Exploring PCB Board Wire Connectors for Auto Wire Applications

PCB board to wire connectors are important components of electronics. They connect wires to the circuit board easily, facilitating the smooth transmission of power and signals. This functionality is crucial for automotive systems to operate effectively. In vehicles, these connectors are utilized in wiring, sensors, and displays. Their compact design conserves space in confined areas. Durable materials ensure they withstand challenging conditions. As automotive electronics advance, these connectors enhance system performance and longevity.

Key Takeaways

PCB board to wire connectors are essential for connecting wires to circuit boards, ensuring efficient power and signal transmission in automotive systems.

Choosing the right type of connector, such as pin headers, terminal blocks, or High-Speed Data (HSD) connectors, is crucial for optimizing performance and reliability in vehicles.

Durable connectors are designed to withstand harsh automotive conditions, including heat, vibrations, and moisture, enhancing the longevity of car electronics.

Using PCB connectors simplifies maintenance and repairs, thanks to their quick-disconnect designs that allow for easy part replacement without special tools.

Investing in high-quality connectors can save money in the long run by reducing production costs and minimizing the need for repairs.

Understanding the specific electrical and environmental requirements of your automotive systems is key to selecting the most suitable connectors.

Adopting standardized connectors ensures compatibility with future technologies, making it easier to upgrade and maintain modern vehicles.

Understanding PCB Board to Wire Connectors

What Are PCB Board to Wire Connectors?

PCB board to wire connectors are key parts of electronics today. They link wires securely to circuit boards, allowing power and signals to flow easily. These connectors are very important for making electronic systems work well, especially in cars.

In vehicles, these connectors handle tough conditions. They resist high heat, shaking, water, and chemicals. Their strength helps them last a long time. For example, automotive connectors are built to handle heat and vibrations, making them great for rough environments. This toughness is needed for things like engine controls and safety systems.

As car electronics become more advanced, better connectors are needed. Cars now use more sensors and electric systems than ever before. Strong PCB connectors improve how these systems work while keeping designs small.

How Do PCB Board to Wire Connectors Work in Automotive Systems?

In cars, PCB board to wire connectors connect electrical parts together. They help send power and data between different systems so everything works smoothly. For example, they join wiring harnesses with circuit boards so sensors can talk to control units.

These connectors are made for strong and safe connections. Locks stop them from coming apart by accident, and crimping keeps cables secure. This design prevents problems even when there’s lots of movement or bumps.

Car connectors also allow fast data transfer, which modern vehicles need. For instance, High-Speed Data (HSD) connectors move large amounts of data quickly for cameras or infotainment systems. These make sure data flows well for features like driver-assist tools or digital screens.

Using PCB connectors in cars makes them more efficient and reliable. They make building cars easier, reduce repairs needed later on, and improve how vehicles perform overall.

Types of PCB Connectors for Cars

Choosing the right connectors is very important in cars. Different PCB connectors do specific jobs to link wires and boards well. Below are three common types used in cars.

Pin Header Connectors

Pin headers are popular in car electronics. They have rows of metal pins that connect boards to devices like sensors. These connectors are easy to attach and remove, great for testing or changes.

Pin headers save space on small boards but stay strong. They also handle many connections, perfect for modern cars with lots of parts.

They are cheap and flexible. Pin headers work well where you need to unplug often, like control units or testing systems.

Terminal Block Connectors

Terminal blocks organize wiring neatly and securely. Screws hold wires directly to the board, so no soldering is needed.

In cars, terminal blocks handle strong currents and shaking well. They’re great for power systems or tough wiring setups.

These connectors let you join many wires at one spot, saving space. This helps keep things tidy in complex car designs.

Wire-to-Board Connectors

Wire-to-board connectors link outside wires to boards easily. They help send power and signals smoothly for car electronics to work right.

You’ll see them in screens, sensors, or battery systems. They make building and fixing easier while staying small and light.

