How to Identify the Right PCB Board to Wire Connectors for Car Electronics

Choosing the right PCB board to wire connectors is crucial for ensuring the safety and performance of your vehicle. High-quality components create strong connections and help prevent issues. Automotive PCBs utilize materials such as copper and aluminum, which are better at handling heat and harsh conditions. These materials also support features like cameras and alarms, enhancing automation and security in cars. Selecting the appropriate connectors and PCBs guarantees reliable automotive electronics.

Key Takeaways

Choose high-quality PCBs and connectors to enhance the safety and performance of your car's electronics.

Understand your car's electrical needs by checking voltage and current requirements before selecting components.

Select materials like copper or aluminum for PCBs to withstand heat and harsh conditions, ensuring longevity.

Ensure compatibility between PCBs and car systems to avoid performance issues and ensure reliable connections.

Consider the environmental challenges your components will face, such as moisture and vibrations, when making your selections.

Opt for standard parts to simplify installation and future upgrades, saving time and costs in the long run.

Test all connections after installation to ensure everything works properly and to identify potential issues early.

Understanding PCB Boards and Wire Connectors

What Is a PCB?

A printed circuit board (PCB) is the base of modern electronics. It holds and connects different electronic parts in vehicles. In cars, PCBs control sensors, run audio systems, and guide navigation tools. These boards use copper paths to send electrical signals quickly.

Car PCBs are built to handle tough conditions like heat and shaking. They keep your car's electronics working well. For instance, PCBs are in safety features like airbags, entertainment systems, and monitors. Their strong design helps your car stay reliable.

What Are Wire-to-Board Connectors?

Wire-to-board connectors link wires to the PCB inside your car. They connect internal circuits with outside devices like sensors or power supplies. These connectors make sure electricity flows smoothly between parts.

In cars, wire-to-board connectors are very important. They help with fast data transfer for cameras or USBs. Many have crimp locks that stop them from coming loose by accident. You can find these connectors in many sizes for different uses.

Wire-to-board connectors make PCB assembly easier and improve how electronics work in cars. Picking good-quality ones keeps your vehicle's systems strong and dependable in any condition.

Key Things to Think About When Picking PCBs and Connectors

Electrical Needs

Know your car's electrical needs before choosing parts. Check the voltage and current the PCB and connector must handle. For example, fast data systems like cameras need special PCBs and connectors. These must manage signals without problems.

Make sure the connector pins match your PCB design. If they don't, it can cause connection issues. Also, check that the PCB thickness fits the connector size. This ensures a strong connection for high-speed uses. Always pick parts that fit your car’s electrical needs for good performance.

Environmental Challenges

Car electronics face heat, shaking, and wet conditions often. Pick materials that can handle these challenges well. Many car PCBs use copper or aluminum because they resist heat and last longer.

Think about where the PCB and connector will go in the car. Near engines, it gets hotter; outside areas may get wet or dusty. Choose connectors with seals to block damage from water or dirt. Handling these challenges keeps your car's electronics working longer.

Strength and Lifespan

Strong parts are key for cars since they face tough use daily. Look for connectors with locks or grips to avoid loose connections.

The PCB’s lifespan depends on its material quality and design too. Boards with solid copper paths work better over time. Also, using standard parts makes future upgrades easier and cheaper later on.

Compatibility with Car Systems

Making sure your PCB and car systems work together is crucial. Every car system has different needs, so choose parts that match. If they don’t fit, the system might fail or work poorly.

First, think about how the PCB and connectors will be used. For instance, infotainment systems need fast data transfer. Safety features like airbags need strong and steady connections. Check that the voltage, current, and signals match between the parts and the system.

The size of the PCB and connectors is also important. They must fit in the space available in your car. Smaller designs are better for tight spots and avoid hitting other parts. Connectors with locks stop them from coming loose during bumpy rides.

