Choosing PCB Board to Wire Connectors for Car Electronics Projects

PCB board to wire connectors are important in car electronics. They create strong links between parts like sensors and control units. Without good connections, car electronics might not work properly. Picking the right connector helps with smooth power and communication. Cars need connectors that handle heat, shaking, and moisture well. A good connector makes your circuit board last longer and work better. This ensures your car's electronics run smoothly even in tough conditions.

Key Takeaways

Choose connectors that meet your car's electrical needs, including current and voltage limits, to ensure safe and reliable operation.

Opt for connectors designed to withstand harsh automotive environments, including heat, vibration, and moisture, to enhance durability.

Consider the size and pin layout of connectors to ensure they fit well on your PCB without crowding other components.

Select high-quality connectors from trusted brands to guarantee performance and longevity, even in challenging conditions.

Utilize specialized connectors like HSD for high-speed data transfer in modern car electronics, ensuring efficient communication between systems.

Plan for easy installation and maintenance by choosing connectors that allow for simple assembly and access for repairs.

Maintain a steady supply of connectors by selecting popular types that are readily available, preventing project delays.

Key Things to Think About When Picking PCB Board-to-Wire Connectors

Choosing the right connectors for car electronics is important. Knowing what to look for helps your system work well and last longer.

Electrical Needs

Current and Voltage Limits

Check how much current and voltage the connectors can handle. Car connectors often have metal parts inside a plastic cover. This design keeps power flowing safely and avoids overheating or damage.

Signal Quality and EMI Issues

Good signal quality is key for smooth communication between parts. High-quality connectors use materials like copper to send signals better. They also resist interference from electromagnetic fields (EMI). This keeps systems like navigation or safety features working properly.

Strength and Lifespan

Wear-and-Tear Resistance

Car connectors should handle frequent use without breaking. If you unplug them often, pick ones built for many uses. This makes them last longer and stay reliable.

Long Life in Tough Conditions

Connectors need to survive harsh car environments. They must meet strict rules, like USCAR-20 standards, to ensure they work well over time.

Protection Against the Environment

Heat Resistance

Car electronics face high temperatures. Choose connectors that can take the heat without failing. Special materials help them stay strong even in hot areas like engines.

Vibration Resistance

Cars shake a lot while moving, which can loosen connections. Strong connectors with locks keep everything secure during bumps or vibrations.

Moisture Protection

Water and rust can harm connectors and circuits. Automotive-grade connectors are made with protective coatings or seals to block moisture. This makes them good for wet conditions too.

Thinking about these things will help you pick the best PCB board-to-wire connectors for your car projects. The right choice means your system will work well and last a long time.

Physical and Design Factors

Connector Size and Shape

The connector's size affects how it fits on the PCB. Smaller connectors save room, which is helpful in tight spaces. But, they should still work well despite being small. Many car connectors have metal strips inside plastic covers to send signals better. This design keeps them small but effective. Always pick a connector that balances size and performance for your project.

Number of Pins and Fit

The pins in a connector decide how many links it can make. For car electronics, match the pin number to your system’s needs. If it doesn’t match, connections might fail or space could be wasted. Also, the pin layout must fit with your PCB design. Car connectors are carefully made to connect well with wires and devices. This ensures smooth power flow and communication between parts.

Limited Space on the PCB

Space is often tight in car electronics projects. Choose connectors that fit without crowding other parts on the board. Small designs like automotive-grade connectors use space wisely and are easy to install or fix later. Thinking about space early helps avoid problems or redesigns later on. It also makes sure all parts fit together perfectly.

Picking the right connector ensures cables and devices link properly for a long time.

Types of PCB Connectors for Car Electronics

When working on car electronics, knowing connector types is important. Each type has specific uses and benefits. Picking the right one ensures strong and lasting connections.

Pin and Socket Connectors

Features and Benefits

Pin and socket connectors are very common in car projects. They have a pin (male) and a socket (female) that join securely. These connectors are simple to use and conduct electricity well. They can be easily put together or taken apart, which helps with repairs or upgrades.

They come in different sizes and pin numbers for various needs. Small ones save space, while big ones handle more power. This makes them useful for both small and large electronic systems.

Common Use Cases in Automotive Systems

You’ll find these connectors in lights, sensors, or control units. They work well where parts need regular fixing or replacing. Their tough design handles heat or shaking without problems.

IDC (Insulation Displacement Connectors)

Features and Benefits

IDC connectors make wiring easier by skipping soldering steps. Sharp metal parts cut through wire insulation to connect securely. This saves time during setup and reduces mistakes.

