How to Identify the Right PCB Board to Wire Connectors for Car Electronics

PCB board to wire connectors are crucial in automotive electronics. They facilitate the connection between components on a circuit board and external devices. These connectors do more than simply join wires; they significantly impact your vehicle's safety, reliability, and performance. Selecting the appropriate connector requires careful consideration of power requirements. Additionally, it's essential to ensure that it can withstand harsh conditions and is compatible with your vehicle's design. A high-quality connector enhances the functionality and safety of your PCB, reducing issues such as signal loss or component failure, making it vital for robust automotive electronics.

Key Takeaways

Choose the right type of connector based on your car's electrical needs, considering factors like power requirements and signal quality.

Select connectors that can withstand harsh automotive conditions, such as heat, vibration, and moisture, to ensure reliability.

Ensure a proper fit between the connector and your PCB design to avoid installation issues and enhance performance.

Use high-quality materials, like gold-plated contacts, to improve durability and prevent rust in connectors.

Follow manufacturer instructions for installation to avoid damaging connectors and ensure they function correctly.

Regularly inspect and maintain connectors to catch issues early, preventing costly repairs and ensuring long-term performance.

Opt for sealed connectors in areas prone to water or dust exposure to protect internal components and enhance longevity.

Types of PCB Board-to-Wire Connectors for Car Electronics

When dealing with car electronics, knowing circuit board connectors is important. Each type has a purpose to keep your vehicle's electrical system working well. Let’s look at the main circuit board connector types you might use.

Wire-to-Board Connectors

Wire-to-board connectors are common for linking wires to a printed circuit board. They connect outside parts to the pcb, helping send signals or power. These are often used in cars where small size and strong links matter.

Wire-to-board connectors come in single-row or double-row styles. They are simple to attach and take off, making repairs easier. Their flexibility fits many car systems like radios or engine controls.

Power Connectors

Power connectors handle high electricity needs. They keep electricity flowing between the pcb and other parts of your car. These can survive tough conditions like heat and shaking, which happen in vehicles.

Power connectors come in different sizes for various car uses. Sealed multi-pin ones block water and dirt, lasting longer. They're great for systems like electric steering or battery controls.

Specialty Connectors

Specialty connectors meet special car needs. High-speed data ones, like HSD, send lots of data for cameras or USBs in modern cars with advanced tech features.

Other specialty types include hybrid connectors that mix power and signal functions into one piece. These save space and work well in tight areas of complex systems.

By learning about these pcb board to wire connectors, you can pick the best type for your car electronics. Each kind helps keep your vehicle's electrical system safe, strong, and efficient.

Key Factors for Choosing Circuit Board Connectors

Picking the right connectors for car electronics is important. Wrong choices can cause bad performance or system failure. Let’s look at key points to help you decide.

Electrical and Signal Needs

First, check your system's electrical needs. Think about how much power your pcb uses. High-power systems, like in electric cars, need strong connectors to handle heat. Low-power systems, like sensors, need precise ones to avoid signal problems.

Signal quality matters too. If your printed circuit board sends data, like in cameras or radios, use high-speed connectors. Look for low resistance and shielding features for better connections. Always match the connector to your system's needs.

Tough Conditions and Strength

Car electronics face tough conditions daily. Heat, shaking, and water can damage circuit board connectors. Pick strong designs that handle these challenges well. Sealed connectors work best where water or dust might reach.

Strength is also key. A connector should stay put even with vibrations. Locks or tight grips stop it from coming loose by accident. Test its strength to ensure it works in tough spots.

Fit with Car Systems

Your connector must fit perfectly with your pcb and car design. Check its size and pin setup to match your pcb board to wire connectors properly. A wrong fit can cause trouble during assembly or later use.

Think about how easy it is to install too. Some connectors are quick to set up, saving time during work. Follow maker instructions to ensure they suit your car systems well.

By focusing on these tips, you’ll pick circuit board connectors that improve car performance and reliability. The right choice keeps things running smoothly and helps your pcb last longer.

How to Pick PCB Connectors for Car Electronics

Choosing connectors for car electronics can seem tricky at first. Breaking it into steps makes the process much simpler.

Knowing Connector Details

First, check the details of the connector you need. Each connector has special features for certain jobs. Look at how many pins it has and its power limits. These details help you find a match for your circuit board. For example, if your board sends fast data, pick connectors with good shielding and low resistance.