Using standard PCBs and connectors makes installation easier. Standard parts work well with most car systems and allow easy upgrades later on. Picking future-ready components ensures your car stays updated longer.

Lastly, think about cost but don’t sacrifice quality. Cheaper options may not last long or perform well in cars. Spending more on good-quality parts saves money by avoiding frequent replacements over time.

Types of PCB Boards and Wire-to-Board Connectors for Car Electronics

Common PCB Types

When picking a PCB for car electronics, know the types. Each type has specific uses and advantages. Below are the most used PCBs in cars:

Single-Sided PCBs

These have one conductive layer only. They are simple and cheap, good for basic tasks like LED lights. But they can't handle complex circuits or fast data.Double-Sided PCBs

These boards have conductive layers on both sides. They support more advanced circuits and are used in dashboards or infotainment systems. They work better than single-sided ones.Multilayer PCBs

Multilayer PCBs stack several conductive layers together. They suit advanced systems like navigation tools or safety sensors. These handle fast signals and stop signal interference.Flexible PCBs

Flexible PCBs bend to fit tight spaces easily. They're great for areas like inside doors or under dashboards. Their flexibility makes them durable against vibrations.Rigid-Flex PCBs

These mix rigid and flexible layers in one board. This makes them useful for complex systems like cameras or driver-assistance tools.

Choose a PCB based on your car's needs, circuit complexity, space available, and conditions it will face.

Common Wire-to-Board Connector Types

Wire-to-board connectors link cables to PCBs securely for smooth power or data flow. Here are common connector types found in cars:

Pin Headers

Pin headers use rows of pins to connect cables to boards simply. They're often seen in basic systems like power units because they're easy to install and affordable.IDC Connectors

IDC (Insulation Displacement Connectors) attach flat cables without removing wire insulation first, saving time in small spaces.Crimp Connectors

