How to Use PCB Board to Wire Connectors in Automotive Systems

PCB board-to-wire connectors are essential components in modern vehicles. They enable seamless power and data transmission, ensuring optimal functionality of various systems. These connectors establish robust connections between wires and circuit boards, which is crucial for the reliable operation of automotive electronics. They are widely used in systems such as infotainment, safety features, and driver assistance technologies. As vehicles continue to advance, pcb board to wire connectors play a vital role in maintaining the strength and efficiency of these systems, making them indispensable in today’s automotive industry.

Key Takeaways

PCB board-to-wire connectors are crucial for reliable power and data transmission in automotive systems, enhancing the performance of features like infotainment and safety technologies.

Choosing the right type of connector—such as pin headers, terminal blocks, or HSD connectors—ensures optimal functionality and durability in challenging automotive environments.

Proper installation of connectors is vital; use the right tools and techniques to create strong, lasting connections that can withstand vibrations and temperature changes.

Regular maintenance, including inspections for rust and misalignment, can prevent common connector issues and prolong the life of automotive electronics.

Adhering to industry standards like ISO 16750 and AEC-Q200 guarantees that connectors meet safety and performance requirements for automotive applications.

Investing in high-quality connectors from trusted brands reduces the risk of failures and enhances the overall reliability of your vehicle's electronic systems.

Understanding PCB Board-to-Wire Connectors

What Are PCB Board-to-Wire Connectors?

PCB board-to-wire connectors join wires to circuit boards. They help transfer power and data in vehicles. You can find them in systems like infotainment, ADAS, and EVs. These connectors are designed for secure and efficient connections. This ensures smooth operation of modern car electronics.

They are made to handle tough conditions in cars. They stay strong even with vibrations, heat changes, or moisture. Using these connectors improves your vehicle's electronic system performance.

Types of PCB Board-to-Wire Connectors

Choosing the right connector type is very important. Each type has its own purpose and benefits.

Pin Headers and Sockets

Pin headers have pins that fit into matching sockets. These create a secure connection that’s easy to disconnect and reconnect. They are great for testing or building new designs.

Terminal Blocks

Terminal blocks connect wires without soldering by using screws. They are simple to set up and adjust when needed. These work well where quick changes are required.

IDC (Insulation Displacement Connectors)

IDC connectors let you insert wires without removing insulation first. This makes them fast for large-scale production, like cable assemblies.

Crimp-Style Connectors

Crimp-style connectors use tools to attach wires tightly. They are strong and resist vibration, making them popular in cars.

Key Functions of PCB Board-to-Wire Connectors in Automotive Systems

These connectors keep automotive electronics working properly by doing key tasks:

Power Delivery

They move electrical power between parts, keeping systems like lights running smoothly.

Signal Transmission

Connectors also send data signals between sensors and control units for accurate performance.

Grounding and Shielding

They reduce interference from electromagnetic waves using grounding features, improving reliability.

Example: HSD Connectors in Automotive Applications

Fast data transfer for infotainment and safety systems

Modern cars need fast data transfer for advanced features. HSD (High-Speed Data) connectors help parts communicate smoothly. They work with USB, Ethernet, and LVDS to send lots of data quickly.

HSD connectors are used in digital infotainment systems. They make sure audio and video play without problems. In safety systems like cameras and sensors, they send real-time data to ECUs. This helps with important tasks like avoiding crashes or staying in lanes.

Using HSD connectors improves your car's electronics performance. Their ability to handle fast data makes them a key part of today’s vehicles.

Strong design with crimp connection and cable retention

HSD connectors are built to last in tough car conditions. They use a crimp connection that tightly joins wires to the connector. This strong bond reduces issues from shaking or movement.

Another great feature is their high cable retention force. Cables stay attached even on bumpy roads or during sudden impacts. Extra locks add more security, stopping cables from disconnecting accidentally.

These features make HSD connectors perfect for cars. They work reliably even under harsh conditions, ensuring long-lasting connections for your vehicle's systems.

