The Future of PCB Board Wire Connectors in Car Wire Connector Types

In cars, PCB board to wire connectors are very important. They help electronic parts talk to each other smoothly. This makes vehicles work well and stay reliable. As electric cars and self-driving systems grow, these connectors matter even more. The market for these connectors is growing fast too. It may rise from $4.48 billion in 2022 to $5.75 billion by 2027. By linking key systems, they improve electrification, safety, and connectivity. These connectors are shaping how transportation will look in the future.

Key Takeaways

PCB board wire connectors are essential for ensuring smooth communication between electronic components in modern vehicles, enhancing reliability and performance.

The demand for smaller and smarter connectors is rising, allowing for efficient use of space and improved functionality in tight areas within cars.

Fast data transmission is crucial for smart cars, with connectors like USB 3.0 and Ethernet enabling quick and clear communication between systems.

Innovative materials are being used to create more durable connectors that can withstand harsh conditions, ensuring longevity and reliability in vehicles.

The integration of smart connectors with IoT technology is paving the way for cars to connect seamlessly with other devices and systems, enhancing overall functionality.

Sustainability is becoming a priority, with manufacturers developing eco-friendly connectors made from recyclable and biodegradable materials to reduce environmental impact.

As the automotive industry evolves, wire-to-board connectors will play a key role in supporting electric vehicles and advanced safety features, making cars smarter and greener.

Current Trends in PCB Board Wire Connectors

Smaller and Smarter Designs

Today’s cars have lots of cool electronics inside. This means we need smaller, smarter connectors for wires and boards. Tiny connectors with more pins fit into tight spaces easily. They help save space and make car systems work better. For example, they let many parts fit together in small areas while staying connected well. Strong materials and new ways of making them keep these connectors tough and reliable.

Faster Data for Smarter Cars

Smart cars need to send data quickly between parts. Systems like cameras, music screens, and safety tools depend on fast data sharing. Wire-to-board connectors help keep signals clear while moving fast. Special connectors like USB 3.0 or Ethernet handle big data smoothly. This helps cars stay safe and fun to use with no delays.

Better Materials for Tough Jobs

New materials make wire-to-board connectors stronger than before. These materials can handle heat, bumps, and wet conditions in cars. For instance, strong plastics and metals stop damage from vibrations or temperature changes. With these improvements, the connectors last longer and work great in modern vehicles.

Uses of Wire-to-Board Connectors in Cars

Electric Cars and High-Power Systems

Electric cars need wire-to-board connectors to run their systems. These connectors move power between the battery, motor, and other parts. In high-power systems, they handle big electric loads safely. You’ll see them in chargers, power units, and battery systems. They carry strong currents and voltages, which is key for EVs. By linking wires to circuits, they keep energy flowing smoothly for good performance.

Self-Driving Cars and Smart Safety Features

Self-driving cars use these connectors for their smart features. Sensors, cameras, and controls share data through these connectors. They send signals fast without any breaks or delays. For example, they connect radars, LiDARs, and processors to make quick decisions. They also link airbags and brakes for safety during accidents. As cars get smarter with robots and automation, these connectors are even more needed.

Entertainment Systems and Internet Features

Modern cars have cool screens, music players, and internet tools. Wire-to-board connectors help these work by moving data quickly. RF connectors help radios and GPS stay connected well. Optical ones make fiber networks send data faster too. These connectors also join IoT gadgets to the car’s system easily. This makes the car connect better with the digital world around it.

Future Innovations and Challenges in PCB Board to Wire Connectors

Smart Connectors and IoT Integration

Smart connectors are changing how cars work. These new wire-to-board connectors help car systems talk to smart devices. They let cars connect with homes, traffic lights, and other vehicles. Sensors and chips inside these connectors check performance and share data fast. For example, they find problems in power parts or save energy in electric cars. As smart technology grows, the need for these connectors will rise. Soon, cars will be smarter and more connected than ever.

Sustainability and Eco-Friendly Connector Designs

Car makers now care more about the environment. They are creating eco-friendly wire-to-board connectors using recyclable materials. Some companies use biodegradable plastics instead of regular ones. This helps cut waste and protect the planet better. These changes make cars greener while staying efficient for drivers like you. The connector market is leading this change with new designs that mix good performance with being eco-friendly.

