What Are the Different Types of PCB Board Wire Connectors for Automotive Use?

In today's car industry, strong electrical connections are very important. PCB board to wire connectors link circuit boards to outside wires. These connectors are made to handle tough conditions like heat, shaking, and wetness. The market for car connectors may grow from *USD 6.92 billion in 2023 to USD 13.27 billion by 2033*. Better car electronics increase the need for good PCB connectors.

Key Takeaways

PCB board-to-wire connectors are essential for linking circuit boards to external wires, ensuring reliable power and data transmission in automotive systems.

Different types of connectors, such as header connectors, FFC/FPC connectors, and terminal blocks, serve specific functions and are designed to withstand harsh automotive environments.

Choosing the right connector involves considering factors like material durability, resistance to heat and vibration, and the connector's current rating to ensure long-lasting performance.

High-Speed Data (HSD) connectors are crucial for modern vehicles, enabling fast data transfer for advanced systems like cameras and infotainment.

Proper selection of connectors can enhance the reliability and efficiency of car systems, contributing to overall vehicle safety and performance.

Smaller and lighter connectors can save space in vehicles, which is vital for modern automotive design, while still maintaining functionality.

Understanding the unique features and applications of each connector type helps in making informed decisions for automotive electrical systems.

The Role of PCB Board-to-Wire Connectors in Cars

PCB connectors are key to modern car electronics. They help parts communicate, making cars work well. Without them, systems like safety features and engines could fail. Knowing their role shows why they matter in cars.

Why Connectors Are Important in Cars

Connectors link circuit boards to wires in cars. They send power and data so all parts work right. For example, in smart driving systems, connectors move data from sensors to controls. This helps make safe and quick decisions.

Different connectors are made for different jobs. Some carry strong power, while others send small signals safely. Picking the right connector keeps systems working without problems.

Challenges for Connectors in Cars

Car environments are tough on connectors. They must work well even under hard conditions. Here are some challenges they face:

Handling Shaking and Bumps

Cars shake and bump a lot when moving. Weak connectors can break or come loose during this time. Strong car connectors stay secure with special locks and sturdy materials.

Dealing with Heat and Weather

Cars face hot summers and cold winters. Connectors must survive these temperatures without breaking down. Moisture, dust, or chemicals can also harm them. Good-quality ones resist rust and keep working well.

Lasting a Long Time

Car connectors need to last many years, often longer than the car itself. Repeated use can wear them out over time. Strong designs ensure they stay reliable for years.

"PCB connectors are vital for electronic devices to work well."

By solving these issues, car-grade PCB connectors keep vehicles running smoothly even in tough conditions.

Types of PCB Board-to-Wire Connectors for Automotive Use

Picking the right pcb connectors is key for cars to work well. Each type has unique uses, so knowing them helps.

Header Connectors

Header connectors are common types of pcb connectors in cars. They link circuit boards to other parts securely.

Pin Headers and Socket Headers

Pin headers and socket headers connect to make a strong link. Pin headers have metal pins in rows, while socket headers hold these pins in place. This setup makes fixing or upgrading easy.

Uses in Cars

Header connectors are used in car systems like ECUs, lights, and screens. They handle power and signals well. For example, pin headers work with high power like starter motors. Socket headers carry smaller signals safely.

FFC/FPC Connectors

FFC (Flexible Flat Cable) and FPC (Flexible Printed Circuit) connectors save space and are light, great for tight car designs.

Features of Flexible Flat Cable Connectors

These connectors join flexible cables to PCBs. Their slim design saves room and weight. They also send data fast between parts.

Where They're Used in Cars

You’ll find FFC/FPC connectors in things like GPS, touchscreens, and cameras. Their bendable nature fits small spaces perfectly, such as rearview cameras where space is tight.

Terminal Blocks

Terminal blocks are tough wire-to-board connectors that stay secure even under stress.

Screw-Type and Spring-Loaded Terminal Blocks

Screw-type terminal blocks use screws to hold wires tightly. Spring-loaded ones use springs instead for a firm grip. Both types resist shaking and stress well.

Why They're Good for Car Wiring

Terminal blocks make wiring easier by joining many wires together quickly. They’re often found in power units or electric systems in cars. These blocks handle high currents and harsh conditions reliably over time.

"Choosing the right connector type based on application is crucial for ensuring the reliability and efficiency of automotive systems."

Knowing about these specialty pcb connectors helps improve your car’s electrical system performance.

