Navigating Wiring Connector Types for Various Applications

Understanding wiring connector types is crucial for electronics. Connectors maintain strong electrical connections and ensure optimal performance. They help prevent failures, which can lead to significant issues in military equipment. Various wiring connector types have different failure rates, influenced by factors such as temperature and the number of contacts. Selecting the appropriate connector type helps avoid problems like loose or broken connections. This knowledge empowers you to make informed choices, ensuring your electronics function effectively.

Key Takeaways

Understanding different wiring connector types is essential for ensuring strong electrical connections and optimal performance in electronics.

Choose connectors based on specific project needs, including current, voltage, and signal type, to prevent failures and enhance reliability.

Consider environmental factors such as temperature, moisture, and vibration when selecting connectors to ensure they can withstand harsh conditions.

Familiarize yourself with various connector types, including electrical wire connectors, data connectors, and automotive electric connectors, to make informed choices.

Always adhere to safety regulations and conduct safety checks to ensure connectors are reliable and suitable for your applications.

Investing time in understanding connector components—contacts, insulation, and housing—can lead to better performance and longevity of your electrical systems.

Understanding Electrical Connectors

Definition and Role

What are electrical connectors?

Electrical connectors are key parts in electronics. They let electricity move between circuit parts. Think of them as a handshake between devices, helping them talk to each other. Connectors come in many shapes and sizes for different uses. Whether it's a simple home task or a big machine, knowing about connectors is important.

Importance in electronics and electrical systems

Connectors keep electrical connections strong. They make sure signals and power flow smoothly. A good connector stops problems that can be costly or dangerous. For example, Hermetically Sealed Connectors use special seals to stay airtight. They work well underwater and in high pressure, showing their value in tough places.

Basic Components of Connectors

Contacts

Contacts are the main part of a connector. These metal pieces connect electricity. They come as male (pins) and female (sockets). Good contacts mean better connection. They lower resistance and boost conductivity, which is key for good performance.

Insulation

Insulation is also important in connectors. It stops electrical shorts by keeping contacts apart. The material must handle heat and moisture. For example, Moisture and Oil Resistant Connectors guard against water and oil, keeping connections safe.

Housing

The housing holds contacts in place. It protects and keeps connections stable. Some housings lock to stop disconnection. Others shield against electromagnetic interference, like in ESD Shielded Connectors. This shielding is vital in noisy environments, ensuring systems work without trouble.

By knowing these parts, you can choose the right connectors. Each part helps make sure your connections are reliable and efficient.

Types of Connectors

Knowing different wiring connectors is important. They help make sure connections work well in many places. Let's look at some types you might see.

Electrical Wire Connectors

These connectors join wires safely. They come in different kinds:

Plug and Socket Connectors

You find these in home gadgets. They connect things to power. They have a plug and a socket, which fit together tightly.

Terminal Blocks

Terminal blocks connect many wires safely. You see them in electric panels. They help keep wires neat and safe.

Splice Connectors

Splice connectors join wires forever. They are good for strong connections. You use them in cars or home wiring.

Data Connectors

Data connectors move info between devices. They are very important today.

USB Connectors

USB connectors are everywhere. They link computers, phones, and more. They move data and power, making them useful.

Ethernet Connectors

Ethernet connectors, or RJ45, are for networks. They connect computers to the internet. They are reliable at home and work.

HDMI Connectors

HDMI connectors send video and sound. They link TVs and computers to players. They give clear pictures and sound.

Automotive Electric Connectors

These connectors handle tough conditions. They are key for cars to work well.

Weatherproof Connectors

Weatherproof connectors keep out water and dust. You find them outside and in cars. They keep connections safe in bad weather.

High-Temperature Connectors

These connectors handle heat. They are used in car engines. They stay strong when it's hot.

Specialty Automotive Connectors

These connectors are for special car parts. They include lights and sensors. Knowing them helps keep cars running well.

Picking the Right Connector

Choosing the right connector is very important. It makes sure your electrical systems work well and last long. You need to think about many things, like what you need it for, the environment, and rules.

What You Need

First, know what your project needs. Check the current and voltage it uses, and the type of signal.

Current and Voltage

Connectors must handle the power your project needs. If not, they might get too hot or break. Always check if they match your system's power needs.

Signal Type

Different projects need connectors for different signals. For example, data projects need connectors that handle fast signals. Knowing this helps keep signals clear.