Overcoming Heat Resistance and Durability Challenges

Cars today face tough conditions like heat and shaking roads. Wire-to-board connectors must stay strong to keep working well. Makers now use better plastics and metals to make them last longer. Power parts especially need to handle heavy electricity without breaking down. You’ll see these stronger connectors in electric cars where durability matters most. The connector industry keeps improving so future vehicles can meet all challenges ahead.

PCB board to wire connectors are key in today’s cars. They help parts share power and data smoothly. This supports electric cars, smart systems, and fun car features. New designs make them smaller, faster, and tougher. Future connectors will be smarter and better for the planet. As cars get more advanced, these connectors improve safety and efficiency. They also make vehicles more connected and reliable. With these changes, cars will become smarter and greener over time.

FAQ

What are PCB board wire connectors?

PCB board wire connectors join wires to circuit boards in electronics. They help move power and data between parts smoothly. These connectors are very important in cars today. They support systems like entertainment, safety tools, and electric engines.

Why are wire-to-board connectors important in cars?

Wire-to-board connectors keep car parts connected and working well. They help things like sensors, cameras, and batteries do their jobs right. Without them, cars would not perform safely or efficiently.

How do smaller connectors benefit modern vehicles?

Smaller connectors save space and fit into tight spots easily. They let more parts work together better inside the car. These designs also make cars lighter, improving fuel use and performance.

What makes OEM automotive wire connectors durable?

OEM automotive wire connectors are made with strong materials using new methods. They can handle heat, shaking, and wet conditions without breaking. This strength helps stop rust or damage in vehicles.

Can wire-to-board connectors handle high-speed data?

Yes, these connectors send data quickly for things like USB 3.0 or Ethernet. They keep signals fast and clear for smart car features like screens or safety tools.

Are wire-to-board connectors used in electric vehicles?

Wire-to-board connectors are key for electric vehicles (EVs). They control power flow between batteries, motors, and other parts safely. These strong connections help EVs run well with high electricity loads.

How do smart connectors improve car systems?

Smart connectors have chips to check how systems work and share info fast. They link cars to devices, traffic lights, or other vehicles easily. This improves energy use and keeps everything running smoothly.

What materials are used to make eco-friendly connectors?

Eco-friendly ones use recyclable or biodegradable materials instead of regular plastics. These choices cut waste while keeping the same good performance levels.

How do wire-to-board connectors handle tough conditions?

These special connectors use strong plastics and metals to last longer under heat or shaking roads. In EVs especially, they stay reliable even with heavy electrical demands.

What trends are shaping the future of wire-to-board connectors?

Future trends include making them smaller, smarter, and more eco-friendly. These changes will improve how they work while helping the environment too.