Wire-to-Board Connectors

Wire-to-board connectors join outside wires to PCBs in cars. They provide stable and efficient electrical links, even in tough conditions. Their reliability makes them essential for modern vehicles.

Crimped and IDC (Insulation Displacement) Connectors

Two popular pcb connectors for wire-to-board use are crimped and IDC connectors. Each has special benefits for different car needs.

Crimped Connectors: These attach wires securely using a crimping method. This process creates strong bonds and excellent electricity flow. Crimped connectors are durable and handle high currents well. They work best in systems like ECUs or power distribution where long-term strength is needed.

IDC Connectors: IDC connectors make wiring easier by skipping insulation removal. Wires go directly into the connector, saving time and reducing mistakes. These are often used in infotainment systems or low-power signal setups where quick connections matter.

Common Automotive Applications

Wire-to-board connectors are vital in many car systems:

Safety Systems: They link sensors to control units in airbags or ABS.

Lighting Systems: These ensure steady power for headlights, taillights, or cabin lights.

Infotainment Systems: They help transfer data for audio, navigation, or touchscreens.

Powertrain Control: These manage power between batteries, motors, and controls in electric cars.

Choosing the right wire-to-board connector improves your car's electrical performance.

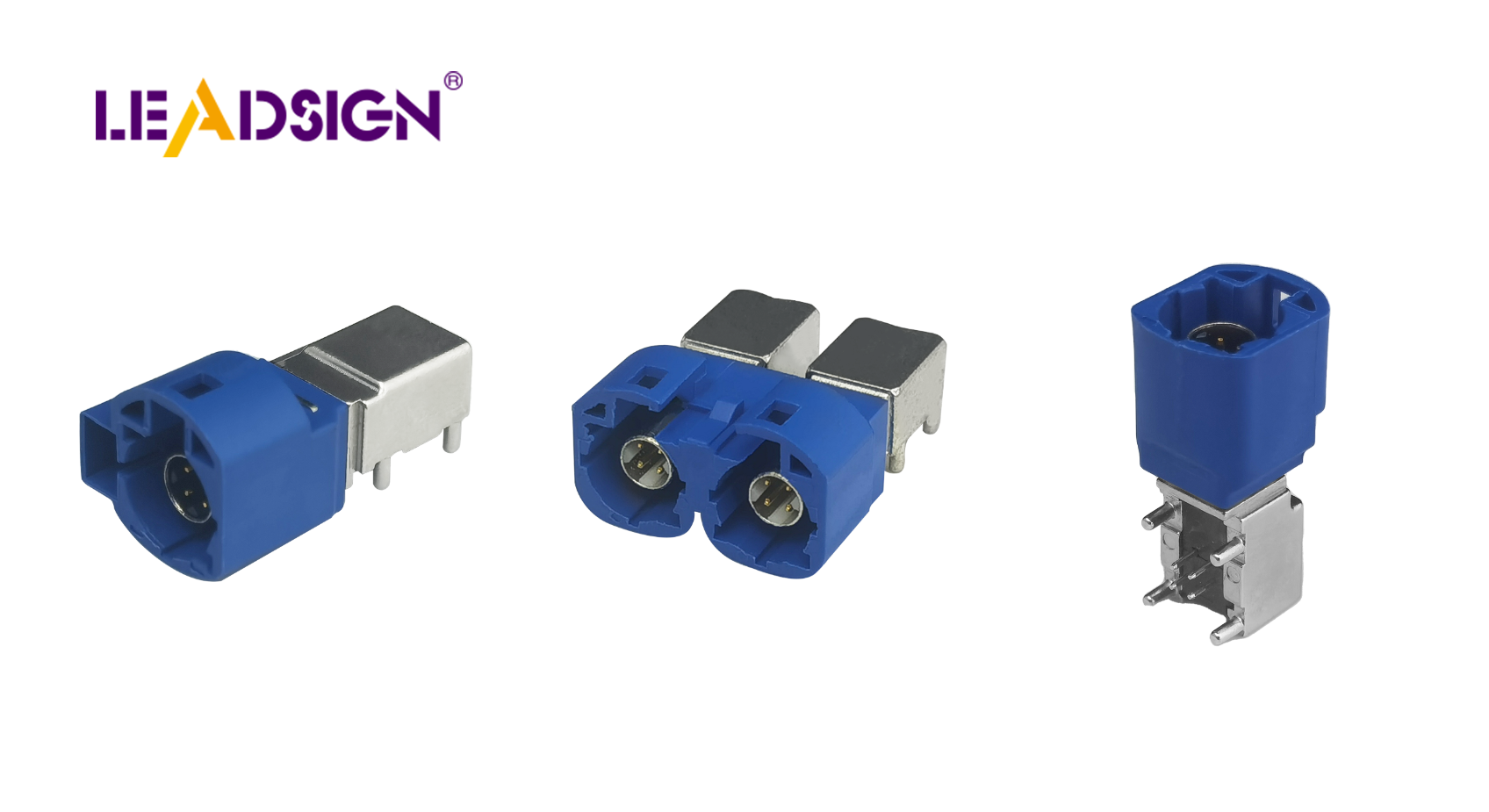

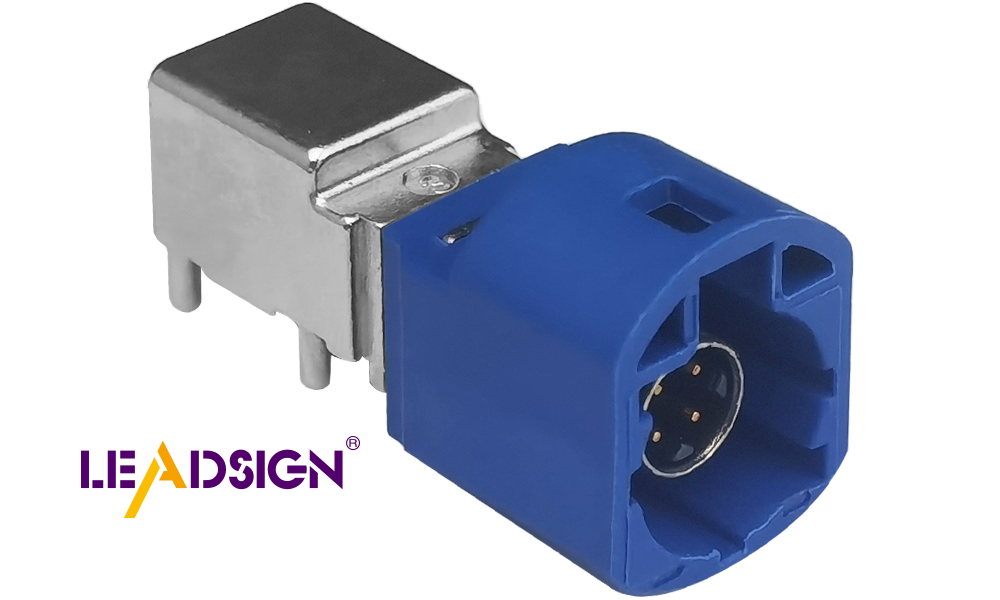

High-Speed Data (HSD) Connectors

High-Speed Data (HSD) connectors are special specialty pcb connectors made for fast data transfer in cars. Modern vehicles need these for advanced communication systems.

Features of HSD Connectors

HSD connectors have features that suit automotive needs:

