Why PCB Board to Wire Connectors Always Matter

PCB board to wire connectors are very important in electronics. They keep parts connected so devices work properly. Without good connectors, systems might lose signals or stop working. Heat and moisture can make things even harder for them. Strong connectors made with tough materials prevent these problems. In medical tools, cars, or circuit boards, good connectors ensure safety and long-lasting use.

Key Takeaways

Durability is crucial; choose connectors made from strong materials like rubber or silicone to withstand harsh conditions.

Ensure compatibility by selecting connectors that match your PCB and wire types for optimal signal integrity.

Look for ease of installation features, such as snap-fit designs, to save time and reduce assembly errors.

Prioritize performance by selecting connectors that maintain signal integrity and can handle high-frequency data transfer.

Consider the specific application needs, such as environmental factors and electrical requirements, when choosing connectors.

Balance cost and quality by investing in durable connectors that reduce long-term repair costs.

Familiarize yourself with industry standards like IEC or IEEE to ensure reliable and safe connections.

Key Features to Look for in PCB Board to Wire Connectors

When picking pcb board to wire connectors, knowing their features helps. These features affect how well your devices work and last.

Durability

Durability is very important for any connector. A strong design keeps the connection steady, even in tough conditions. Good pcb connectors use materials like rubber, silicone, or strong plastics. These materials protect against heat, moisture, and shaking. For rough uses like in cars or factories, specialty pcb connectors with strong covers and locks are better. Strong connectors need less fixing and make devices last longer.

Compatibility with PCB and Wire Types

Picking the right pcb connectors for your wires and boards is key. This ensures they fit well and signals stay clear. For example, wire-to-board connectors link wires directly to a pcb, helping send power or data smoothly. Newer designs of pcb connectors can fit different wire sizes and board layouts. Always check if the connector's specs match your system's needs for voltage or current.

Ease of Installation

Easy installation makes assembly faster and reduces mistakes. Many modern pcb connectors have simple designs like snap-fits or crimp connections for quick setup. Lightweight rectangular ones with ribbon cables are great for large projects. New modular designs let you replace parts quickly without big changes to the system. A good connector saves time while keeping the connection safe and secure.

Performance and Signal Integrity

The way pcb connectors work affects device performance. A good connector helps send data, power, and signals smoothly. Strong pcb board to wire connectors stay connected even in heat or shaking.

Signal integrity stops data loss or errors. Bad connectors can cause problems like broken communication or device failure. Pick pcb connectors that handle fast data and keep signals clear. For example, high-frequency pcb connectors are great for cars or telecom systems needing steady signals.

Good pcb connectors have features like grounding and strong covers. These protect against things like EMI or water damage. Secure locks on connectors stop them from coming loose during use.

Materials also matter for high-performing systems. Gold-plated contacts improve signal flow by cutting resistance. Rubber seals guard against tough environments, keeping the connectors safe.

Check if your pcb connectors follow standards like IEC or IEEE. This ensures they fit well and work reliably with your boards. Focusing on performance keeps devices running better for longer periods.

Comparing Top PCB Connector Brands

Picking the right pcb connectors brand is very important. It affects how well your electronics work and last. Each brand has special features for different needs. Here's a simple comparison to guide you.

Brand A: Features, Pros, and Cons

Brand A makes flexible pcb connectors for many uses. Their products are strong and fit different pcb types.

Features:

Handles high heat in tough places.

Easy-to-change modular designs.

Gold-plated parts for better signal flow.

Pros:

Works well in rough conditions.

Durable materials need less fixing.

Many choices for various pcb setups.

Cons:

Costs more than other brands.

Harder to find in some areas.

Choose Brand A if you want strength and quality over saving money.

Brand B: Features, Pros, and Cons

Brand B focuses on board-to-board connectors and wire-to-board connectors. Their products are small but powerful, perfect for tight spaces.

Features:

Snap-fit design makes setup quick.

Small size saves space on pcb boards.

Keeps signals clear with impedance-matching tech.

Pros:

Easy to install quickly.

Strong signals even with lots of data use.

Good prices for budget projects.

Cons:

Not great for high-power tasks.

Less sturdy in extreme conditions.

Pick Brand B if you need fast assembly and good signal performance at a low cost.

Brand C: Features, Pros, and Cons

Brand C creates advanced pcb connectors, great for high-tech systems. They focus on making precise and reliable connections.

Features:

Protects signals with EMI shielding.

Prevents wrong connections with coding tech.

Crimp wiring ensures secure fits.

Pros:

Perfect for fast data transfers.

Stops signal problems like interference.

