH works with fewer wires while JST-SHD handles more wires affordably. These options balance cost with function for small electronics or prototypes.

Use proper crimp tools even with budget parts to avoid loose wires. A good tool ensures tight connections that stay secure over time.

Tips for Picking the Best Connector

For DIY and Hobby Projects

If you’re doing DIY or hobby work, pick simple connectors. They should be cheap, easy to use, and reliable. Wire-to-board connectors are a great option. They let you attach wires straight to your PCB without needing fancy tools. These connectors work for both power and data tasks, making them perfect for small gadgets like Arduino or Raspberry Pi projects.

Learning to crimp is important for DIY fans. Good crimping keeps wires tight and working well. Bad crimping can cause loose wires or bad signals. A basic crimp tool is worth buying to avoid problems. Choose connectors with labels or colors to make setup easier. JST PH Series connectors are small and simple, ideal for tiny projects.

For testing circuits or building prototypes, reusable connectors are best. Snap-fit or push-lock types make it easy to take apart and rebuild without breaking anything. This helps you try different setups quickly and safely.

For Tough Jobs in Industry

In factories or high-performance jobs, strong connectors matter most. These need to handle heat, water, and shaking without breaking down. PCB power connectors are built for these hard conditions. They deliver steady power even in tough places.

Crimping is very important in industrial settings too. Use top-quality crimp tools for strong connections that last long. Good crimping stops overheating and electrical problems that could damage machines. TE Connectivity’s Dynamic Series works well in factories because they resist wear over time.

For fast data systems, pick connectors that keep signals clear. LEADSIGN’s HSD connector is great for cars or telecoms because it sends data quickly while staying secure. Its smart design avoids mistakes during setup, keeping things running smoothly.

For Everyday Use

For regular tasks, go with flexible and adaptable connectors that fit many needs. Wire-to-board ones are popular since they work in electronics like home appliances or office gear. Molex Micro-Fit 3.0 offers a good mix of size and power handling for daily use.

Even here, crimping matters a lot! A proper crimp keeps the connection safe over time—no loose ends! Use tools made for your connector type to avoid issues later on. Molex Mini-Fit Jr. series is perfect for powering devices like gaming consoles or printers reliably.

Think about your PCB’s size when picking a connector too! Small ones save space but bigger ones carry more power if needed—choose wisely! Look out for user-friendly designs like snap-fit features; they make installing much easier while saving time.

Tips for Making Connectors Work Well and Last Long

Picking the right connector is just the beginning. To make it work well and last longer, you need to focus on some key things. Here are simple tips to help you use your connectors better.

1. Choose Connectors That Fit Your Needs

Check if the connector matches your project needs. Look at its power limits, voltage, and pin setup. Wire-to-Board Connectors are flexible and good for power or data tasks. They work in USB setups or high-power systems too. Using a wrong connector can harm your device or make it fail.

2. Pick Strong Materials

The material decides how long a connector lasts. Use metal connectors for better strength and electricity flow. Heat-proof plastics are great for hot places. For tough jobs like factories or cars, PCB Power Connectors handle hard conditions well. Good materials prevent breaks and keep them working longer.

3. Install Them Correctly

Bad installation can ruin how a connector works. Use proper tools for crimping or soldering wires tightly. Loose connections may cause power cuts or signal problems later on. Follow instructions carefully when setting up snap-fit or push-lock connectors to avoid mistakes.

4. Test Before Final Setup

Always test connectors with your PCB before finishing the design. Check if they fit right, align properly, and stay secure during use. Misaligned pins can cause issues like bad signals or poor performance later on.

5. Protect From Bad Conditions

Heat, water, or dust can damage connectors over time if not protected well enough! Waterproof seals stop moisture; rust-proof coatings fight corrosion outdoors; heat-tolerant materials survive extreme temperatures easily! PCB Power Connectors excel under these challenges making them perfect choices where needed most!

6 Maintain Regularly

Even top-quality ones need care now & then! Inspect often looking out signs wear tear cleaning dirt debris replacing damaged parts promptly ensures reliability stays intact throughout lifespan saving costs downtime repairs alike!

By following these steps above ensures better results reliability longevity efficiency electronic projects every single time guaranteed success ahead always!

PCB board to wire connectors are important for electronic devices to work well. These connectors vary in quality, performance, and price. Picking the right one depends on your needs. Look at things like material strength, power limits, and size before deciding. Brands such as Molex, JST, TE Connectivity, and LEADSIGN have many options for different uses. Expensive connectors last longer and perform better, while cheaper ones are fine for simple tasks. Using proper crimp tools helps make strong and safe connections that last a long time.

What are PCB board wire connectors used for?

PCB board wire connectors join wires or cables to a PCB. They help send power and data between parts of a device. You can find them in computers, phones, and car systems.

How do I choose the right connector for my project?

Pick a connector based on your project’s needs. Think about current, voltage, size, and environment. For example, high-speed ones are good for fast data. Strong connectors work better in tough places.

"The right connector ensures smooth performance and easy maintenance," experts say.

What types of PCB connectors are available?

There are different types of PCB connectors:

Pin Headers: Simple and easy to use.

Wire-to-Board Connectors: Attach wires directly to PCBs.

Terminal Blocks: Best for high-power tasks.

Wire-to-Wire Connectors: Link two wires without using a PCB.

Each type has its own job, so pick wisely.

Why is material quality important in connectors?

Good materials make connectors last longer and work better. Metals and heat-proof plastics handle tough jobs well. For example, car or factory connectors resist heat, water, and rust.

Are expensive connectors always better?

Not always! Expensive ones have extra features like durability or clear signals. Cheaper options work fine for simple projects. For instance, JST models are affordable for small gadgets.

How do I ensure my connector fits my PCB design?

Check the size, pins, and how it mounts on your PCB. Make sure it doesn’t block other parts on the board. Testing before final setup avoids costly mistakes later.

Can connectors handle harsh environments?

Yes! Some are made for tough conditions like heat or water exposure. Look for waterproof seals or rust-proof coatings. LEADSIGN HSD models work well even in extreme settings like cars or telecoms.

What tools do I need for connector installation?

You’ll need crimping tools or soldering gear depending on the type. Good crimp tools make tight connections that don’t loosen easily over time.

How do I maintain connectors for long-term use?

Clean them often to remove dirt or dust buildup. Check regularly for damage and replace broken parts quickly to keep them working well.

Why is connector selection critical in electronic design?

Choosing the right connector affects how your device works overall. Experts say it ensures proper function with cables and other system electronics throughout its life span!

See Also

Exploring FAKRA Connectors for Enhanced Automotive PCB Performance

Why FAKRA PCB Connectors Matter for Automotive Connectivity

Key Benefits of FAKRA Connectors in Automotive Systems

FAKRA PCB Mount Connectors: Essential for Automotive and RF Use