Should You Choose OEM or Aftermarket Car Harness Connectors

When choosing between OEM and aftermarket auto harness connectors, think about a few things. OEM connectors are high quality, fit perfectly, and come with a warranty. On the other hand, aftermarket connectors are cheaper, can be customized, and are easy to find. Pick based on what matters most to you, like long-lasting use or saving money.

Key Takeaways

OEM connectors are high quality and fit your car perfectly. They are reliable and last a long time.

Aftermarket connectors cost less and can be customized. They are a good choice if you want to save money.

Picking the right connector affects your car's warranty. OEM connectors keep it safe, but bad aftermarket ones might void it.

Understanding OEM Auto Harness Connectors

What Are OEM Connectors?

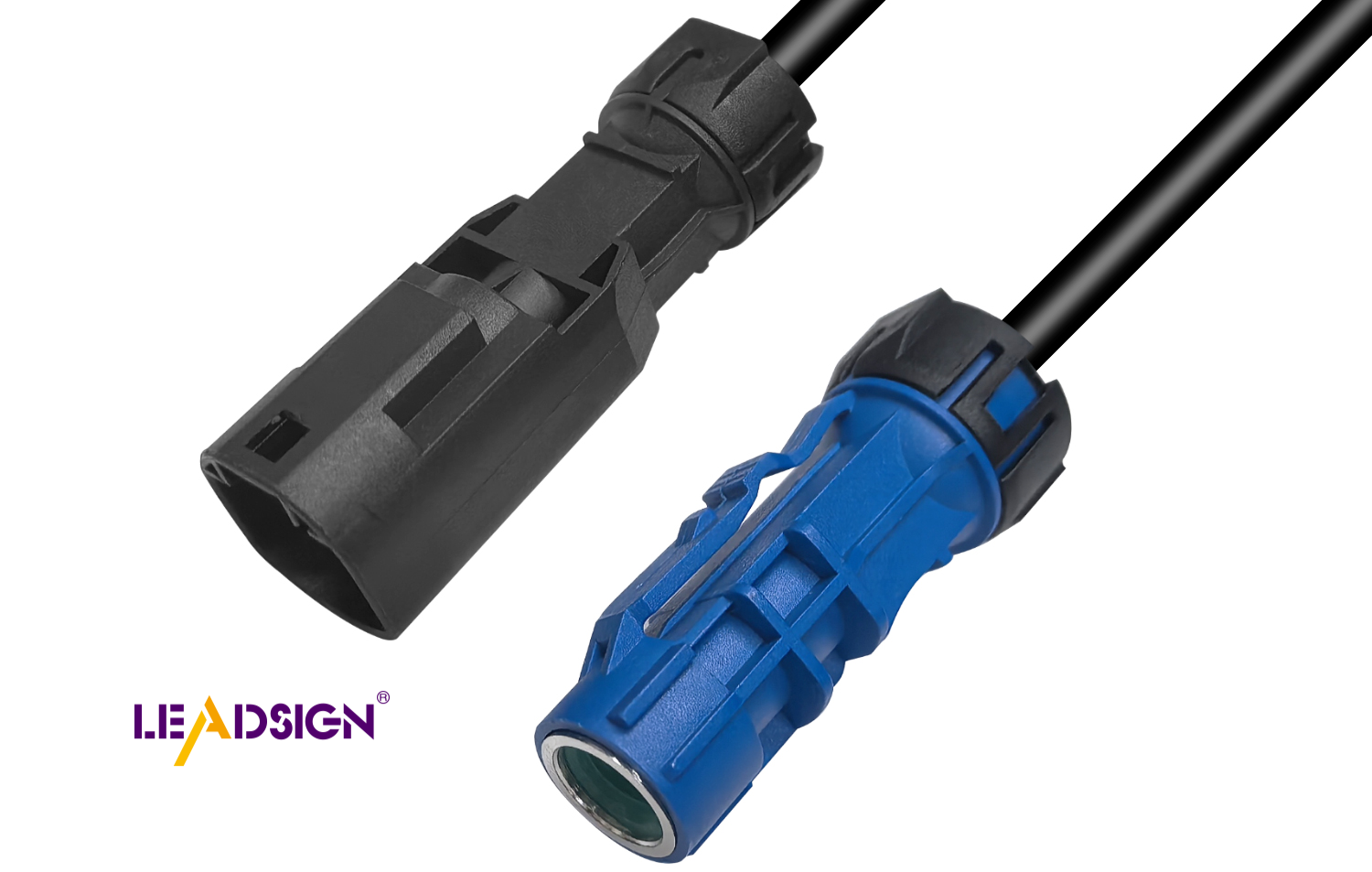

OEM connectors are made by your car's manufacturer. They are designed to work perfectly with your car's electrical system. These connectors are built with strong materials like nylon and thermoplastics. This makes them last long and resist heat, water, and chemicals. They have precise designs for good electricity flow and tight locks to stay connected. Even when the car vibrates, they won’t come loose. OEM connectors help link important parts, like the engine or entertainment systems.