Best for cars or telecom devices needing precision.

Cons:

Needs special tools due to complex designs.

Takes time to learn installation steps.

Brand C is best if you're working on detailed projects needing top performance and accuracy.

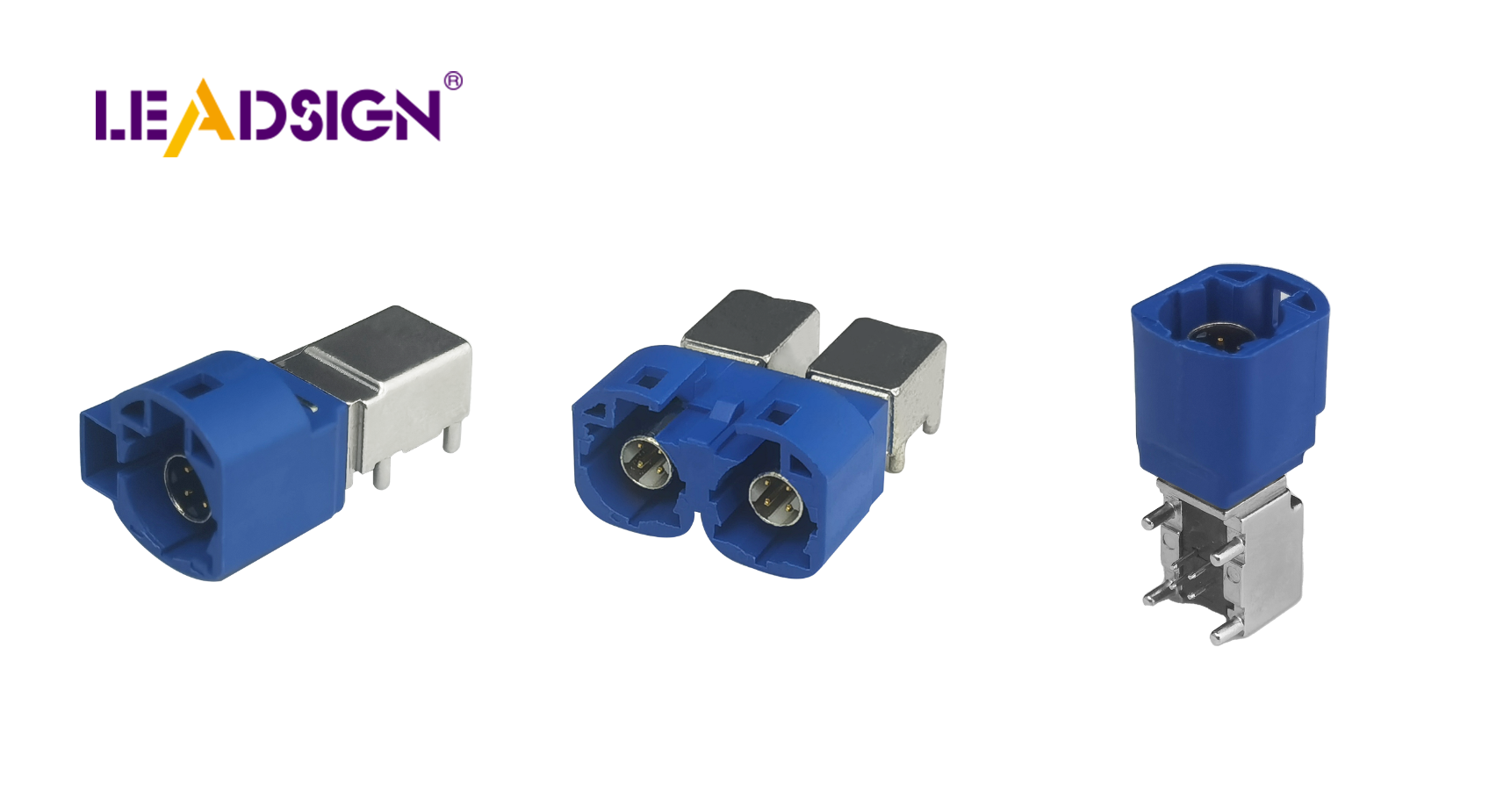

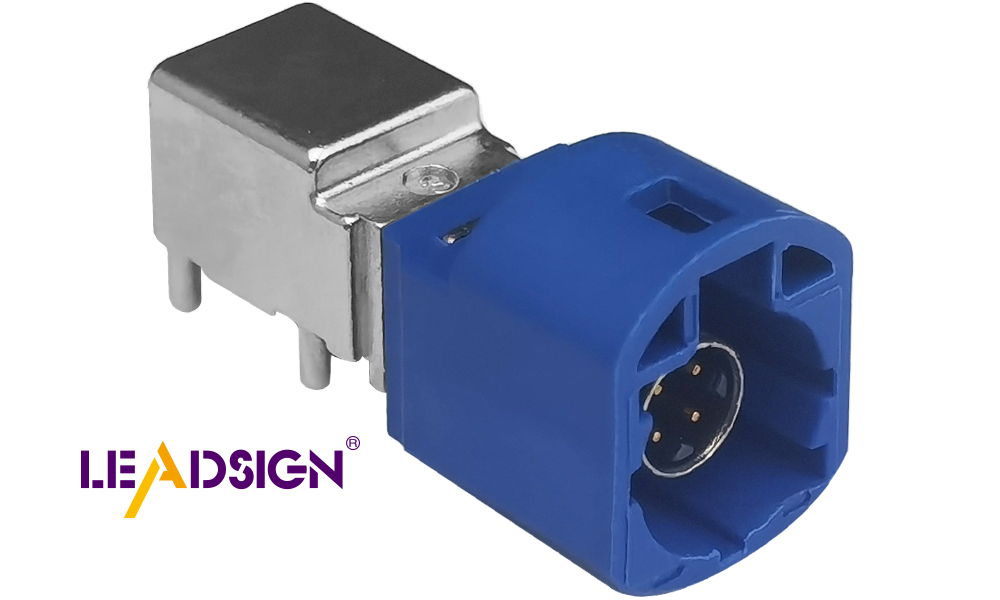

LEADSIGN HSD Connector: Features, Pros, Applications

LEADSIGN’s HSD Connector is a top choice for fast data transfer. It's made for tough environments like car electronics or telecom systems while staying reliable.

Features

Double locks keep the connection secure.

Strong cables stay steady during use.

Works with USB 1.0–3.0, Ethernet, LVDS too!

Applications include automotive cameras (LVDS), infotainment networks & telecom gear like radio bases!

For jobs needing speed & accuracy choose LEADSIGN HSD

LEADSIGN HSD Connector: Features, Pros, and Applications

The LEADSIGN HSD Connector is great for fast data transfer. It works well in cars, telecom systems, and digital networks. Its strong design makes it a favorite for tough jobs.

Features of the LEADSIGN HSD Connector

Primary and Secondary Lock Mechanism

The double-lock system keeps connections secure during use. This stops accidental disconnections, even in hard conditions.Crimp Connection for Stability

The crimp connection holds wires tightly to the connector. This reduces signal loss and makes the connection more reliable.High Cable Retention Force

Strong cable retention keeps wires steady during movement or shaking. This helps prevent loose connections in vibrating environments.High Coding Efficiency

Coding on the plastic housing avoids wrong connections. This saves time by making setups faster and error-free.Compatibility with Multiple Standards

