OEM or Aftermarket Vehicle Connectors What Works Best for You

Choosing between OEM and aftermarket vehicle connectors can be confusing. Both options offer benefits for different needs. OEM connectors are known for their quality, fit, and warranty, while aftermarket connectors are more affordable and can be customized. Understanding these facts helps you select the best connectors for your vehicle.

Key Takeaways

OEM connectors provide a perfect fit and high quality, ensuring your vehicle's electrical systems operate safely and efficiently.

Aftermarket connectors are more affordable and customizable, making them a popular choice for upgrades and replacements, but quality can vary.

Consider your budget and vehicle needs carefully; while OEM connectors may cost more upfront, they often save money in the long run by reducing repair risks.

Understanding OEM Automotive Connectors

What Are OEM Automotive Connectors?

OEM connectors are made by the car's original maker. They fit perfectly and work well with your car's electrical system. These connectors are strong because they use materials like nylon and plastic. They are waterproof and keep out dust, so they last a long time. Special locks stop them from coming loose, even if the car shakes a lot.

Feature | Details |

|---|---|

Material | Made from strong materials like nylon and plastic for long use. |

Sealing | Keeps water and dust out, making them last longer. |

Locking Mechanism | Locks tightly to stop them from coming apart in vibrations. |

Terminal Design | Built for great electrical flow and long-lasting use. |

These connectors are called "genuine parts" because they match the original ones in your car.

How OEM Connectors Are Made

OEM connectors are made carefully to meet high standards. Makers use strong materials like nylon and plastic that resist damage. They use special methods like molding and plating to make sure the connectors work well and last long.

Materials include nylon and other tough plastics.

Steps include:

Careful manufacturing methods

Low-heat molding

Designing for electric signals and layouts

This careful process makes sure OEM connectors stay strong and reliable.

Why OEM Connectors Matter for Cars

OEM connectors are important for your car's safety and performance. They keep the electrical parts working properly. Using these connectors lowers the chance of problems that could make your car unsafe. They are made to fit your car exactly, so repairs and maintenance are easier.

They keep electric systems working without problems.

They last through tough conditions, saving repair costs.

Perfect fit reduces risks and keeps your car safe.

Choosing OEM connectors gives your car the quality it needs to run well.

Pros and Cons of OEM Parts

Benefits of OEM Automotive Connectors

OEM connectors have many good points for your car. They make sure your car's electrical parts work well. This helps avoid problems and keeps your car running better. Strong materials and careful design make them last longer, even in bad weather. They also make your car safer and perform better.

Some reasons to pick OEM wiring connectors:

Quality Guarantee: They pass strict tests to meet high standards.

Proper Electrical Connections: They stay secure and prevent electric issues.

Durability: They handle tough conditions and need fewer repairs.

Compatibility: They fit perfectly, making installation easy.

Warranty Protection: They help keep your car’s warranty safe.

Choosing OEM connectors means better safety, strength, and performance for your car.

Drawbacks of OEM Parts

OEM parts are great but have some downsides too. The biggest problem is their high price. They cost more because of their quality and brand name. Also, finding the right OEM connectors can be hard since they are not always available.

Drawback | Description |

|---|---|

They are pricey due to their quality and brand. | |

Limited availability | They might not be in stock, causing delays. |

These issues can make OEM parts less ideal if you need something cheap or fast. Still, their quality and fit often make them worth it.

