How to Select PCB Board to Wire Connectors for Automotive Projects

Choosing the right PCB board to wire connectors is crucial. Cars operate under challenging conditions such as heat, vibration, and moisture, which can cause electrical connections to fail or break. High-quality PCB board to wire connectors are designed to withstand these issues effectively. They maintain strong connections even under intense vibration, preventing wires from coming loose and ensuring safety. Selecting the appropriate connectors enhances the performance of your project and increases the longevity of your cable systems.

Key Takeaways

Choose high-quality PCB connectors to ensure strong electrical connections that withstand heat, vibration, and moisture in automotive environments.

Understand the current and voltage limits of connectors to prevent overheating and ensure safe operation in your car projects.

Select connectors with high Ingress Protection (IP) ratings to guard against dust and water, especially in outdoor or engine areas.

Opt for vibration-resistant connectors with strong locking mechanisms to maintain secure connections during the constant movement of vehicles.

Consider the materials used in connectors; thermoplastics and metal alloys provide durability and resistance to harsh conditions.

Test connectors under real-life conditions to ensure they meet performance standards and can handle the challenges of automotive applications.

Match connector features to your project's specific needs, including size, speed, and environmental conditions, for optimal performance.

Understanding PCB Board to Wire Connectors

What Are PCB Board-to-Wire Connectors?

PCB board-to-wire connectors join a circuit board and a cable. They let electricity or signals move smoothly between parts. These connectors are very important in cars for safety and good performance.

There are different types, like wire-to-board or board-to-board connectors. Each type is made for specific needs in projects. For instance, Hirose's Automotive Connector Series offers strong options that meet tough car standards. They work well even in hard conditions.

Key Features of PCB Board-to-Wire Connectors

Good-quality PCB connectors have features for tough environments. These features help your car project work well over time:

Durability: Some, like the ZE05 Series 0.5mm Terminal, handle heat and shaking.

High-Speed Transmission: A few can send data up to 2.2Gbps, perfect for modern car tech.

Shielding: Shielded designs block interference to keep signals clear.

Locking Mechanisms: Locks stop wires from disconnecting during heavy vibrations.

These features make these connectors a safe choice for cars where safety matters most.

Common Applications in Automotive Projects

PCB board-to-wire connectors are used in many car systems. You’ll see them in:

Infotainment Systems: Fast connectors like the HSD Connector help USB and networks work smoothly.

Safety Systems: Strong connections keep cameras and sensors working without problems.

Power Distribution: Wire-to-board types move power between circuit parts easily.

Telecommunication Modules: These support radios and communication devices inside vehicles.

Picking the right connector improves how your car project works and lasts longer.

How to Pick PCB Connectors for Cars

Checking Current and Voltage Limits

Knowing the current and voltage rating is very important. Each pcb connector can handle only a certain amount of current. If too much flows, it may overheat or stop working. Match the connector's limit with your system's needs. For high-current systems, pick heavy-duty connectors. These prevent overheating and keep things running smoothly.

Voltage limits matter too. They show how much voltage a connector can safely take. Going over this limit can cause damage like sparks or insulation failure. Always check that the voltage rating fits your system’s needs. This keeps your printed circuit board safe and working well.

Considering Temperature and Environment Protection

Car parts face extreme heat, cold, and dirt often. Choose a pcb connector that handles these tough conditions easily. Look for materials that stay strong in both hot and cold weather.

Protection from water and dust is also key. Some connectors have IP ratings showing their resistance levels. For outdoor or engine areas, use higher-rated connectors. This choice guards your cable setups and printed circuit board, making them last longer.

Picking Vibration-Resistant Connectors

Cars shake a lot during use, which can loosen weak connectors. To avoid this, pick ones with strong locking systems. These locks hold the cable tightly to the pcb connector, even when shaking happens.

Also, look for features like crimp connections or high grip strength in connectors. These make sure connections stay firm under pressure or shocks. Using vibration-resistant connectors makes your system dependable in hard situations.

Understanding Ingress Protection (IP) Ratings

IP ratings show how well a pcb connector blocks dust and water. The system uses two numbers to explain protection levels. The first number tells how much it stops dust or solid objects. The second number shows how well it handles liquids like water. For example, an IP67 connector fully blocks dust and resists water for short periods.

