Navigating FAKRA Connectors with Custom Automotive Wire Harness Manufacturers

FAKRA connectors are important in cars. They help send data and power between sensors and controllers. This is key for self-driving cars. FAKRA connectors allow easy communication with cloud servers and traffic systems. Custom wire harness makers improve how these connectors fit in. They offer special solutions for car needs. This makes systems work better and more reliably.

Understanding FAKRA Connectors

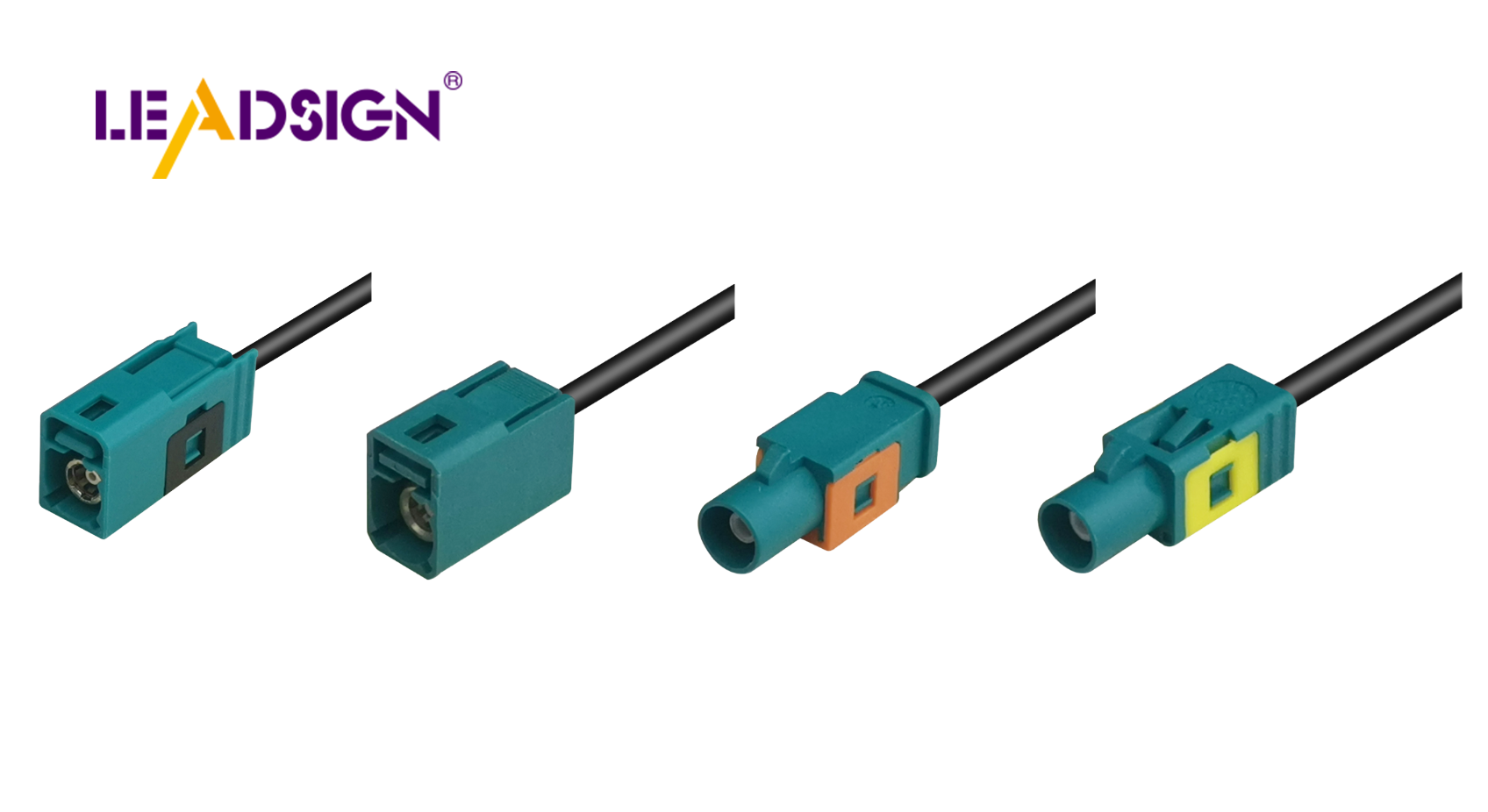

Design and Structure

FAKRA connectors use the SMB connector style. This design keeps connections safe for high-frequency signals. The structure helps send data well in car systems. Engineers have improved the design over time. Each change makes them work better and last longer. These updates meet modern car needs.

