Key Developments in PCB Board Wire Connectors for 2024

PCB board to wire connectors are important in modern electronics. They help parts connect and work smoothly together. As industries want smaller and better tools, these connectors have become more needed. New PCB-making methods use better materials and smart designs. This makes connectors stronger and work better. In 2024, these changes will improve the industry a lot. More IoT devices and faster data needs push this progress. Consumer electronics are also growing quickly. This year is a big step for connectors, changing how electronics will work in the future.

Key Takeaways

PCB board to wire connectors are essential for modern electronics, enabling reliable connections for power and data transfer.

In 2024, advancements focus on smaller, more efficient designs that cater to the growing demand for compact and powerful devices.

Faster data transfer capabilities are crucial for supporting technologies like 5G and IoT, enhancing communication and performance.

The use of eco-friendly materials in connector production is on the rise, promoting sustainability and reducing electronic waste.

Flexible PCB connectors are revolutionizing device design by allowing for space-saving solutions in various industries, including automotive and healthcare.

Investing in the latest connector technology can help businesses stay competitive and meet evolving market demands.

Overview of PCB Board to Wire Connectors

What are PCB Board to Wire Connectors?

PCB board to wire connectors are key parts of electronics. They link wires or cables to circuit boards securely. This helps devices work by sharing signals and power. These connectors are very important in cars, gadgets, and factories.

They also make building circuit boards easier. Designers can add or remove them quickly in complex setups. This helps meet the need for smaller and smarter devices.

Different Types of PCB Connectors

There are many kinds of PCB connectors for different uses. Knowing these types helps engineers pick the right one.

Wire-to-board connectors

Wire-to-board connectors join outside wires to a circuit board. They send data and power safely. Some have special features that protect delicate circuits, making them great for repeated use.

Board-to-board connectors

Board-to-board connectors link multiple circuit boards together. They help boards share information easily in layered designs like phones or laptops.

Coaxial connectors

Coaxial connectors handle high-frequency signals well. They are used in fast systems like telecoms because they keep signals clear and strong.

Main Uses and Benefits

PCB board to wire connectors do many important jobs in electronics.

Keeping connections stable

These connectors keep electrical links steady and safe. This stops signal problems so devices work properly.

Helping with fast data transfer

Modern connectors move data quickly for things like 5G or IoT tech. They keep signals strong and reduce delays for better communication.

Making smaller designs possible

PCB connectors help create small, neat designs by cutting down on wires. This lets companies build tiny but powerful devices without losing quality.

Latest Improvements in PCB Board Wire Connectors for 2024

Smaller and Compact Designs

Tiny connectors for tight spaces

Smaller gadgets need tiny PCB connectors to save space. Engineers now make connectors that fit small areas but still work well. These new designs help industries like car electronics, where space is tight but performance matters. Flexible PCB connectors replace big cables, making devices smaller. This matches new technology trends, helping companies build better and sleeker products.

Better performance in smaller sizes

Even though they are small, modern PCB connectors work great. Strong materials make them last longer and send signals clearly. They stay stable and reliable even in tough conditions. Industries use these to create powerful devices that meet what customers want today.

Faster Data Transfer Abilities

Ready for 5G and more

5G networks need fast PCB connectors for quick data sharing. These connectors now support faster systems and next-gen networks easily. Car makers and telecoms use them to share real-time data better. New tech trends show how important these fast connectors are for keeping up with modern standards.

Clearer signals with less delay

New PCB connectors keep signals clear without interference or delays. Engineers design them to improve device speed, like IoT gadgets or smart screens. These upgrades meet the need for strong, efficient connections in electronics and factories.

Working with Smart Technologies

AI and IoT ready

PCB connectors now work well with AI and IoT systems. They help smart devices connect smoothly, from home gadgets to factory tools. This shows how much they shape future technology by matching new trends.

Strong links for smart gadgets

Smart devices need good connections to run properly. Special PCB connectors give steady links in tricky setups like wearables or home tech gear. By solving these needs, they push forward the growth of cool electronic products.

New Ideas in PCB Making Methods

Bendable PCB connectors for many uses

Bendable PCB connectors have changed how devices are made. They remove the need for old-style cables, making gadgets smaller and lighter. Car electronics and personal gadgets now use bendable PCBs to make compact designs. These connectors fit into tight spots, perfect for modern tools needing space-saving solutions.

New trends in PCB making focus on adding bendable PCBs to strong systems. These connectors are flexible, working well in tricky device shapes. For example, cars use them because they handle shaking and tough conditions while staying reliable. They also save time and money during assembly, helping industries build faster.