Many have locks so they don’t come loose in rough conditions. This keeps them working even with heat or vibrations.

Knowing these connector types helps you pick the best ones for your car projects.

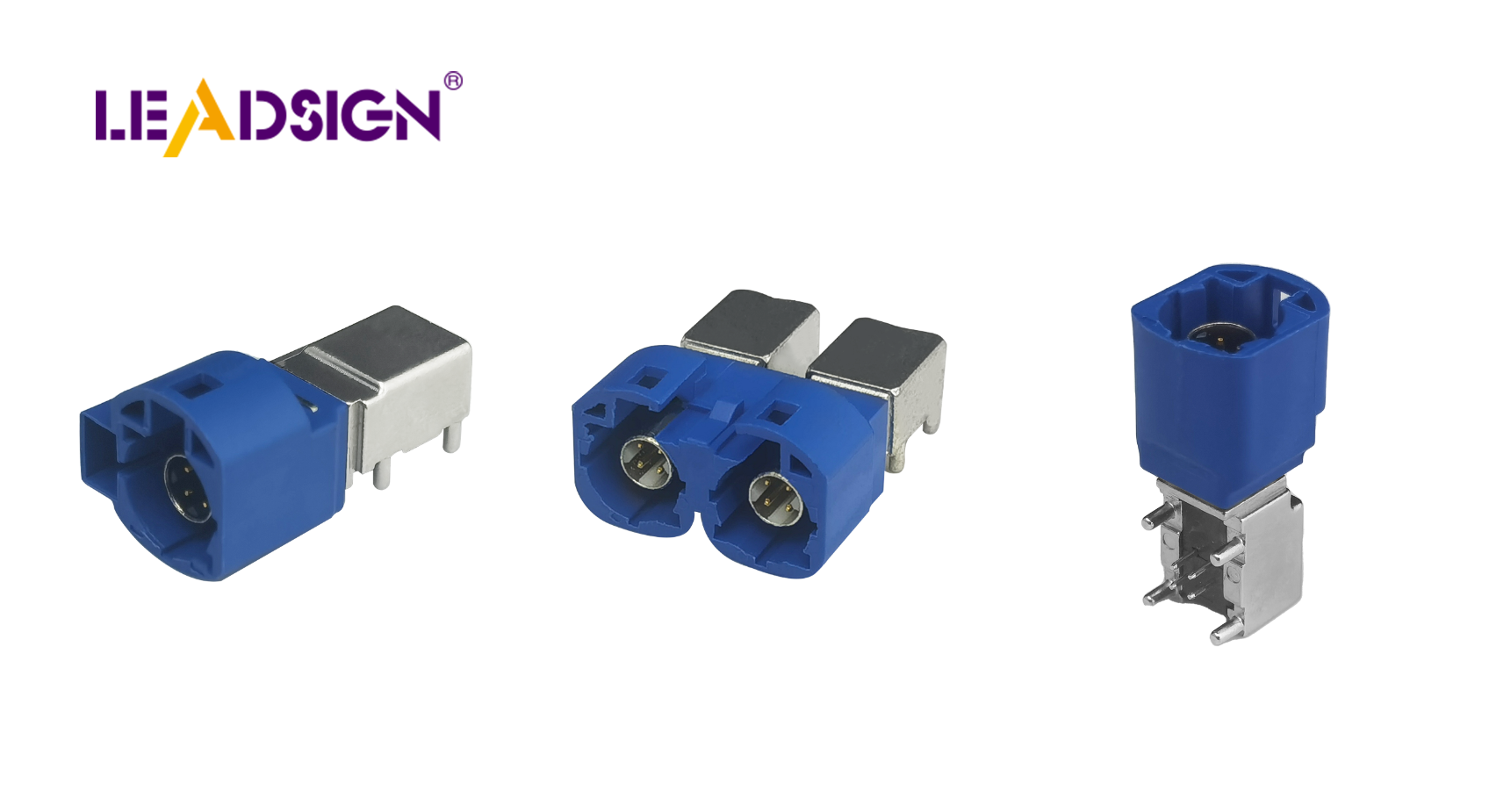

High-Speed Data (HSD) Connectors

High-Speed Data connectors are important for modern car systems. They help send large amounts of data quickly and reliably. These connectors are used in cameras, entertainment systems, and safety tools. Their ability to handle fast data makes them essential today.