Picking the Best PCB Board-to-Wire Connectors for Cars

Choosing the right connectors is very important for cars. Good connectors improve system performance and reduce repair needs. They also make your car's electronics last longer. Here’s how to pick the best ones.

Things to Think About

Check these key points before picking a connector:

Electrical needs (voltage, current, resistance)

Know your system's power needs first. Pick a connector that handles voltage and current safely. It should not overheat or waste power. Low resistance helps send power and signals better. For fast data systems like cameras, stable connectors are a must.

Strength and toughness

Cars face bumps and shakes often. Weak connectors can break easily in such conditions. Choose strong ones with crimp connections and good cable grip. These features keep them secure even during rough rides.

Resistance to heat, water, and shaking

Car parts deal with extreme weather and movement daily. Get connectors that resist heat changes, moisture, and vibrations well. HSD connectors work great in tough conditions like these.

Size and fit on circuit boards

Connectors must fit perfectly on your circuit board design. Modern cars need small parts due to limited space inside vehicles. Make sure they match the slots without causing issues for other components.

Important Standards for Automotive Connectors

Follow industry rules to ensure safety and quality:

ISO 16750 (Testing under real-world conditions)

This checks if connectors survive temperature changes, moisture, or shaking in cars.

AEC-Q200 (Stress tests for parts)

This standard makes sure parts stay strong under stress from heat or force.

Tips for Finding Good Connectors

Here are some helpful tips:

Look at trusted brands

Buy from known brands with good products. For instance, Rosenberger made HSD connectors in 2007, improving vehicle data transfer greatly.

Read reviews and examples

Check user feedback about durability or installation ease before buying. This helps you avoid problems later by choosing reliable options.

By following these tips and standards, you’ll find great PCB board-to-wire connectors for your car systems! They will help your car run smoothly while staying safe too.

Installing PCB Board-to-Wire Connectors in Automotive Systems

Installing PCB board-to-wire connectors correctly ensures they work well in cars. By using the right tools and steps, you can make strong connections that last, even in tough car conditions.

Tools and Materials You Need

Before starting, gather these important tools and materials:

Crimping tools: These help attach wires tightly to connectors. This makes them strong and able to handle vibrations.

Soldering equipment: Use a soldering iron and wire to join wires permanently to the PCB connector.

Heat shrink tubing and insulation materials: These protect connections from water or heat, making them last longer.

Steps for Installation

Follow these simple steps to install connectors properly:

Get the PCB and wires ready

Clean the PCB to remove dirt or dust. Strip off some wire insulation so you can connect it securely. Make sure the wires fit your connector type.Attach the connector to the PCB

Place the connector on the PCB as per its design. For through-hole types, put pins into holes; for surface-mount ones, align with pads. Solder it firmly onto the board.Connect wires to the connector

Use crimping tools to fix wires onto terminals tightly. If needed, solder this connection too for extra strength. Cover it with heat shrink tubing and seal by heating.Test your connection

After finishing, check everything with a multimeter. Look for proper continuity without loose parts or breaks. This ensures your setup works perfectly.

Tips for Better Installation

Following good practices helps make connections stronger and last longer:

Align parts carefully

Match connector pins exactly with holes or pads on PCBs. Misalignment can cause weak links or damage components.Don’t over-tighten connectors

Use just enough force when securing parts together; too much pressure might break them.Use strain relief methods

Add supports like clamps or ties around cables to reduce stress on wires, preventing wear over time.

Tip: Follow rules like RoHS and AEC-Q200 standards for safety checks. They confirm that connectors meet strict car-use needs like handling stress from weather changes or hazardous materials.

By sticking to these steps and tips, you’ll install PCB board-to-wire connectors easily! Your car systems will then work reliably even under hard conditions.

Common Problems with PCB Board-to-Wire Connectors

PCB board-to-wire connectors are strong but can face problems. Finding these early helps keep your car systems working well.

Loose or Weak Connections

Connections can loosen from wear or poor alignment. Car vibrations over time lower contact pressure, causing unstable links. This might lead to power cuts or signal problems, affecting system performance.