It supports USB 1.0–3.0, Ethernet, LVDS, and FireWire (IEEE 1394). This makes it useful for many tasks like car cameras or infotainment systems.

Pros of the LEADSIGN HSD Connector

Exceptional Signal Integrity

It ensures smooth data flow without interference or loss. This is perfect for high-frequency tasks needing clear communication.Durability in Harsh Environments

Made from strong materials, it handles heat, moisture, and stress well. It lasts long even in tough places like factories or cars.Ease of Installation

Its simple design makes setup easy and quick to do. Crimping and coding features reduce mistakes during installation.

Applications of the LEADSIGN HSD Connector

The connector works well in many areas because it’s versatile:

Automotive Electronics

It’s used in car cameras (LVDS), infotainment systems, and Ethernet networks inside vehicles.Telecom Systems

Telecom equipment like radio stations rely on this connector for stable data transfer under heavy use.Digital Networks and Infotainment

It connects multimedia devices smoothly for sharing data without issues.

Scientific Research Findings: Studies show signal integrity matters when picking connectors. For high-speed uses, connectors like this one ensure clear signals with no errors or mismatches.

LEADSIGN HSD Connectors are strong, versatile, and dependable tools for many industries!

How to Pick the Right PCB Connector Type for Your Needs

Choosing the right pcb connector types is very important. It helps your electronic systems work well and last longer. By checking certain factors, you can pick the best one for your project. Here are steps to help with connector selection.

Understanding Application Needs

Knowing what your project needs is the first step. Every use has different demands, and connectors must meet them to work properly.