HSD connectors are built to work well in tough conditions. They have locks to stop accidental unplugging. Crimping keeps cables secure even with constant shaking. High coding efficiency prevents wrong connections from happening. This design ensures your car systems always work properly.

In cars, HSD connectors support USB 3.0, Ethernet, and LVDS technologies. For example, they connect cameras to control units for real-time safety features. They also power entertainment systems with clear audio and video for passengers. Using these connectors means faster data speeds and better system reliability.

Their small size saves space in cars where room is limited. They are strong enough to handle heat and vibrations without breaking down. This makes them a dependable choice for car electronics. Among PCB connectors, HSD ones stand out for handling fast data while staying strong.

If you want better car electronics, think about using HSD connectors. They make assembly easier, need less fixing later on, and improve system performance overall. Their versatility makes them an important part of modern car technology.

Better Performance in Tough Conditions

Cars often deal with tough situations like heat, shaking, and water. PCB board to wire connectors are built to handle these challenges well. They stay strong and keep working even in hard conditions. For example, High-Speed Data (HSD) connectors have locks and crimped cables. This design keeps them secure during bumps or movement.

These connectors also block interference, keeping signals clear. They send data fast without mixing signals, even up to 6GHz. This makes them great for advanced car systems like ADAS or Ethernet setups. Using strong connectors makes your car safer and more durable.

Faster and Easier Connections

Good electrical connections are very important in modern cars. PCB connectors make it easy to link wires to boards quickly. This saves time when building cars and reduces mistakes too. Their small size fits well into tight spaces in car electronics. Wire-to-board connectors help parts like sensors work smoothly by sending power and signals easily.

Fast connectors like HSD ones move data quickly between parts of the car. They support tech like USB 3.0 for quick communication between systems. These smart designs improve how your car’s electrical system works while wasting less energy.

Saving Money and Adapting Easily

Picking the right types of PCB connectors can save money when making cars. Their simple design means fewer complicated wires are needed, cutting costs on production and repairs later on. For instance, terminal blocks let you connect wires easily without soldering, saving both time and effort.

These connectors can also grow with new technology as cars become smarter over time. High-quality ones used in V2X systems adjust to future needs easily. Their universal coding works across brands, making them a smart choice for long-term use.

By using dependable and flexible connectors, you save money while improving your car’s features for years ahead.

Easier Maintenance and Repairs

Taking care of car systems is simpler with PCB board to wire connectors. These connectors make fixing or replacing parts faster and less difficult.

A helpful feature is their quick-disconnect design. You can attach or remove parts easily without special tools. For instance, High-Speed Data (HSD) connectors have locks that keep them secure but are easy to unlock when needed. This makes regular maintenance or part replacement much easier.

"The Z-coding in HSD connectors works with different brands, making replacements simple."

These connectors also reduce mistakes in wiring. Their neat design means no tricky soldering, which lowers the chance of loose wires or errors. For example, terminal block connectors use screws to hold wires tightly to the board. This setup saves time and keeps connections strong for a long time.

Modern cars need fast data transfer for systems like ADAS (Advanced Driver Assistance Systems) and V2X communication. Connectors such as HSD connectors send data quickly at up to 6GHz without mixing signals. Even during repairs, these systems stay reliable and work well.

Their small size fits into tight spaces in cars easily. You can fix things without taking apart large sections of the vehicle. This is especially useful for areas like screens or sensors where space is limited.