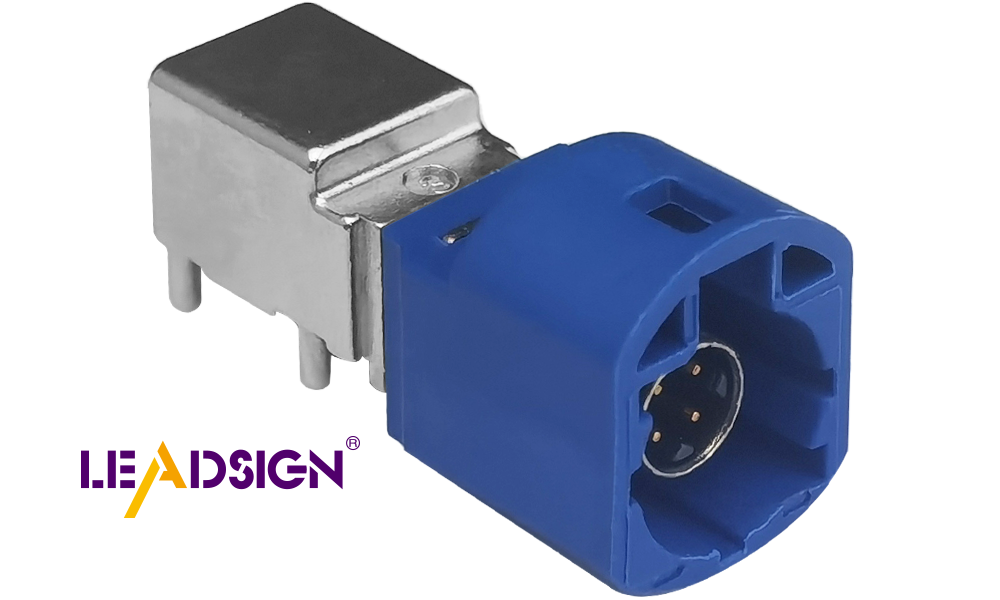

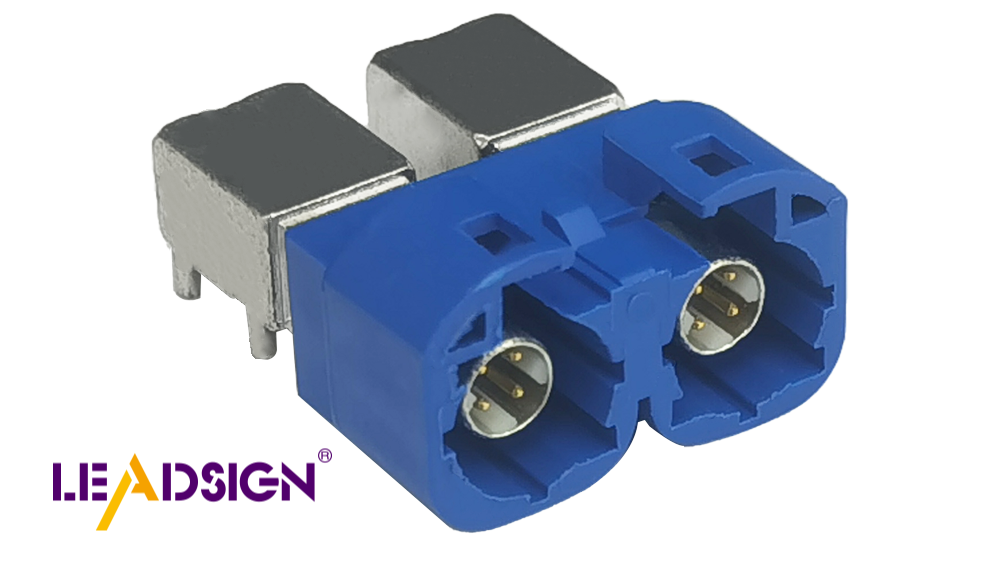

Crimp connectors secure wires with crimped ends tightly attached to terminals, ideal for high-vibration spots like engines.HSD Connectors

High-Speed Data (HSD) connectors transfer data quickly for things like cameras or USB ports while staying locked securely during use.PCB-Mounted Connectors

These attach directly onto the PCB itself, cutting down extra wiring needs while saving space in compact setups.Terminal Blocks

Terminal blocks make connecting/disconnecting wires easy when frequent maintenance is needed later on.

Pick connectors based on what they’ll do, speed needed, and where they'll be placed in the car system! Always go for quality options that last longer!

Tips for Picking Car Electronics Parts

How to Choose PCB Boards

Picking the right PCB for your car needs thought. First, figure out where it will be used. For tight spaces like doors or dashboards, use flexible PCBs. For stable areas like control units, pick rigid PCBs. If your system needs fast data or complex circuits, go for HDI PCBs or multilayer PCBs. These reduce signal problems and handle advanced tasks well.

Think about how tough the PCB is. Car systems face heat, shaking, and wet conditions often. Use metal-base PCBs, like aluminum or copper ones, as they last longer in harsh places. For engine controls or power systems, try component-embedded PCBs to save space and improve performance.

Size matters too! Make sure the PCB fits in its spot in the car. Compact designs like flex-rigid PCBs are great for tricky setups like cameras or sensors because they bend but stay strong. Always choose quality over cheap prices since good parts last longer and need fewer repairs.

How to Pick Wire-to-Board Connectors

Choosing good connectors keeps your car's electronics working well. Start by checking how much electricity your system uses. Ensure the connector can handle it without breaking down. For fast data systems like cameras, use HSD connectors, which are secure and quick.

Look at where the connector will be placed in the car. In wet or dusty spots, pick sealed connectors to block damage. Near engines with lots of shaking, use strong-grip options like crimp connectors, so they don’t come loose.

Match the connector size to your wires and PCB design too! Flat cables work best with IDC connectors, while basic systems do fine with pin headers. In small spaces, try using space-saving types like PCB-mounted connectors, which make setup easier.