Exploring Aftermarket Parts for Vehicle Connectors

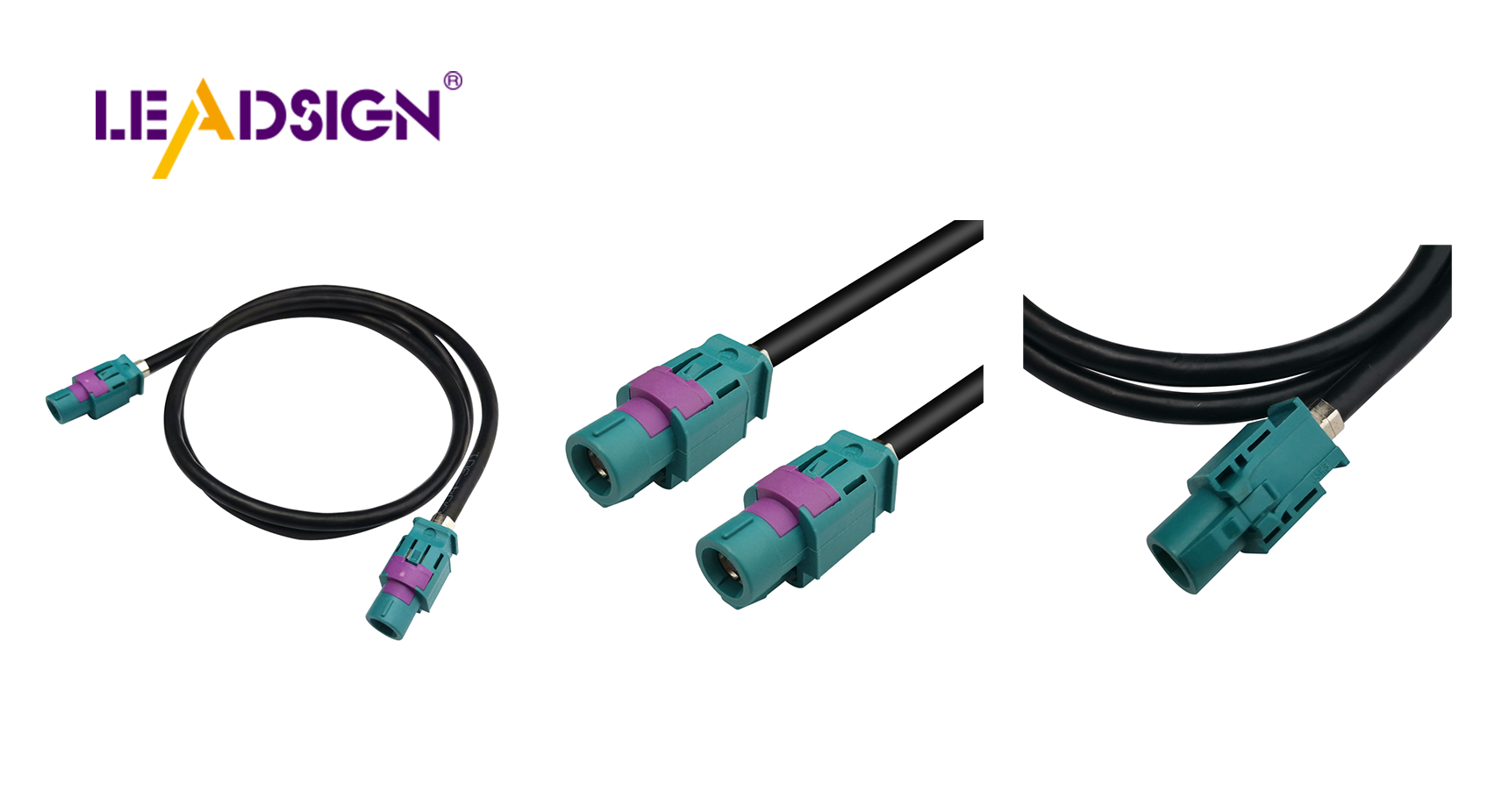

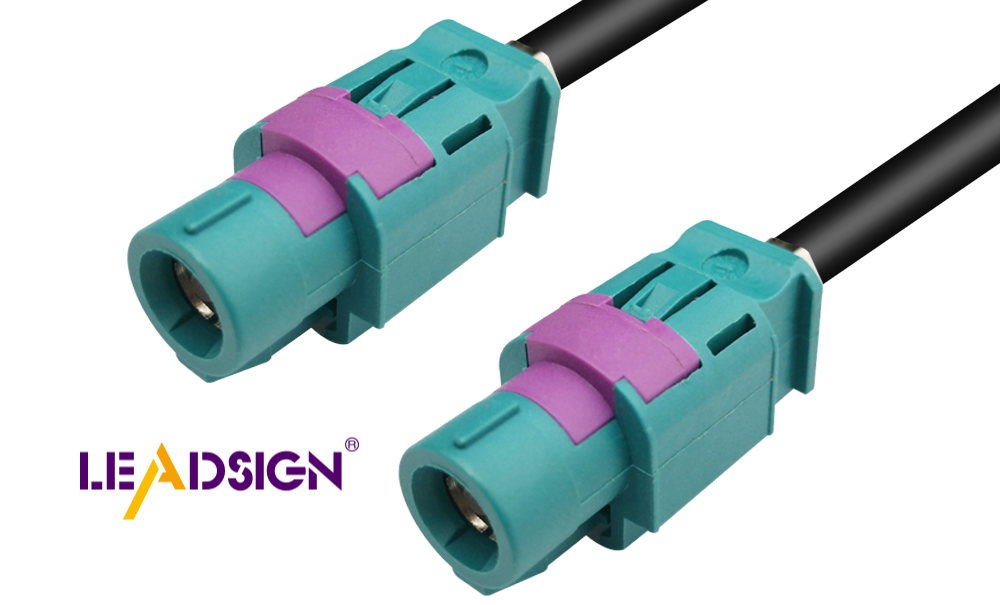

What Are Aftermarket Vehicle Connectors?

Aftermarket connectors are made by companies other than the car maker. They are cheaper and can replace or improve your car's electrical system. Unlike OEM connectors, these can be customized. You can pick different colors, shapes, or sizes to match your needs.

These connectors are easy to find, making them a quick option. Their low price and flexibility make them popular with car owners.

Key Differences Between OEM and Aftermarket Connectors:

OEM connectors fit perfectly and work best for your car.

Aftermarket connectors are cheaper and offer more choices.

How Aftermarket Parts Are Made

Aftermarket connectors are made using modern methods to last long. Plastic shells are made with injection molding. Metal parts are shaped by stamping.

Manufacturing Process | Description |

|---|---|

Injection Molding | Makes the plastic outer part of the connector. |

Insert Molding | Adds screws or terminals into the plastic. |

Stamping | Shapes metal parts like terminals. |

Electroplating | Covers metal with a protective layer. |

Precision Production Technology | Makes small parts with great accuracy. |

Low Temperature Forming | Adds insulation and heat resistance. |

These steps help aftermarket connectors work well in modern cars. Some even include electronic parts for extra features.

Common Uses of Aftermarket Connectors

Aftermarket connectors are used in cars and other industries. They replace broken connectors or improve systems. Many people pick them because they are cheap and easy to get.

They are used for:

Adding new infotainment systems.