Stronger materials for better performance

New materials make PCB connectors tougher and more efficient. Makers now use advanced stuff that improves signal strength and lasts longer. These materials let connectors send fast data without losing quality. Cars especially need these upgrades since they face rough conditions but must work well.

Better materials also help bendable PCBs last longer through bending or twisting. New trends include eco-friendly options like recyclable parts to protect nature. Using these helps reduce waste from electronic products.

Bendable PCBs keep changing how electronics are built by being flexible and useful. Adding them to different devices shows why keeping up with new ideas in PCB making is important. As technology grows, bendable PCBs will lead the way in improving gadget design and function.

How New Connectors Help Different Industries

New pcb board to wire connectors have changed many industries. They improve how things work, making them faster and more reliable.

Cars and Vehicles

Helping smart driving systems (ADAS)

Cars use advanced connectors for smart driving systems like ADAS. These systems need fast data sharing to work well. Modern connectors link sensors, cameras, and controls smoothly. Strong materials make them last in tough conditions like heat or shaking.

Boosting electric car tech

Electric cars need strong connectors for high-power PCBs. These parts move power and data between batteries and other parts. New pcb assembly methods create small but powerful connectors. This helps make eco-friendly cars that save energy.

Health Devices

Tiny connectors for wearable gadgets

Doctors use tiny connectors in health gadgets like wearables. These small parts keep devices compact but useful. Wearable monitors send real-time data using these connectors. Flexible PCB designs make them comfy for users.

Reliable parts for medical machines

Important machines like scanners need very reliable connectors. High-power PCBs with good connectors keep these tools running nonstop. Better materials make these parts stronger and meet strict health standards.

Home Electronics

Better smartphones and laptops

Phones and laptops are better thanks to new pcb assembly ideas. Small, fast connectors help make thinner yet stronger devices. They also last longer, giving users better value.

Smarter home gadgets

Smart home tools need good connections to work well together. The newest pcb board to wire connectors give quick, steady links for things like cameras or voice assistants. These updates make smart homes easier to use and more dependable.

Industrial Automation

Strong connectors for tough conditions

Factories need connectors that handle hard conditions like heat and moisture. Machines in these places face shaking, high temperatures, and wetness. New PCB board to wire connectors are made with better materials. These strong parts last longer and work well in rough spots. They keep machines running without stopping, even in harsh environments.

Flexible PCB connectors are very useful for factory machines. They can bend to fit tight spaces in tricky layouts. New material improvements make them even stronger now. These upgrades help them handle stress without breaking or failing. Factories save time and money by using these reliable connectors.

Helping smart factories grow

Industry 4.0 has changed how factories work today. Smart systems need devices to share data quickly and easily. PCB connectors help connect sensors, controllers, and machines together fast. This allows real-time checks and smarter decisions during production.

Next-gen flex PCB connectors are leading this change forward. Their small size helps add IoT devices into factory setups smoothly. These connectors let factories use tools like predictive maintenance to improve work flow. With new manufacturing ideas, industries can build smarter systems that work better.

"New material technology will make next-gen flex PCB connectors stronger."

This quote shows why improving connector designs is so important now. As factories get smarter with Industry 4.0, strong and flexible connectors will stay key for success.

Sustainability Trends in PCB Connector Technology

Using Eco-Friendly Materials

Parts that break down or can be reused

The electronics world now focuses on eco-friendly PCB connectors. Makers use parts that can break down or be recycled. These materials lower waste and are better for the planet. Flexible and rigid-flex PCBs now include these green components to meet demand. This change supports the global goal of making greener technology.

Cleaner production methods

New ways to make PCBs cause less harm to nature. Modern methods use fewer resources and create less trash. Robots and smart tech help make production faster and cleaner. These changes help companies follow strict environmental rules. By using these ideas, the industry balances progress with caring for Earth.

Saving Energy with Better Designs

Connectors that use less power

Energy-saving designs are key for today’s PCB connectors. Engineers create connectors that need less energy but still work well. These designs help devices like IoT tools save power while running smoothly. Using less energy also makes devices last longer, saving money for users.

Helping clean energy grow

PCB connectors are important for green energy systems like solar panels. They allow smooth power flow in renewable setups like wind farms too. By supporting clean energy, these connectors help more people switch to eco-friendly options.

Recycling Old Parts

Reusing materials from old devices

Recycling programs are growing in the PCB world now. Companies collect old connectors to reuse valuable materials like copper or gold. This saves natural resources and cuts costs at the same time.

