OEM Automotive Harness Connectors vs Aftermarket Connectors Explained

When selecting auto harness connectors, prioritize quality and reliability. OEM connectors are genuine components manufactured to high standards. These parts fit your vehicle perfectly and help prevent electrical issues. Aftermarket options are often less durable and can break more easily, leading to problems such as shorts, overheating, or damage to your car. Utilizing OEM parts safeguards your vehicle’s warranty and can save you money in the long run. OEM wiring harnesses and connectors are designed for longevity, making them the optimal choice for your car’s wiring requirements.

Key Takeaways

Pick OEM connectors for great quality and dependability. They fit your car well and stop electrical problems.

Spending on OEM connectors saves cash over time. They last longer, so you need fewer fixes or swaps.

OEM connectors keep your car’s warranty safe. They follow the maker’s rules for safety and work well.

High-Quality Materials in OEM Auto Harness Connectors

Made with care and strong materials

OEM auto harness connectors are made carefully and checked for quality. They use strong materials like nylon, polypropylene, and thermoplastic elastomers. These materials make the connectors tough, heat-resistant, and long-lasting. Unlike aftermarket parts, OEM connectors follow strict rules to ensure they work well. This means they stay reliable and perform the same way for a long time.

OEM connectors are made by the same companies that build the cars. This ensures the parts match or are better than the car's original design. Careful planning and testing make sure these connectors handle tough conditions in cars.

Tough against damage and bad weather

OEM connectors are built to handle rough conditions. They resist damage from heat, cold, vibrations, and water. To make sure they last, manufacturers test them in many ways, like rubbing, salt spray, and water tests. These tests copy real-life situations to prove the connectors stay strong over time.

The materials, like thermoplastic elastomers, help them fight damage from the environment. This makes them great for important uses like GPS, radios, and sensors. Aftermarket connectors don’t go through the same tests and often fail sooner.

Work well in all conditions

OEM connectors work well even in tough situations. Their strong wires and sturdy design keep electrical connections safe. Whether it’s hot, cold, or wet, these connectors keep working.

Materials like nylon and polypropylene make them stable and durable. This is why OEM connectors are the best choice for cars where safety and performance matter. Picking OEM parts helps your car run safely and avoids problems with cheaper aftermarket options.

Compatibility and Fit: Why OEM Connectors Are Made for Your Car

Made to fit your car perfectly

OEM connectors are made to match your car exactly. They are not generic parts but are designed for your car’s make and model. This ensures they fit your car’s wiring system without any problems. Aftermarket connectors often use one-size-fits-all designs, which can cause fitting issues. OEM connectors are made to fit right, keeping your car’s electrical system working properly.

Using OEM connectors avoids problems caused by poorly fitting aftermarket parts. These connectors meet the original standards set by your car’s maker. This means your car will work as it should, with no loss in safety or performance.

Easy to connect with your car’s systems

OEM connectors are easy to install and work with your car’s systems. Their plug-and-play design makes installation quick and simple. They keep electrical connections steady, so there are no loose wires or interruptions.

OEM parts are carefully designed to work well with your car’s wiring. This is important when fixing or upgrading your car. New parts will work smoothly with the old ones. Choosing OEM connectors keeps your car running efficiently and reliably.

Fewer electrical problems or failures

Aftermarket connectors can cause loose wires, rust, or overheating. These problems may lead to power loss, short circuits, or damage to your car’s wiring. OEM connectors are made to stop these issues. They use strong materials and fit perfectly to block moisture and ensure good performance.

By using OEM connectors, you lower the chance of electrical problems. These parts are built to last and work well even in tough conditions. Picking OEM connectors protects your car’s wiring and saves you from expensive repairs caused by aftermarket parts.

Durability and Longevity of Original Equipment Manufacturer Connectors

Made to last as long as your car

OEM parts are built to be strong and long-lasting. These connectors are made to work for as long as your car does. Manufacturers use special materials and careful designs to make them tough. Unlike aftermarket parts, OEM connectors stay strong even in harsh conditions. This makes them a dependable choice for your car’s wiring system.