See Also

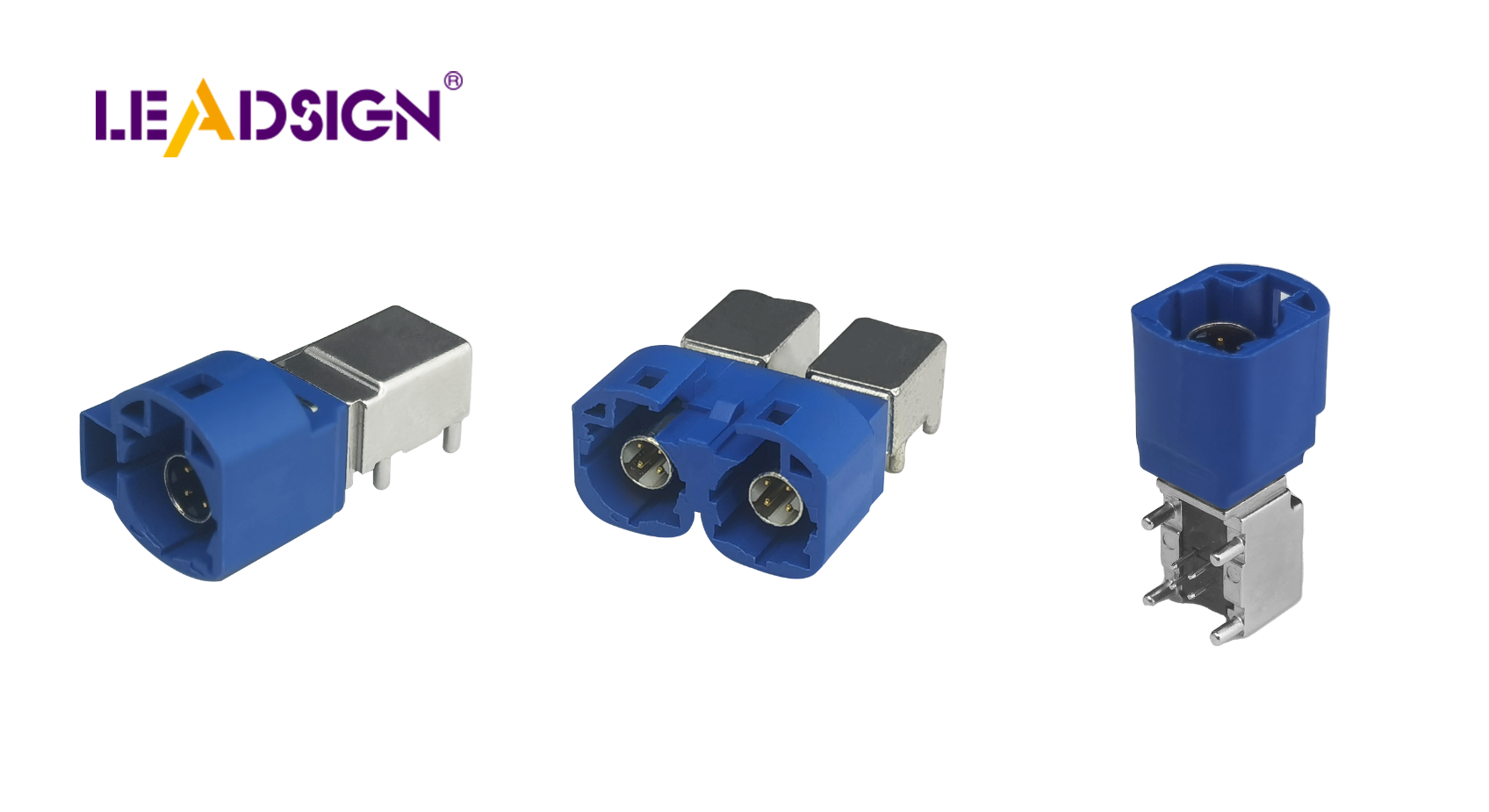

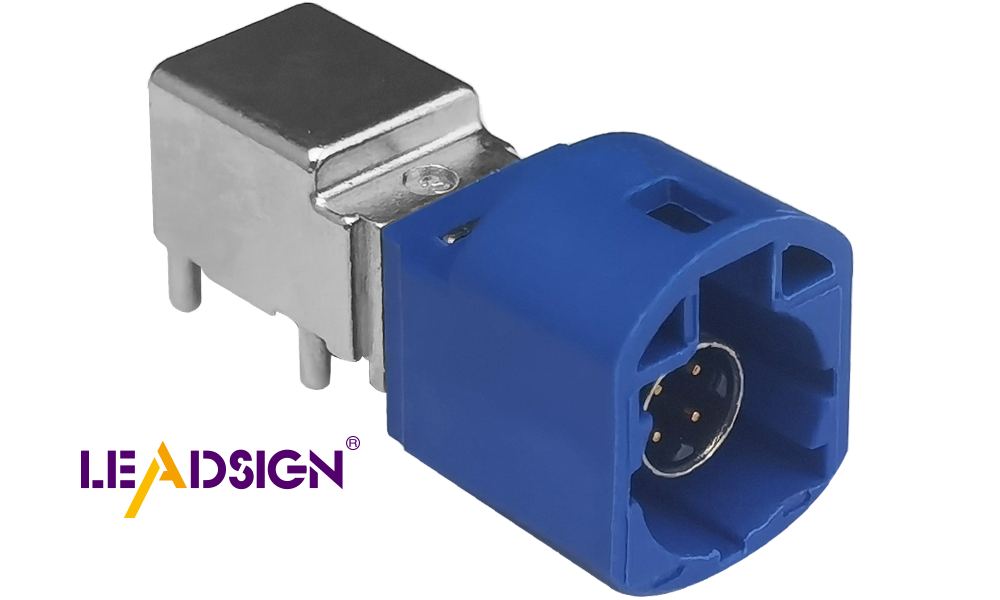

Exploring FAKRA PCB Connectors for Automotive Benefits

Why FAKRA PCB Connectors Are Great for Automotive Use

HFM Connectors: Key Advantages for Automotive Applications