Exploring the Significance of OEM Wire Connectors Automotive Type

OEM wire connectors are very important in cars today. They keep connections safe, making cars more reliable and secure. These automotive electrical connectors types follow strict safety rules to ensure all parts work well together. Picking the right connectors is key for the best car performance. OEM connectors are made to be top quality and fit perfectly with car systems. This ensures everything works smoothly, so you don't need to replace them often. Knowing different types of automotive electrical connectors helps choose the best one for each job.

Benefits of Using OEM Automotive Electrical Connectors

Reliability and Durability

OEM Automotive Electrical Connectors are very reliable and strong. They keep connections safe, which is important for a car's electrical system. These connectors can handle tough conditions like heat, shaking, and wetness. Their strong build means they don't break easily, so you won't need to replace them often. Made with strict rules, OEM connectors last long and are a top choice for cars.

Safety Assurance

Safety is very important in cars. OEM connectors help keep cars safe. They meet strict safety rules to make sure all parts work right. These connectors help follow safety and pollution rules, lowering danger risks. By using OEM connectors, car makers can make their cars safer for everyone inside.

Compatibility with Vehicle Systems

It's important that car parts fit well together. OEM connectors are made to fit perfectly with different car systems. They make sure everything works well together, making the car run better. Unlike other options, OEM connectors promise good quality and fit, which helps with the car's warranty and service needs. Choosing OEM connectors helps keep the car working its best.

Types of OEM Automotive Connectors

Sealed Connectors

Sealed connectors are important for car electrical systems. They stop water, dust, and dirt from getting in. This keeps the connections working well for a long time. These connectors are great for tough spots like engines or under cars. Their strong build helps the car's electrical system last longer.

Unsealed Connectors

Unsealed connectors are used where protection isn't as needed. They are easy to reach and often found inside cars. These places don't have much water or dirt. Unsealed ones don't protect as much but are simple to install and fix. They work well where you need to connect and disconnect often.

Specialized Connectors for Specific Applications

Specialized connectors meet special car needs with custom solutions. They fit advanced tech like self-driving and entertainment systems in cars. Eigen, a leader in car parts, stresses good installation for safety and efficiency. These connectors have features like fast data transfer, making them key in new cars.

Automotive Electrical Connectors Types

Knowing different automotive electrical connectors types is important for cars to work well. These connectors help parts talk to each other in the car. Here are some common ones:

Blade Connectors: These are popular because they are simple and work well. They have a flat piece that fits into a slot. Blade connectors are good for quick connections.

Ring Connectors: Ring connectors fit over bolts or screws tightly. This makes them great for places with lots of shaking.

Pin Connectors: Pins make connections here. They fit in small spaces, saving room.

Butt Connectors: These join two wires by squeezing them together tightly. They're used often to fix car wires.