These connectors are small, light, and fit tight spaces easily. They can link several wires at once, making them efficient for car electronics.

Applications in Car Electronics

IDC connectors are used in dashboards, infotainment systems, or wiring setups. Their small size fits cramped areas but still works reliably under stress.

Terminal Block Connectors

Features and Benefits

Terminal block connectors attach wires firmly to PCBs using screws. This creates stable links that are easy to adjust or replace when needed.

They come in many sizes for different wire thicknesses or power levels. Their sturdy build lasts long even under tough conditions.

Use Cases in Automotive Projects

You’ll see terminal blocks in batteries, motors, or power systems. They’re great for high-power needs or frequent changes to setups. Their strength makes them dependable for car projects.

Specialty Automotive Connectors

Built for Tough Conditions

Specialty automotive connectors are made to handle tough vehicle conditions. They work well in extreme heat, constant shaking, and wet or dusty areas. Their strong build ensures they perform reliably even in hard environments.

Important features include:

Heat Resistance: These connectors use special materials that can take high heat. This makes them great for engines or near hot parts.

Vibration Durability: Strong locks stop them from coming loose during movement or bumps.

Moisture and Corrosion Protection: Sealed designs keep water out and stop rust, helping them last longer.

Using these connectors keeps your car electronics working well, even in harsh situations.

Examples of Trusted Automotive Connectors

Some automotive-grade connectors are known for being reliable and strong. For example:

Deutsch Connectors: These tough connectors are used in heavy vehicles and off-road cars.

AMP Superseal Connectors: They block water and dust, making them great for outdoor systems.

Molex MX150L Connectors: Small but sturdy, they fit tight spaces while working efficiently.

These examples show why picking the right connector is important for car projects.

High-Speed Data (HSD) Connectors

Special Features for Secure Connections

HSD connectors are needed for modern cars that send data quickly. They have advanced features to make sure connections stay secure and work well:

Primary and Secondary Locks: These locks keep the connector from disconnecting by accident.

High Coding Efficiency: Unique codes help avoid wrong matches during assembly.

Crimp Connection: This feature holds wires tightly, creating a stable link.

These features make HSD connectors a smart choice for high-tech car systems.

Uses in Car Electronics Systems

HSD connectors are useful in many car electronics. They allow fast data transfer, which is important for:

Infotainment Systems: Help screens, sound systems, and controls connect smoothly.

USB Connections: Provide quick and steady data transfer for USB devices.

Ethernet Networks: Ensure strong links for car communication systems.

LVDS (Low Voltage Differential Signaling): Send clear video signals to cameras or displays.

Adding HSD connectors improves how well your car's electronic systems work.

Practical Tips for Picking the Right PCB Board-to-Wire Connectors

Choosing the right pcb board to wire connectors helps your car electronics work well and last longer. Here are simple tips to help you make a smart choice.

Matching with PCB Design

Aligning Pin Layouts

Make sure the connector’s pin layout fits your printed circuit board design. If pins don’t match, connections might fail. For example, pin header/socket connectors come in different shapes like surface mount or right-angle types. These designs fit various layouts easily. Always check that the connector matches your PCB to avoid fixing mistakes later.

Checking Electrical Limits

Look at the connector's electrical ratings to meet your project needs. Check current and voltage limits to stop overheating or damage. For high-power systems, terminal block connectors are strong options. They connect wires securely without soldering, making them great for reliable car electronics.

Easy Installation and Fixes

Simple Assembly and Removal

Pick connectors that are easy to put together or take apart. This is important if you need frequent changes or repairs. IDC connectors let you connect wires quickly without soldering, saving time during setup. Their design keeps them secure but still easy to use in tight spaces.

Easy Access for Repairs

Think about how easily you can reach connectors for fixes or upgrades later on. Small designs like wire-to-board connectors save space but stay easy to access. These connectors link wires neatly to the PCB, helping with smooth operation and simple maintenance in cars.

Quality and Trusted Brands

Buying from Reliable Makers

Get connectors from trusted brands for better quality and performance. For example, Molex’s MX-DaSH family of data-signal hybrid connectors combines power, signal, and fast data transfer into one system. These products show both innovation and reliability, perfect for modern car projects.

Checking Certifications

Make sure the connectors follow industry rules and standards for safety and performance. Look for durable options like circular connectors, which resist water and vibration well. Certifications ensure they will last long even in tough conditions.

By following these tips, you can create an effective PCB design with strong connections that last long. The right pcb connectors improve your system’s performance while making future repairs easier.