Technical Specifications

FAKRA connectors work within a set frequency range. This range goes from DC to 6 GHz. The impedance is usually 50 ohms. These details keep signals clear. Waterproof ratings make them tough in bad weather. They handle temperatures from -40°C to +105°C. These traits suit many car conditions.

Features and Standards

Colors help tell different FAKRA connectors apart. This stops wrong connections when setting up. Each color matches a certain job. Locking parts keep them attached securely. These stop accidental unplugging. Following industry rules is important. FAKRA connectors meet ISO and USCAR rules, ensuring quality and fit in cars.

Uses of FAKRA Connectors

Car Uses

Mobile Radios and GPS Antennas

FAKRA connectors link radios and GPS in cars. They help send data between car systems and networks. Their strong design handles high-frequency signals well. This keeps communication clear. Car makers use them for good navigation and talking features.

Telematics and Bluetooth Systems

Modern cars need FAKRA connectors for telematics. They connect these units with other car parts. Bluetooth also works better with FAKRA connectors. The locks stop disconnections, keeping data flowing smoothly. This helps with hands-free calls and music streaming.

Factory Uses

Fast Industrial Cameras

FAKRA connectors aren't just for cars. Fast cameras in factories use them to send data quickly. They handle high-frequency signals, great for clear pictures. Industries trust them for their strength and performance.

Machine-to-Machine Modules

Machines in factories use FAKRA connectors too. They help machines share data, boosting automation. Their tough build keeps connections strong even in hard conditions. This is key for steady device communication.

Performance and Reliability

Signal Transmission Effects

Matching Impedance and Keeping Signals Strong

FAKRA connectors match impedance well. This keeps signals strong in cars. They are made to fit the 50-ohm standard. This stops signal bouncing and loss. Good matching helps data move better in cars. High-frequency signals pass easily through these connectors.

Insertion Loss and How It Affects Performance

Insertion loss changes how FAKRA connectors work. Less insertion loss means better signal flow. Makers try to lower insertion loss when designing them. This makes sure they work well in cars. FAKRA connectors keep low insertion loss even when things get tough. This helps important car systems talk clearly.

Special Things to Think About

Use in Bending, Wet, and Shaky Places

FAKRA connectors do great in hard spots. These spots can bend, be wet, or shake a lot. Their strong build handles stress without hurting signals. Cars often face water and shakes. FAKRA connectors stay connected well here. They are good for many car parts.

Why Design Rules and Testing Matter

Design rules help FAKRA connector reliability a lot. Following these rules makes sure they work right always. Makers test them hard to meet these rules too. Tests check electric, mechanical, and weather effects on them. Schleuniger has top systems for making cables with FAKRA connectors using semi-auto or full-auto setups. Tests show they handle high-frequency signals well too. Sticking to rules ensures quality and safety in cars.

Making and Using Machines

Using Machines to Build

Schleuniger makes machines for putting cables with FAKRA connectors together. They have machines that are partly automatic and fully automatic. These machines help make cables faster. Schleuniger's machines put parts together exactly right, which is important for keeping signals clear in cars. The partly automatic ones save money by doing some work automatically. This helps companies spend less but still make good products.

The fully automatic machines help make lots of cables quickly. They use special parts to do jobs like cutting shields and stripping wires. They also crimp both ends and test with high voltage electricity. These steps make sure FAKRA connectors are really good. Companies save money on workers and can make more products fast. The machines keep the quality the same even when making many cables.

How Custom Wire Harness Makers Help

Custom wire harness makers are important for using FAKRA connectors in cars. Companies like Dongguan Heju Precision Electronic Technology Co., Ltd. design special car wire parts. They make solutions that fit what each car needs best. Their skill makes sure FAKRA connectors work well in tricky car systems. This custom work makes car electronics better and more reliable.

These makers focus on sending signals without problems, which is key for car communication systems and controls to connect well. FAKRA connectors help send data between sensors, control boxes, and sound systems in cars easily. Custom wire harness makers ensure these links meet quality rules so everything works great.

FAKRA connectors are very important for cars and factories. They help send data and power, which is key for self-driving cars. Their strong design helps sensors and controllers talk well, making cars work better.

Custom wire harness makers help fit FAKRA connectors perfectly. They know how to make them work best and last long. This teamwork makes sure car systems run smoothly and follow rules.

See Also

Exploring the Significance of Fakra Connectors in Auto Sector

Discovering the Advantages of Fakra Auto Connectors

The Significance of FAKRA Connectors in Auto Uses