Picking good connectors helps you save money on repairs over time. They last long and are easy to use, keeping your car’s systems working well for years ahead.

How PCB Connectors Are Used in Cars

Wiring and Power Systems

PCB connectors are key for wiring and power systems in cars. They help connect parts, letting electricity flow smoothly. Modern cars use wiring harnesses to combine circuits into one system. This saves space and makes things less complicated. PCB connectors make these connections strong and dependable.

In electric cars, these connectors handle high-voltage power from the battery. They send power to the motor and other important parts. Their tough design handles heat and shaking well, keeping them working in harsh conditions. Using these connectors makes your car's power system stronger and better.

Sensors and Data Sharing

Sensors are very important in today’s cars for safety features. PCB connectors link sensors to car electronics for sharing data quickly. These connections let sensors talk to control units in real time.

HSD connectors are great for sensor tasks because they send data fast. They help with things like crash warnings, staying in lanes, or cruise control. These connectors stop signal problems so safety systems work perfectly.

Adding PCB connectors improves how sensors share data, making your car safer and smarter.

Managing Car Batteries

Battery management systems (BMS) keep electric car batteries safe and efficient. PCB connectors join battery cells to monitors that check voltage or temperature. They also send power where it’s needed.

Strong automotive-grade connectors handle big currents without breaking down easily. They last long even under tough conditions, helping batteries work better over time.

These connectors also make fixing or upgrading BMS easier with their simple design. You can replace parts quickly without much trouble, saving time and money. This makes them a smart choice for building better electric vehicles.

Digital Infotainment and Connectivity Systems

Modern cars now offer entertainment and communication features. These rely on PCB board to wire connectors for smooth operation. Thanks to these connectors, you get clear screens, great sound, and accurate maps.

PCB connectors link infotainment parts to the car's main system. They send power and data quickly for multimedia systems to work well. For example, High-Speed Data (HSD) connectors help stream videos fast and play clear audio. This makes your car’s entertainment system fun without delays.

"Car connectors must handle heat, shaking, and moisture while working well." – Acumen Research and Consulting

Besides entertainment, these connectors keep you connected while driving. Bluetooth, Wi-Fi, and phone pairing need strong connections to work properly. PCB connectors make sure these features stay reliable in tough conditions like vibrations or temperature changes.

Newer cars also use advanced communication tools like Vehicle-to-Everything (V2X). This lets cars talk to other vehicles or devices for safer driving. PCB connectors allow quick data sharing so these systems respond instantly.

Their small size saves space inside the car for more features without crowding it. They are built to last long with little need for fixing or replacing. Choosing good-quality connectors means better connectivity and entertainment during every ride.

Checking Electrical and Mechanical Needs

To pick the right connectors, check your system's needs first. Find out how much voltage and current they will handle. This helps ensure the connectors won’t overheat or fail. For example, car systems often need connectors for high currents in batteries.

Next, think about their size and shape to fit tight spaces. Small designs are great for crowded car areas. Also, look for features like locks or crimping to keep them secure. These stop wires from coming loose during use.

"PCB connectors guide connections correctly, reducing mistakes and boosting reliability."

By understanding these needs, you can choose connectors that work well for your project.

Thinking About Environmental Challenges

Car systems face tough conditions like heat, shaking, and moisture. Pick connectors that can handle these challenges easily. For example, those near engines must resist heat and vibrations to work properly.

Choose strong materials that last in harsh environments. Sealed connectors block water and dust, making them good for outdoor or engine use. Insulation is also important to avoid short circuits caused by wetness or dirt.

"Standardized PCB interfaces let technicians fix problems quickly without delays."

By planning for these challenges, your connectors will stay reliable longer in cars.

Picking Long-Lasting Connectors

Strong connectors are key for long-lasting performance in vehicles. Look at what they’re made of—good metals and plastics last longer without breaking down.