Following global eco-rules

Worldwide rules push companies to handle e-waste responsibly. Laws like RoHS encourage safer materials in PCB connectors today. By following these rules, businesses show they care about protecting our planet while meeting customer needs.

"Better materials and new ways of making things will change PCBs."

This shows how sustainability is shaping future connector designs as technology grows.

In 2024, PCB wire connectors are changing electronics greatly. Smaller sizes, quicker data sharing, and smart tech use make them vital. These updates improve how cars, health tools, and factories work. Using eco-friendly materials and saving energy shows their growing value. Companies need these new connectors to stay ahead in the market. By adding advanced connectors, businesses can create better products, meet new needs, and help the planet.

FAQ

What are PCB board to wire connectors?

PCB board to wire connectors join wires or cables to PCBs. They help move power and data in electronic devices. These parts are very important in cars, gadgets, and factories.

Why are PCB connectors important in modern electronics?

PCB connectors make building and fixing devices easier. They give strong connections, send data fast, and allow smaller designs. These features help create new tech like IoT tools, 5G systems, and wearables.

What are the main types of PCB connectors?

There are different kinds of PCB connectors for various uses:

Wire-to-board connectors: Attach outside wires to a PCB.

Board-to-board connectors: Connect circuit boards inside a device.

Coaxial connectors: Carry high-frequency signals used in telecoms.

How have PCB connectors evolved in 2024?

In 2024, PCB connectors became smaller and worked better with AI and IoT. Flexible designs and stronger materials made them last longer too.

"New material technology will make next-gen flex PCB connectors stronger."

These changes meet the need for faster, smaller, and smarter electronics.

What industries benefit the most from PCB connector advancements?

Many industries use improved PCB connectors:

Automotive: Helps electric cars and smart driving systems (ADAS).

Healthcare: Makes small health gadgets and reliable medical machines.

Consumer electronics: Upgrades phones, laptops, and smart home tools.

Industrial automation: Improves factory machines for Industry 4.0 setups.

How do PCB connectors contribute to sustainability?

Modern PCB connectors use eco-friendly materials that save energy. Companies also recycle old parts to reduce waste while following global green rules.

What are flexible PCB connectors, and why are they important?

Flexible PCB connectors bend easily instead of staying stiff like cables. They save space, weigh less, and work well in tiny gadgets. Industries use them for making advanced products that fit today’s needs.

How do PCB connectors support high-speed data transfer?

High-speed PCB connectors keep signals clear without delays or loss. They’re key for fast tech like 5G networks or USB 3.0 systems.

What challenges do PCB connectors address in harsh environments?

Specially made PCB connectors handle heat, moisture, or shaking well. Strong materials keep them working even in tough places like cars or factories.

How can businesses stay ahead with PCB connector advancements?

Businesses can lead by using the newest connector tech. Advanced designs improve products while helping meet eco-friendly goals for modern markets.