Lastly, think about repairs later on. If you’ll need frequent fixes, go for easy-to-use options like terminal blocks, which don’t need special tools to adjust wires quickly. After installing everything, test it all to ensure it works properly.

By following these tips, you’ll find reliable PCBs and connectors that keep your car safe and running smoothly for a long time.

Common Mistakes to Avoid

Wrong Parts

Using the wrong parts can harm your car's electronics. Always check that connectors match your PCB and system needs. For instance, a connector not made for high voltage may overheat or fail. Mismatched connectors can also slow data in fast systems like cameras.

The size and shape of the connector are important too. If it doesn’t fit well, it might come loose. Loose connections cause systems to fail or stop working completely. Make sure the connector pins line up with the PCB design and cables fit properly.

Think about the type of cable you’re using as well. Flat cables work best with IDC connectors, while round ones need crimp connectors. Picking the right pair helps power and data flow smoothly, keeping your car’s electronics reliable.

Ignoring Environment

Not thinking about conditions can damage electronic parts quickly. Car systems face heat, water, and shaking often. Without waterproofing, moisture can get in and cause rust or shorts. This is a big problem for parts near rain or hot engines.

Heat changes affect how PCBs and connectors work too. A connector near an engine must handle heat without breaking down. Outside parts should block dust and dirt as well. Sealed connectors are great because they keep out harmful stuff.

Driving vibrations can loosen weakly secured parts easily. Use strong-locking options like crimp connectors to avoid this issue. Flexible PCBs are better than rigid ones for places like doors since they handle movement well.

By preparing for these challenges, your car’s electronics will last longer and work better overall.

Choosing the right PCB and connector is very important. Good parts make your car safer and work better. Always check if they fit your car’s systems. Think about heat, water, or other tough conditions too. Research and test to avoid expensive problems later. For example, water can harm circuits and cause failures. Strong connectors and good PCBs keep your car's electronics working well for a long time.

FAQ

What do PCB connectors do in car electronics?

PCB connectors join electronic parts in your car. They help systems like sensors and cameras work together. Strong connections improve how safe and efficient your car is.

Why are car PCBs made for tough conditions?

Car PCBs face heat, shaking, and wetness often. They use strong materials like copper to handle these challenges. This keeps your car's electronics working well over time.

How can I pick the right PCB for my car?

First, know what your system needs. Flexible PCBs fit tight spaces easily. Multilayer PCBs work best for advanced tools like GPS. Match the size and material to where it will be used.

Why are HSD connectors good for cars?

HSD connectors send data fast, great for cameras or USBs. Their locks keep them secure even when there’s a lot of movement.

Can all car systems use standard parts?

No, not every system can use standard parts. Safety features need strong connections, while entertainment systems need fast data transfer. Pick parts that match each system’s job.

How do conditions affect PCB and connector performance?

Heat, water, and vibration can harm weak parts. Unsealed connectors might let water in, causing rust or damage. Sealed ones protect better in tough spots.

Why use flexible PCBs in cars?

Flexible PCBs bend to fit small or odd spaces like doors. They also handle movement well, lasting longer in cars.

How can I make my car’s electronics last longer?

Use high-quality PCBs and connectors that resist heat and water. Check them often to avoid wear or damage. Good parts save money by lasting longer.

What mistakes should I avoid with PCB connectors?

Don’t pick mismatched parts that don’t meet voltage needs. Wrong types may cause loose connections or slow data flow. Always check if they fit your design and location.

Why test PCBs and connectors after installing them?

Testing makes sure everything works properly together. It finds problems like loose wires early on. Testing ensures safety before you start using the system regularly.