Connecting USB devices or cameras.

Supporting Ethernet or LVDS systems in cars.

These connectors are also used outside of cars. Industries like telecom use them for radios and networks.

Aftermarket connectors let you upgrade your car without spending too much. They are flexible and useful for many purposes.

Pros and Cons of Aftermarket Parts

Advantages of Aftermarket Vehicle Connectors

Aftermarket parts have many benefits for car owners. They are flexible and affordable, making them a good choice for saving money.

Affordability: These connectors cost less than OEM ones. They are a smart option if you want to save money but still need working parts.

Customization: You can pick from different colors, shapes, and sizes. This helps you find parts that fit your needs or style.

Availability: Aftermarket parts are easy to find. If you need a quick fix, you can get them without waiting long.

These benefits make aftermarket connectors useful for fixing or improving your car. Whether you’re adding new features or replacing old parts, they work well for most needs.

Disadvantages of Aftermarket Parts

Even though aftermarket parts are helpful, they have some downsides. Be careful when picking these connectors to avoid problems.

Quality can be uneven. Some use cheap materials that don’t last long.

No strict standards. Unlike OEM parts, car makers don’t check them. This can lead to parts that don’t fit or work right.

Limited warranty. Many don’t come with a good warranty, so you’re not covered if they break.

Too many choices. The large number of brands can confuse buyers, especially if they don’t know much about the options.

Low-quality aftermarket parts can cause problems and even be unsafe. Always pick trusted brands to avoid these risks.