Think about the size and shape of the connector too. Small designs fit better in tight spaces, like in modern cars. Also, make sure it matches your board's thickness and pin setup to avoid problems during installation.

Checking Material and Strength

The material of a connector affects how well it works. Good materials, like gold-plated parts, stop rust and improve connections. Strong plastic covers should handle heat and shaking found in cars.

Look at how the connector locks in place too. A strong lock keeps it steady even when conditions are tough. Weak locks might loosen over time, causing problems later on. Always pick connectors made to handle car system demands.

Reading Manufacturer Instructions

Connector makers give helpful guides about their products. These guides explain how to install them and what they work best with. Always read these guides before choosing a connector.

Some makers suggest specific connectors for certain car systems, like high-power setups or fast data needs. Following these tips ensures your choice fits your car's electronics perfectly.

By following these steps, you’ll choose PCB connectors that boost your car’s performance and last longer.

Best Practices for Using PCB Board to Wire Connectors

When using pcb board to wire connectors, follow good practices. This keeps your car electronics working well and lasting longer. Careful handling and regular checks can stop problems early.

Installation Techniques

Installing connectors correctly is very important. Line up the connector with the printed circuit board carefully. If it’s not aligned, pins can bend or break, causing issues. Always read and follow the maker's instructions to install them right.

Use proper tools for the job. Wrong tools or too much force can damage parts. For locking connectors, make sure they snap in place securely. This stops them from coming loose when the car shakes or moves.

In areas with lots of vibration, use extra secure connectors like ones with screws or clips. These hold tight even under stress. Doing this during setup helps your connectors work better and last longer.

Maintenance and Inspection

Check your circuit board connectors often to keep them in good shape. Look for rust, dirt, or loose parts that might cause trouble. Clean dirty connectors gently with a soft cloth and mild soap if needed.

If you see rust, clean it off carefully with a small brush. After cleaning, add a protective coating to stop more rust from forming. This is especially useful in cars exposed to rain or snow.

Also check for bent pins or cracks in the casing of the connector. Replace any damaged ones quickly to avoid bigger problems later on. Regular care prevents small issues from becoming expensive repairs.

Ensuring Long-Term Durability

To make your connectors last longer, pick strong materials made for cars. Gold-plated contacts are great because they resist rust and stay reliable over time. Strong plastic cases that handle heat and shaking are also important.

Sealed connectors are best where water or dust might get inside. They block out harmful stuff and protect the parts inside well. You could also coat your pcb to guard against moisture and dirt.

Don’t tighten connectors too much when putting them together; this can harm them over time. Follow torque advice from makers instead of guessing force levels yourself. By choosing wisely, handling carefully, and doing regular upkeep, you’ll keep your connectors working for years!

Picking the right PCB connectors is very important for car safety. Think about power needs, tough conditions, and how they fit your board. Using strong materials and installing them correctly makes them last longer. Regular checks help keep the connectors working well over time. Follow good practices to avoid problems and ensure smooth performance. With smart choices and care, your PCB will work reliably for a long time.

FAQ

What are the types of PCB connectors?

PCB connectors come in different kinds for specific jobs. Common ones include wire-to-board, power, and specialty connectors. Wire-to-board connectors join outside parts to the circuit board. They help send signals or power smoothly. Power connectors handle big electricity needs like in electric steering systems. Specialty connectors, like high-speed data ones, work for cameras or USBs in modern cars.

How do I pick the right connector?

First, know what your system needs. Think about how much power and signal your PCB uses. For strong systems, pick connectors that handle heat and stress well. For sending data, choose ones with low resistance and shielding. Make sure the connector fits your board’s size and pin setup to avoid problems.

Why does material quality matter?

The material affects how long a connector lasts and works well. Good materials like gold-plated contacts stop rust and keep connections strong over time. Tough plastic covers protect against heat and shaking found in cars. Strong materials make connectors last longer.

Can connectors survive tough car conditions?

Yes, many are built for hard conditions. Sealed ones block water, dirt, or dust, making them great for extreme places. Connectors with tight locks stay put even when there’s heavy shaking in cars.

How often should I check my PCB connectors?

Check them every few months to keep them working well. Look for rust, dirt, or damage on them regularly. Clean dirty ones gently and replace broken ones quickly to avoid bigger issues later.

What tools should I use to install them?

Use tools suggested by the maker of the connector. These tools help you line up parts correctly without breaking anything during setup. Locking types should snap tightly into place to stay secure.