Locking Mechanisms: These keep connections secure during vibrations.

Crimp Design: This ensures strong mechanical and electrical performance.

Cable Grip Strength: Cables stay firmly connected without slipping out.

Coding Options: Different codes prevent wrong connections, improving reliability.

These features make HSD connectors tough against heat, moisture, and stress.

Uses in Automotive Electronics

HSD connectors support fast data transfer in key areas:

Cameras/Sensors: They send data from cameras to control units for ADAS.

Infotainment: They enable smooth USB, Ethernet, or digital audio transfers.

Navigation/Displays: HSD helps GPS and screens share real-time information.

Adding HSD connectors boosts your vehicle’s system speed and efficiency.

Key Things to Check When Picking Automotive Connectors

Choosing the right connectors helps your car work well. These tips will guide you in picking reliable ones for tough conditions.

Strong and Long-Lasting Materials

Good connectors last a long time without breaking. They should be made from strong materials like thermoplastics or stainless steel. For example, pcb connectors with sturdy plastic covers and rust-proof metal parts stay reliable. These materials protect against damage from weather or wear.

Strong connectors also handle frequent use without failing. Whether it's wire-to-board connectors or others, durable designs stop problems caused by plugging and unplugging often. This is very important for systems like safety controls or power units that need to work all the time.

Staying Secure During Movement

Cars vibrate and bump a lot while driving. Weak connectors can come loose during this motion. To prevent this, pick ones with tight locks. Some specialty pcb connectors, like HSD types, have extra locks to keep them steady even when shaking happens.