See Also

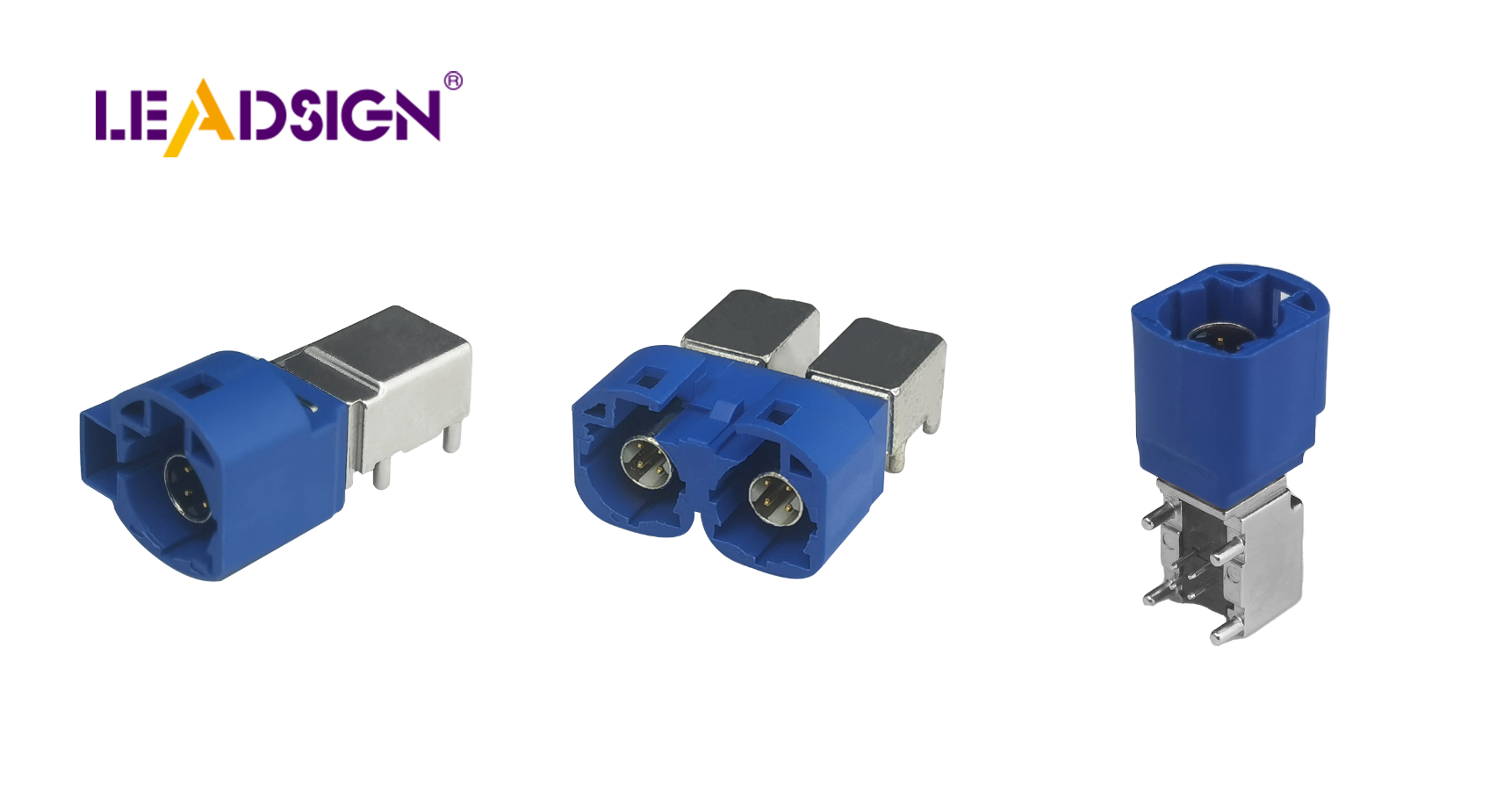

Why FAKRA PCB Connectors Matter for Car Communication

Key Benefits of FAKRA PCB Connectors for Vehicles

Boosting Vehicle Communication Through FAKRA PCB Connectors