Design also matters for durability. Locks on connectors add extra security against movement or shaking. Crimped cables hold tightly so they don’t come apart under stress.

Lastly, easy-to-remove designs make repairs faster when needed. This saves time while keeping systems running smoothly with little effort.

By focusing on strength and lifespan, you’ll get dependable connectors that work well over time.

Meeting Automotive Standards for Connectors

Car systems need connectors that follow strict rules. These rules ensure safety, reliability, and good performance. When picking PCB board to wire connectors, check if they meet important standards.

First, see if the connectors follow ISO/TS 16949 or IATF 16949 guidelines. These focus on making high-quality car parts. Certified connectors work well under tough conditions like heat or shaking.

Next, look for ones meeting Automotive Electronics Council (AEC-Q) standards. These test how strong parts are in harsh environments. AEC-Q-certified connectors can handle extreme heat, moisture, and stress. They’re great for systems like sensors or batteries.

"The PCB connector ensures correct connection direction, reducing errors and boosting system reliability."

Also, choose connectors with standard designs. Standardized interfaces make repairs easier and faster. Technicians can replace parts without confusion or mistakes. This design avoids mismatched connections and keeps systems running smoothly.

Finally, think about advanced car technologies. For example, ADAS or V2X communication needs fast data transfer without problems. Picking connectors that support these features ensures your car stays updated with modern tech.

Using connectors that meet automotive rules improves safety and efficiency in cars. It also boosts performance while lowering repair time and costs.

PCB connectors are important in today’s car systems. They help send power and signals smoothly, improving infotainment, sensors, and power parts. Picking the right connectors makes cars more reliable and easier to fix. These connectors also work well with new car technologies as they change. Check what your system needs to choose connectors that fit your goals and last a long time.

FAQ

What are PCB connectors used for in vehicles?

PCB connectors join electronic parts in cars. They send power and signals between systems like sensors, controls, and screens. These connectors help car electronics work smoothly and reliably.

Why are PCB connectors important for electric vehicles (EVs)?

Electric cars need complex systems to manage power and batteries. PCB connectors link key parts like motors, chargers, and batteries. Their strength and efficiency make them vital for EVs to function well.

How do PCB connectors improve vehicle reliability?

PCB connectors create strong, stable links between parts. They can handle heat, shaking, and moisture without breaking. This keeps systems like engines, ADAS, and screens working properly.

What makes High-Speed Data (HSD) connectors unique?

HSD connectors move data quickly, perfect for advanced car systems. They support USB 3.0 and Ethernet technologies. Their design stops signal problems for cameras or safety tools.

Can PCB connectors handle harsh automotive environments?

Yes, PCB connectors are built tough for hard conditions. Strong materials and locks protect them from heat or water damage. This makes them great for engines or outdoor use.

How do PCB connectors contribute to advanced driver-assistance systems (ADAS)?

PCB connectors help sensors talk to control units fast in ADAS features. They send accurate data for lane-keeping or collision warnings. This improves safety while driving.

Are PCB connectors compatible with future automotive technologies?

Yes, modern PCB connectors work with new technologies easily. They support V2X communication or updated infotainment systems. This ensures they stay useful as cars advance.

What should you consider when selecting PCB connectors for your vehicle?

When picking PCB connectors, check their power limits and toughness. Look for secure locks and standards compatibility to ensure they last long in your car.

How do PCB connectors simplify vehicle maintenance?

PCB connectors have quick-disconnect designs that make repairs easy. Standardized shapes reduce mistakes during fixes, saving time on maintenance jobs.

Why are smaller PCB connectors beneficial for automotive applications?

Smaller PCB connectors fit into tight spaces in cars better. They allow more parts to fit without losing performance—ideal for today’s compact car designs.

See Also

Exploring FAKRA Connectors for Enhanced Automotive PCB Use

Key Benefits of FAKRA Connectors in Automotive Systems

Why FAKRA PCB Connectors Are Essential for Vehicles