Choosing OEM connectors means you get parts that work well over time. Their strong build helps them resist damage and protect wires. This strength means you won’t need to replace them often, saving you money and effort.

Tested to work for a long time

OEM connectors go through tough tests to meet high standards. Manufacturers test them in heat, cold, water, and vibrations. These tests show they can handle real-life conditions and still work well.

The testing ensures the connectors stay secure and avoid electrical problems. Aftermarket parts don’t usually go through such strict checks. With OEM connectors, you can trust your car’s wiring will stay safe and reliable.

Less likely to fail than aftermarket parts

OEM connectors are less likely to break because they are well-made. They are designed to fit perfectly and work at their best. Aftermarket parts often cut corners to save money, which can cause them to fail early. This might lead to expensive repairs or safety risks.

By picking OEM connectors, you lower the chance of wiring problems. Their strong design and proven quality make them the best choice for your car. Using these parts gives you confidence and keeps your car running smoothly for a long time.

Cost-Effectiveness of OEM vs Aftermarket Connectors

Higher upfront cost but fewer replacements needed

OEM connectors cost more at first but last longer. Their higher price reflects their strong quality and durability. These parts are made to work as long as your car does. They go through strict tests to meet high standards, so they rarely need replacing. Aftermarket connectors are cheaper but often break faster. This happens because they use weaker materials and skip important steps in making them. You might replace aftermarket parts many times, which costs more in the end.

Avoiding costly repairs caused by aftermarket failures

Aftermarket connectors can cause big problems like poor fit or bad connections. Badly fitting parts may lead to electrical issues like overheating or short circuits. These problems can harm your car’s wiring and cost a lot to fix. Using OEM connectors avoids these issues because they fit perfectly and work well with your car. OEM parts are made for your car’s systems, reducing the chance of expensive repairs. They keep your car running safely and smoothly.

Better value for money in the long run

OEM connectors may seem pricey at first, but they save money later. Their strong build and perfect fit mean fewer replacements and repairs. These parts are made to handle tough conditions and work reliably for a long time. By picking OEM connectors, you avoid hidden costs from aftermarket parts, like frequent failures or damage to your car. Choosing OEM connectors is a smart way to save money and keep your car in good shape.

OEM connectors are better than aftermarket ones in every way. They are high-quality, fit well, and last a long time. Many car owners pick OEM parts to avoid electrical problems and save money over time.

"The connector I got worked perfectly. It saved me because I couldn’t find it anywhere else. If you didn’t have it, I’d have gone to the dealer, and they’d charge me so much more. It came in great condition and faster than I thought. Thanks for the awesome service."

— Hector M.

Using OEM connectors keeps your car’s electrical system steady and reliable. These parts meet the maker’s rules, protecting your warranty and avoiding costly fixes. Aftermarket connectors might cost less at first, but they often break or don’t fit right, costing more later.

OEM connectors are tested carefully to ensure they work well.

They are made to fit your car exactly, with no issues.

They protect your warranty, giving you peace of mind and trust.

For reliable use and saving money, OEM connectors are the best choice.

FAQ

Why are OEM connectors better than aftermarket ones?

OEM connectors are made with strong materials and accurate designs. They fit well, work reliably, and lower the chance of electrical problems.

Can aftermarket connectors harm my car?

Yes, aftermarket connectors often don’t fit or last well. Weak parts can lead to electrical issues, overheating, or damage to your car’s wiring.

Are OEM connectors worth the extra money?

Yes, they are. OEM connectors last longer and need fewer replacements. Their strength and perfect fit help avoid expensive repairs from bad parts.