Checking Supply Chain and Availability

Keeping a Steady Supply for Long Projects

For long car electronics projects, ensure connectors are always available. A good supply chain avoids delays and keeps work moving smoothly. Choose brands known for delivering products on time. For example, Molex’s MX-DaSH family of data-signal hybrid connectors is reliable for cars. These connectors combine power, signals, and fast data transfer, perfect for modern systems.

Also, pick popular connector types that are easy to find. Common ones like terminal block connectors or IDC connectors are widely used across industries. Their high demand makes them easier to replace or expand when needed. Using well-known connectors lowers the chance of running out of stock.

Balancing Cost with Quality

It’s important to balance cost and quality when choosing connectors. Cheap ones might not last long or work well in tough conditions. High-quality options like circular connectors perform better in heat, water, and vibration. They may cost more but are worth it for reliability.

To save money smartly, compare different connector types based on your needs:

Wire-to-wire connectors are flexible and good for changing setups.

Pin header/socket connectors fit many PCB designs like surface mount or angled layouts.

Board-to-board connectors link circuit boards tightly in small spaces.

By comparing these choices, you can pick affordable yet durable options. Buying from trusted brands ensures safety standards are met and avoids costly repairs later on.

Choosing the right PCB board-to-wire connectors is very important. They help car electronics work well and stay reliable. Check electrical, environmental, and physical needs for good performance. For modern uses like infotainment or Ethernet, use HSD connectors or MX-DaSH family of data-signal hybrid connectors. These provide fast and stable data transfer. Always read datasheets and work with trusted brands. Focus on quality instead of just low prices. This way, you can create strong and long-lasting electronic systems for your projects.

FAQ

What do PCB board-to-wire connectors do in cars?

These connectors link the PCB to parts like sensors or motors. They help power and data flow smoothly, keeping car systems working well.

How can I pick the right connector for my project?

Think about your project's needs like power, heat, and size. Check if it handles current, vibration, and fits your PCB design.

Why is clear signal quality important in connectors?

Good signals mean parts can communicate without issues. High-quality connectors stop interference and keep systems like navigation reliable.

What makes automotive-grade connectors special?

They are built for tough conditions like heat and shaking. Many have locks and seals to last longer in harsh environments.

Can regular connectors work for car electronics?

Regular ones might not handle heat or moisture well. Automotive-grade ones are better for rough conditions in cars.

Why use HSD connectors in car electronics?

HSD connectors send data fast, great for screens or USBs. They also stay secure with strong locking features.

How do I check if a connector fits my PCB?

Make sure its pins match your board’s layout. Also check that it meets your project’s electrical needs like voltage limits.

Are smaller connectors better for cars?

Small ones save space but must still be durable. Pick one that balances size with strength and performance.

What should I consider when choosing a connector brand?

Choose brands known for quality with proper certifications. Reliable makers give good support and detailed product info too.

How can I avoid running out of connectors during projects?

Pick common types that are easy to find later on. Work with suppliers who deliver consistently to prevent delays.