Expert Tip:

"Keeping good contact pressure is key for stable connections. Low pressure can cause weak signals or lost links."

Rust or Surface Damage

Moisture and bad weather may cause rust on connectors. This harms electrical contact, lowering efficiency and possibly breaking systems. Rust happens more in humid places or where temperatures change a lot.

Connector Breaks from Shaking or Hits

Cars shake and sometimes hit bumps, which can harm connectors. If not installed well or made of weak materials, they may crack, loosen, or fail completely. Broken connectors hurt the system's strength.

Fixing Connector Issues

When problems show up, fixing them quickly helps maintain proper function.

Checking for Visible Problems

Look closely at the connectors for cracks, rust, or wear signs. Check if pins and sockets align correctly since misalignment disrupts connections.

Testing with a Multimeter

A multimeter checks if the circuit is complete without breaks. Use it to find weak spots and ensure steady readings for solid connections.

Replacing Bad Parts

Replace broken wires or connectors right away with quality ones like pcb-mounted types. Avoid cheap options as they might break under tough conditions.

Pro Tip: Strong materials built for cars last longer and prevent future issues.

Preventing Future Problems

Preventative care reduces connector troubles before they happen. Follow these steps to protect your systems:

Regular Checks and Cleaning

Inspect often for rust, dirt, or misalignment signs. Clean parts regularly to remove anything that could block their work.

Adding Protective Covers

Use coatings against moisture damage and enclosures to guard from dust and shakes. These steps make your connectors last longer in harsh environments.

Expert Advice:

"Choosing durable designs improves safety and reliability in modern vehicles."

By solving common issues early and maintaining parts well, you’ll keep your car’s electronics running smoothly!

Choosing the right connectors is very important for cars. Strong connectors handle vibrations and shocks without breaking. Good ones, like HSD connectors, last longer in tough conditions. Weak or cheap ones often fail when stressed. Make sure to install them properly by aligning parts carefully. Don’t use too much force during installation to avoid damage. Pick trusted brands and use good tools for better results. This helps your car’s electronics work well and stay reliable for a long time.

FAQ

What are PCB board-to-wire connectors used for in automotive systems?

These connectors help move power and data in cars. They connect wires to circuit boards, making systems like infotainment and safety features work well. They also make repairs easier and improve system strength.

Why is selecting the right connector important for vehicles?

Picking the right connector keeps car systems working properly. Cars face tough conditions like shaking, heat changes, and wetness. A strong connector handles these challenges, lasts longer, and prevents failures.

How do I know if a connector meets automotive standards?

Check for labels like ISO 16750 or AEC-Q200. These tests ensure connectors survive real-world challenges such as vibrations or temperature shifts. Certified ones work reliably over time.

What makes HSD connectors suitable for automotive applications?

HSD connectors send large amounts of data quickly. This makes them great for infotainment and safety features. Their strong build keeps them secure even during shakes or impacts.

How can I prevent connector failures in my car?

To avoid problems:

Check often for rust or loose parts.

Use covers to protect from water and dirt.

Pick high-quality connectors that meet rules like USCAR-20.

What tools are essential for installing PCB board-to-wire connectors?

You’ll need:

Crimping tools to attach wires tightly.

Soldering equipment to create lasting connections.

Heat shrink tubing to shield connections from damage.

Can I use any connector for automotive systems?

No, not all connectors are made for cars. Automotive ones must handle shaking, heat, and moisture well. Always choose those designed specifically for vehicles.

What are common causes of connector failure?

Failures happen due to:

Loose links from shaking over time.

Rust caused by water exposure.

Damage from hits or bad installation practices.

How do wire-to-wire connectors differ from PCB board-to-wire connectors?

Wire-to-wire ones join two wires directly together. PCB board-to-wire ones link wires with circuit boards, helping electronic systems work smoothly.

How does the rise of electric vehicles (EVs) impact connector design?

EVs need better-designed connectors now more than ever before! Modern ones must be small but strong while handling fast data transfer.