Environment

The place where you use connectors matters. Think about temperature, wetness, shaking, and pressure.

Temperature and Wetness

Connectors must handle the heat and wetness where they are used. In tough places, you need ones that resist heat and water. This stops rust and keeps them working.

Shaking and Pressure

In places with lots of shaking, like cars, connectors must be strong. Pick ones with tough covers and locks to stop them from breaking.

Rules and Safety

Following rules is key for safety. These rules make sure connectors work well.

Rules

Rules help you pick connectors that fit with other parts. Learn these rules to choose right.

Safety Checks

Safety checks show connectors are safe. Look for checks from trusted groups. This is vital where failure is risky.

By thinking about these things, you can pick the best connectors. This helps your systems work well and last long.

Picking the right connector is very important. It helps your electrical systems work well and last longer. Think about technical and environmental needs. For cars, choose connectors that handle heat and shaking. Knowing these needs helps you decide better. This way, your systems stay reliable and last longer. Always focus on what your project needs for the best results.

FAQ

What are the different types of connectors?

Connectors have different shapes for special jobs. Electrical wire connectors join wires safely. Data connectors, like USB and HDMI, move data. In cars, automotive electric connectors are key for working well. Knowing these helps pick the right one.

Why are automotive electric connectors important?

Car connectors are very important. They handle tough conditions like heat and shaking. This makes them vital for car wiring. They help all car parts work right, keeping cars safe and running well.

How do HDMI connectors work?

HDMI connectors send sound and pictures. They link TVs, computers, and games. They give clear sound and video. HDMI works with both old and new signals, making them useful for many things.

What are the uses of electrical wire connectors?

Electrical wire connectors join wires safely. They are used in homes, businesses, and factories. They stop loose wires, cutting down on electrical problems.

What are the types of automotive electric connectors?

Car connectors include weatherproof, high-heat, and special ones. Weatherproof keep out water and dust. High-heat handle hot places. Special ones fit certain car parts, helping them work best.

How do USB connectors facilitate data transfer?

USB connectors are everywhere. They move data between computers, phones, and cameras. They work at different speeds, from USB 1.0 to USB 3.0. USB also gives power to devices, making them better.

What are RJ45 connectors used for?

RJ45 connectors are for networks. They link computers to the internet. They are fast and reliable, used at home and work for good internet.

What are D-sub connectors, and where are they used?

D-sub connectors, like DB9 and DB25, are used in factories. They link things needing many pins, like printers. They are strong and last long, good for tough places.

How do RCA connectors transmit audio and video signals?

RCA connectors send sound and video. They link DVD players and stereos. They are easy to use and found everywhere, great for home setups.

What are XLR connectors, and why are they preferred for high-quality audio?

XLR connectors are used in pro audio for clear sound. They are in microphones and mixers. They cut noise, making them great for live shows and studios.