Are there special connectors for fast data transfer?

Yes! High-speed data connectors move lots of information quickly. They’re used in things like cameras or USBs in cars today. These have low resistance and good shielding to keep signals clear.

How can I make my connectors last longer?

Pick strong materials made for tough spots like cars’ insides. Use sealed types where moisture or dust might get inside easily. Don’t tighten too much when setting up; it can weaken parts over time.

What happens if I use a wrong connector?

A wrong one can cause bad performance or even break things! It may lead to signal loss or overheating issues on your PCB board too! Always match specs carefully before choosing any part.

Can old connectors be reused again later?

Sometimes they can if they aren’t damaged yet! Check their condition first—look out for bent pins or worn-out areas before reusing anything again safely.

See Also

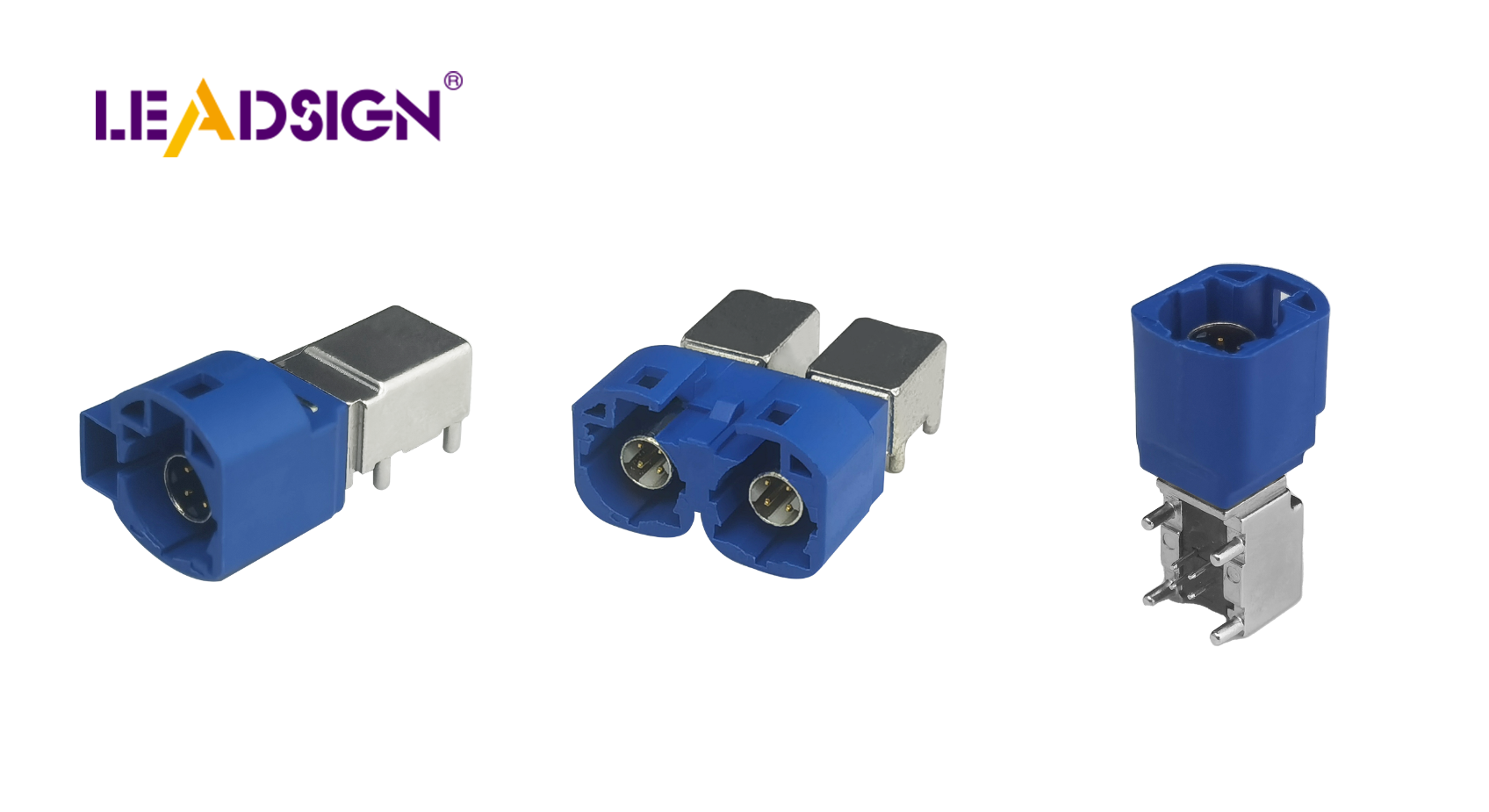

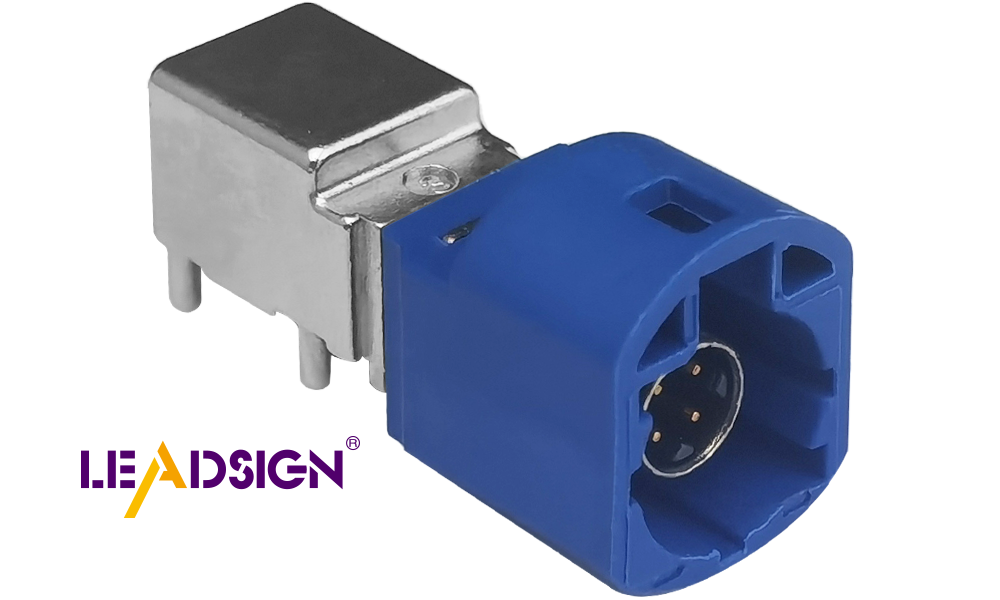

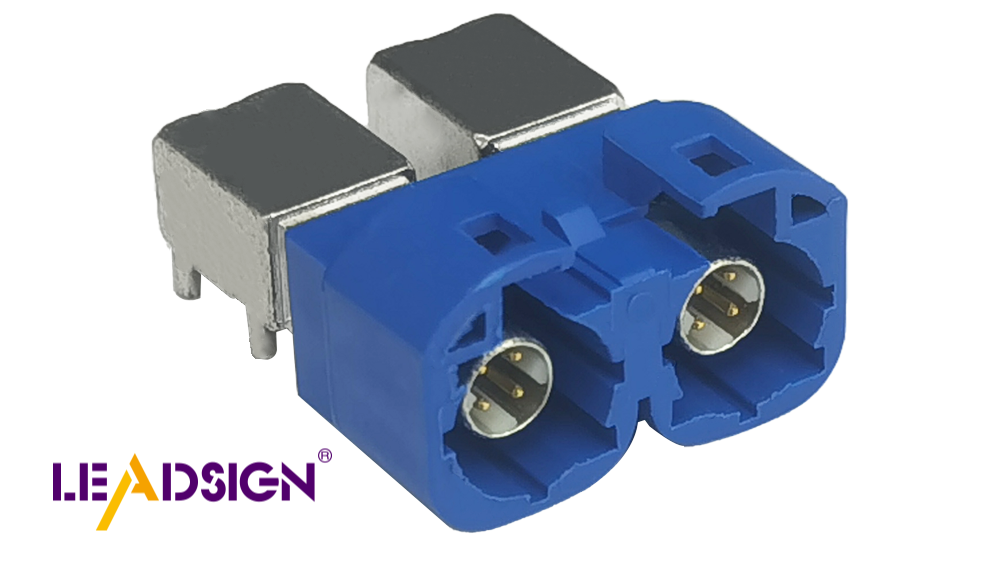

Why FAKRA PCB Connectors Matter for Car Communication

Key Benefits of FAKRA PCB Connectors for Vehicles

Improving Vehicle Communication Through FAKRA PCB Connectors