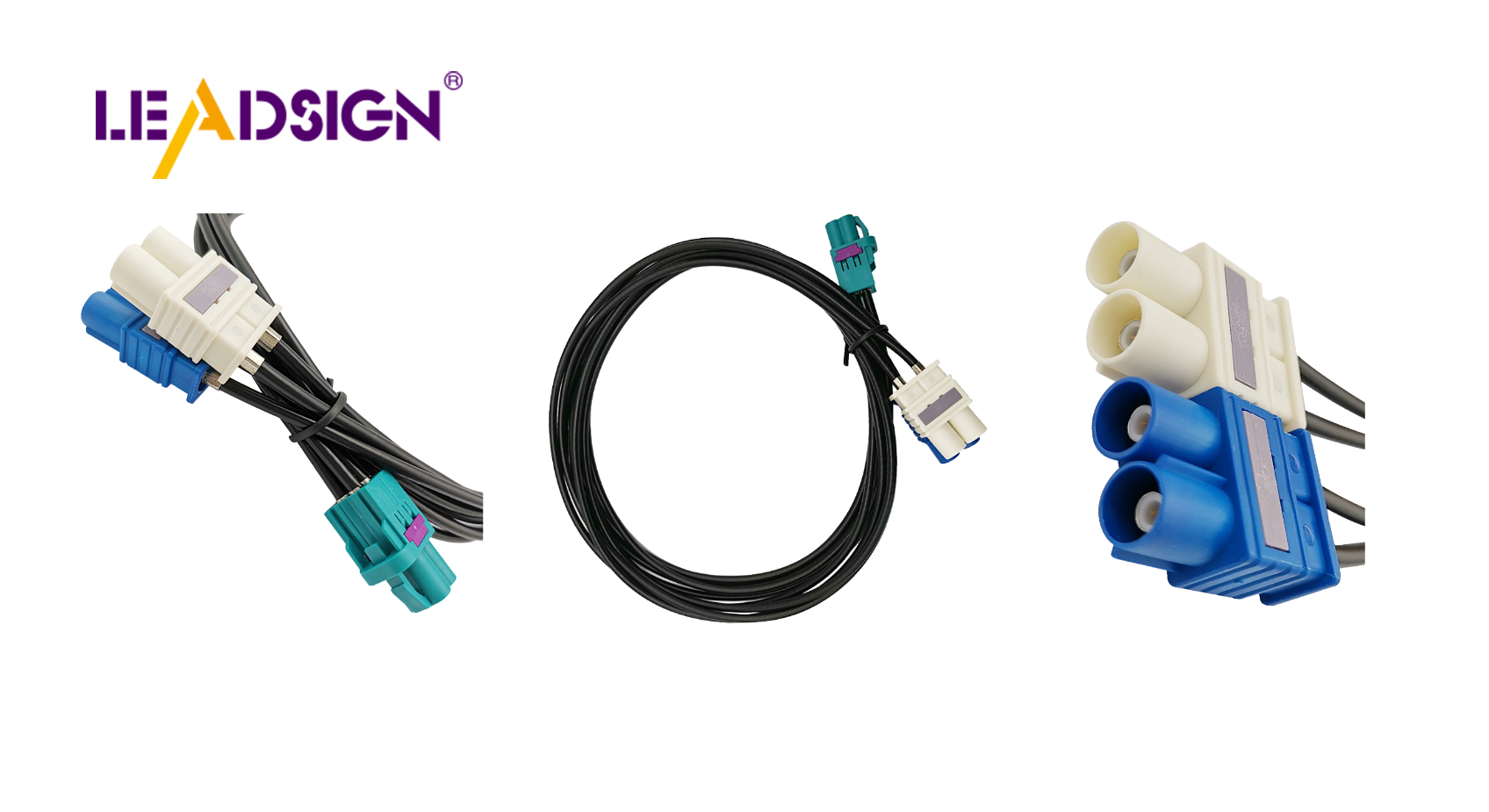

Coaxial Connectors: Coaxial ones send high-frequency signals, like in car radios and GPS.

Expert Testimony:

Eigen, a leader in car parts, says installing right is very important for safety and working well. "High standards during installation matter," they say.

Each connector type has its own job, and picking the right one helps the car run better. By knowing these types, people can make sure cars stay safe and work properly.

Uses of OEM Connectors in Cars

Engine Systems

OEM Automotive Electrical Wiring Connectors are key in engine systems. They keep parts like sensors and controls connected well. These connectors handle heat and shaking in engines. Strong connections stop electrical problems that might break the engine. This means fewer repairs, saving time and money for car owners.

Power Systems

In power systems, OEM Style Connectors make sure electricity flows safely in the car. They stop wiring mistakes by keeping connections tight, helping the car work well. These connectors send power to things like lights and screens. Their strong build lasts long, stopping electrical issues and making cars more reliable.

Safety Systems

Car safety systems need OEM Automotive Electrical Wiring Connectors a lot. They help parts like airbags and alarms talk to each other smoothly. Good connections keep these safety parts working right, which is important for people inside the car. High-quality materials stop problems, making cars safer. Car makers use these connectors to meet safety rules and keep everyone safe.

Installing and Taking Care of OEM Connectors

How to Install Correctly

Putting in OEM connectors right makes them last longer. Here’s how to do it:

Use the Right Tools: Use tools made for car connectors. This stops damage and fits them well.

Follow Manufacturer Guidelines: Read and follow the maker's instructions. This keeps them working and under warranty.

Ensure Clean Connections: Clean connectors before putting them in. Dirt can mess up connections.

Secure Connections Firmly: Make sure they click in tight. Loose ones can cause problems.

Avoid Excessive Force: Be gentle with connectors. Too much force can break them or wires.

Regular Check-ups

Checking OEM connectors often is important for safety:

Visual Inspections: Look at connectors often for wear or damage. Finding problems early helps fix them fast.

Check for Secure Fit: Ensure they stay tight over time as driving shakes things loose.

Clean Periodically: Use cleaners to get rid of dirt buildup, keeping connections good.

Replace Damaged Connectors: If broken, change them quickly to keep the car safe.

Tips to Avoid Damage

Handling OEM connectors well makes them last:

Avoid Pulling on Wires: Disconnect by holding the connector, not pulling wires, to avoid breaking inside parts.

Store Properly: Keep unused ones clean and dry so moisture doesn’t ruin them.

Protect from Extreme Conditions: Don’t let extreme heat or chemicals weaken their materials.

Use Protective Covers: Use covers if you have them to protect from weather effects.

By doing these steps, cars stay safe and work well with OEM connectors, keeping warranties intact too.

OEM wire connectors are very important in cars. They keep cars safe and working well. These connectors are strong and last a long time. They fit perfectly with car parts. Picking the right connector, like sealed ones, helps in tough spots. This keeps connections safe even when it's rough outside. Using OEM connectors also helps keep car warranties good. This saves money on repairs. Choosing OEM connectors makes cars work better and last longer. It's smart for anyone who wants their car to run well and stay safe.

See Also

Why Fakra Connectors Matter in Today's Automotive Sector

Uncovering the Advantages of Fakra Connectors for Vehicles

Significance of Fakra Connectors in Contemporary Automobiles