Advantages of OEM Connectors

OEM connectors have many benefits. First, they are high quality and meet your car’s standards. This makes them reliable and long-lasting. Second, they fit your car perfectly, so they are easy to install. You won’t worry about mistakes or damage during installation. Third, using OEM connectors keeps your car’s warranty safe. They also ensure your car’s systems, like the engine, work well. Plus, they resist heat and moisture, making them dependable in tough conditions.

Drawbacks of OEM Connectors

OEM connectors are great but can cost more money. They are often more expensive than aftermarket options. Sometimes, they are harder to find and may need to be ordered. This can take extra time if they are not in stock. Even with these downsides, their quality and warranty protection make them a smart choice for many car owners.

Exploring Aftermarket Auto Harness Connectors

What Are Aftermarket Connectors?

Aftermarket connectors are made by companies other than your car's maker. They replace or improve the original parts in your car. These connectors use materials like plastic for the outside and copper for the inside. Sometimes, the copper is coated with gold or tin to last longer and stop rust. Making these connectors involves shaping metal pins, forming plastic covers, and putting them together. These steps make sure the connectors work well for different uses.

Benefits of Aftermarket Connectors

Aftermarket connectors have many good points. They usually cost less than OEM connectors, so they save money. There are also many types to choose from, making them easy to find. You can pick different colors, shapes, or sizes to fit your needs. This is helpful when adding new parts to your car’s wiring system. Because of these benefits, aftermarket connectors can be a smart choice in many cases.

Limitations of Aftermarket Connectors

Aftermarket connectors also have some downsides. Their quality depends on who makes them, and some might not be as good as OEM ones. This can cause problems like bad wiring or loose connections. These issues might lead to power loss or weak signals in your car. They may not fit as well as OEM connectors, which can make installation harder. Some might not seal properly, letting in water or dirt. These problems show why it’s important to pick good aftermarket parts.

Warranty Implications of OEM vs. Aftermarket Connectors

How OEM Connectors Impact Warranty

OEM connectors help keep your car’s warranty safe. They are made to match the exact design of your car. Using them ensures your car’s electrical system works as it should. This lowers the chance of damage to important parts like the engine. Car makers often require OEM connectors to keep the warranty valid. If your car has issues, the warranty will cover repairs. By choosing OEM connectors, you avoid arguments about using the wrong parts.

Warranty Risks with Aftermarket Connectors

Aftermarket connectors can sometimes risk your car’s warranty. Their quality and fit depend on who makes them. A bad connector might not work well with your car. This could cause electrical problems or harm key parts. These issues might cancel your warranty.

Using the wrong connectors can cancel warranties for electrical parts. Car makers require specific connectors to keep their products working well. If you don’t follow these rules, they may not fix or replace broken parts.

To stay safe, pick aftermarket connectors carefully. Choose ones that are high quality and fit your car. This protects your car and keeps your warranty valid.

Comparing OEM and Aftermarket Auto Harness Connectors

Quality and Durability

OEM connectors are known for their strong quality and durability. They are made to meet strict rules and pass tough tests. These connectors use materials that handle heat, vibrations, and moisture well. This makes them last a long time and work reliably. They also fit your car perfectly, so they don’t come loose or cause problems.

Aftermarket connectors can be different in quality. Some work great, but others might have issues like bad wiring or loose fits. While they can be customized, they don’t always match OEM quality. Picking a trusted brand is important to avoid these problems.

Cost and Affordability

OEM connectors cost more at first but save money later. They last longer and need fewer replacements, lowering future costs. Aftermarket connectors are cheaper to buy, which helps if you’re on a budget. But they might need replacing more often or not fit as well. Think about short-term savings versus long-term costs when choosing.

Compatibility and Fit

OEM connectors are made to fit your car exactly. This ensures strong connections and good performance. Aftermarket connectors might not fit as well. Problems like bent pins or loose fits can happen. These issues can make installation harder or damage other parts. If you pick aftermarket, make sure they match your car to avoid trouble.

Availability and Options

OEM connectors are made for specific cars, so they can be hard to find. You might need to order them, which takes time. Aftermarket connectors are easier to get and come in many choices. They are a good option if you need something fast or live where OEM parts are rare. They also offer more styles for custom wiring or upgrades.

Deciding on OEM or aftermarket connectors depends on your needs. OEM connectors fit perfectly, last long, and protect warranties. They are made for certain cars and are easy to install. Aftermarket connectors are cheaper and can be customized but wear out faster. If you want to save money over time, pick OEM. If you need a cheaper option now, go with aftermarket. Think about your car’s needs and your budget before choosing.

FAQ

What’s the big difference between OEM and aftermarket connectors?

OEM connectors are made by your car’s maker to fit perfectly. Aftermarket connectors come from other companies, offering more choices but mixed quality.

Can aftermarket connectors hurt my car?

Bad aftermarket connectors might cause wiring problems or damage parts. Always pick trusted brands to make sure they fit and work well.

Are OEM connectors worth the extra money?

Yes, if you want long-lasting parts, warranty safety, and perfect fit. OEM connectors last longer and lower the chance of mistakes during installation. They’re a smart choice for your car.

See Also

Why Fakra Connectors Are Essential for Today's Vehicles

Fakra Connectors: A Key Component in Automotive Technology

HSD Connectors: Vital Elements for Modern Automotive Systems

Fakra Connectors: Crucial for Honda's Automotive Innovations