See Also

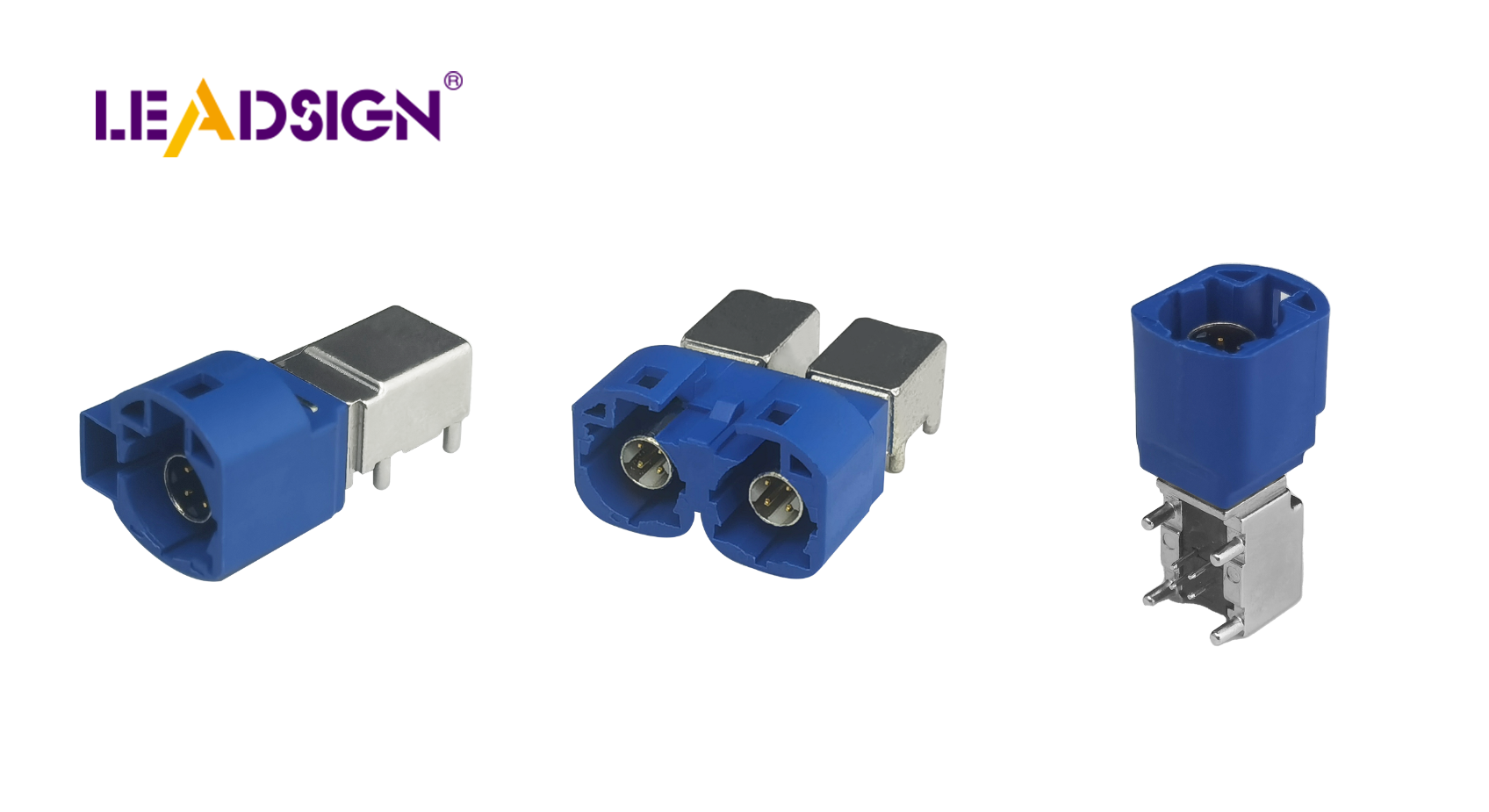

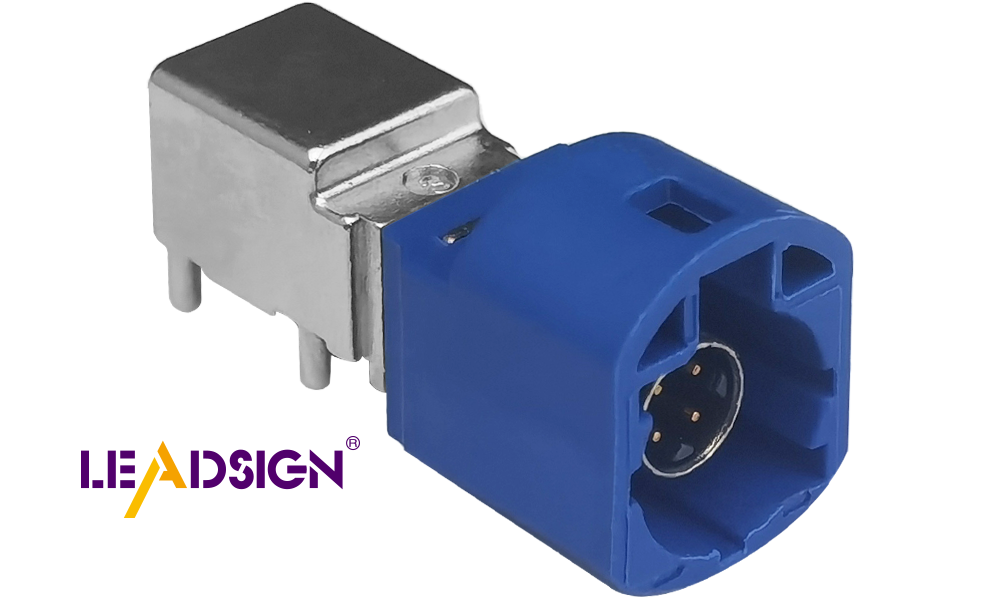

Exploring FAKRA Connectors for Enhanced Automotive PCB Performance

Why FAKRA PCB Connectors Are Essential for Automotive Use

Key Benefits of FAKRA PCB Mount Connectors in Automotive and RF

Utilizing FAKRA PCB Connectors for Automotive Application Benefits

Significance of FAKRA PCB Connectors in Automotive Communication