Know the Environment

Think about where the connector will be used. For cars, you need connectors that handle heat, shaking, and wet conditions. For gadgets, small and light designs may matter more.Check Electrical Needs

Look at how much power your system needs. High-power projects need strong pcb connectors, while low-power ones focus on clear signals.Think About Durability

Will the connector be plugged in and out often? If yes, it needs to be tough. If not, a simple design might do fine.Look at Space Limits

Check how much room is on your board. Small designs save space but still need to work well.

Tip: Match the connector’s features with what your project requires to avoid problems later.

Balancing Cost and Quality

Finding a balance between price and quality is key when picking a connector. Expensive ones have great features but may not always be needed.

Compare Prices Wisely

Look at prices of different types of connectors that fit your needs without going over budget.Choose Long-Lasting Options

Spending more on durable connectors saves money later by reducing repairs or replacements.Decide if Features Are Worth It

Some high-end connectors have extra features like gold-plated parts for better signals but may not be necessary for all uses.

Remember: The best connector fits both your budget and system needs perfectly.

Checking Technical Details and Standards

Technical specs and rules are important when choosing connectors. They ensure everything works smoothly together in your system.

Review Electrical Specs

Make sure voltage, current, and frequency ratings match what your system needs to avoid problems like overloads or weak signals.Pick Good Materials

Strong materials like gold-plated contacts or sturdy plastics make connectors last longer even in tough conditions like heat or moisture exposure.Follow Industry Rules

Choose standardized connectors (like IEC or IEEE) so they easily fit with other parts now or during future upgrades.Keep Signals Clear

For fast systems, pick connectors that stop interference using things like EMI shields or grounding features for better performance.Use Coding & Locks for Safety Coding stops wrong connections; locks keep them steady during movement or vibrations—great for shaky environments!

Pro Tip: Always check a connector’s datasheet before buying it to ensure it meets all requirements of your project!

By understanding what you need, balancing cost vs quality wisely, and checking technical details carefully—you’ll find the perfect PCB connector type! This ensures reliable performance every time!

PCB board to wire connectors are crucial for reliable electronics. Focus on features like strength, fit, easy setup, and good performance. This helps you pick better options for your projects. Comparing brands shows which ones suit your needs best. For instance, LEADSIGN HSD connectors give fast data transfer and prevent errors with special designs. They work well in cars and telecom systems. Choosing strong connectors improves how devices work and makes them last longer too.

FAQ

What are PCB board to wire connectors?

PCB board to wire connectors join wires to a PCB. They help send power, data, or signals smoothly in devices. These parts are key for keeping electronics working well and reliably.

Why is choosing the right connector important?

Picking the right connector helps your system work better and last longer. A good connector stops problems like signal loss or overheating. It also needs fewer repairs, saving both time and money.

How do I determine the best connector for my project?

To pick the best connector:

Application Needs: Know where and how it will be used.

Durability: Choose ones that handle heat, moisture, or shaking if needed.

Compatibility: Make sure it fits your PCB and wires perfectly.

Cost: Find one that balances quality with your budget.

What materials are commonly used in PCB connectors?

Common materials include gold-plated contacts for strong signals and rust resistance. Plastic or rubber housings protect against heat and moisture damage, making them tough and reliable.

Can high-quality connectors save costs in the long term?

Yes! High-quality connectors cost more upfront but save money later by avoiding failures or fixes. They’re a smart choice for projects needing lasting performance.

Are there specific standards for PCB connectors?

Yes, many follow rules like IEC or IEEE standards. These ensure they fit well with other parts and work safely while meeting technical needs.

How do I install PCB board to wire connectors?

Most modern connectors are easy to install with snap-fit designs or crimping methods. Follow instructions from the maker to avoid mistakes during setup.

What are the common applications of PCB board to wire connectors?

These connectors are used in many fields like:

Automotive Electronics: For cameras or infotainment systems in cars.

Telecom Systems: In equipment transferring large amounts of data quickly.

Consumer Electronics: For gadgets like phones or home devices.

Industrial Equipment: In machines needing strong connections under stress.

How do I balance cost and performance when selecting connectors?

To balance cost with performance:

Compare prices across brands carefully before buying one.

Pick only features you need; skip extras that add cost.

Invest in durable options to avoid frequent replacements later on.

This way, you get good value without losing quality!

What makes LEADSIGN HSD connectors unique?

LEADSIGN HSD stands out by offering fast data transfer with a tough build design. Features include double locks, crimp wiring, and steady cables under movement—perfect for cars, telecoms, or networks needing clear signals!

See Also

Why FAKRA PCB Connectors Matter for Automotive Communication

Exploring FAKRA Automotive Connectors for PCB Benefits

Key Advantages of FAKRA PCB Connectors in Vehicles