See Also

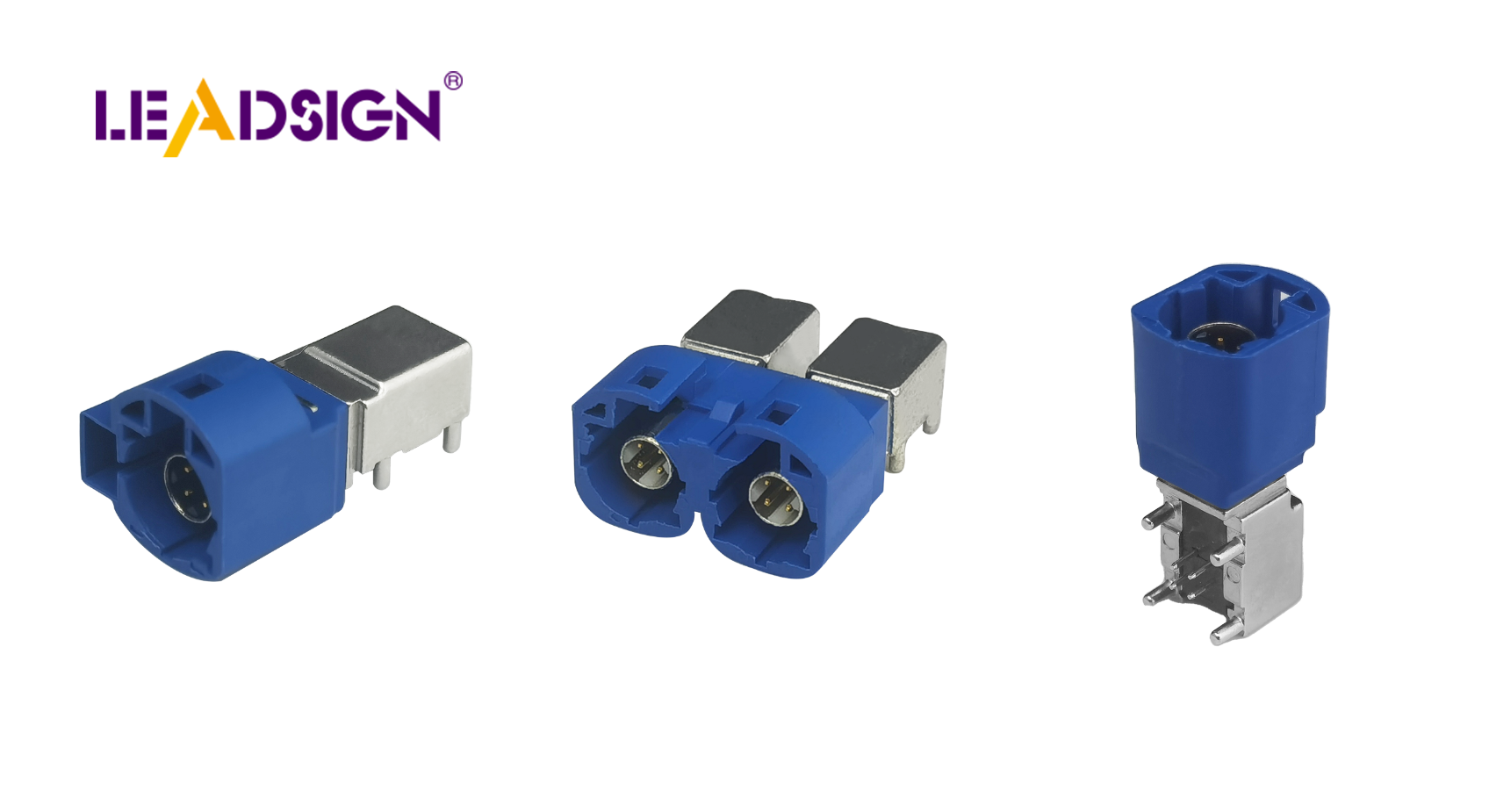

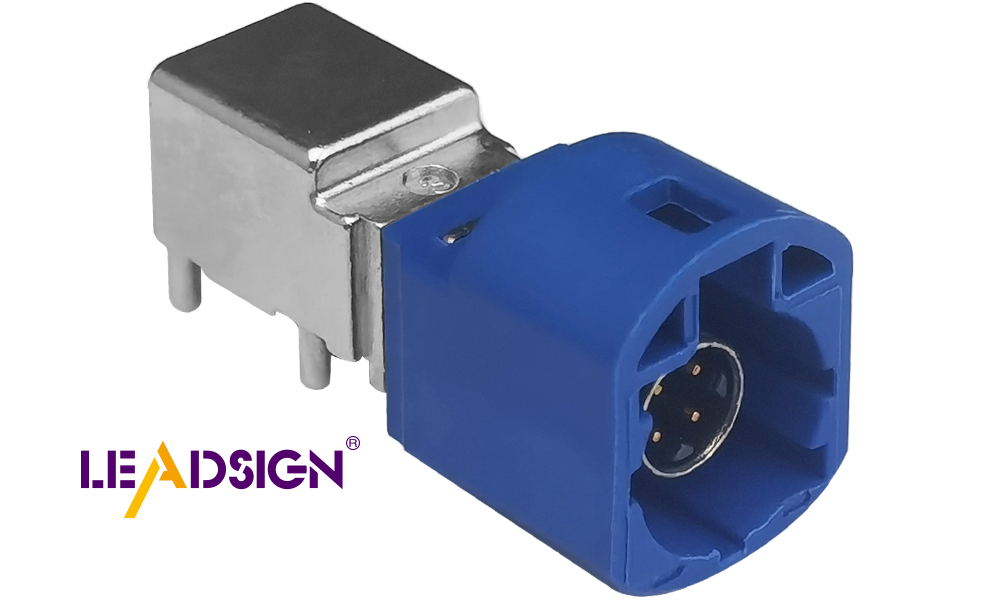

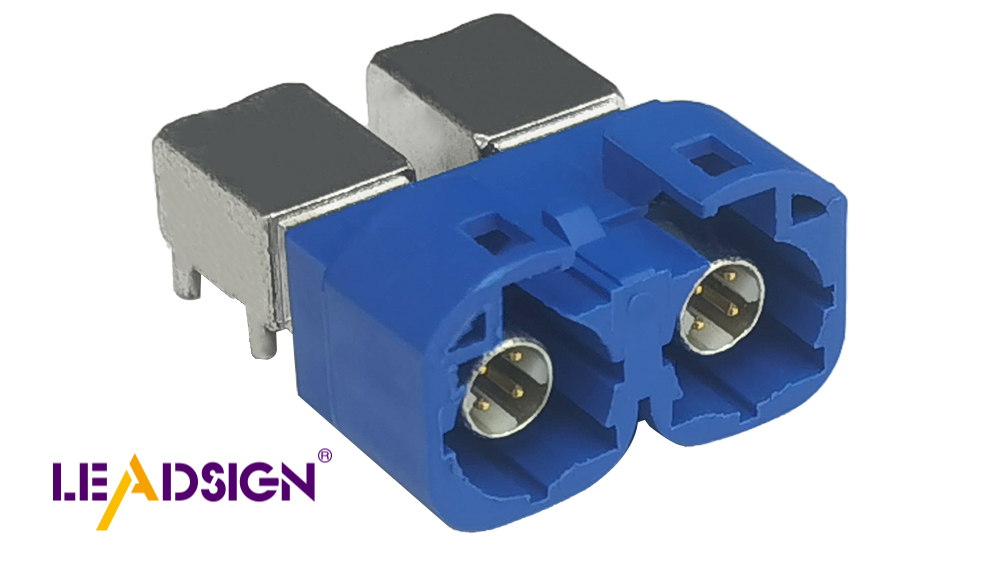

Why FAKRA PCB Connectors Are Essential for Automotive Use

Exploring FAKRA PCB Connectors' Benefits for Automotive Systems

Improving Vehicle Communication Through FAKRA PCB Connectors

Key Benefits of FAKRA Connectors for Automotive PCBs

Boosting Automotive Data Transfer Using FAKRA PCB Connectors