See Also

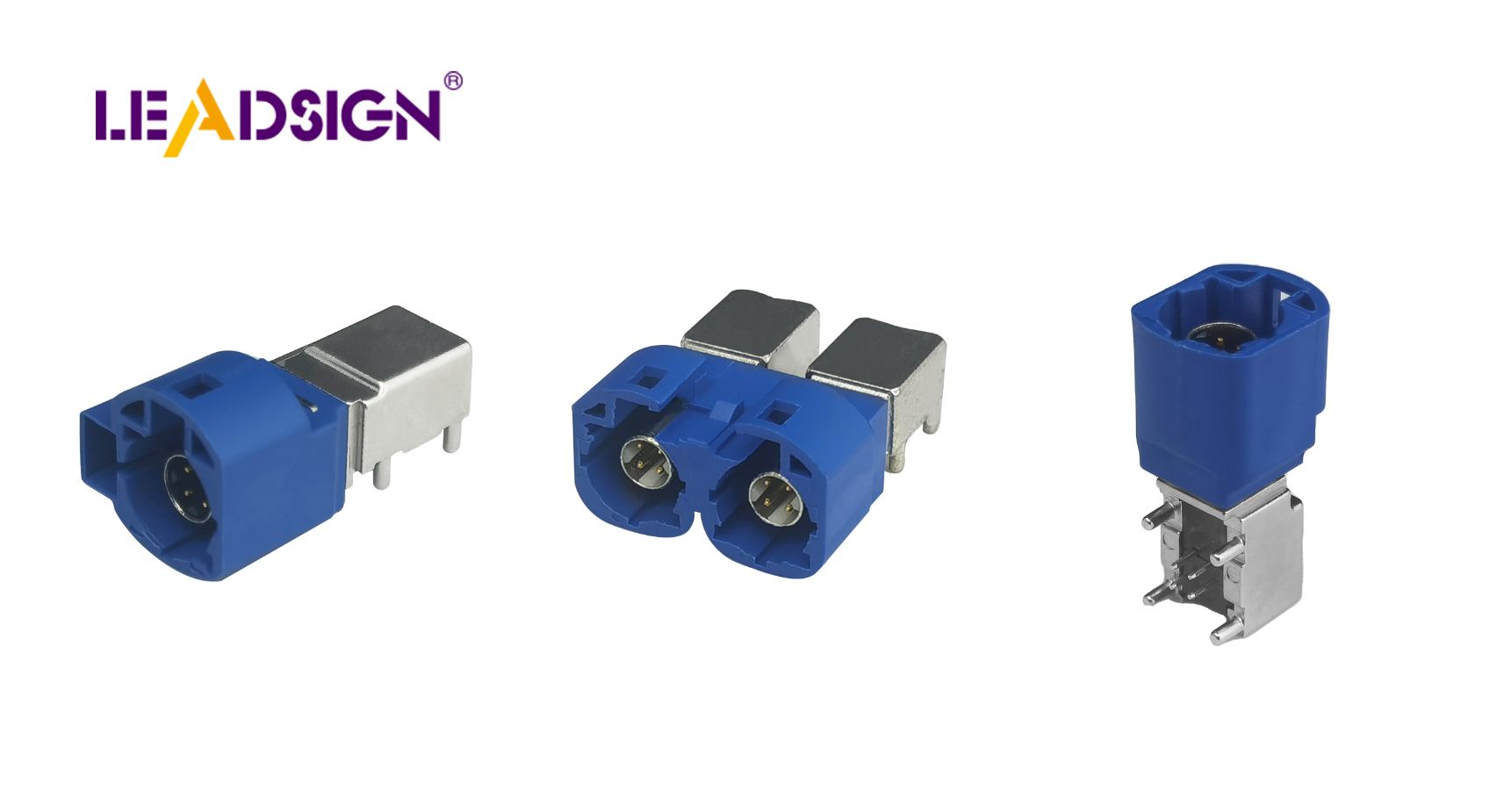

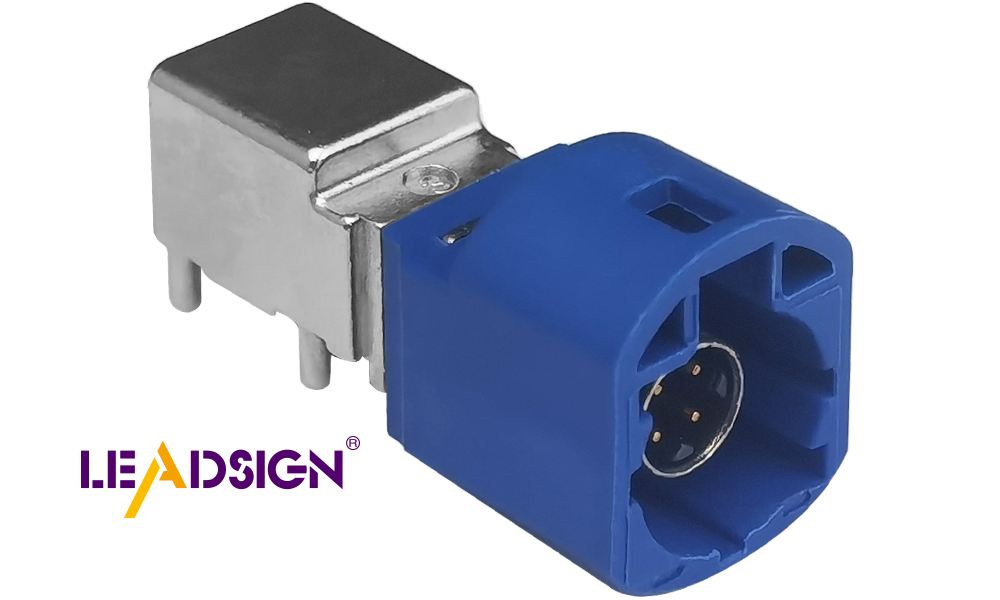

Exploring FAKRA PCB Connectors' Benefits for Automotive Use

Why FAKRA PCB Connectors Are Essential for Vehicles

FAKRA PCB Connectors: Key to Automotive Communication