Comparing OEM and Aftermarket Vehicle Connectors

Quality and Durability

OEM connectors are known for their strong quality and durability. They go through strict tests to ensure they last long. These connectors are made to fit your car perfectly. This lowers the chance of damage and keeps your car safe. They are a reliable choice for keeping your car working well.

Aftermarket connectors can have mixed quality. Some brands use good materials, but others may not. This can make them less durable and safe. However, aftermarket connectors often come in different colors and designs. This makes them a fun option for personalizing your car.

Cost and Affordability

Price is important when picking between OEM and aftermarket parts. OEM connectors cost more because of their quality and brand name. Aftermarket connectors are cheaper and save money. A study showed aftermarket parts cost 27% less than OEM ones. In some cases, the price difference can be as much as 68%. This makes aftermarket connectors a good choice for saving money.

Compatibility and Fit

OEM connectors are made by the car’s original maker. They fit your car exactly and work perfectly with its systems. This reduces problems during installation and improves performance. Aftermarket connectors are made to fit many cars but may not fit perfectly. If they are from unknown brands, they might not work as well.

Availability and Customization

Aftermarket connectors are easy to find because many companies make them. This makes them a quick option for replacing parts. They also come in different shapes, sizes, and colors. This lets you change or upgrade your car to match your style. OEM connectors are harder to find and don’t offer as many customization choices.

Picking the Best Connectors for Your Car

Checking Your Budget

Your budget is important when picking connectors. Think about these:

Current rating: Make sure connectors handle your car’s electricity safely.

Voltage rating: Choose ones that match your car’s voltage to avoid damage.

Number of contacts: More contacts mean better signals and future upgrades.

Environmental conditions: Pick connectors that can handle tough weather.

Mechanical factors: Get connectors that resist shaking and movement.

Type of termination: Decide between soldering, crimping, or screw-on ends.

Material: Use plastic for light jobs or metal for heavy-duty tasks.

Balancing these helps you get good connectors without spending too much.

Thinking About Your Car’s Needs

Your car’s needs should guide your choice. OEM parts fit perfectly and work best. They are made for your car, so they are safer and easier to install. Using OEM connectors also keeps your car’s warranty safe, saving repair costs.

Aftermarket connectors are flexible and good for upgrades like USB ports. But check their quality to avoid problems later.

Short-Term vs. Long-Term Value

Think about now and the future. OEM parts cost more but last longer. They fit perfectly, lowering repair risks and saving money later. They also protect your car’s warranty, giving peace of mind.

Aftermarket parts are cheaper at first but may not last. Poor quality can mean more replacements, costing more over time. If you want long-lasting parts, OEM connectors are a better choice.

Tip: Compare the short-term savings of aftermarket parts with the long-term benefits of OEM ones to decide wisely.

OEM and aftermarket connectors each have their own advantages. Your decision should match your needs. If you want top quality and a perfect fit, choose OEM connectors. They offer:

High quality from strict manufacturing processes.

Exact fit for your car’s specific model.

Warranty safety, reducing surprise repair expenses.

On the other hand, aftermarket connectors are cheaper and customizable. Think about your budget and what your car requires. OEM connectors protect warranties, while lower-quality aftermarket ones might cause issues.

Tip: Check and clean connectors often to make them last longer. Apply dielectric grease to stop rust and keep them working well.

By considering these points, you can pick the right connectors for your car.

FAQ

How are OEM and aftermarket connectors different?

OEM connectors are made by your car’s maker to fit perfectly. Aftermarket connectors cost less, can be customized, and are made by other companies.

Can using aftermarket connectors harm my car?

Bad-quality aftermarket connectors might not fit or work correctly. This can cause electrical problems. Pick trusted brands to keep your car safe.

Are OEM connectors worth the extra money?

Yes, if you want strong, reliable parts that fit well. OEM connectors last longer and help avoid costly repairs later.

See Also

Enhancing Vehicle Data Transfer With Superior Connectors And Cables

Why Fakra Connectors Are Essential For Today's Vehicles

Benefits Of HFM Connectors For Automotive Applications