Connectors with strong grips hold cables tightly in place too. This stops wires from disconnecting accidentally. In systems like engine controls or smart driving tools, secure connections keep power and data flowing smoothly.

Handling Heat and Weather Changes

Car connectors must survive hot summers and freezing winters without breaking down. High-quality pcb connectors are built to handle extreme temperatures safely. Heat-resistant materials won’t melt, and moisture-proof designs stop rust from forming.

HSD connectors are great for outdoor car parts like cameras or sensors because they resist dust, water, and chemicals well. By choosing weather-tough connectors, your car’s systems will work reliably in any condition.

"Picking the right connector features keeps your vehicle running smoothly."

By checking these points carefully, you’ll find the best types of pcb connectors for your car's needs. This ensures your vehicle stays safe, durable, and efficient over time.

Electrical Performance and Current Rating

When picking pcb connectors for cars, think about their power and data abilities. These decide how well they send electricity and signals in car systems. Bad connectors can cause signal issues or overheating, which might harm safety features or entertainment systems.

Good pcb connectors keep connections steady. They deliver power and data smoothly, even in tough situations. For example, wire-to-board connectors work with both low-power sensors and high-power parts like electric motors.

The current rating is also very important. It shows the most current a connector can carry safely. Picking the right rating keeps your car's systems working properly. Powertrain systems need connectors for high currents, while infotainment ones need precise low-power connections.

"Using a connector with the right current rating avoids problems and improves performance."

By focusing on these factors, your car's systems will stay reliable and efficient.

Connector Size and Space Constraints

Cars often have little room, so pcb connector size matters a lot. Small connectors fit tight spaces without losing function. Lighter connectors can also make cars use less fuel.

New designs like HSD PCB connectors save space but still transfer data fast. Their small size works well in dashboards, cameras, or screens where space is tight.

Smaller sizes should also be easy to install and fix later. User-friendly designs help avoid mistakes during setup or repairs. This is key for parts like navigation tools or driver-assist systems that may need updates often.

"Picking the right size helps save space while keeping systems strong."

By choosing wisely, you balance good design with working car electronics effectively.

PCB board to wire connectors are important for car systems. Picking the right one helps cars work well in tough conditions. Different connectors have special features for specific tasks. Some carry strong power, while others send data smoothly. Knowing about these connectors helps you choose better options. This improves how long and how well your car works. For safety or entertainment systems, good connectors make sure everything stays reliable and lasts a long time.

FAQ

What do PCB board-to-wire connectors do in cars?

PCB board-to-wire connectors link circuit boards to outside wires. They help send power and data smoothly. This makes important car systems like safety controls, screens, and engines work well.

"Without these connectors, cars couldn’t connect their electronic parts properly."

How can I pick the best connector for my car?

Choose a connector based on strength, power needs, and weather resistance. For tough conditions, use ones that handle heat and shaking well. Also, check size and fit for your system's needs.

How are wire-to-board and wire-to-wire connectors different?

Wire-to-board connectors join wires directly to circuit boards in small spaces. Wire-to-wire connectors link two wires together without using a circuit board. Each type has its own job in cars.

Why does vibration resistance matter for car connectors?

Cars move and shake all the time. Weak connectors might come loose or stop working. Strong car connectors stay secure with locks and tough materials during movement.

Can car connectors survive extreme temperatures?

Yes, good car connectors handle very hot or cold weather. Materials like strong plastics or steel keep them working in freezing winters or hot summers without breaking.

Why are crimped connectors useful in cars?

Crimped connectors tightly press wires into place for strong links. They last long and work well with high-power systems like engines or batteries in tough conditions.

How do HSD connectors help modern vehicles?

HSD (High-Speed Data) connectors send data quickly between cameras, sensors, or screens. They have locks to stay secure and codes to avoid wrong connections.

Are smaller-sized connectors better for cars?

Small-sized connectors save space but must still work well. FFC/FPC types are slim yet reliable for tight areas like dashboards or cameras where space is limited.

What should I check before buying a connector?

Look at power limits, temperature range, lifespan, and pin type. For example, high-power ones suit engines while low-power ones work best for screens or radios.

How do terminal blocks make wiring easier in cars?

Terminal blocks connect many wires quickly and securely together. Screw-type ones hold wires tightly while resisting shaking. They make wiring simple for power units.

See Also

Exploring FAKRA PCB Connectors' Benefits for Vehicles

Understanding HSD Connectors in Automotive Systems

FAKRA Connectors: Key Advantages for Automotive PCBs