In car projects, pick connectors with high IP ratings. Cars often deal with rain, mud, and dirt. A low-rated connector might fail in these tough conditions. This can cause problems in your system. For outdoor or engine use, choose IP67 or higher-rated ones. These keep your cable and printed circuit board safe.

Think about where the connector will go before choosing its rating. Inside systems like screens may need lower ratings. Outside parts or under-the-hood areas need higher ones. High ratings protect your project from damage and make it last longer.

Choosing Strong Materials for Long Use

The material of a pcb connector affects how long it lasts. Car parts face heat, shaking, and chemicals often. Picking strong materials helps connectors survive these challenges.

Thermoplastics resist heat and rust, great for hot places in cars. Metal alloys are strong and work well in shaky spots too. These materials keep the cable connection steady even under stress.

Check the plating on the connector as well. Gold or tin plating improves electricity flow and stops rusting over time. This keeps connections stable in hard conditions.

Match materials to where you’ll use them in your car project. Engine bay connectors need heat-proof materials while cabin ones don’t need as much protection. Using the right material ensures good performance and fewer failures later on.

Types of PCB Cable Assembly Connectors for Automotive Projects

Picking the right connector is very important for your car project. Different connectors do different jobs, so knowing their features helps a lot. Here are some common connectors used in cars.

Wire-to-Board Connectors

Wire-to-board connectors connect wires to circuit boards safely. They move power and signals between parts easily and securely.

These connectors are simple to use and work in many places. They often have locks to stop wires from coming loose during shaking. Their small size fits tight spaces like dashboards or panels. Always check they can handle your system’s power needs before using them.

Sealed Connectors for Tough Conditions

Sealed connectors are made for harsh car environments. They have covers that block water, dirt, and chemicals, keeping them safe.

These connectors usually have high IP ratings like IP67 or more. This means they can handle dust and even short dips in water without breaking. Using sealed connectors protects your system from damage caused by tough conditions.

High-Speed Data (HSD) Connectors for Electronics

HSD connectors help send fast data in modern car systems. They’re great for things like screens, cameras, or driver-assist tools.

These connectors stop signal problems with special shields and stay strong under stress. Their design keeps data moving smoothly between devices like USBs or Ethernet ports. Adding HSD connectors makes sure your car tech works well every time.

By learning about these connector types, you can pick the best ones for your project needs. Each type has special benefits to keep your project safe, working well, and lasting long.

Small Connectors for Tight Spaces in Cars

Small connectors are important for car projects with little space. They help make designs work well without losing quality or strength. Their tiny size fits perfectly in tight spots like dashboards or control panels.

When picking these connectors, check if they stay strong despite being small. Good-quality ones have locks to keep cables attached during shaking. This is very important because cars move and vibrate a lot.

These connectors also make connecting cables easier and faster. Their design saves time when attaching them to the printed circuit board. This is helpful in big car factories where speed matters.

There are different types of small connectors for various jobs. Some send data quickly, great for screens or safety tools in cars. Others focus on giving power safely in small spaces. Knowing the types helps you pick the right one.

The material of these connectors must handle tough car conditions like heat and dirt. Strong materials like thermoplastics or metal alloys work best as they last long and resist damage.

IP ratings show how well a connector blocks dust and water. Higher ratings like IP67 protect better in hard conditions outside or under the hood.

Small connectors save space but still perform well. Picking the right ones ensures your car project works smoothly and lasts longer.

Step-by-Step Guide on How to Choose PCB Connectors

Understand Your Project's Needs

First, figure out what your project requires. Think about the electrical needs like current and voltage levels. If your system uses fast data transfer, choose High Speed Transmission Connectors. These connectors keep signals clear and parts connected.

Physical space is also important. Check how much room you have for the connector. Small designs, like the FH75/FH75M Series, fit tight spaces well. They are strong and reliable, perfect for car projects. Knowing these details helps you pick the right connector.

Match Connector Features to Surroundings

The environment affects how connectors work. Hot or dirty places can harm them. Pick ones with features that match these conditions. For example, Sealed Connectors block water and dust with IP67/IP68 ratings, great for outdoor use.