See Also

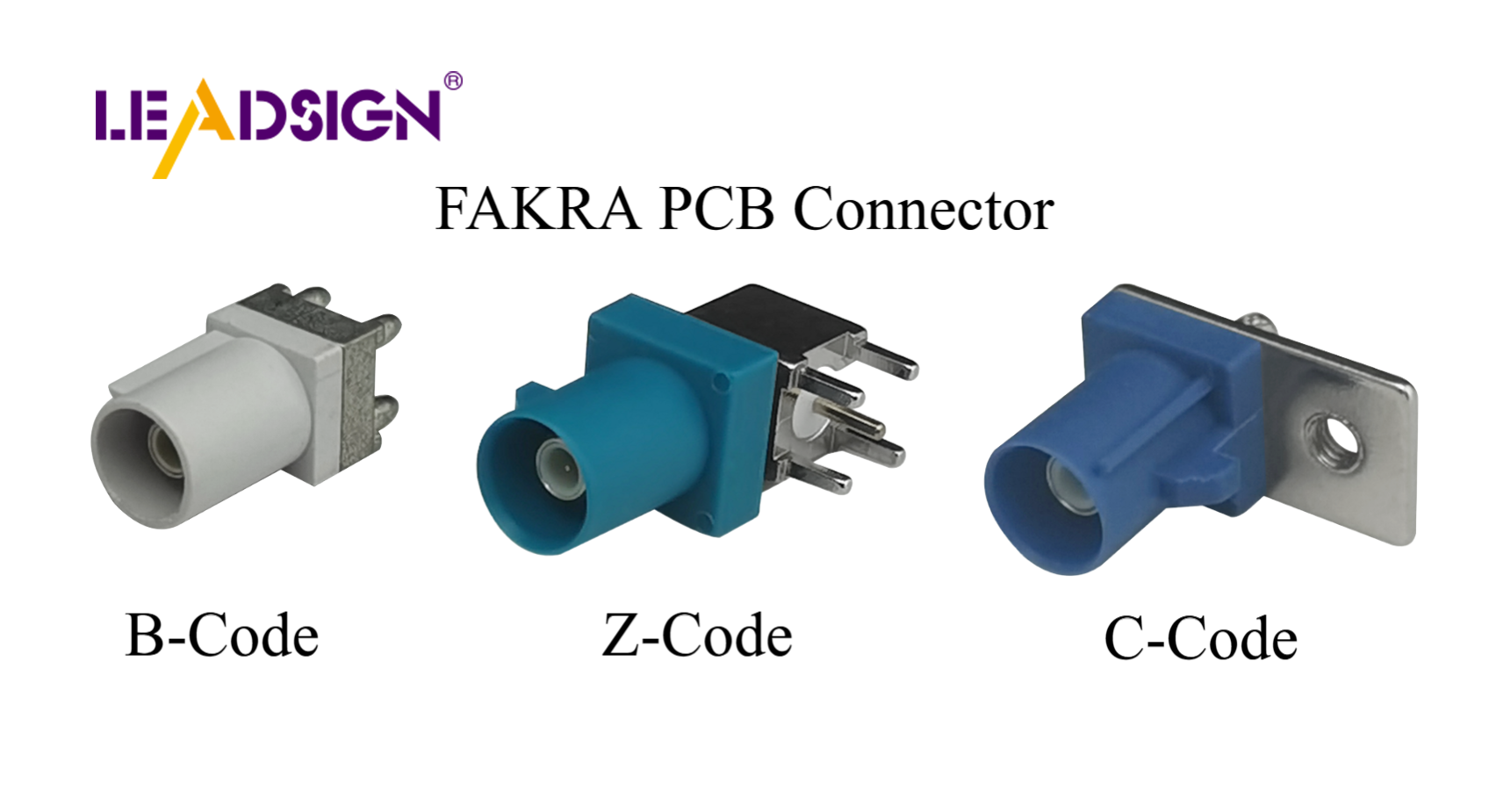

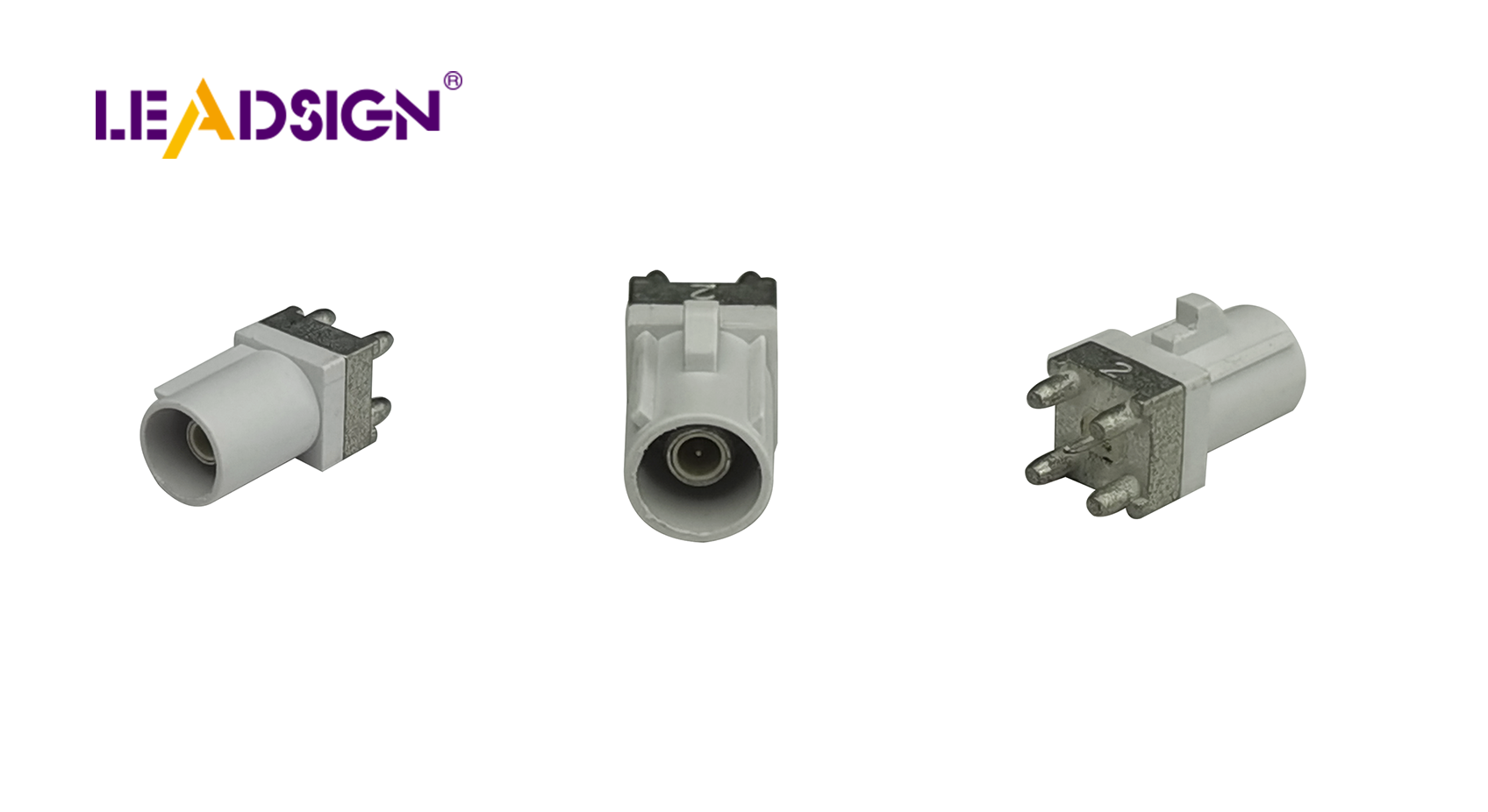

Why Fakra Connectors Are Essential For Today's Vehicles

Fakra Connectors: A Key Component In Automotive Technology

Understanding The Advantages Of Fakra Connectors In Cars

HFM Connectors: Enhancing Performance In Automotive Applications