See Also

Understanding Fakra Connectors: Types, Uses, and Fundamentals

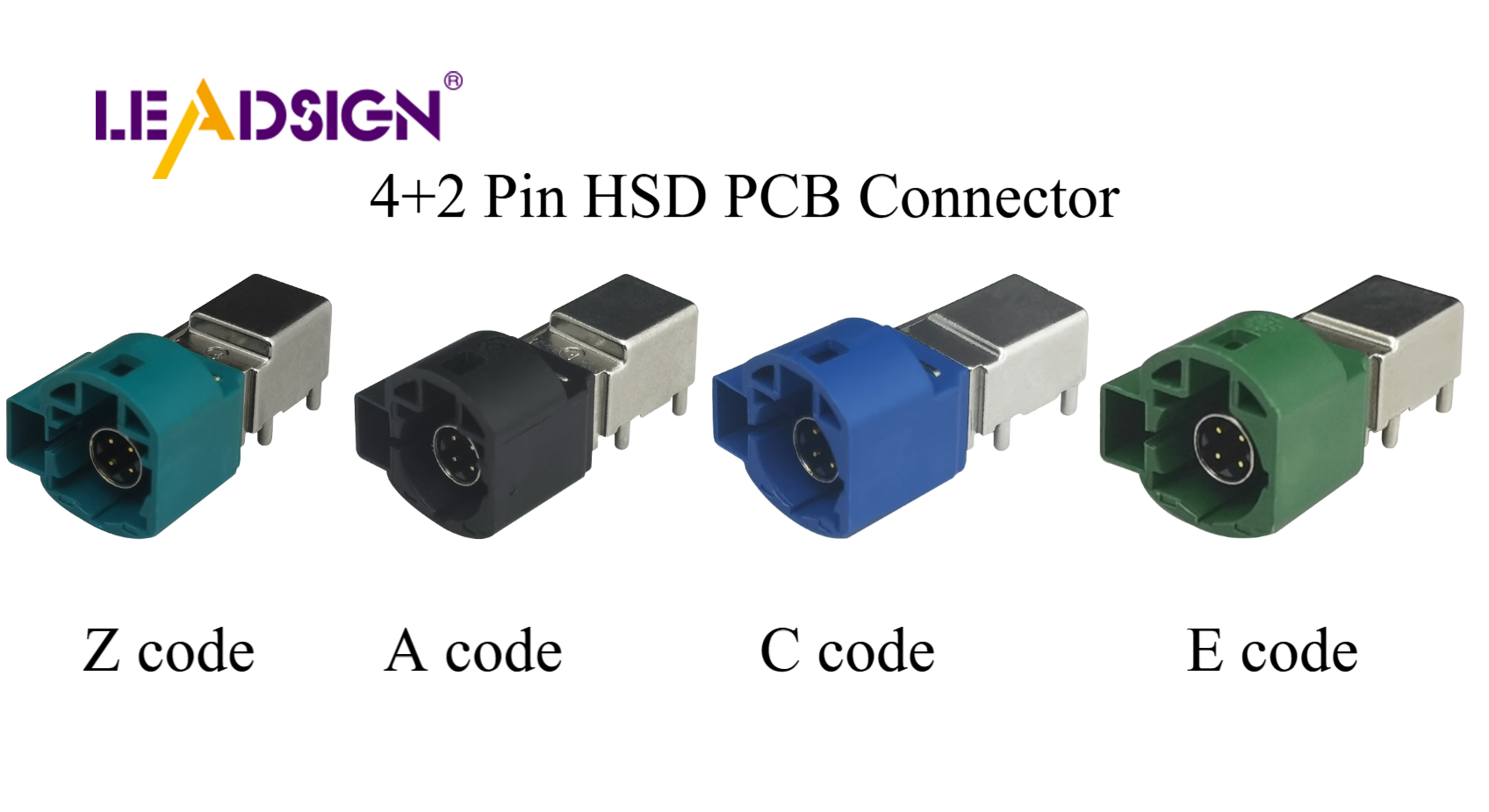

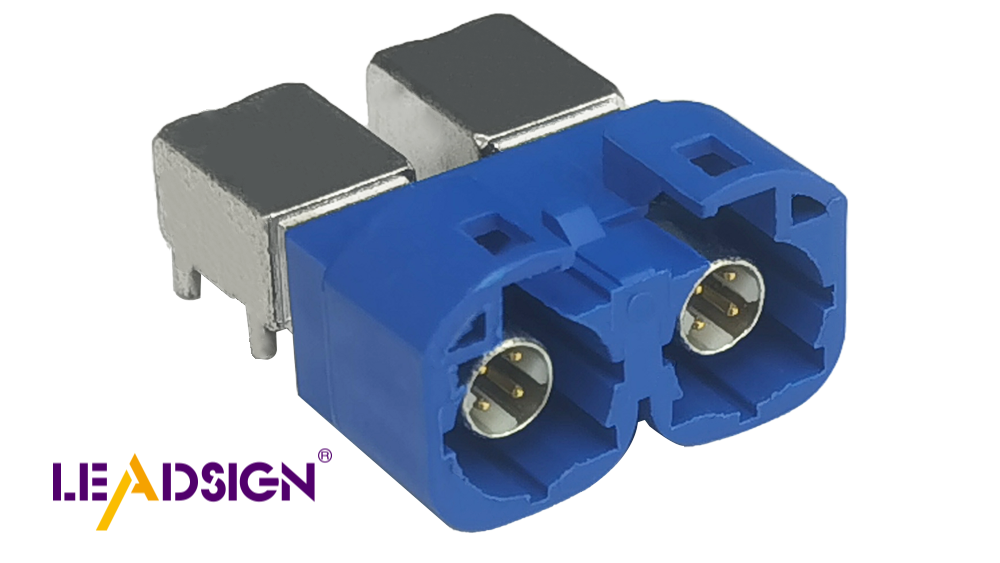

In-Depth Overview of HSD Connectors and Their Uses

Introduction to HSD Connectors for Automotive Applications