Heat resistance matters too. Some connectors, like the FH75/FH75M Series, handle heat up to 125℃ easily. This makes them good for hot areas in cars. Choosing connectors based on their features ensures they last longer.

Check Fit with PCB and Cables

The connector must fit your circuit board perfectly. A bad fit can cause weak connections or failures later on. Good-quality connectors are easy to install and stay secure.

Think about the cables it supports too. For instance, High Speed Transmission Connectors work well with shielded FPC/FFC cables for fast data use. Strong locks in Sealed Connectors keep wires attached even when shaking happens.

By checking these points, you’ll find a connector that works well and improves your project’s performance.

Test and Check Connectors for Real-Life Use

Testing connectors ensures they work well in real car conditions. This step finds problems before adding them to your project. Follow these steps to check if connectors meet your needs:

Simulate Tough Conditions

Test connectors in heat, shaking, and wetness to check strength. For example, the FH75/FH75M Series can handle up to 125℃ and stay reliable. Do similar tests to ensure your connectors survive harsh car environments.Check Electrical Work

Test how much current and voltage the connector handles safely. Make sure it doesn’t overheat or lose power efficiency. Fast connectors like High Speed Transmission Connectors should also be tested for clear signals without data loss.Test Lock Strength

Check how strong the locks are on the connector. Strong locks stop cables from coming loose during shaking or bumps. Sealed types with IP67/IP68 ratings are waterproof and great for outdoor or engine use.Match with Cables

Try the connector with your actual cables to see if they fit well. Ensure connections stay firm under stress. Products like Sealed Connectors and High Speed Transmission Connectors work with many cable types for flexibility.Do Long-Use Tests

Simulate long-term use to find wear issues early on. This shows if materials last through repeated use without breaking down. The FH75/FH75M Series, for instance, uses strong materials that perform well over time.

By testing thoroughly, you ensure connectors meet safety and performance needs for cars. This process reduces risks and improves system reliability overall.

Choosing the right PCB connectors is very important for car projects. Think about things like current limits, toughness, and lasting strength. Good connectors make systems safer and last longer. Check what your project needs for power and strength. Test them in real situations to see if they work well. Picking the right ones helps create strong systems that handle tough car conditions.

FAQ

What should I think about when picking car PCB connectors?

Focus on strength, vibration resistance, and heat handling. Car parts face high heat and constant shaking. Choose connectors that follow the USCAR-20 rules for lasting performance. Also, check IP ratings to ensure they block dust and water.

How can I make sure connectors fit my cables?

Check your cable's details first. Make sure the connector works with your cable type and size. Some connectors are made for shielded cables, great for fast data transfer. Test them with your cables to confirm a snug fit.

Why is vibration resistance important in car connectors?

Cars shake a lot, especially near engines or suspension parts. Weak connectors may loosen and cause problems. Vibration-resistant ones have locks to keep cables secure. This keeps systems working well even in tough conditions.

What does an IP rating mean for connectors?

IP ratings show how well a connector blocks dust or water. The first number rates solid protection; the second rates liquid protection. For cars, use IP67 or higher-rated ones to protect against dirt and rain.

Can one connector work everywhere in my car project?

No, different areas need different types of connectors. Engine bay ones need heat-proof materials, while cabin ones can be smaller but strong. Pick based on each area’s needs for better results.

How do I test if connectors handle real car conditions?

Test them under heat, shaking, and wetness like they’ll face in use. Sealed IP67 types work well in wet spots. Also test their current and voltage limits to avoid failures later.

Why are high-speed data connectors useful in modern cars?

They send data quickly without errors—great for screens or cameras. These often have shields that stop signal issues so devices work smoothly together.

Are small-sized connectors good for cars?

Yes, compact ones save space but still perform well. They’re great for tight spots like dashboards and often include locks to stay secure during shaking.

How do I pick the right material for my connector?

Material matters for durability and strength. Thermoplastics resist rust and heat; metals handle vibrations better. Match materials to where you’ll use them—for example, engine bays need heat-proof options.

Why is the USCAR-20 standard important for car connectors?

USCAR-20 ensures reliable connections over time by setting strict rules. Using these approved connectors means safer systems that last longer under tough conditions.

See Also

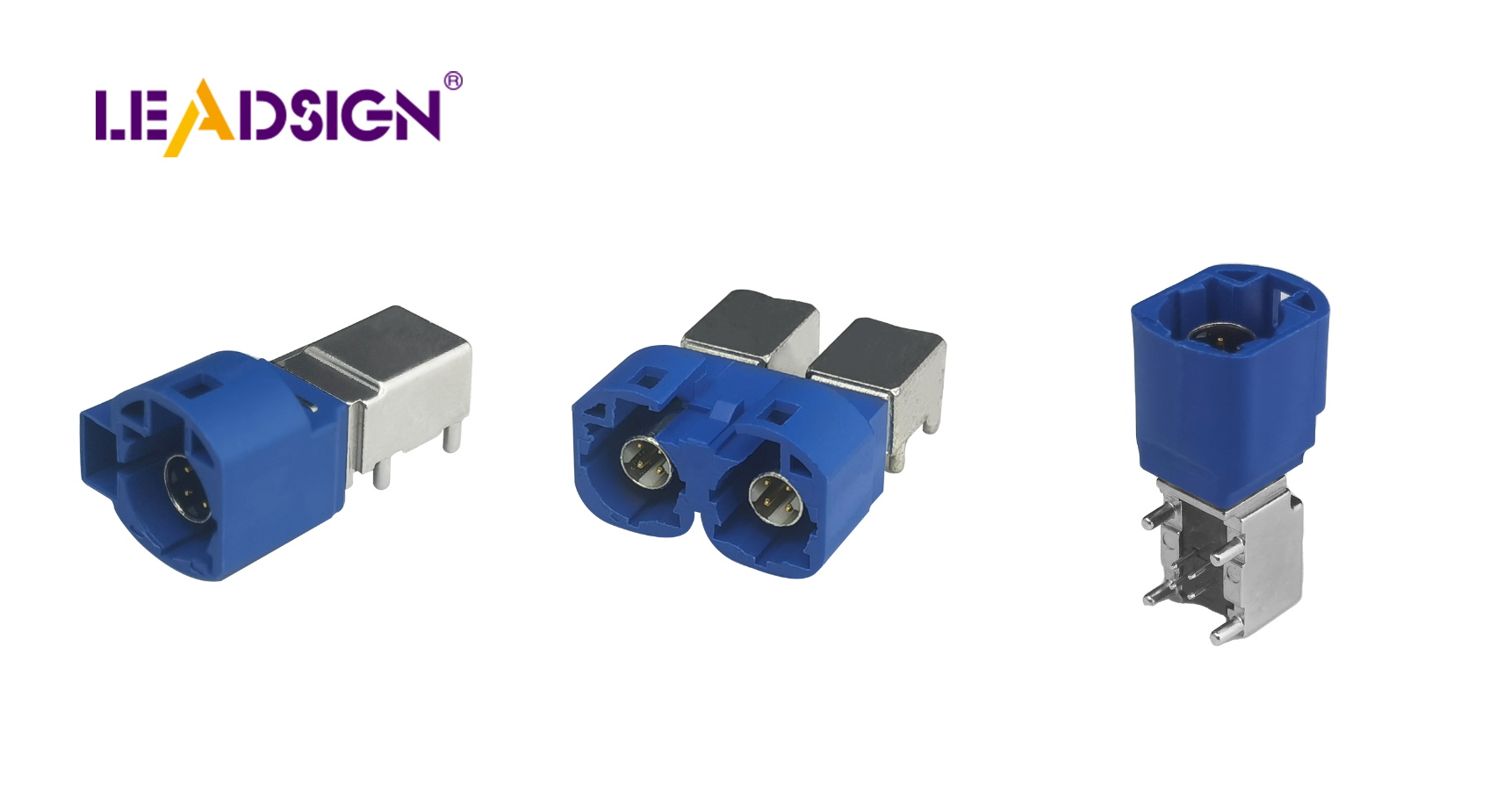

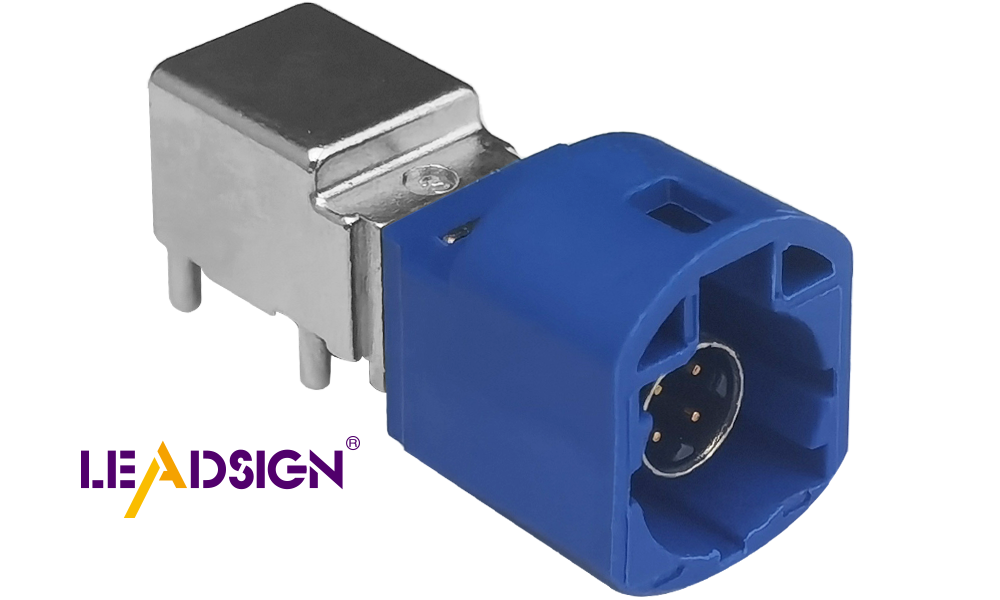

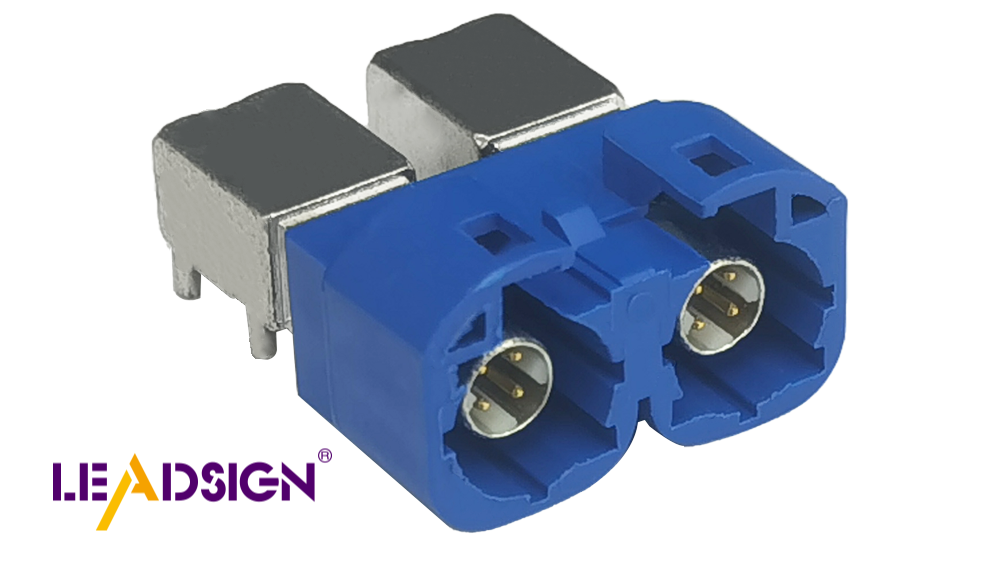

Exploring FAKRA PCB Connectors for Automotive Benefits

Why FAKRA PCB Connectors Are Essential for Automotive Use

Key Role of FAKRA PCB Connectors in Auto Communication

Improving Vehicle Communication Through FAKRA PCB Connectors